Catalog

Correct use and application

1. Truck Description.............................................................................................................. 3

1.1Application................................................................................................................... 3

1.2 Assemblies................................................................................................................. 4

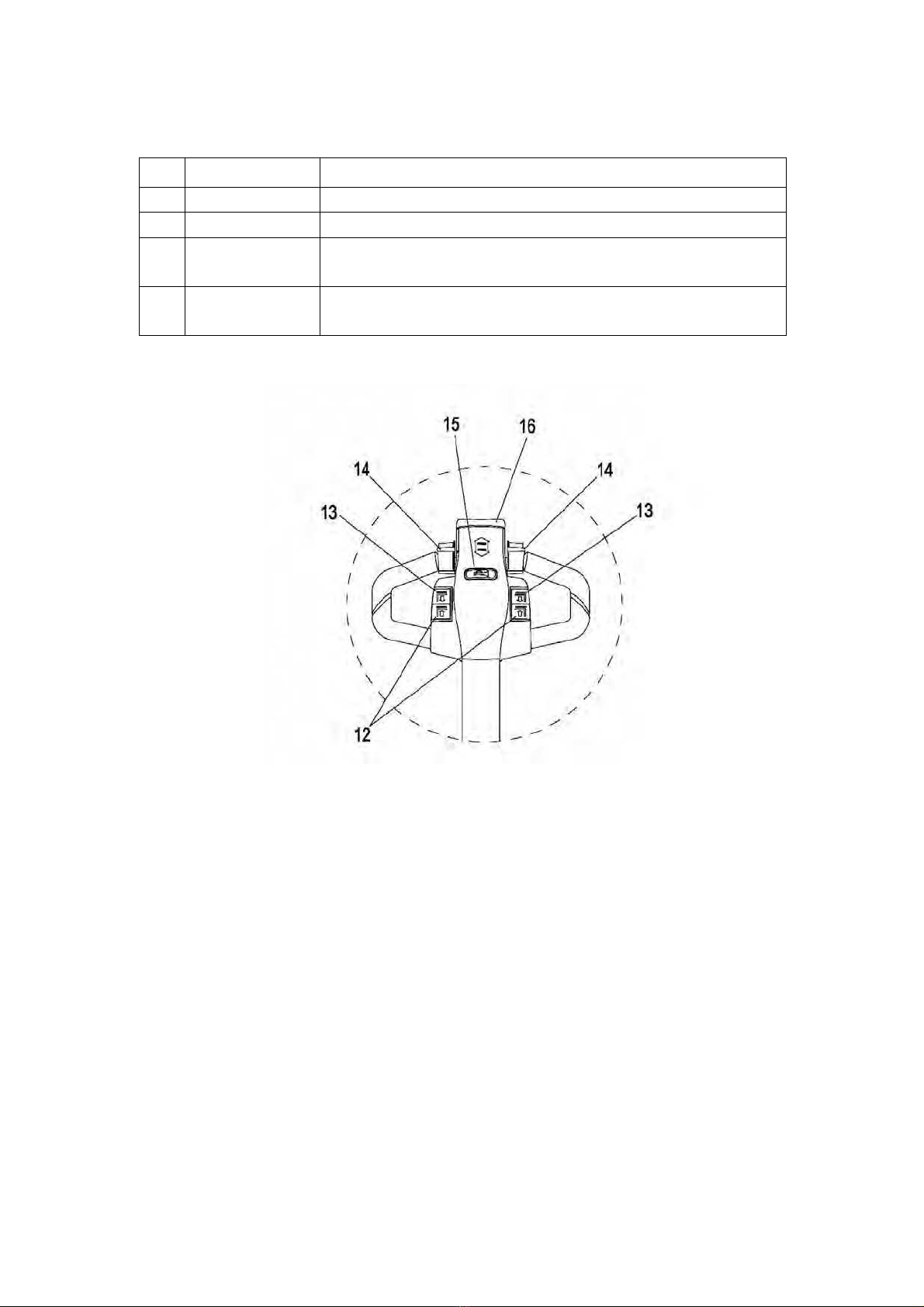

1.2.1Control Handle................................................................................................. 5

1.2.2Key switch......................................................................................................... 5

1.2.3Battery discharge indicator............................................................................ 6

1.2.4Emergency brake switch................................................................................ 6

1.3 Identification points and data plates....................................................................... 7

1.3.1Truck data plate............................................................................................... 8

1.4.Standard Version Specifications............................................................................. 9

1.4.1Performance data for standard trucks.......................................................... 9

1.4.2Dimensions..................................................................................................... 10

2.Transport and Commissioning..................................................................................... 14

2.1Transport................................................................................................................... 14

2.2Using the Truck for the First Time.......................................................................... 14

2.3During brake-in......................................................................................................... 15

3.Operation........................................................................................................................... 16

3.1Safety Regulations for the Operation of pallet Trucks........................................ 16

3.2 Operate and run the truck...................................................................................... 17

3.2.1 Preparing....................................................................................................... 17

3.2.2 Travel............................................................................................................. 17

3.2.3Lifting, transporting and depositing loads.................................................. 20

3.2.4Parking the truck securely............................................................................ 21

4.Battery Maintenance & Charging................................................................................. 22

4.1 Safety regulations for handling acid batteries..................................................... 22

4.2 Battery type & dimension....................................................................................... 22

4.3Charging the battery................................................................................................ 23

4.3.1Exposing the battery..................................................................................... 23

4.3.2 Charging........................................................................................................ 23

4.4Battery removal and installation............................................................................. 24

4.5Battery maintenance................................................................................................ 24

4.6Battery Disposal....................................................................................................... 25

5.pallet Truck Maintenance............................................................................................... 26

5.1Operational safety and environmental protection................................................ 26

5.2Maintenance Safety Regulations........................................................................... 26

5.3Servicing and inspection......................................................................................... 28