Free Manual winding

Date setting Day setting

Difference is under 45 seconds within max value and min value.

* Measurement should be done within 10 60 minutes after fully wound up.

* Direction of 4 positions.

(1) 12 o'clock up (2) 9 o'clock up (3) 6 o'clock up (4) 3 o'clock up

Isochronisms

(24h-0h)

-10 +20 seconds per day.

* Direction of position. : Dial up

* Difference of static accuracy of 24h and 0h

Duration time

More than 45 hours Mainspring after fully wound up.

* Posture to confirmation : Dial up

Normal position

Right rotation

-15 +25 seconds per day

* Measurement should be done within 10 60 minutes after fully wound up.

* All measurements are made without the calendar in function.

Direction of 3 positions. (1) Dial up (2) 9 o'clock up (3) 6 o'clock up

Lift angle

52 deg.

First click

Jewels

29 jewels

20 seconds

* Equipment to be used : Witschi WATCH EXPERT

Posture

difference

Manual winding

Automatic winding with ball bearing

Stop second device

Day-date correction

<< Movements >>

・Fully wounded up by turning the crown min 55 times.

・Fully wounded up by turning the ratchet wheel screw 8 times.

<< Complete Watch >>

A winding machine is needed to wind up the mainspring.

Full wind up conditions

・Rotary speed : 30 rpm

・Operating time: 60 minutes

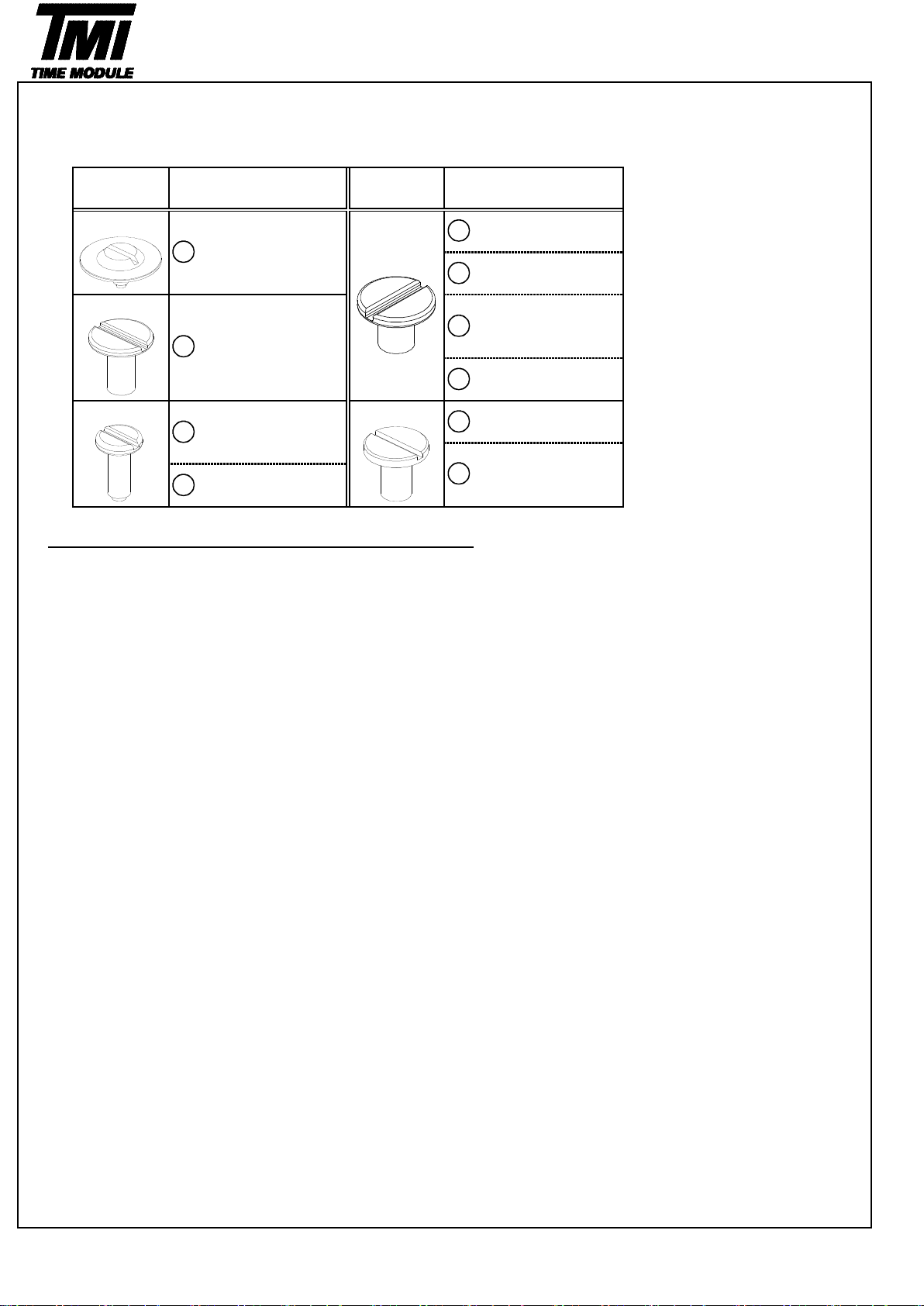

Crown

position

Left rotation

Casing diameter

Ф27.00mm

Total height

Winding the mainspring

Frequency

28,800 vibrations per hour

Accuracy

Static accuracy

6.15 mm

PARTS CATALOGUE / TECHNICAL GUIDE

Cal.NE20

Version-01

Time indication

Basic function

3 Hands ( Hour , Minute , Second )

Day-date calendar hands

Power reserve hand

Ф27.40mm

1

NE20

Second click Hand setting Hand setting

Movement

Movement

size

Outside diameter