Sigma 18.30.061 User manual

FORM SIG 085 Revised 6-01-18

Page 1 of 4

Pressure Balancing Valve

Shower or Tub/Shower

Installation Instructions

Notice:These instructions do not represent step-by-step directions.

They are a pruduct supplement only to be used by a qualified and

licenced plumber.We recommend all plumbing fixtures be installed

by a professional.

SPECIFICATIONS

Minimum operating pressure 20 psi

Maximum operating pressure 125 psi

Max hot water inlet temp. 190°F

Hot and cold water inlets ½” NPT male

Shower and tub outlet ½” NPT male

Flow capacity 5 GPM/ 60 psi

This valve is precision engineered to provide satisfactory performance provided it is installed and operated in accordance with recom-

mendations contained in these instructions. Please be sure tofamiliarize yourself with these instructions.

PRIOR TO STARTING:

1. FLUSH lines of debris prior to starting. Debris may clog cartridge.

2. The mud guard represents a typical hole size required to access the integral service stops and the removable

cartridge. The rough valve comes PRE-ASSEMBLED and FACTORY READY TO INSTALL.

3. Be alert that the valve body is not installed upside down. See markings on BACK of valve.

4. The screwdriver service stops should always be in the full-open position with the valve in use. They are not to be used

INLETS

6. Shower valve (Part # 18.30.061 or Part # 78.30.061) may be used for shower only or tub only. The unused port

must be capped by plumber during installation.

ROUGH-IN OF VALVE

copper sockets or 1/2” Male I.P. nipples. NOTE “UP AND DOWN” MARKINGS ON BACK OF VALVE.

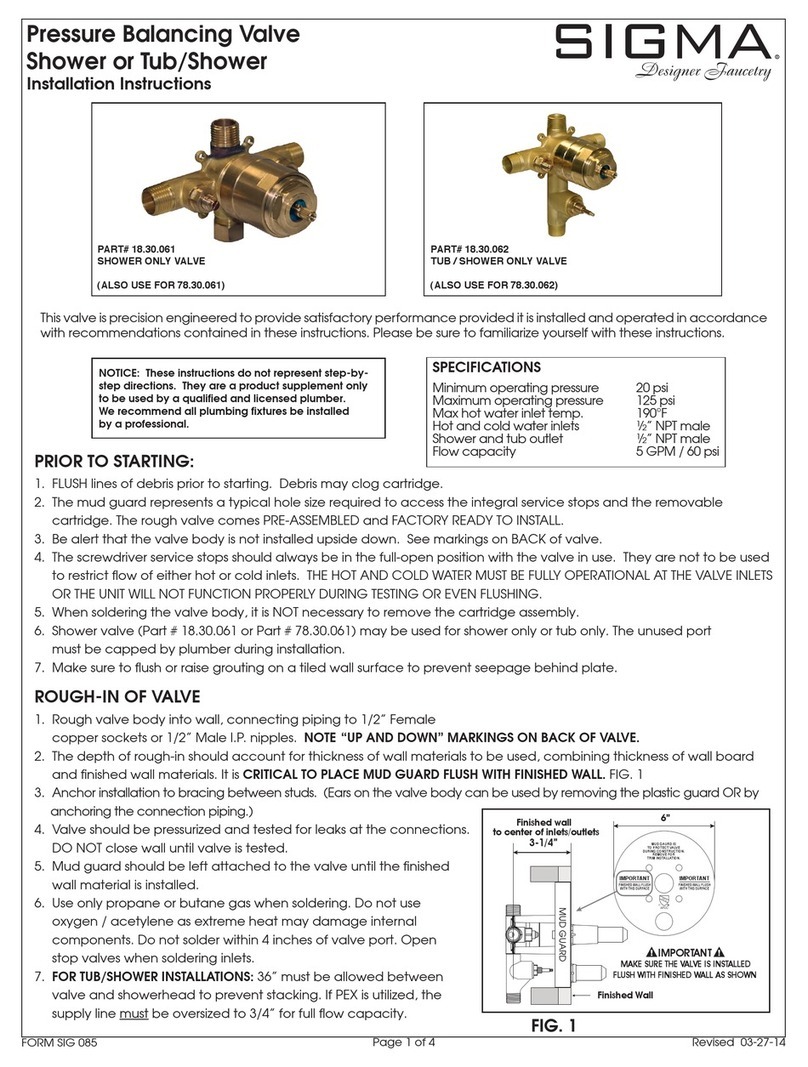

CRITICAL TO PLACE MUD GUARD FLUSH WITH FINISHED WALL. FIG. 1

3. Anchor installation to bracing between studs. (Ears on the valve body can be used by removing the plastic guard OR by

anchoring the connection piping.)

DO NOT close wall until valve is tested.

wall material is installed.

6. Use only propane or butane gas when soldering. Do not use

oxygen / acetylene as extreme heat may damage internal

components. Do not solder within 4 inches of valve port. Open

stop valves when soldering inlets.

7. FOR TUB/SHOWER INSTALLATIONS: 36” must be allowed between

supply line must

Finished wall

to center of inlets/outlets

3-1/4”

6”

Finished Wall

IMPORTANT

MAKE SURE THE VALVE IS INSTALLED

FLUSH WITH FINISHED WALL AS SHOWN

MUD GAURD IS

TO PROTECT VALVE

DURING CONSTRUCTION.

REMOVE FOR

TRIM INSTALLATION.

AFCC

FINISHED WALL FLUSH

WITH THIS SURFACE

IMPORTANT

FINISHED WALL FLUSH

WITH THIS SURFACE

IMPORTANT

U

P

C

C

R

PART# 18.30.061

SHOWER ONLY VALVE

(ALSO USE FOR 78.30.061)

PART# 18.30.062

TUB / SHOWER ONLY VALVE

(ALSO USE FOR 78.30.062)

Notice:3200 spout is provided with 3/4” NPSM to1/2” NPT bushing

separately. Water sealing should be done by a licensed plumber.

FORM SIG 085 Revised 6-01-18

Page 2 of 4

!!

SETTING HOT LIMIT STOP

IT IS THE RESPONSIBILITY OF THE INSTALLER TO SET THE MAXIMUM OUTPUT TEMPERATURE OF THE VALVE AS SPECIFIED BY

THE AUTHORITY HAVING JURISDICTION IN ACCORDANCE WITH ASSE/ANSI 1016-2005 4.2.2 REQUIREMENTS.

thermometer or calibrated sensing device to accurately measure the outlet water temperature.

2. Turn off the water using both screw driver service stops.

3. Expose the top of the cartridge by removing the top hex cap from the valve body. FIG. 2

4. Remove the temperature ring by placing the blade of aknife into the groove and

prying it off. FIG. 3. It is not necessary to remove the inner hex nut.

5. Locate the stop tab on the bottom of the ring. The further it is re-oriented in a counter-clock

vary and water supply temperatures vary as well.

6. IMPORTANT!! BEFORE RE-ORIENTING THE RING, BE SURE THE STEMIS INTHE FULL OFF

POSITION.

maximum hot water temperature.

FIG. 2

FIG. 3

HEX CAP

TEMPERATURE

RING

1. Install extended stem and all thread onto cartridge stem. Fully seat stem onto cartridge by tightly securing all

thread nipple and locking nut onto valve. Install plate and centering nut. FIG 4a.

to extend. FIG 4b.

3. Place handle on stem and measure excess between escutcheon and handle base. Remove handle and cut

excess from end of stem using cut marks provided. FIG 4c.

4. FOR TUB/SHOWER TRIM:

REPLACEMENT PARTS:

18.30.893 Cartridge

18.30.894 Diverter Cartridge

18.30.891 16 pt. stem extension

18.30.892 20 pt. stem extension

18.30.890 All thread

FIG. 4c

Cut this distance

from end of Stem Extension

so handle sits just above

the escutcheon

Gap

Handle

Stem Extension

Diverter Handle Sleeve

Diverter Handle Stem and Sleeve

thread directly onto Valve Extension

FIG. 4a

Trim Plate

Trim Plate Centering Nut

(not used on all handle trim)

FIG. 4b

Cut All-thread Flush with

top of escutcheon

Escutcheon

All-thread

Cut

INSTALLING TRIM

FORM SIG 085 Revised 6-01-18

Page 3 of 4

HANDLE TENSION ADJUSTMENT

SIGMA offers many handles of varying sizes and weights. Each

design allows the installer to set the torque (tension) on each

valve that uses the standard assembly B through F as shown.

Part C is a loose brass O-ring that is compressed inside Part E by

tightening or loosening Part D.

REVERSING CARTRIDGE FOR BACK-TO-BACK INSTALLATIONS ONLY

allow normal operation. FIG. 5

1. Expose top of valve.

2. Loosen and remove hex cap above cartridge with wrench.

3. Remove cartridge from valve cavity.

4. Look into cavity tosee upper and lower locating holes for cartridge pin on

cutaway by discharge opening).

7. Secure cartridge by tightly re-assembling the cap using wrench.

8. Re-assemble trim.

FIG. 5

Malfunction Cause Remedy

Shower control opening

through hot.

Hot and cold water supplies have been

connected in reverse.

Rotate cartridge as described in

”Back to Back Installation”

drips after shutting off

valve.

the shower head (this is normal)

Failure to close cartridge before

setting temperature ring causing

a partially opened cartridge.

Seal on the inlet of the cartridge

is faulty.

Allow approx. 3-5 min. to drain column.*

Reset the temperature ring as described on Figure 3.

Check the seal for cuts or damage and replace if necessary.

Adjustable handle position stop incor-

rectly set.

- Reset handle position.

- Check hot water source temperature setting.

cold water.

Either the hot or the cold side is not fully

pressurized.

Debris caught inside the inlets of the

cartridge.

Be sure service stops are both wide open and system

is fully pressurized.

Install stem extension kit.

Trim parts do not

operate valve correctly.

Stem and all thread not installed to

proper lengths. or call customer service.

Trim plate will not install

wall.

Re-install valve to proper depth or call dealer for

custom trim plate.

Maintenance

The cartridge is designed for minimum maintenance in normal domestic use. If a malfunction occurs then this will

probably necessitate a complete replacement. The cartridge contains no internally serviceable parts! Contact your installer or dealer.

To Clean trim

and should never be used for cleaning decorative faucets.

Trouble Shooting - Pressure Balancing Valve

FORM SIG 085 Revised 6-01-18

Page 4 of 4

CONSUMER WARNING

CALIFORNIA PROPOSITION 65 WARNING

AMERICAN FAUCET & COATINGS CORPORATION

LIMITED PRODUCT WARRANTY

Product/Finish Warranty -

-

-

-

What we will do

What you must do:

use only. The faucets cannot be altered in any way. You must maintain and clean the faucets in accordance with the instructions

provided with the product. You must use the faucet(s) for residential use only.

How to obtain service:

American Faucet & Coatings Corporation

3280 Corporate View

Vista, CA 92081

contribute small amounts of lead to water that is allowed to stand in contact with the brass. This faucet complies with all E.P.A. regula-

tions regarding the amount of lead used in plumbing brass and solder. The amount of lead contributed by any faucet is highest when

AMERICAN AMERICAN

What is not covered:

-

ings Corporation's printed instructions. In the case of in-the-wall installations American Faucet and Coatings Corp. will as-

sume no liability if there is no access. In no event will we be liable for labor of any kind, incidental or consequential

damages. Many in-

(This does not include

Unless otherwise contrary to state law governing the purchase, American Faucet and Coatings Corporation's liability will not exceed the wholesale

also have other rights which vary from state to state. Some states do not allow exclusion of incidental or consequential damages, so the above

limitation may not apply to you.

LIFETIME WARRANTY ON 1/4 TURN CERAMIC DISC CARTRIDGE

hoses unless we have contacted you and have sent you an approved RGA form. All transportation charges for returned goods

must be paid by the customer.

known to the State of California to cause birth defects or other reproductive harm.

• Always run the water for a few seconds prior to use for drinking or cooking.

• Use only cold water for drinking or cooking.

This manual suits for next models

1

Other Sigma Control Unit manuals

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual