Ver.11

MT-512Ri

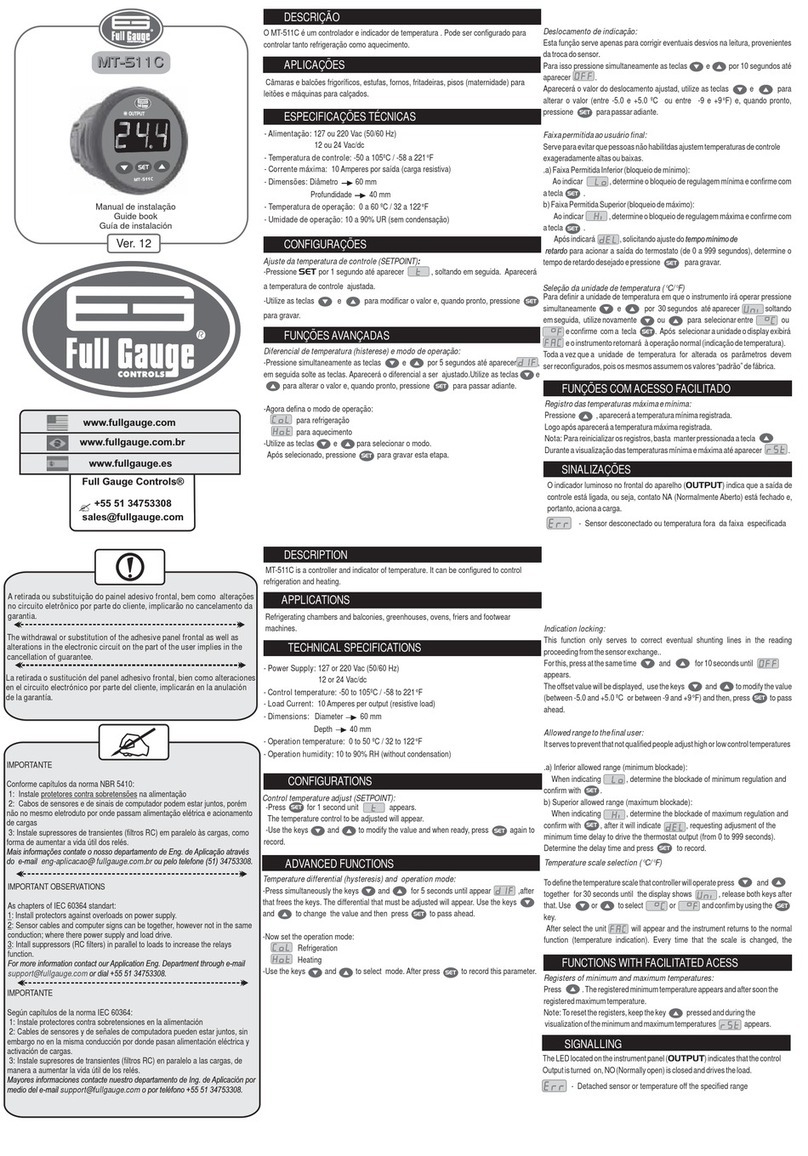

1. DESCRIPTION

The MT-512Ri is a temperature controller and gauge, with adjustable settings for cooling and

defrosting processes. It controls cooling and defrost by stopping the compressor. The controller uses an

intelligent system to lock the keys and deactivate the control functions.

( )

* Th

Product complies with CE (European Union), NSF (United States) and UL Inc. (United States and

Canada).

2. APPLICATIONS

• Counters

• Cooled chambers

3. TECHNICAL SPECIFICATION

- Power supply: MT-512Ri 115 or 230 Vac 10%(50/60 Hz)

MT-512RiL 12 or 24 Vac/dc

- Control temperature: -50 to 105ºC (-58 to 221°F)

- Maximum current: NO 16(8)A/250Vac 1HP

NC 8A/250Vac

- Dimensions: 71 x 28 x 71mm

- Operating temperature: 0 to 50 ºC / 32 to 122°F

- Operating humidity: 10 to 90% RH (without condensation)

is instrument can measure and control up to 200ºC temperatures, since used with silicone cable

sensor (ex.: SB59).

→

→

→

→

±

( )

*

4. CONFIGURATIONS

4.1 - Control temperature adjust (SETPOINT)

- Press @ for 2 seconds until appears[set], and then release the key.

The set control temperature will appear.

- Use the > or < keys in order to change the value and, when ready, press @ to record.

CLASSIFICATION ACCORDING TO IEC60730-2-9 STANDARD:

- Temperature limit of the installation surface: 50°C / 122°F

- Type of construction: Built-in electronic controller

- Automatic action: Type 1

- Control of pollution: Level 2

- Impulse voltage: 1,5kV

- Temperature for the test of sphere pressure: 75°C and 125°C / 167°F and 257°F

- Insulation: Class II

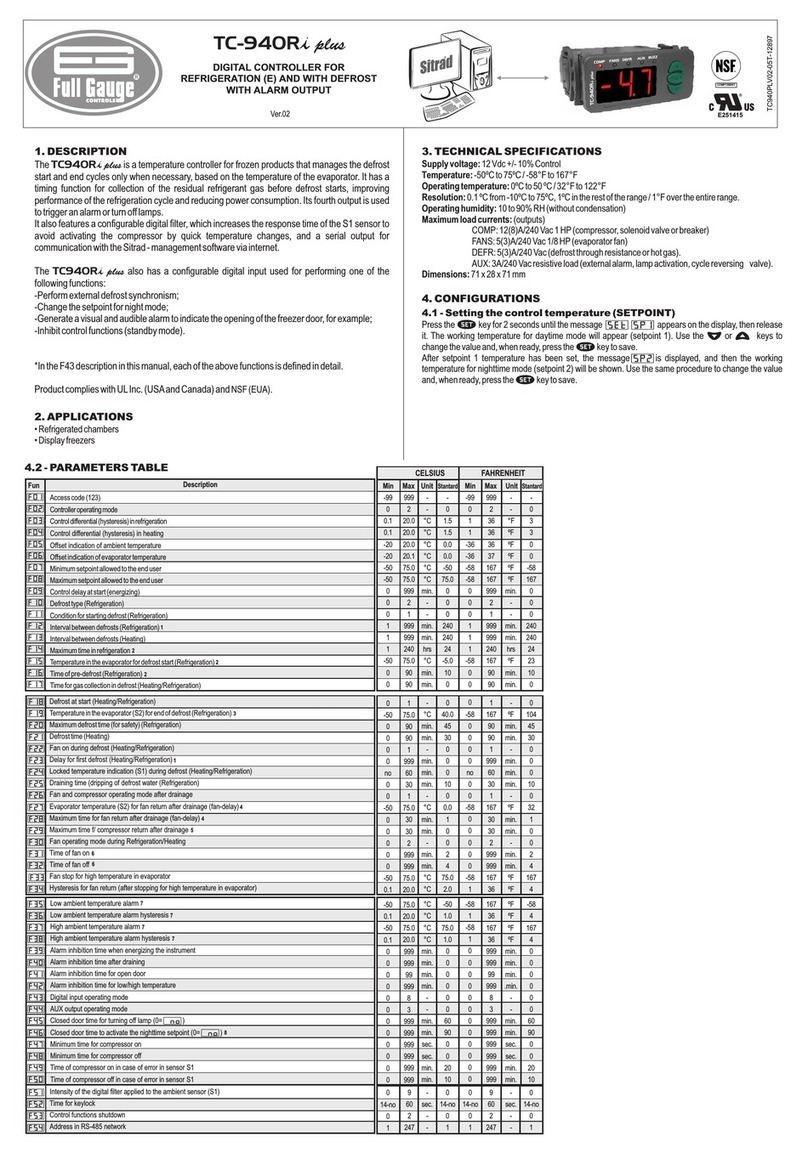

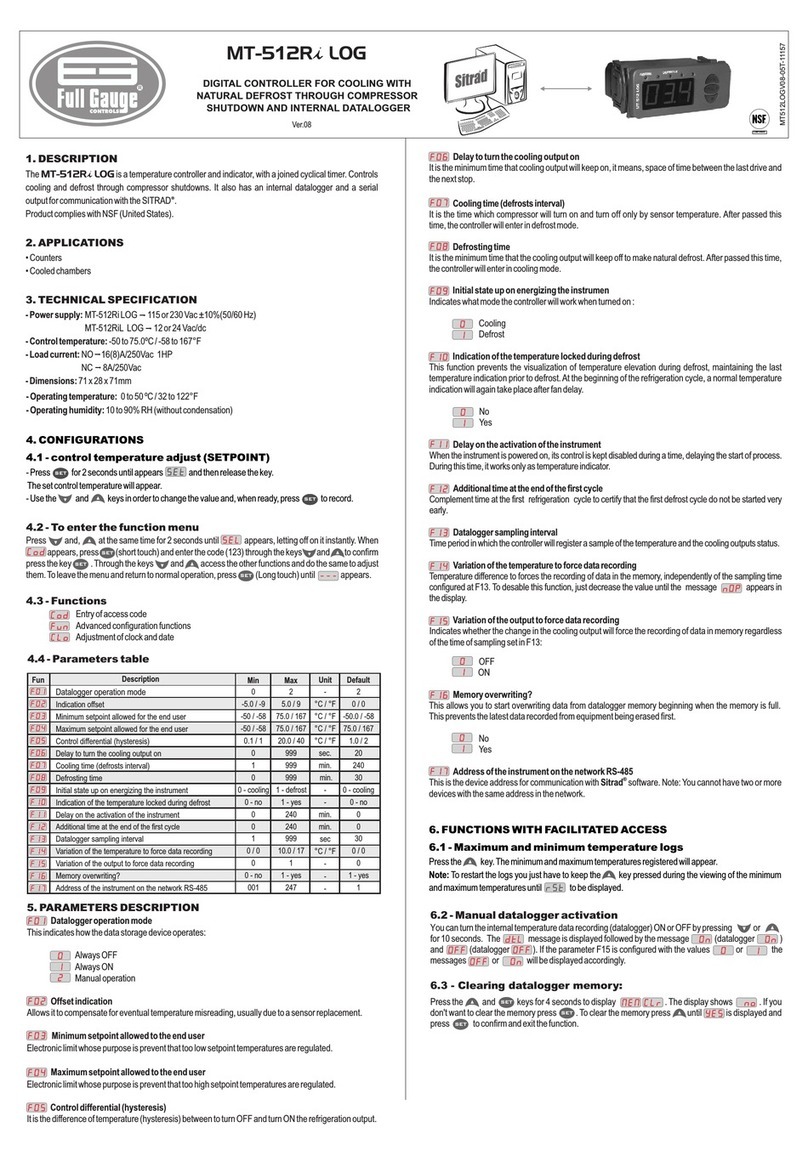

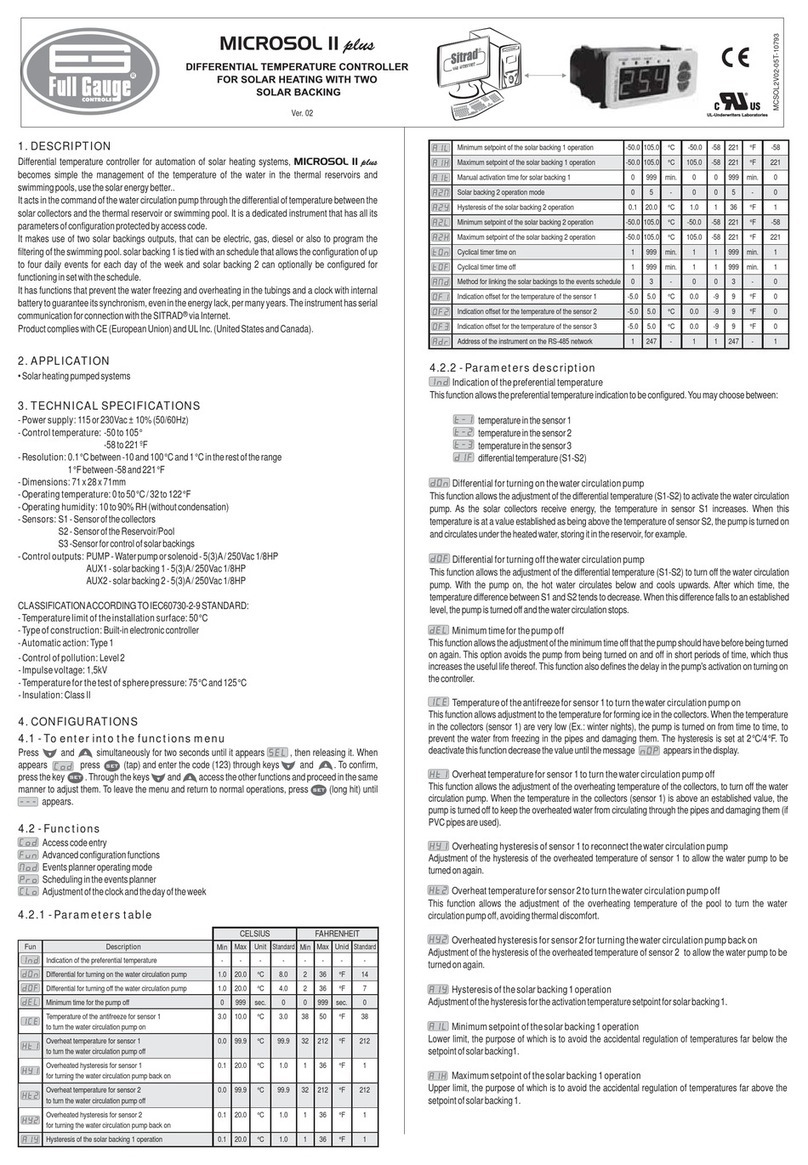

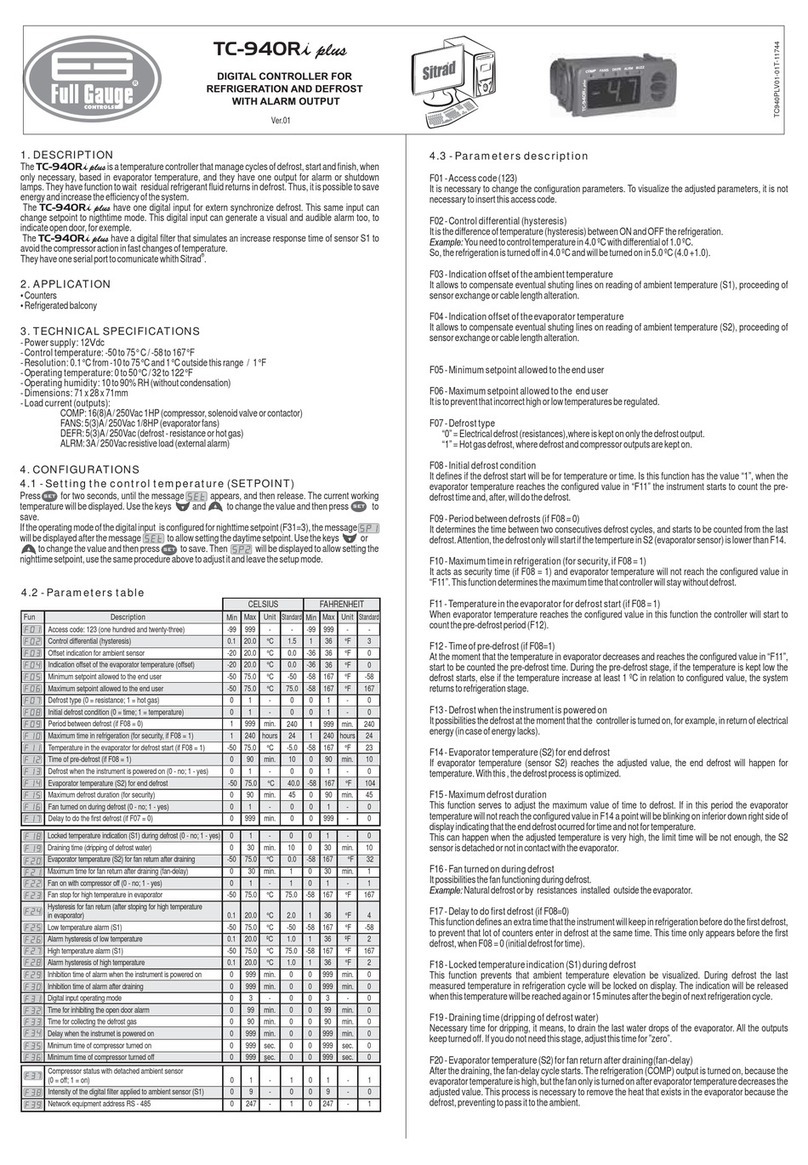

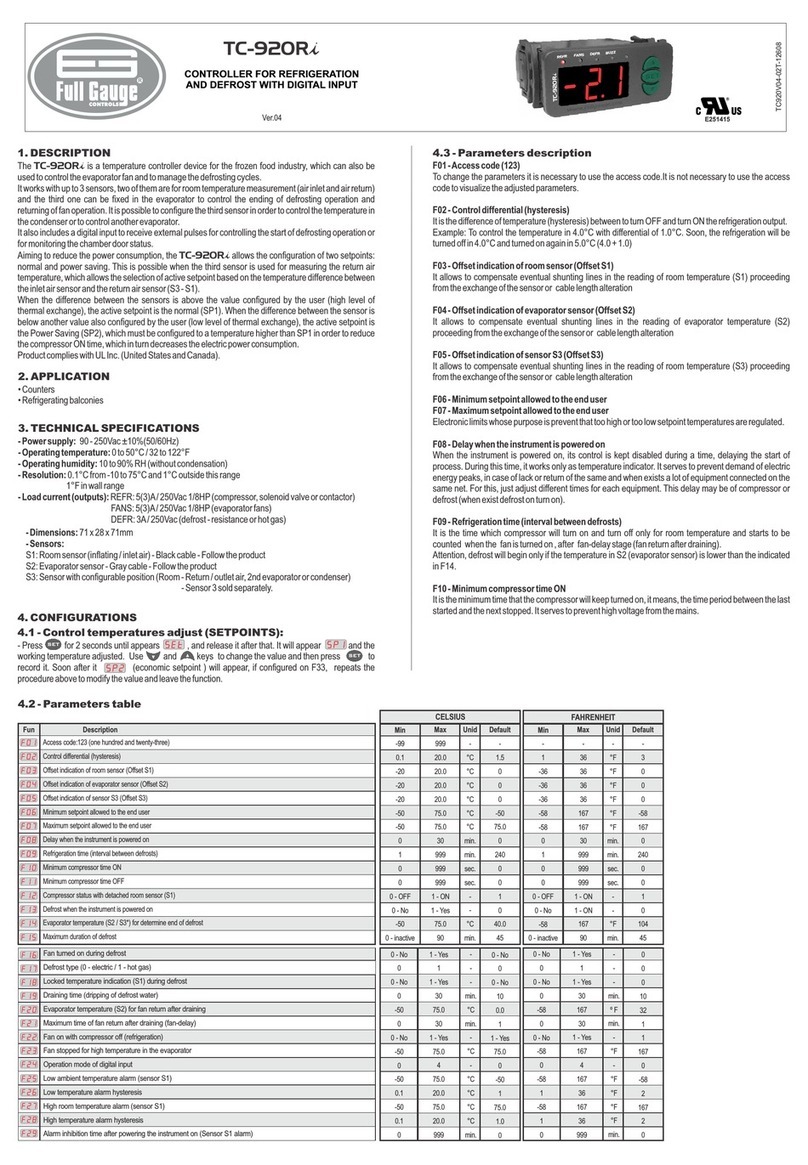

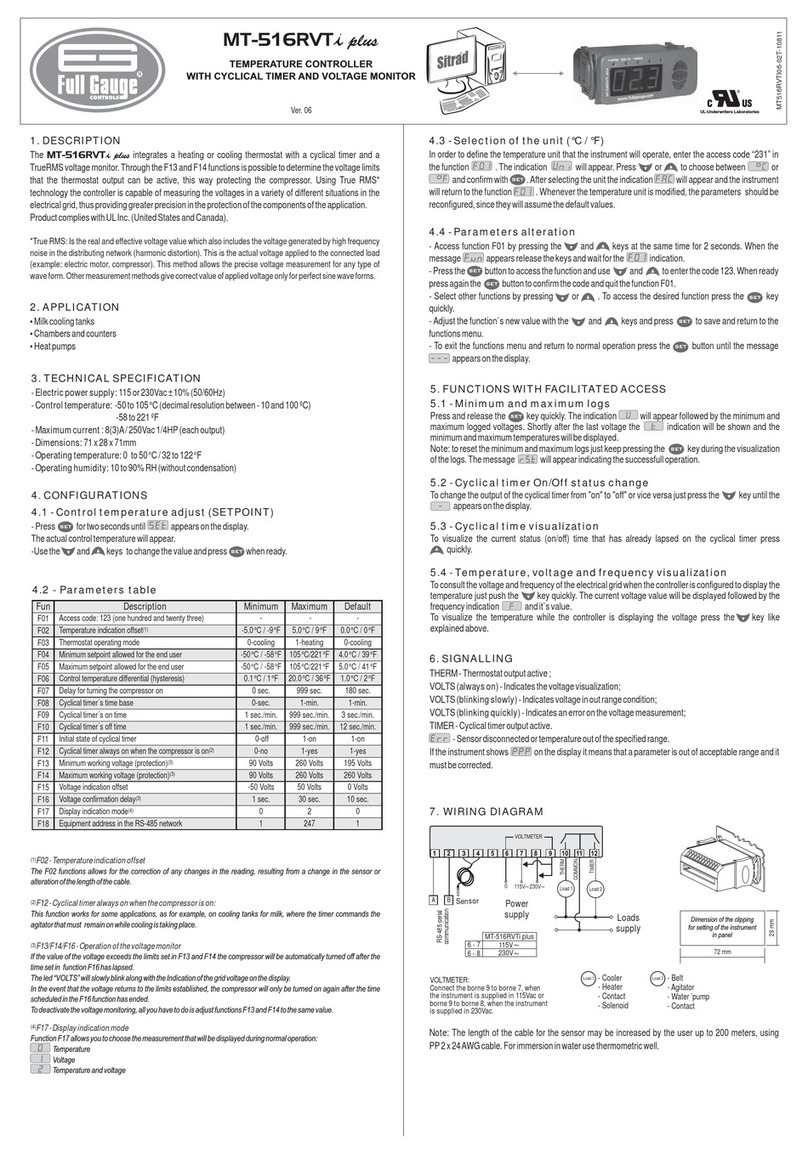

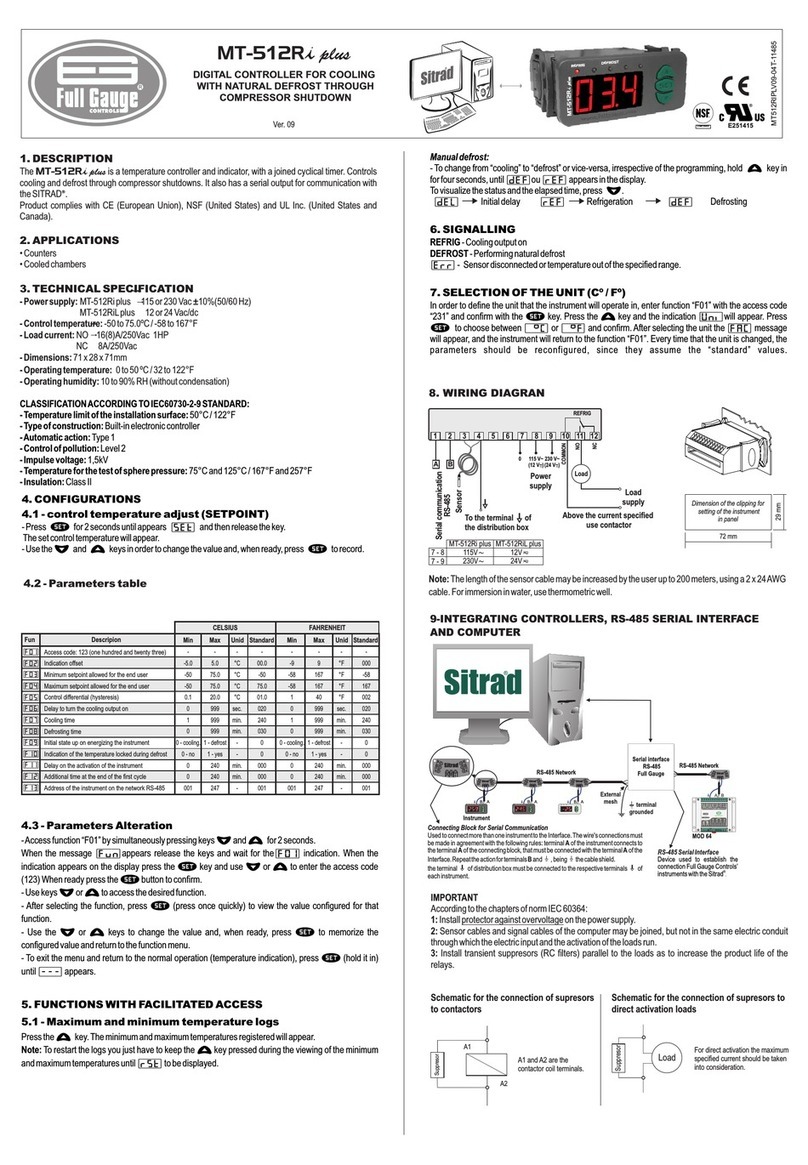

4.2 - Parameters table

Configuration parameters protected by access code.

[F01]

[F02]

[F03]

[F04]

[F05]

[F06]

[F07]

[F08]

[F09]

[F10]

[F11]

[F12]

[F13]

[F14]

[F15]

[F16]

Fun

CELSIUS FAHRENHEIT

Access code: 123 (one hundred and twenty three)

Indication offset

Minimum setpoint allowed for the end user

Maximum setpoint allowed for the end user

Control differential (hysteresis)

Delay in restarting the cooling operation

Cooling time

Defrosting time (*)

Initial state when turning the device on again

Indication of the temperature locked during defrost (**)

Delay on the activation of the instrument

Additional time at the end of the first cycle

Situation of the compressor with the damaged sensor

Intensity of the digital filter (***)

Time to Key blocker

Deactivation of the control functions

-

5.0

200

200

20.0

999

999

999

1-defrost

1-yes

240

240

1-on

9

60

2

-

°C

°C

°C

°C

sec.

min.

min.

-

-

min.

min.

-

-

sec.

-

-

-9

-58

-58

1

0

1

0

0-cooling

0-no

0

0

0-off

0

14-no

0

-

9

392

392

40

999

999

999

1-defrost

1-yes

240

240

1-on

9

60

2

-

°F

°F

°F

°F

sec.

min.

min.

-

-

min.

min.

-

-

sec.

-

-

-5.0

-50

-50

0.1

0

1

0

0-cooling

0-no

0

0

0-off

0

14-no

0

5.2 - Manual Defrost

- To change from “cooling” to “defrost” or vice-versa, irrespective of the programming, hold < key in

for four seconds, until[def][Off]or [def][,on]appears in the diplay.

5.3 - Processes Viewing

To visualize the status and the elapsed time, press>.

[del] → Initial delay , [ref] → Refrigeration, [def] → Defrosting.

If the control functions are turned off, the MT-512Ri will work as a simple temperature gauge,

without controlling the cooling and defrost. Therefore, the status and the time elapsed will not be

displayed.

E251415

REFRIG

MT-512Ri

DEFROST

5.4 - Key blocking

For security reasons this controller permits blocking the key settings.

With this feature enabled, the setpoint and further settings are protected against undue alterations.

After key blocking, the user can only see the setpoint and settings, when trying to change the settings

the controller will display the message[LOC].

To proceed with the key blocking it is required that the parameter "F15 -Time to key Blocker" is

configured with a different value than" 14-No " (15-60 seconds).

If F15 is set as "No" the key lock is not allowed.

To block, hold the key > for the time programmed in function F15.

The controller will display the message [LOC] +[On,].

To unblock, turn off the controller and turn it back on holding the key > for 10 seconds untill the

message[LOC]+[Off]be displayed.

5.5 - Deactivation of the control functions

When the control functions are turned off, the controller starts to operate as a temperature gauge

only and the output switch is turned off.

The method used to turn off the control functions depends on the configuration of the parameter

"F16- Deactivation of the control functions":

.

[,0,] - Does not allow the control functions to be turned off;

[,1,]- Allows the control functions to be turned on and off only if the keys are not

locked;

[,2,]- Allows the control functions to be turned on and off even if the keys are

locked;

To turn off the control functions, press the < key for 10 seconds until the message [CtL] is

displayed. When the key is released, the message [OFF] will be displayed. With the control

functions turned off, the message [Off] and the temperature sensor will be displayed

alternately.

To turn on the control functions again, press the < key for 10 seconds until the message

[CtL] is displayed. When the key is released, the message [,On] will be displayed.

NOTE: When the control functions are turned on again, the MT-512Ri will continue to follow the

functions "F06 - Delay in restarting the cooling operation" and "F09 - Initial state when

turning the device on again".

6. SIGNALLING

REFRIG - Cooling output on

DEFROST - Performing natural defrost

[err] - Sensor disconnected or temperature out of the specified range.

[OFF] - Control function turned off

[def][,On] - Activation of defrost cycle manually

[def][OFF] - Activation of refrigeration cycle manually

[LOC][,On] - Keypad locked

[LOC][OFF] - Keypad unlocked

DIGITAL CONTROLLER FOR COOLING

WITH NATURAL DEFROST THROUGH

COMPRESSOR SHUTDOWN

Unit

Standard

Description Min Max Unit

Standard

Min Max

* Heating operation mode - To make the instrument work in heating operation mode, simply adjust the F08 function with

minimum value until [Hot] appears.

** Frozen indication on display - If F10 is enabled, the indication is only released in the next cooling cycle after the temperature

reaches that "locked" value again or after 15 minutes in refrigeration (as security).

*** This filter aims at simulating an increase of the mass of sensor , thus increasing its response time (thermal inertia). The larger the

value adjusted in this function, the longest the response time of sensor.

A typical application requiring this filter is the freezer for ice cream or frozen goods, because when the door is opened a hot air mass

reaches the sensor directly, causing the indication of the measured temperature to rise quickly and the compressor to be activated

unnecessarily many times.

4.3 - Parameters alteration

- Access function “F01” by simultaneously pressing keys > and < for 2 seconds.

When the message[fun]appears release the keys, when the indication [f01]appears on the

display press the @ key and use > or < to enter the access code (123) When ready press the

@ button to confirm.

- If the keys are locked, the controller will show the message [LOC] in the display upon pressing the

> or < key and will not permit any change in value

> or <

@

> or < @

@

[---]

- Use keys to access the desired function.

- After selecting the function, press (press once quickly) to view the value configured for that

function.

- Use the keys to change the value and, when ready, press to memorize the

configured value and return to the function menu.

- To exit the menu and return to the normal operation (temperature indication), press (hold it in)

until appears.

5. FUNCTIONS WITH FACILITATED ACCESS

5.1

- Maximum and minimum temperature logs

Press the< key. The minimum and maximum temperatures registered will appear.

Note: To restart the logs you just have to keep the < key pressed during the viewing of the minimum

and maximum temperatures until [rst] to be displayed.

7. SELECTION OF THE UNIT (ºC / ºF)

In order to define the unit that the instrument will operate in, enter function “F01” with the access code

231 and confirm with the @ key. Press the < key and the indication [Uni]will appear.

Press @to choose between [,=C] or [,=F] and confirm. After selecting the unit the [faC]

message will appear, and the instrument will return to the function “F01”. Every time that the unit is

changed, the parameters should be reconfigured, since they assume the “standard” values.

-

0

-50

75.0

1.0

20

240

30

0-cooling

0-no

0

0

0-off

0

14-no

0

-

0

-58

167

2

20

240

30

0-cooling

0-no

0

0

0-off

0

14-no

0

MT512RIV11-01T-13387

COMPONENT