Signet 8900 User manual

‡ SIGNET

8900 Multi-Parameter Controller

Multi-Parameter

C1 2.50 µS/cm

F2 58.43 GPM

Relay 1 Relay 2

ENTER

Contents

Important Safety Information ................................................................................................................. 2

1. Description............................................................................................................................................... 3

2. Compatibility............................................................................................................................................ 3

3. System Overview..................................................................................................................................... 4

4. Specifications .......................................................................................................................................... 5

5. Installation and Basic Functionality ...................................................................................................... 7

5.1 Unpacking....................................................................................................................................................................... 7

5.2 Tools and Equipment Required: ................................................................................................................................... 7

5.3 Plug-in Modules ............................................................................................................................................................. 7

5.3.1 I/O Module ....................................................................................................................................................................... 8

5.3.2 Power Module .................................................................................................................................................................. 8

5.3.3 Output Module ................................................................................................................................................................. 9

5.3.4 Relay Module ................................................................................................................................................................... 9

5.3.5 External Relay Module................................................................................................................................................... 10

5.4 Mounting the Base Unit ............................................................................................................................................... 11

5.4.1 Panel Mounting .............................................................................................................................................................. 11

5.4.2 Mounting Accessories .................................................................................................................................................... 12

6. Wiring ..................................................................................................................................................... 13

6.1 I/O Module (3-8900.401-X) ........................................................................................................................................... 13

6.1.1 What is S3L™?............................................................................................................................................................... 13

6.1.2 Wiring Topologies........................................................................................................................................................... 13

6.1.2.1 Point-to-point.................................................................................................................................................................. 13

6.1.2.2 Daisy-chain .................................................................................................................................................................... 13

6.1.2.3 Multi-drop ....................................................................................................................................................................... 14

6.1.2.4 Combinations ................................................................................................................................................................. 14

6.1.2.5 Accessory Junction Boxes ............................................................................................................................................. 14

6.1.3 Maximum Cable Lengths ............................................................................................................................................... 14

6.1.3.1 Signal Type: Frequency ................................................................................................................................................. 14

6.1.3.2 Signal Type: S3L............................................................................................................................................................. 15

6.1.4 I/O Module (3-8900.401-X) Wiring Diagrams................................................................................................................. 16

6.2 Power Module (3-8900.402-X) ..................................................................................................................................... 19

6.3 Output Module (3-8900.405-X) .................................................................................................................................... 19

6.4 RS232 Communication Module (3-8900.404-1) ......................................................................................................... 19

6.5 Relay Module (3-8900.403-X)....................................................................................................................................... 20

6.6 External Relay Module................................................................................................................................................. 20

7. Operational Overview ........................................................................................................................... 21

7.1 Keypad Functions........................................................................................................................................................ 21

7.2 General Operation Flowchart...................................................................................................................................... 21

7.3 View Mode .................................................................................................................................................................... 22

7.3.1 Channel Types ............................................................................................................................................................... 22

7.3.2 Measurement Display Screens ...................................................................................................................................... 22

7.3.3 Derived Functions .......................................................................................................................................................... 23

7.3.4 Analog Output Values .................................................................................................................................................... 23

7.3.5 Relay Status Indicators .................................................................................................................................................. 23

7.3.6 Memo ............................................................................................................................................................................. 23

7.3.7 System Configuration..................................................................................................................................................... 24

7.3.8 Menu Directory............................................................................................................................................................... 24

28900 Multi-Parameter Controller

‡ SIGNET

Important Safety Information

• Read and understand instruction manual before using this product.

• This unit is designed to be connected to equipment which can be hazardous to persons and property if used incorrectly.

Read and understand all associated equipment manuals and safety warnings before using with this product.

• Do not remove rear panel slot shields if the modules are not installed.

• Remove power to unit before wiring input and output connections.

• Wiring connections to this product should only be performed by qualified personnel.

• Do not exceed published specifications in the use of this product.

• In case of communication error or loss of source signal:

• Relays will be deactivated.

• Current outputs will go to 22.1 mA.

• Voltage outputs will go to 0 V.

3-8900.620

100 - 240VAC

50-60Hz, 24VAMAX

~

11 - 24 VDC

0.7 A MAX.

N

L

+

-

Power Connection

DO NOT attempt to connect both

AC and DC at the same time

C

NO

NC

NO

NC

C

Solid State Relays

Rating:

50 mA 30V

Mechanical Relays

Rating:

5A 250 VAC

5A 30 VDC

~

+

-

+

-

~

CAUTION

8. Menus ..................................................................................................................................................... 25

8.1 General Guideline ........................................................................................................................................................ 25

8.1.1 Pre-configuration Guidelines.......................................................................................................................................... 26

8.1.2 Making Measurements after Pre-configuration .............................................................................................................. 26

8.2 System Setup ............................................................................................................................................................... 27

8.3 Channel Settings.......................................................................................................................................................... 28

8.3.1 Flow ............................................................................................................................................................................... 28

8.3.2 pH .................................................................................................................................................................................. 29

8.3.3 ORP ............................................................................................................................................................................... 29

8.3.4 Conductivity ................................................................................................................................................................... 29

8.3.5 Pressure......................................................................................................................................................................... 30

8.3.6 Temperature................................................................................................................................................................... 30

8.3.7 Level .............................................................................................................................................................................. 31

8.4 Hold Inputs ................................................................................................................................................................... 32

8.5 Relay ............................................................................................................................................................................. 33

8.6 Output ........................................................................................................................................................................... 35

8.7 Calibration .................................................................................................................................................................... 36

8.7.1 Flow ............................................................................................................................................................................... 36

8.7.2 pH .................................................................................................................................................................................. 37

8.7.3 ORP ............................................................................................................................................................................... 37

8.7.4 Conductivity ................................................................................................................................................................... 38

8.7.5 Pressure......................................................................................................................................................................... 38

8.7.6 Temperature................................................................................................................................................................... 38

8.7.7 Level .............................................................................................................................................................................. 38

8.8 Options ......................................................................................................................................................................... 39

8.8.1 Standard password ........................................................................................................................................................ 39

8.8.2 Enhanced password ...................................................................................................................................................... 39

8.8.2.1 Enhanced password Reset Procedure: ......................................................................................................................... 39

Appendix A: Derived Functions........................................................................................................................................................ 41

Appendix B: Level System Configuration ....................................................................................................................................... 42

Appendix C: Conductivity/Resistivity Application.......................................................................................................................... 44

Appendix D: USP Limits .................................................................................................................................................................... 45

Appendix E: Relay mode descriptions ............................................................................................................................................ 46

Appendix F: 8900 display messages ............................................................................................................................................... 47

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

SENSOR INPUTS

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

N

L

+

-

AC ONLY

+

-

+

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

SENSOR INPUTS

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

N

L

+

-

DC ONLY

+

-

+

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

For additional operator safety, an adhesive power indication

label (AC ONLY or DC ONLY) is packaged with each Power

Module and should be applied to the 8900 rear panel as

illustrated.

IMPORTANT SAFETY INFORMATION

38900 Multi-Parameter Controller ‡ SIGNET

1. Description

The 8900 Multi-Parameter Controller takes the concept of modularity to the extreme. Two base units, one with back-lit LCD and the

other with vacuum fluorescent display can be configured by the user in the field. Ultimate flexibility is achieved via plug-in modules for

either two or four input channels, universal AC line voltage or 12 to 24 VDC power, up to four analog outputs, and up to four relays.

The controller will support up to four additional relays, for a total of eight, by way of external relay modules. Absolute input versatility

allows mixing and matching of up to four sensors with S3L™ output including pH, ORP, conductivity/resistivity, pressure, temperature,

and level. Up to two of the possible four input channels may be used for any combination of the many +GF+ SIGNET flow sensors with

frequency output. See Section 2 Compatibility for sensor models and other devices available for use with this controller.

2. Compatibility

Model numbers of sensors and external relays compatible with

the 8900 are identified in the tables below.

• For two channel systems, mix and match up to two of any of these sensors.

• For four channel systems, mix and match up to four sensors with S3L output. Up to two of the four channels may be used for

frequency inputs.

• It is not necessary to select sensor types or external relays prior to purchasing 8900 Base Units. All 8900 systems are completely

“field commissionable”.

• The optional external relays connect via S3Lto the I/O Module, but do NOT consume a sensor input channel.

• pH and conductivity sensors include temperature sensors. These "secondary" measurements are treated by the 8900 as separate

sensors with respect to display, output and relay functionality, but they do NOT consume separate input channels.

SIGNET

FLOW

+GF+

XXDN XX X

XX

+GF+

XXDN XX X

XX

515 525 2517 2536 2540 2541 2100 2000 2507 2550 2560 7000 7001 7002

Freq. Freq. Freq. Freq. Freq. Freq. Freq. Freq. Freq. Freq. nc nc

Freq. Freq.

Paddlewheel Turbine, Mini & Micro Flow Insertion Mag Vortex

Flow Sensors

Freq.

S3L

nc

Le

g

end

Compatible with the 8900; signal type is Frequency

Compatible with the 8900; signal type is S 3L

Not compatible with the 8900

RELAYA RELAYB

+

S

3

L

- +

S

3

L

-

OUTPUT24VDC

+ -

ACINPUT

Relay Module

DATA

POWER

TESTA

TEST B

RelayA

Relay B

TEST C

TEST D

Relay C

Relay D

INPUT PASS-THRU

L N

RELAYC RELAYD

8059 External

Relay Modules

2850 Sensor

with DryLoc Electrodes

281x to 282x and

2839-1X to 2842-1x

2450

2350

2750 Sensor with

DryLoc Electrodes

S

3

L

2720 Preamplifier

with Twist-Lock Electrodes

nc nc nc

2721 Preamplifier

S

3

LS

3

LS

3

LS

3

L

pH & ORP

Sensors

Cond/Res

Sensors

Pressure

Sensors

Tem p.

Sensors

Other

48900 Multi-Parameter Controller

‡ SIGNET

3. System Overview

The most basic 8900 system consists of a Base Unit, an I/O Module and a Power Module. Outputs and relays are optional. Each item

is ordered separately. The variety of configurations attainable from this modularity is extraordinary.

See Section 5 Installation & Basic Functionality, and Ordering Information for more details.

a. Base Unit, required; choose one (1) either back-lit LCD or Vacuum Fluorescent display.

b. Rear panel shown installed with shields in place for the optional modules. No plug-in modules are installed in this view.

c. Slot for the required I/O Module. Choose one (1) for either two or four input channels. This module is also used for optional

Analog Outputs 1 & 2.

d. Slot for the required Power Module. Choose one (1) to power the unit with either universal AC line voltage or 12 to 24 VDC.

e. Slot for an optional Output Module. Choose Analog Outputs 3 & 4, or RS232, or neither.

f. Slot for an optional Relay Module. Choose Relays 1 & 2, or not.

g. Slot for another optional Relay Module. Choose Relays 3 & 4, or not.

h. External Relay Modules connect via S3L™to the I/O Module and are optional.

i. Plug-in modules slide into the base unit on rails and are then held securely in place by the rear panel. Changes and upgrades can

be made in the field at any time.

OUT 2 OUT 1

SENSOR INPUTS

POWER

COMM PORT/

OUT 4 OUT 3

RELAY 4RELAY 3

RELAY 2RELAY 1

c

d

h

eg

b

f

i

aMulti-Parameter

C1 2.50 µS/cm

F2 58.43 GPM

Relay 1 Relay 2

ENTER

58900 Multi-Parameter Controller ‡ SIGNET

General:

Configurability: Modular (completely field-commissionable)

Number of input channels: 2 or 4

Compatible sensor models: See Section 2. Compatibility

Input signal types:

S3L™: Serial ASCII, TTL level 9600 bps

Frequency: Range: 0 to 1500 Hz

Accuracy: 0.5% of reading

Measurement types: Flow, pH, ORP, Conductivity/

Resistivity, Pressure, Temperature,

Level

Derived measurements: Sum, Difference, Ratio, % Recovery,

% Reject, % Passage

Number of relays supported:

Avail. in pairs: 0, 2, 4, 6 or 8

(Dry-contact and/or Solid State)

Number of analog outputs: Avail. in pairs: 0, 2 or 4

(active and/or passive

4 to 20 mA; and/or 0 to 5/10 VDC)

Enclosure and Display

Enclosure Rating:NEMA 4X/IP65 (front face only)

Case Material: PBT

Panel Gasket: Silicone Sponge

Window: Self-healing polyurethane-coated

polycarbonate

Keypad: 4-buttons, highly tactile and audible

Injection-molded silicone rubber seal

Display: Alphanumeric 2 x 16 Back-lit

LCD or Vacuum Fluorescent versions

Update rate: 1 second

Accuracy: Sensor dependent

Vacuum Fluorescent

Brightness: 4 intensity levels

LCD Contrast: 4 settings

Display ranges:

(Refer to Sensor Specifications for actual measurement limits)

pH: 0.00 to 15.00 pH

pH Temp.: -40 to 150°C (-40 to 302°F)

ORP: -9999 to +9999 mV

Flow Rate: 0.0000 to 999999 units per

second, minute, hour or day

Totalizer: 0.00 to 99999999 units

Conductivity: 0.0000 to 999990 µS, mS, PPM & PPB (TDS),

kΩ, MΩ

Cond. Temp.: -99.9 to 250°C (-148 to 482°F)

Temperature: -99.9 to 999.9°C (-148 to 999.9°F)

Pressure: -99.99 to 9999 psi, kPa, bar

Level: -99999 to 99999 m, cm, ft, in, %

Volume: -99999 to 999999 cm3, m3, in3, ft3, gal, L, lb, kg, %

Electrical:

Power Requirements (AC or DC via Power Modules)

Universal AC: 120 to 240 VAC ±10%, 50-60 Hz, 24 VA max.

DC: 11 to 24 VDC ±10%, unregulated, 0.7A max.

Output Power to Sensors:

5VDC up to 40 mA total

Terminal type: Screw clamp, removable via plug-in modules

4. Specifications

Dimensions

NC C NO

RELAY A

NC C NO

RELAY B

NC C NO

RELAY C

NC C NO

RELAY D

+

S

3

L

- +

S

3

L

-

OUTPUT 24VDC

+ -

AC INPUT

‡ SIGNET

Relay Module

DATA

POWER

TESTA

TEST B

Relay A

Relay B

TEST C

TEST D

Relay C

Relay D

INPUT PASS-THRU

L N

89 mm

(3.5 in.)

57 mm

(2.25 in.) 108 mm (4.25 in.)

68900 Multi-Parameter Controller

‡ SIGNET

Analog Outputs (via I/O Modules and Output Modules)

Any and all analog outputs are freely assignable to any channel.

4 to 20 mA Output:

Endpoints are adjustable and reversible:

Min. default: 4.0 mA; adjustable from 3.8 to 5.0 mA

Max. default: 20.00 mA; adjustable from 19.0 to 21.0 mA

Test mode: Produces an adjustable 4 to 20 mA signal for

functional verification of each output circuit

Isolation: Up to 48 V AC/DC

Error condition: 22.1 mA

(default state if output source not configured)

Update rate: 100 mS

Accuracy: ±32 µA over entire operating temperature range

Resolution: 6 µA

Power Supply Rejection: ±1 µA/V

Short circuit and reverse polarity protected

Passive 4 to 20 mA:

Voltage: ` 12 to 24 VDC +/- 10%

Max. Impedance: 250 ohms @ 12 VDC

500 ohms @ 18 VDC

750 ohms @ 24 VDC

Active 4 to 20 mA:

Max Impedance: 650 ohms

0 to 5/10 VDC Output:

Output range: 0 to 5 VDC or 0 to 10 VDC, software selectable

Endpoints are adjustable and reversible:

Min. default: 0 VDC; programmable from 0 to 0.5 VDC

Max. default: 5 VDC; programmable from

4.5 to 5.5 VDC, or 9.5 to 10.5 VDC

Output load: 10 kΩminimum

Test mode: Produces an adjustable signal for functional

verification of each output circuit

Isolation: Up to 48 V AC/DC

Error condition: 0 VDC (default state if output source not

configured)

Update rate: 100 mS

Accuracy: ±20 mV over entire operating temperature

range

Resolution: 5 mV

Power Supply Rejection: 0.5 mV/V

Relay Modules

Any and all relays are freely assignable to any channel.

Internal relay modes of operation:

Off, Low, High, Window, Pulse, PWM, USP

External relay modes of operation: Off, Low, High, Window, USP

Hysteresis: User adjustable

Time Delay: 0 to 6400 seconds

Solid State Relays (non-mechanical switches)

Normally open/closed operation:

Software selectable

Max. pulse rate: 600 pulses per minute

(volumetric pulse & PWM modes)

400 pulses per minute

(prop. pulse mode)

Max. voltage rating: 30 VDC or 42 VAC p-p

Current rating: 50 mA DC or 50 mA AC RMS

On-state impedance: 30 ohms or less

Off-state leakage: 400 nA or less, AC or DC

Isolation: Up to 48 V AC/DC

Transient protection: Embedded, up to 48 V over-voltage

Dry-contact Relays (mechanical contacts)

Type: SPDT

Form: C

Max. pulse rate: 600 pulses per minute

(volumetric pulse & PWM modes)

400 pulses per minute

(prop. pulse mode)

Max. voltage rating: 30 VDC or 250 VAC

Current rating: 5 A

RS232 Communication Module

Connector: Female DB-9

Utilization: Clone Mode, initially

(fully functional RS232 output is pending)

Environmental

Ambient operating temperature:

Back-lit LCD: -10 to 55°C (14 to 131°F)

Vacuum Fluorescent Display:

-10 to 50°C (14 to 122°F)

Storage Temp.: -15 to 80°C (5 to 176°F)

Relative Humidity: 0 to 95%, non-condensing

Maximum Altitude: 2,000m (6,560 ft.)

4,000m (13,123 ft.); use only DC

power supply and, if applicable,

solid state relays to maintain UL safety

standard up to this altitude

Standards and Approvals

UL 3101-1

CSA Standard C22.2

CE rating for heavy industry

Immunity: EN61326-1 and EN 61326-2

Emissions: EN55011, Class A and Class B

Low Voltage Directive: EN61010

Manufactured under ISO 9001 and ISO 14001

Shipping Weights

Base Unit 1.00 kg (2.25 lb.)

Power Module 0.12 kg (0.25 lb.)

I/O Module 0.12 kg (0.25 lb.)

Output Module 0.12 kg (0.25 lb.)

Relay Module 0.12 kg (0.25 lb.)

RS232 Communication Module 0.12 kg (0.25 lb.)

78900 Multi-Parameter Controller ‡ SIGNET

5. Installation and Basic Functionality

This section lists all items included with individual 8900 system components, describes installation detail for plug-in modules and base

units, and provides information and instruction on the basic functionality of the plug-in modules.

5.1 Unpacking

Base units, plug-in modules, accessories and spare parts are sold, packaged and shipped

separately from the factory. Unpack all components carefully. The following items accompany every 8900 base unit:

• 8900 Base Unit (back-lit LCD or Vacuum Fluorescent display)

• Front Face Panel Gasket (pre-installed on base unit)

• Quick-clip panel mounting bracket

• Adhesive Template for panel cutout

• Instruction Manual, Paper copy – English (paper copies of other languages sold separately)

• CD-ROM containing instruction manuals in English, French, German, Spanish, Italian and Portuguese; +GF+ SIGNET briefcase

website (www.gfsignet.com); PowerPoint presentation; other useful information.

5.2 Tools and Equipment Required:

• Philips screwdriver (medium tip)

• Standard screwdriver (small/medium tip)

• Diagonal cutters (small)

• File (fine)

•1/4DIN punch or jigsaw suitable for cutting panel opening to within 1 mm (0.020 in.) tolerance.

• Remove terminals from the receptacle of each plug-in module prior to installation.

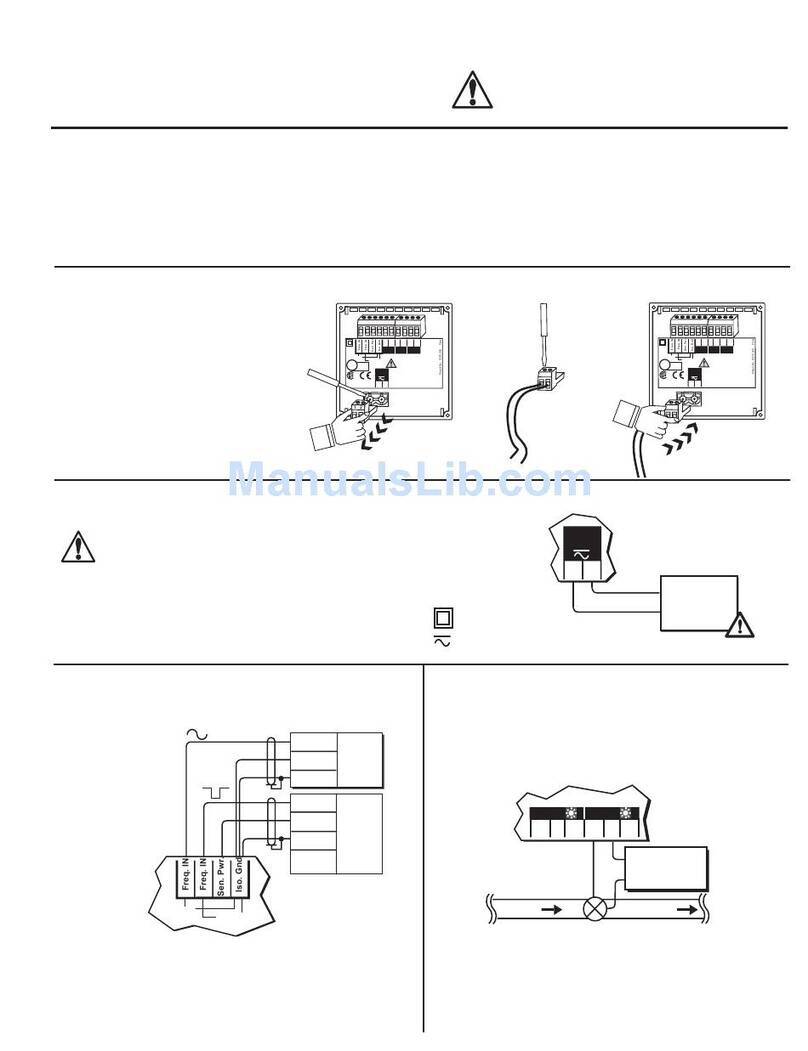

• Identify the appropriate slot per the illustrations below, then use the guide rails and slide the plug-in

modules all the way into the base unit until the self-aligning electrical connections "click" to a positive

seat.

• Use diagonal cutters to remove slot shields from the rear panel for optional plug-in modules as required.

Only remove shields for slots to be used (UL safety requirement).

• Smooth any protruding edges with a file.

• Reinstall the rear panel; it will hold the modules securely in place.

5.3 Plug-in Modules

• If the 8900 Base Unit will be mounted in a panel, plug-in modules may be installed either before or after the base unit is mounted.

If the 8900 Base Unit will be mounted using the accessory Wall Mount Bracket, first install plug-in modules.

• Plug-in modules are packaged in anti-static bags and contain individual instruction sheets and removable terminals for convenient

wiring. Minimize handling of plug-in modules to reduce the probability of damage due to static discharge.

• I/O Modules and Power Modules also include adhesive labels to be applied to the outside of the 8900 enclosure in specific

locations as illustrated in sections 5.3.1 and 5.3.2.

• The rear panel of the 8900 must be removed prior to installing or removing plug-in modules. And

if plug-in modules are already installed, the terminals must be removed prior to removing the rear

panel! It may be helpful to use a standard screwdriver to gently pry removable terminals away

from the receptacle on the plug-in modules.

• Use a Philips screwdriver to loosen the two captive screws at the bottom of the panel. Pinch one

of the screws and swing the panel up approximately 90°, using the tab hinge at the top of the

panel, and pull it straight away from the base unit. Reverse this step to reinstall the panel after

the plug-in modules are installed.

Base unit 3-8900- _______ S/N___________________

I/O Module 3-8900.401-____ S/N___________________

Power Module 3-8900.402-____ S/N___________________

Relay Module 3-8900.403-____ S/N___________________

Relay Module 3-8900.403-____ S/N___________________

Ext Relay Module 3-8059-________S/N__________________

Output Module 3-8900.405-____ S/N___________________

Comm Module 3-8900.404-____ S/N___________________

OUT 2 OUT 1

SENSOR INPUTS

POWER

COMM PORT/

OUT 4 OUT 3

RELAY 4RELAY 3

RELAY 2RELAY 1

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

BLK

RED

SHLD

BLK

RED

S L

SHLD

BLK

S L

SHLD

+

-

+

-

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

SENSOR INPUTS

3

3

+

-

+

-

N

L

+

-

For future reference, for each installation, it is recommended to record the part number and serial number of each of the

components listed here:

Facility Tag Number or System ID (user assigned):_______________________

88900 Multi-Parameter Controller

‡ SIGNET

3-8900.621C

I/O Module 3-8900.401-X 1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (White/Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

5.3.1 I/O Module, required; install one (1)

Mfr. Part No. Description

3-8900.401-1 Two inputs, no outputs

3-8900.401-2 Two inputs, two passive 4 to 20 mA outputs

3-8900.401-3 Two inputs, two active 4 to 20 mA outputs

3-8900.401-4 Two inputs, two 0 to 5/10 VDC outputs

3-8900.401-5 Four inputs, no outputs

3-8900.401-6 Four inputs, two passive 4 to 20 mA outputs

3-8900.401-7 Four inputs, two active 4 to 20 mA outputs

3-8900.401-8 Four inputs, two 0 to 5/10 VDC outputs

• These modules determine the maximum number of sensor input channels available for

the instrument. Unwanted or unused channels can remain completely hidden for

uncluttered single or three-channel operation.

• Optional analog outputs are contained on the I/O Module, and will always be identified

as Outputs 1 & 2 in the 8900 menus. Any and all analog outputs are freely assignable

to any channel. All analog outputs available from the 8900 are isolated.

• An adhesive terminal designation label is included with each I/O Module and should be

applied to the side of the 8900 base unit as illustrated, or to a more convenient surface

for quick and easy access.

3-8900.620

100 - 240VAC

50-60Hz, 24VAMAX

~

11 - 24VDC

0.7 A MAX.

N

L

+

-

Power Connection

DO NOT attempt to connect both

AC and DC at the same time

C

NO

NC

NO

NC

C

Solid State Relays

Rating:

50mA 30V

Mechanical Relays

Rating:

5A 250 VAC

5A 30 VDC

~

+

-

+

-

~

CAUTION

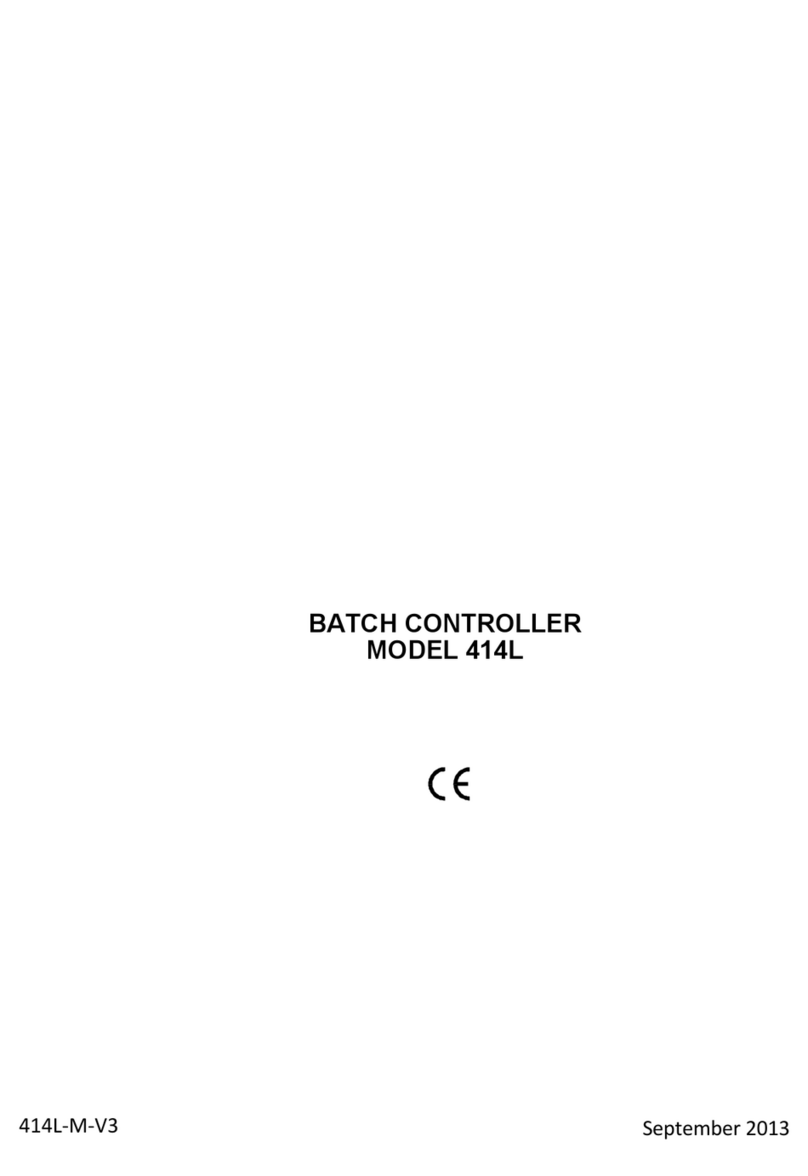

5.3.2 Power Module, required; install one (1)

Mfr. Part No. Description

3-8900.402-1 85 to 264 VAC, 50/60 Hz

3-8900.402-2 12 to 24 VDC +/-10%

• Each 8900 Base Unit may be powered with either AC or DC voltage, but not both

simultaneously (no "uninterruptible" power option).

• The AC Power Module is universal; no jumper selection is required.

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

SENSOR INPUTS

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

N

L

+

-

AC ONLY

+

-

+

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

SENSOR INPUTS

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

N

L

+

-

DC ONLY

+

-

+

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

For additional operator safety, an adhesive power indication label

(AC ONLY or DC ONLY) is packaged with each Power Module

and should be applied to the 8900 rear panel as illustrated.

IMPORTANT SAFETY INFORMATION

98900 Multi-Parameter Controller ‡ SIGNET

5.3.3 Output Module, optional; install zero (0) or one (1)

Mfr. Part No. Description

3-8900.405-1 Two passive 4 to 20 mA outputs

3-8900.405-2 Two active 4 to 20 mA outputs

3-8900.405-3 Two 0 to 5/10 VDC outputs

3-8900.404-1 RS232 Communication Module (see NOTE below)

• Optional analog Outputs 1 & 2 are obtained via the I/O Module, but are not

required to be installed in order to use the optional analog output modules

listed immediately above.

• However, the analog outputs obtained via these separate modules will always

be identified as Outputs 3 & 4 in the 8900 menus. The slot on the rear panel

is labeled accordingly.

• It is perfectly acceptable to mix and match analog output types between those

contained on the I/O Module and those obtained via these separate modules.

• Any and all analog outputs are freely assignable to any channel.

• All analog outputs available from the 8900 are isolated.

• Passive outputs throttle current in loops powered by a supply external to the

8900.

• Active outputs throttle current in loops powered by the 8900; no external

power source is required.

• Voltage outputs are independently software selectable for operation from 0 to 5 or 0 to 10 VDC.

• NOTE: Upon initial introduction of the 8900 product series, the RS232 Communication Module will be limited to Clone Mode

functionality. This feature requires the accessory DB-9 Crossover Cable and allows an 8900 instrument to adopt all software

settings of another 8900 instrument. Both instruments must have RS232 Communication Modules installed.

• Fully functional RS232 output is pending.

Mfr. Part No. Description

3-8900.390 DB-9 Crossover Cable

5.3.4 Relay Module, optional; install zero (0), one (1) or two (2)

Mfr. Part No. Description

3-8900.403-1 Two dry-contact relays

3-8900.403-2 Two solid-state relays

• Up to two sets of two relays may be installed directly into the 8900. The modules are

completely independent of one another, so it is not necessary for Relays 1 & 2 to be

installed in order to use Relays 3 & 4.

• However, in accordance with the labeling on the rear panel, relays installed directly into

the 8900 via these plug-in modules will always be identified in the 8900 menus as Relays

1 & 2 and 3 & 4, respectively.

• The red LED relay status indicators on the front panel of the 8900 are hardwired to

Relays 1 & 2. If the slot for Relays 1 & 2 is vacant, the red LEDs will be inoperative.

Status of all relays is available at all times in a single screen in View mode.

• It is perfectly acceptable to mix and match the relay types installed directly in the 8900,

as well as between internal and external modules.

• Any and all relays are freely assignable to any channel. Hysteresis

and time delay are adjustable for each relay.

• Dry-contact relays are electromechanical switches that "click" during

operation. They are suitable for many general-purpose applications,

AC or DC, including AC loads up to 250 V.

• Solid-state relays are electronic switches that operate silently and

may be used with AC or DC loads, but have lower current handling

capability and voltage ratings than Dry-contact relays. Solid-state

relays will outlast Dry-contact relays in pulsing applications.

• Switching active loads (most commonly inductive) can cause contact

arcing sufficient to damage both types of relays. The RC Filter Kit or

"snubber" is available as an accessory to reduce or eliminate these

damaging effects.

Mfr. Part No. Description

3-8050.396 RC Filter Kit

3-8900.620

100 - 240VAC

50-60Hz, 24VA MAX

~

11 - 24 VDC

0.7 A MAX.

N

L

+

-

Power Connection

DO NOT attempt to connect both

AC and DC at the same time

C

NO

NC

NO

NC

C

Solid State Relays

Rating:

50 mA 30V

Mechanical Relays

Rating:

5A 250 VAC

5A 30 VDC

~

+

-

+

-

~

CAUTION

10 8900 Multi-Parameter Controller

‡ SIGNET

8059-2

NC COM NO

RELAYA

NC COM NO

RELAY B

DC OUTPUT

+ - DC INPUT

‡ SIGNET

Relay Module

DATA

POWER

TESTA

TEST B

Relay A

Relay B

- +

+

S

3

L

- +

S

3

L

-

INPUT PASS-THRU

8059-4

NC COM NO

RELAYA

NC COM NO

RELAY B

NC COM NO

RELAY C

NC COM NO

RELAY D

DC OUTPUT

+ - DC INPUT

‡ SIGNET

Relay Module

DATA

POWER

TESTA

TEST B

Relay A

Relay B

- +

TEST C

TEST D

Relay C

Relay D

+

S

3

L

- +

S

3

L

-

INPUT PASS-THRU

5.3.5 External Relay Module, optional; install zero (0) or one (1)

Mfr. Part No. Description

3-8059-2 Two external dry-contact relays

3-8059-2AC Two external dry-contact relays w/ power supply

3-8059-4 Four external dry-contact relays

3-8059-4AC Four external dry-contact relays w/ power supply

• The 8900 will support up to eight (8) relays, though only four actually fit directly

inside its compact 1/4DIN enclosure! 8059 External Relay Modules of either two

or four relays may be connected to the 8900 via S3L at the I/O Module (this does

NOT consume a sensor input channel).

• External relays are completely independent of internal relays, so it is not

necessary for Relays 1 & 2 or 3 & 4 to be installed in order to use the external

relays. In the 8900 menus, external relays will always be identified as Relays A,

B, C and D.

• 8059 versions with power supply are powered by universal AC line voltage and

may be used to power the 8900 with 24 VDC. Also, S3Lpass-thru terminals on

the 8059 can help to reduce sensor wiring congestion at the 8900. See Section

6 Wiring and/or the 8059 instruction manual for more details.

• External Relays mount on DIN rail inside a panel and can be tested remotely

from the 8900, or locally with switches built-in for convenience. They also

include LED relay status indicators, but the status of these and all relays is

available at all times in a single screen in the 8900 View mode.

• Any and all relays are freely assignable to any channel. Hysteresis and time

delay are adjustable for each relay.

• It is perfectly acceptable to mix and match relay types between internal and

external modules. However, NOTE: The 8900 only allows external relays to be

used in modes Off, Low, Hi, Window and USP.

• 8059 External Relay Modules contain dry-contact relays only. These

electromechanical switches “click” during operation and are suitable for many

general-purpose applications, AC or DC, including AC loads up to 250 V.

• Switching active loads (most commonly inductive) can cause contact arcing

sufficient to damage relays. The RC Filter Kit or “snubber” is available as an

accessory to reduce or eliminate these damaging effects.

Mfr. Part No. Description

3-8050.396 RC Filter Kit

6205-0002 DIN Rail, 1m

6205-0003 End Clips, DIN Rail

RELAYA RELAY B

+

S

3

L

- +

S

3

L

- OUTPUT 24VDC

+ - AC INPUT

‡ SIGNET

Relay Module

DATA

POWER

TESTA

TEST B

Relay A

Relay B

INPUT PASS-THRU

L N

8059-2AC

+

S

3

L

- +

S

3

L

- OUTPUT 24VDC

+ - AC INPUT

‡ SIGNET

Relay Module

DATA

POWER

TESTA

TEST B

Relay A

Relay B

TEST C

TEST D

Relay C

Relay D

INPUT PASS-THRU

L N

8059-4AC

NC COM NO

RELAY C

NC COM NO

RELAY D

NC COM NO

RELAYA

NC COM NO

RELAY B

NC COM NO NC COM NO

NC C NO

RELAYA

NC C NO

RELAY B

NC C NO

RELAY C

NC C NO

RELAY D

+ S

3

L- + S

3

L-

OUTPUT 24VDC

+ - AC INPUT

‡ SIGNET

Relay Module

DATA

POWER

TESTA

TEST B

Relay A

Relay B

TEST C

TEST D

Relay C

Relay D

INPUT PASS-THRU

L N

89 mm

(3.5 in.)

57 mm

(2.25 in.) 108 mm (4.25 in.)

118900 Multi-Parameter Controller ‡ SIGNET

5.4 Mounting the Base Unit

The 8900 may be mounted in a panel, on a wall, or on virtually

any surface including shelves, racks and pipes. All methods of

mounting the 8900 make use of the +GF+ SIGNET Quick-clip for

holding the instrument securely in place. This unique clip

eliminates the hassle of locating and drilling holes for mounting

screws.

If the 8900 will be mounted in a panel, plug-in modules may be

installed either before or after the base unit is mounted. If an

accessory Wall Mount Bracket will be used, first install plug-in

modules.

5.4.1 Panel Mounting

• The 8900 enclosure conforms to the 1/4DIN standard, which

requires a panel opening of 92 mm x 92 mm (3.6 x 3.6 in.).

•1/4DIN punches are available and recommended for creating

clean, precise openings quickly and easily in most instrument

panels.

• Alternatively, a jigsaw or other cutting tool may be used. An

adhesive template is provided to help guide the cutting

process.

• Recommended minimum clearance on all sides between

instruments and panel edges is 25 mm (1 in.) as illustrated.

• Use an appropriate file as necessary to shape and size the

opening, and to remove burrs.

123 mm/

4.85 in. 56 mm/

2.21 in.

Splashproof

Rear Cover

(accessory)

Multi-Parameter

C1 23.45 µS/cm

L2 -16.58 ft

Relay 1 Relay 2

ENTER

96 mm/3.78 in.

96 mm/

3.78 in. 92 mm/

3.62 in.

Quick-clip

mounting

bracket

Multi-Parameter

C1 23.45 S/cm

L2 -16.58 ft

Relay 1 Relay 2

ENTER

Quick-clip

gasket on

front side

of panel

3-8050.395

Splashproof

rear cover

panel

terminals

mounting

bracket

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

SENSOR INPUTS

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

+

-

+

-

N

L

+

-

BLK

RED

SHLD

BLK

RED

S L

SHLD

BLK

S L

SHLD

+

-

+

-

3

3

AC ONLY

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

Panel Cutout

92 x 92 mm

(+ 0.8, - 0 mm)

3.6 x 3.6 in.

(+0.031, -0 in.)

minimum

clearance

25 mm

(1 in.)

To install 8900 in a panel:

1. Slide the 8900 into the opening from the front of the panel.

Ensure the Front Face Panel Gasket is properly seated

against the panel and around the instrument case.

2. Slide the Quick-clip mounting bracket over the back of the

instrument as illustrated. The Quick-clips will snap into

engagement with the molded latches on the side of the

instrument. Press the bracket against the inside of the panel

to secure the instrument firmly in place.

• To remove, press the Quick-clips outward while pulling the

bracket away from the instrument panel. DO NOT ALLOW

THE INSTRUMENT TO FALL FORWARD OUT OF THE

PANEL OPENING! It may be necessary/helpful to

temporarily secure the instrument from the front with tape,

etc.

3-5000.399 Panel adapter,

5 in. x 5 in. to 1/4DIN 3-8050.392 Panel adapter,

1/2DIN to 1/4DIN

Multi-Parameter

C1 23.45 S/cm

L2 -16.58 ft

Relay 1 Relay 2

ENTER

• Two panel adapter accessories are available for installing the

8900 into panels with existing cutouts larger than the 1/4DIN

standard.

12 8900 Multi-Parameter Controller

‡ SIGNET

5.4.2 Mounting Accessories

Refer to section 5.4.1 regarding the use of the Quick-clip for securing the 8900 instrument in panel adapters or brackets.

Mfr. Part No. Description

3-8050.395 Splashproof rear cover

• Use in conjunction with liquid tight connector kits to seal wiring

ports.

• Protects rear of instrument and terminals from moisture intrusion

and corrosion.

• Suitable for indoor and outdoor installations.

• 3-9000.392 Liquid tight connector kit, NPT (3 connectors)

• 3-9000.392-1 Liquid tight connector kit, NPT (1 connector)

• 3-9000.392-2 Liquid tight connector kit, PG13.5 (1 connector)

Mfr. Part No. Description

3-0000.596-1 1/4DIN wall mount bracket, 6.5 in. depth

• Use to mount the 8900 (without a splashproof rear cover) to a solid wall or

bulkhead.

• Powder coated aluminum, black, 3.2 mm (0.125 in.) thick

Mfr. Part No. Description

3-0000.596-2 1/4DIN wall mount bracket, 9.0 in. depth

• Use to mount the 8900 (with a Splashproof rear cover) to a solid wall or

bulkhead.

• Powder coated aluminum, black, 3.2 mm (0.125 in.) thick

Mfr. Part No. Description

3-5000.598 Shelf/pipe mount bracket, 1/4DIN instrument

• Use for surface mount installations under a shelf, or on a counter or

rack.

• Powder coated aluminum, black, 3.2 mm (0.125 in.) thick

• Nylon straps or other suitable fasteners may be used to secure this

bracket to a pipe.

Mfr. Part No. Description

3-8050.392 Panel adapter, 1/2DIN to 1/4DIN

• Converts existing panel cutouts, up to 96 x 192 mm (3.8 x 7.6

in.), to 1/4DIN (92 x 92 mm)

• Powder coated aluminum, black, 3.2 mm (0.125 in.) thick

• Neoprene gasket and machine screw hardware included

Mfr. Part No. Description

3-5000.399 Panel adapter, 5 x 5 in. to 1/4DIN

• Converts 127 x 127 mm (5 x 5 in.) panel cutouts to 1/4DIN

• Primarily used when replacing retired 500-series

+GF+ SIGNET instruments with modern 1/4DIN instruments

• Injection molded black plastic (Acetal)

• Neoprene gasket and machine screw hardware included

1/2" NPT

138900 Multi-Parameter Controller ‡ SIGNET

6. Wiring

All wiring connections to the 8900 are made via the removable terminals of the plug-in modules. This section contains instructions and

diagrams for wiring each type of module. Several helpful tables, explanations and recommendations are also provided. In general:

• Do not allow any AC leads that may be connected to the Power Module, or to optional internal relays, to come in contact with low

voltage wiring.

• Terminals accept 12 to 24 AWG wire.

• Strip 10 to 12 mm (0.4 to 0.5 in.) of insulation from wire tips and tin bare ends to eliminate fraying.

• Use ferrules when connecting more than one wire to a single terminal of a module or a junction box.

• Insert wire tip or ferrule completely into the terminal and secure with the screw until finger tight.

6.1 I/O Module (3-8900.401-X)

• The I/O Module provides the terminals for sensor inputs, optional external relays, and optional Analog Outputs 1 & 2.

• These modules (3-8900.401-X) support frequency and S3L™ sensor input signal types. External relays are controlled via S3L and

connect to the I/O Module just as if they were S3L sensors. External relays do NOT consume a sensor input channel.

• Refer to Section 6.3: Output Module for wiring optional Analog Outputs 1 & 2.

6.1.1 What is S3L™?

S3L™ is a +GF+ SIGNET trademark meaning Signet Sensor Serial Link. It is a serial communication system that provides a common

digital interface between +GF+ SIGNET sensors, instruments, and other devices. Two very practical benefits of S3L are explained

below. Visit www.gfsignet.com for more details.

1. Digital networks like S3L™ have better noise immunity and pose fewer ground loop problems compared to analog methods of

signal transmission. This can be extremely important when measurement systems must be installed in close proximity to notorious

sources of EMI such as high-power lines, three-phase transformers, motor starters, generators, etc.

2. In an S3L network, measurement data and other information are exchanged in "packets" marked by individual device identification

codes. This means that if multiple S3L devices will be used with an 8900, then the interconnecting wiring may be shared in Multi-

drop and/or Daisy-chain topologies. When compared to traditional point-to-point wiring, these topologies may reduce total wire and

conduit requirements significantly.

6.1.2 Wiring Topologies

Several options for the physical routing of wire and conduit used to connect sensors and external relays to I/O Modules

(3-8900.401-X) are described in this section. Diagrams are provided to convey the basic idea of each topology. These configurations

plus variations and many possible combinations exemplify the extraordinary versatility of the 8900 system. Consult the tables in

Section 6.1.3: Maximum Cable Lengths to determine the total maximum allowable cable length for any installation.

6.1.2.1 Point-to-point

This familiar topology is characterized by the direct wiring of

individual devices to an I/O Module.

• All frequency inputs MUST be wired in this fashion.

•S

3L devices may also be connected point-to-point, and/or by the

other topologies described below.

• Integral junction boxes are built-in to some sensors for

convenience. Other very useful versions with either 3/4in. NPT

or Universal mount are available as accessories for all other

sensors.

6.1.2.2 Daisy-chain

This topology is characterized by the sequential connection of one S3L device to another, and may allow significant reductions in

total wire and conduit when compared to point-to-point

configurations.

• Suitable for S3L devices only.

• Consider this topology especially if multiple sensors will be

installed in relative proximity to one another. A single run of

cable may then connect all the sensors to the 8900.

• Integral junction boxes are built-in to some sensors for

convenience. Other very useful versions with either 3/4in.

NPT or Universal mount are available as accessories for all

other sensors.

• All +GF+ SIGNET junction boxes provide dual conduit ports

to simplify this wiring scheme.

Point-to-point

Multi-Parameter

Output1 19.5 mA

Output2 12.3 mA

Relay 1 Relay 2

ENTER

+GF+ SIGNET

PartNo. XXXX

SerialNo. XXXXX

Daisy-chain

Multi-Parameter

Output1 19.5 mA

Output2 12.3 mA

Relay 1 Relay 2

ENTER

14 8900 Multi-Parameter Controller

‡ SIGNET

6.1.2.3 Multi-drop

This topology is characterized by a single run of cable to which

sensor branches are connected via junction boxes. Substantial

reductions in total wire and conduit compared to point-to-point

and daisy-chain configurations may be possible.

• Suitable for S3L™ devices only.

• Consider this topology especially if a multiple sensor

deployment includes significant vertical as well as horizontal

wire distances (that is, if sensor wiring must span walkways,

driveways, or multiple floors of a building, etc.).

• +GF+ SIGNET junction boxes can be useful in making the

3-way junctions necessary in this configuration.

• Another variation of this topology can be used to reduce

congestion at the I/O Module resulting from some point-to-

point wiring configurations. Consolidate S3L signal lines with

a terminal strip just prior to connecting to the I/O Module.

Multi-Parameter

Output1 19.5 mA

Output2 12.3 mA

Relay 1 Relay 2

ENTER

Multi-drop

Combinations

Multi-Parameter

Output1 19.5 mA

Output2 12.3 mA

Relay 1 Relay 2

ENTER

RELAYA RELAY B

+ S

3

L- + S

3

L-

OUTPUT 24VDC

+ -

AC INPUT

Relay Module

DATA

POWER

TEST A

TEST B

Relay A

Relay B

TEST C

TEST D

Relay C

Relay D

INPUT PASS-THRU

L N

RELAY C RELAY D

NC C NO NC C NONC C NO NC C NO

6.1.3 Maximum Cable Lengths

The I/O Module (3-8900.401-x) supports frequency and S3L signal types. These signal types are fundamentally different from one

another, and the rules governing maximum cable lengths also differ, so the two types must be treated separately. Refer to the following

two sections as necessary to determine the cable length limitations of any system.

6.1.2.4 Combinations

The basic topologies described above may be combined to

suit specific installation requirements in systems containing

multiple S3L devices. All three configurations are featured in

the example here.

6.1.2.5 Accessory Junction Boxes

Various junction boxes are available to facilitate the wiring configurations described above, and to achieve and maintain reliable sensor

connections even in harsh industrial environments.

Maximum cable length 515 525 2000 2100 2507 2517 2536 2540 2541 2550 7000 7002

60 m (200 ft.) xx x

305 m (1000 ft.) xxx xxxxxx

+GF+ SIGNET Flow sensor models with frequency output

6.1.3.1 Signal Type: Frequency

The maximum allowable cable length for flow sensors with frequency output is dependent upon the output signal strength of the

sensors themselves, and the degree to which the signals are susceptible to EMI or "noise". This is largely a function of whether the

sensors are self-powered, or powered by an external source.

All of the sensors in the table below are compatible with the 8900. The three models limited to 60 m (200 ft.) are self-powered sensors.

The 8900 automatically provides power to the others via the I/O Module (normal sensor wiring).

These maximum recommended cable lengths apply to individual sensors and are completely independent of one another. Additionally,

these cable lengths have no relevance to any S3L devices that may also be connected to the I/O Module.

Mfr. Part No. Code Description

3-8050-1 159 000 753 Universal Mount Junction Box

3-8050-1CR 159 000 889 Universal Mount Junction Box w/Ranges (for use with 2850)

3-8050-2 159 000 754 Universal Mount Junction Box w/EasyCal (for use with 2750)

3-8050-2CR 159 000 802 Universal Mount Junction Box w/EasyCal (for use with 2850)

3-8052-1 159 000 755 3/4 in. NPT Mount Junction Box

3-8052-1CR 159 000 890 3/4 in. NPT Mount Junction Box w/Ranges (for use with 2850)

3-8052-2 159 000 756 3/4 in. NPT Mount Junction Box w/EasyCal (for use with 2750)

3-8052-2CR 159 000 803 3/4 in. NPT Mount Junction Box w/EasyCal (for use with 2850)

158900 Multi-Parameter Controller ‡ SIGNET

The Maximum Current table above applies only to S3L devices powered by the 8900 (normal sensor wiring). If an auxiliary power

source more local to the sensor is used, then wire size may be reduced and S3L wiring distances may be substantially increased.

Contact your local +GF+ sales office for more information.

6.1.3.2 Signal Type: S3L™

The total maximum allowable cable length for all S3L devices in a system is primarily dependent upon the connecting instrument, not

the sensors or external relays themselves. From an instrument’s EMI filtering capability, and its capacity to provide power to these

devices, maximum cable length guidelines can be established. For the 8900, these guidelines are defined here.

In order to use this table, the total maximum current consumption of all the S3L devices in the system must be known. Refer to the

current consumption table and add the appropriate mA values to find the total.

Round up to the nearest column heading in the cable length table, or extrapolate between columns to approximate the maximum

allowable cable length for all S3L devices in the system (regardless of topology). Notice the influence of wire size and capacitance on

maximum allowable cable lengths. Proper cable selection is imperative, especially when long runs are required in an installation.

Maximum total cable length from S3L Devices to 8900

Wire Size (AWG) 1 mA 2 mA 4 mA 10 mA 20 mA 40 mA

24 1800 ft 900 ft 450 ft 180 ft 90 ft 40 ft

22 2850 ft 1420 ft 710 ft 280 ft 140 ft 70 ft

20 n/a 2290 ft 1140 ft 450 ft 220 ft 110 ft

18 n/a n/a 1810 ft 720 ft 360 ft 180 ft

16 n/a n/a 2840 ft 1130 ft 560 ft 280 ft

14 n/a n/a n/a 1850 ft 920 ft 460 ft

12 n/a n/a n/a 2940 ft 1470 ft 730 ft

Cable capacitance

<30 pf/ft

Cable capacitance <50 pf/ft

(practically all cables)

Cable capacitance

<15 pf/ft

Total Current Consumption of S3Lª Devices

S3L Device Current Consumption

per Device

2350 Temperature Sensor 1 mA

2450 Pressure Sensor 1 mA

2750 pH and ORP Sensors 3 mA

2850 ConductivitySensor 2 mA

8059 External RelayModule * 1 mA

Maximum Current Consumption for S3L Devices

* The S3L communication link between the 8900 and the 8059 is powered by the

8900 and consumes 1 mA maximum. However, the 8059 External Relay Module

always requires a separate power source for its operation.

16 8900 Multi-Parameter Controller

‡ SIGNET

Number of

Frequency

Inputs

Number of

Separate S3Lª

Signal Lines

Wiring

Diagram(s) Note(s)

10 A

20 B 1

01 C

1 1 A & C

2 1 B & C 1

0 2 D 2, 3, 5

1 2 A & D 2, 3, 5

2 2 E 1, 3, 5

0 3 F 2, 3, 4, 5

1 3 A & F 2, 3, 4, 5

2 3 G 1, 3, 4, 5, 6

0 4 H 2, 3, 4, 5

1 4 A & H 2, 3, 4, 5, 6

0 5 I 2, 3, 4, 5, 6

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

6.1.4 I/O Module (3-8900.401-X) Wiring Diagrams

Determine the number of frequency inputs and the number of separate S3L™ digital signal lines to be wired directly to the I/O Module,

then use the table below and the corresponding wiring diagram(s) for instruction.

A

C

B

Notes:

1) If two frequency inputs are required, then the terminals for

Frequency Inputs 1 and 2 must be used. In such cases, any

and all S3L devices must be connected via S3L Input

(terminals 8, 9 and 10).

2. Multiple S3L devices may be connected to a single S3L input

(terminals 8, 9 and 10 for example). However, for best EMI

filtering in point-to-point wiring topologies involving more than

one S3L device, use S3L Inputs 1 and 2 if possible.

3) Consider daisy-chain or multi-drop wiring topology for S3L

devices. This will reduce the number of separate digital

signal lines to be connected to the I/O Module.

4) In point-to-point wiring topologies involving more than two

S3L devices it will be necessary to connect more than one

S3L device to a single set of terminals. In such cases, for

best EMI filtering, combine the wiring of sensors that are

located nearest to one another in the installation.

5) Ferrules are recommended when connecting multiple S3L

devices to a single set of terminals.

6) This combination is only possible if one of the S3L devices is

the 8059 External Relay Module.

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

3

S L device

178900 Multi-Parameter Controller ‡ SIGNET

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

S3L“ device

S3Ldevice

D

F

E

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

S3L

device

S3L

device

S3L

device

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

S3L

device

S3L

device

18 8900 Multi-Parameter Controller

‡ SIGNET

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

S3L

device

S3L

device

S3L

device

S3L

device

S3L

device

S3L

device

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

3-8900.621C

I/O Module 3-8900.401-X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

S L (Red)

GND (White/Shield)

+5VDC (Black)

S L (Red)

GND (White/Shield)

3

3

Analog Output 1

Analog Output 2

(if applicable)

(if applicable)

Frequency

Input

1

Frequency

Input 2

OR

S3L

Input

2

S3L

Input

1

+

-

+

-

S3L

device

S3L

device

S3L

device

S3L“

device

S3L

device

S3L

device

H

G

I

198900 Multi-Parameter Controller ‡ SIGNET

6.2 Power Module (3-8900.402-X)

• Exceeding voltage ratings may damage the unit and pose a shock hazard.

• To simultaneously connect AC and DC to these power modules will not cause damage to the unit, however invalidates the double

insulation rating and UL safety standards.

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

BLK

RED

SHLD

BLK

RED

S L

SHLD

BLK

S L

SHLD

+

-

+

-

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

SENSOR INPUTS

3

3

+

-

+

-

N

L

+

-

3-8900.620

100 - 240VAC

50-60Hz, 24VAMAX

~

11 - 24 VDC

0.7 A MAX.

N

L

+

-

Power Connection

DO NOT attempt to connect both

AC and DC at the same time

C

NO

NC

NO

NC

C

Solid State Relays

Rating:

50 mA 30V

Mechanical Relays

Rating:

5A 250 VAC

5A 30 VDC ~

+

-

+

-

~

CAUTION

6.3 Output Module (3-8900.405-X)

The 8900 will support up to four analog outputs.

• Analog outputs 3 & 4 are obtained via these separate plug-in

modules.

• Analog outputs 1 & 2 are located on selected I/O Modules

and are also wired as shown here.

COMM PORT /

OUT 4 OUT 3

+

-

+

-

Active 4-20 mA Loop wiring

+

-

+

-

COMM PORT /

OUT 4 OUT 3

+

-

+

-

0-5 VDC Output wiring

+

-

COMM PORT /

OUT 4 OUT 3

+

-

+

-

Passive 4-20 mA Loop wiring

12-24 VDC

power

+

-

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

SENSOR INPUTS

3

3

+

-

N

L

+

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+

-

• Active 4-20 mA Loop Output Module

The DC power required for the loop is supplied by the 8900.

No additional power source is needed.

• Passive 4-20 mA Loop Output Module

The DC power required for the loop must be provided by an

external source.

• 0-5 or 0-10 VDC Output Module

The 8900 provides power for the 0-5 or 0-10 VDC output.

N

L

+

-

AC Line

AC Neutral N

L

+

-

DC -

DC +

AC ONLY DC ONLY

6.4 RS232 Communication Module (3-8900.404-1)

DB-9 Crossover Cable (3-8900.390)

Master

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

SENSOR INPUTS

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

N

L

+

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

OUT 2 OUT 1

POWER

COMM PORT /

OUT 4 OUT 3

RELAY 2 RELAY 1

RELAY 4 RELAY 3

SENSOR INPUTS

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

N

L

+

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Upon initial introduction of the 8900 product series, the RS232

Communication Module will be limited to Clone Mode functionality.

This feature requires the accessory DB-9 Crossover Cable and

allows an 8900 instrument to adopt all software settings of another

8900 instrument. Both instruments must have RS232

Communication Modules installed. Fully functional RS232 output is

pending.

Mfr. Part No. Description

3-8900.390 DB-9 Crossover Cable Clone

20 8900 Multi-Parameter Controller

‡ SIGNET

RELAY 2 RELAY 1RELAY 4 RELAY 3

C

NO

NC

NO

NC

C

C

NO

NC

NO

NC

C

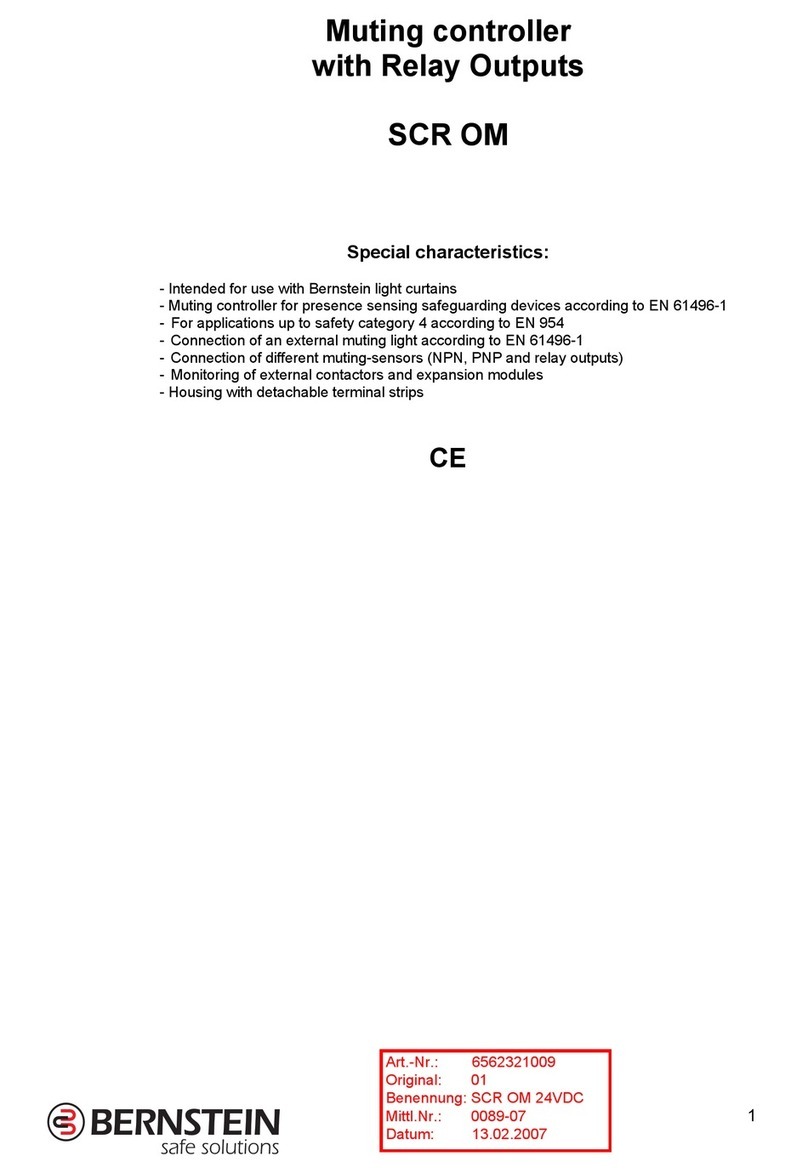

flow

AC or DC

power

valve

AC or DC

power

ALARM!

6.5 Relay Module (3-8900.403-X)

6.6 External Relay Module

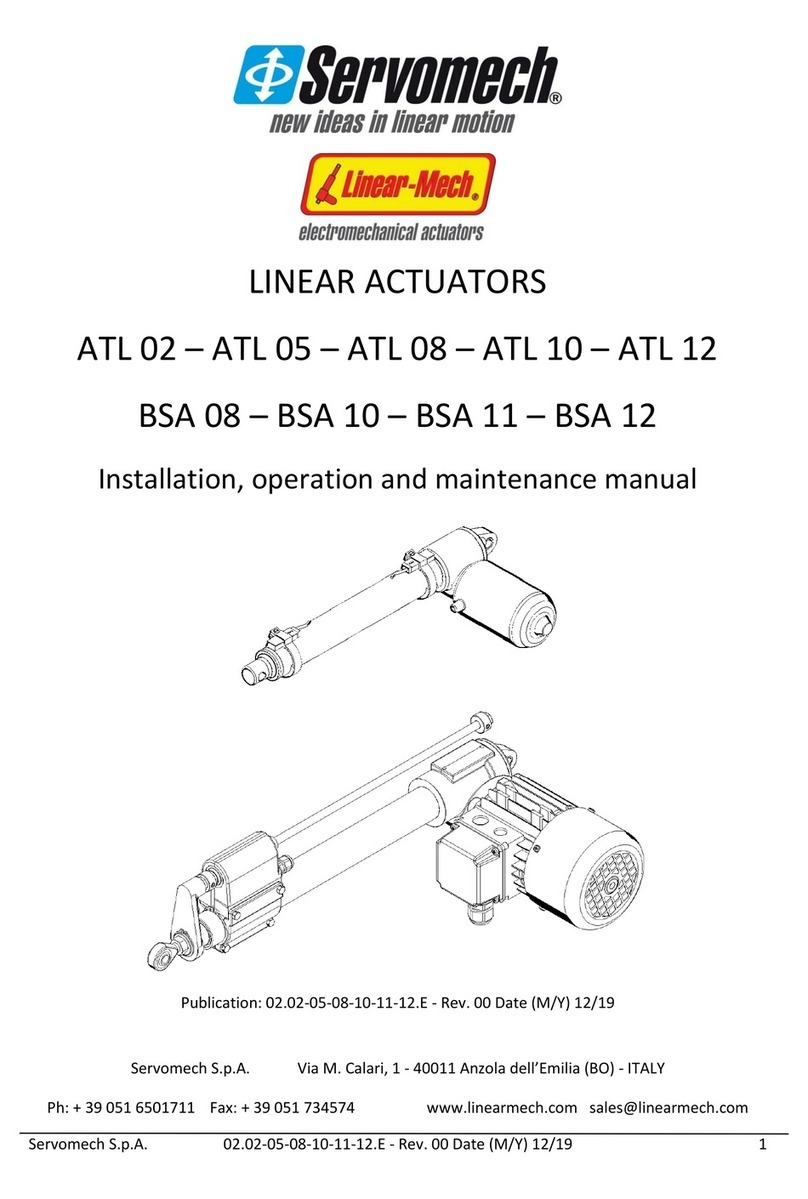

• 8059 external relay modules provide either 2 or 4 additional

dry-contact relays.