Sime FORCED 200 User manual

FR

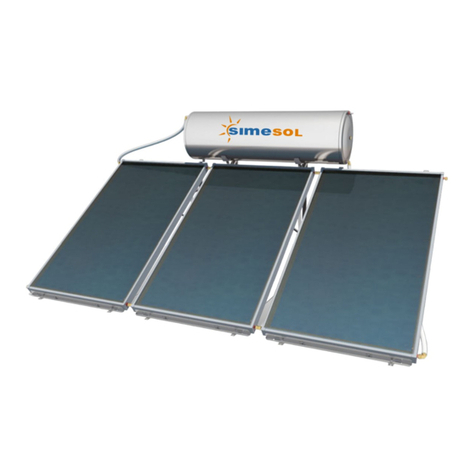

SIME FORCED 200 - 300

ENG

IT

ES

INDEX

Fonderie Sime SpA reserves the right to amend all of the product and relative accessories specications

without prior warning.

32

34

λ

7

0

10

110

815

915

925

4

0

13

148,5

188,5

338,5

1721,5

1871,5

1911,5

2047

2060

1

0

12

35

141

1299

2074

2105

2129

2

0

11,5

34

338

432

792

886

1190

1212,5

1224

3

0

15

55

490

925

965

980

6

5

SUPPLY

Fig. 3

36

2

1

3

4

6

5

7

5a 5b

35°

* Tighten the ttings ONLY. ANY BREAKAGE DUE TO THE TORSION OF THE PIPE BUNDLE IS NOT COVERED BY THE WARRANTY.

75

38

2

22

6

1

11

4

5

3a

5

7

7

35°

* Tighten the ttings ONLY. BREAKAGE DUE TO THE TORSION OF THE PIPE BUNDLE IS NOT COVERED BY THE WARRANTY.

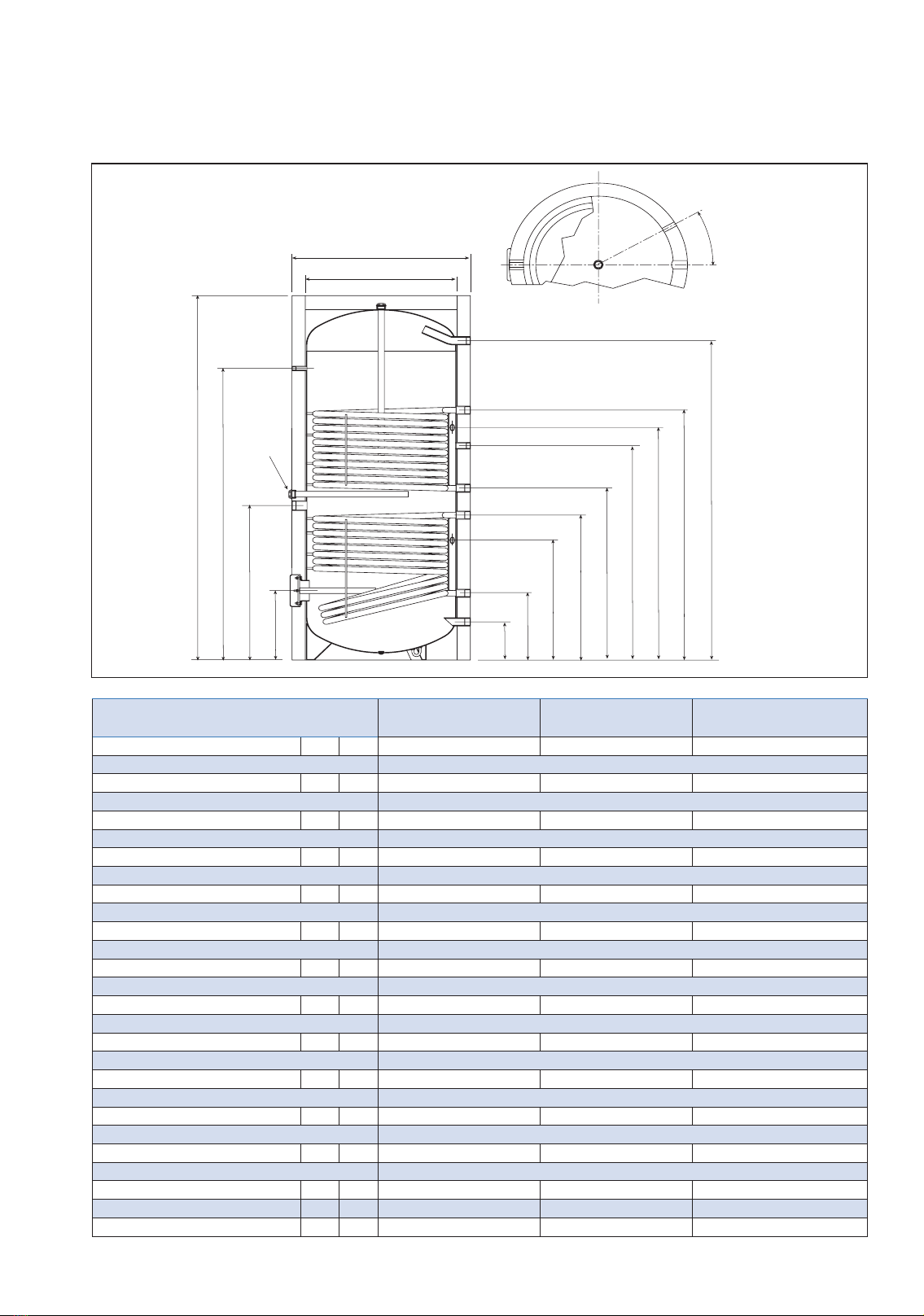

40

ø int.

C

ø est.

H

B

A

30ϒ

F

G

M

L

N

Q

R

P

S

BS 2S

3000 lt

Fig. 4

Dimensional values and hydraulic connections BS 2S

200

BS 2S

300

BS 2S

400

ΦΦ

42

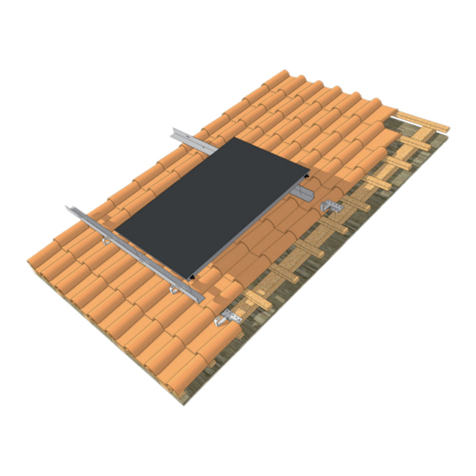

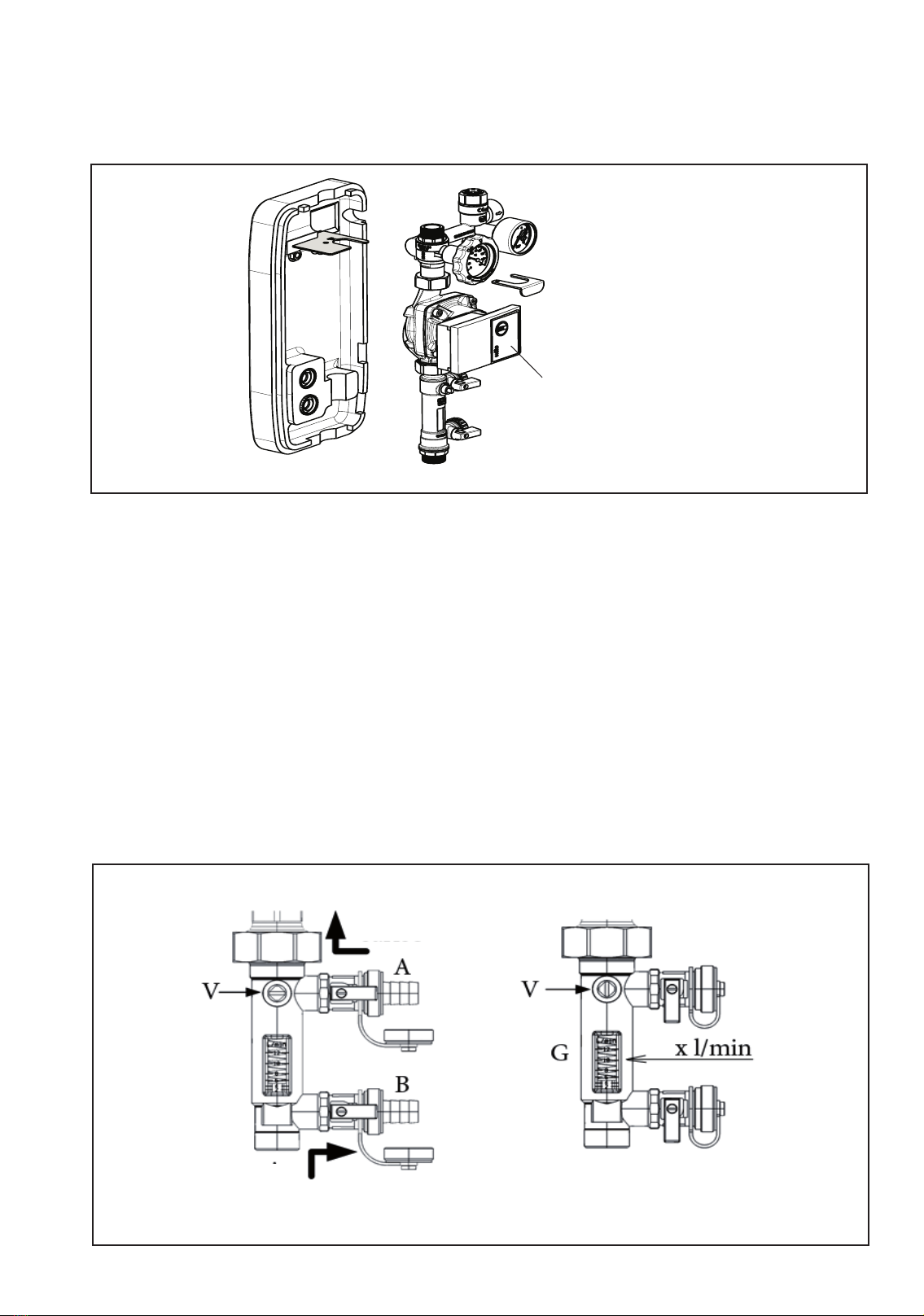

(Fig. 1)

(Fig. 2) (Fig. 3)

1- 2 3

9

87

6

5

4

3

1

2

10

LED indicator for

viewing the pump op-

erating status

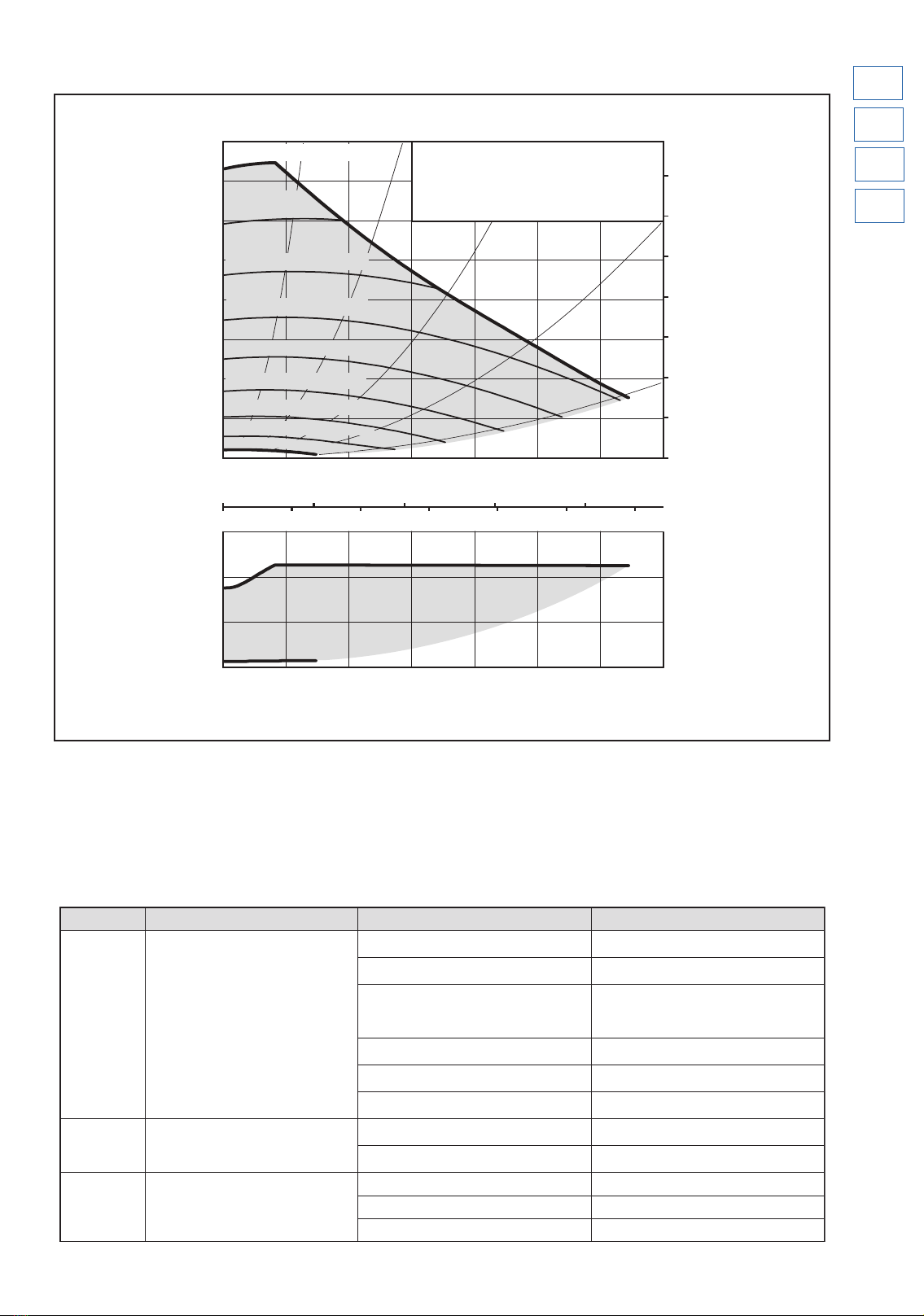

SOLAR UNIT HIGH EFFICIENCY PUMP

The solar unit circulator is the WILO type, model Yonos PARA ST 15/7 PWM (code 6272328). Find hereafter any

anomaly reported by the pump’s LED and the possible solutions:

HIGH EFFICIENCY PUMP CURVE (code 6272328)

0 0,5 1,0 1,5 2,0 2,5 3,0

0 0,2 0,4 0,6 0,8

02468 10

0

1

2

3

4

5

6

7

0

10

20

30

40

50

60

70

0 0,5 1,0 1,5 2,0 2,5 3,0

0

20

40

3695/ 25

PWM1

/75

PWM2

4178/ 15

PWM1

/85

PWM2

4660/ ≤5

PWM1

/≥95

PWM2

3213/ 35

PWM1

/65

PWM2

2730/ 45

PWM1

/55

PWM2

2248/ 55

PWM1

/45

PWM2

1765/ 65

PWM1

/35

PWM2

1283/ 75

PWM1

/25

PWM2

800/ 85

PWM1

/15

PWM2

Wilo-Yonos PARA ST 15/7.0

1~230 V - Rp½, Rp 1, Rp 1¼

n=1/min/ % PWM 1 / % PWM 2

p/kPa

H/m

P

1

/W

Q/m3/h

Q/l/s

Q/Igpm

Q/m3/h

max.

max.

External control via PWM

Pompa ad alta ecienza (cod. 6272328)

Eventuali anomalie della pompa e possibili rimedi

Colore LED Stato della pompaEventuale anomalia Possibile rimedio

Rosso-Verde

lampeggiante

Arresto di “blocco transitorio”;

Anomalia in corso

Dopo l’eliminazione dell’anomalia, la

pompa riparte automaticamente

Tensione di rete Troppo alta o troppo bassa;

(160V > Vn > 280V)- Veric are la tensione di rete

Sovra carico del motore; attrito o

bloccaggio della girante per presenza di

detriti

- Veric are le caratteristiche dell’acqua

dell’impianto; pulire l’impianto dai detriti

Velocità eccessiva; il rotore della pompa

è azionato, da un fattore esterno, oltre la

velocità massima consentita

- Veric are l’assenza di un usso esterno

(altra pompa in funzione) nell’impianto

Sovra corrente; l'avvolgimento di statore è

in corto circuito a causa dell'acqua

- Veric are l’assenza di perdite

nell’impianto

La temperatura all'interno del motore è

troppo alta

- Veric are il livello di temperatura

dell'acqua in rapporto con quello della

temperatura ambiente

La pompa è ostacolata da un usso esterno

(> 1200l/h) di direzione opposta

- Eliminare o ridurr e il usso esterno (<

1200l/h)

Rosso

lampeggianteArresto di “blocco permanente”

Pompa bloccata per detriti nell’impianto - Togliere e ridare l’alimentazione elettrica

(OFF – ON)

Guasto alla scheda elettronica e/o al

motore

- Se il “LED ros so” continua a lampeggiare:

- SOSTITUIRE LA POMPA

LED Spento Ferma

Mancanza di alimentazione elettrica - Veric are il collegamento

all’alimentazione elettrica

LED guasto- Vericare se la pompa può funzionare

Scheda elettronica guasta - SOSTITUIRE LA POMPA

Posibles fallos de la bomba y posibles soluciones

Color del LEDEstado de la bomba Posible falloPosible solución

Rojo-verde

parpadeando

Parada de “bloqueo temporal”; Fallo en

curso

Una vez corregido el fallo, la

bomba se vuelve a poner en marcha

automáticamente

Tensión de red demasiado alta o demasiado

baja;

(160V > Vn > 280V)

- Compruebe la tensión de r ed

Sobrecarga del motor; fricción o bloqueo del

rodete por presencia de detritos

- Compruebe las características del agua de

la instalación; elimine los detritos que haya

en la instalación

Velocidad excesiva; el rotor de la bomba

está accionado, por un factor externo, a una

velocidad que supera la máxima admitida

- Compruebe que no haya un ujo e xterno

(otra bomba en funcionamiento) en la

instalación

Sobrecorriente; el bobinado del estátor está

cortocircuitado a causa del agua

- Compruebe que no haya pérdidas en la

instalación

La temperatura interna del motor es

demasiado alta

- Compruebe el nivel de t emperatura del

agua en relación con el de la temperatura

ambiente

La bomba está obstaculizada por un ujo

externo (> 1200l/h) de dirección opuesta

- Elimine o reduzc a el ujo externo (<

1200l/h)

Rojo

parpadeandoParada de “bloqueo permanente”

Bomba bloqueada por detritos en la

instalación

- Desconecte y restablezca la alimentación

eléctrica (OFF – ON)

Avería en la tarjeta electrónica y/o en el

motor

- Si el “LED rojo” sigue parpadeando:

- SUSTITUYA LA BOMBA

LED apagadoParada

Interrupción de la alimentación eléctrica- Revise la c onexión a la alimentación

eléctrica

LED averiado - Compruebe si la bomba puede funcionar

Tarjet a electrónica averiada - SUSTITUYA LA BOMBA

Any pump faults and pos sible solutions

LED colour Pump status FaultPossible solution

Red-Green

ashing

"Transient safety shutdown"; Anomaly

in progress

After eliminating the anomaly, the pump

restarts automatically

Network voltage too high or too low;

(160V > Vn > 280V) - Check network v oltage

Motor overload; rotor friction or blockage

due to the presence of debris

- Check the charact eristics of the system

water; clean the system of any debris

Excessive speed; the pump rotor is

actuated by an external factor and is

rotating at a speed exceeding the maximum

permitted speed

- Check that there is no e xternal ow in the

system (no other pump in operation)

Overcurrent; stator winding is in short

circuit due to water- Check for l eaks in the system

The temperature inside the motor is too

high

- Check the water temperature in relation

to ambient temperature

The pump is obstructed by an external ow

(> 1200l/h) in the opposite direction

- Eliminate or r educe the external ow (<

1200l/h)

Flashing red "Permanent safety shutdown"

Pump blocked due to debris in the system- Remov e and reconnect the electrical

power supply (OFF - ON)

Fault in the electronic board and/or the

motor

- If the "red LED" continues to ash:

- REPLACE THE PUMP

LED o Stationary

No electrical power - Check the electric al power connection

LED faulty - Check if the pump can oper ate

Electronic board faulty- REPLACE THE PUMP

IT -

ENG -

ES -

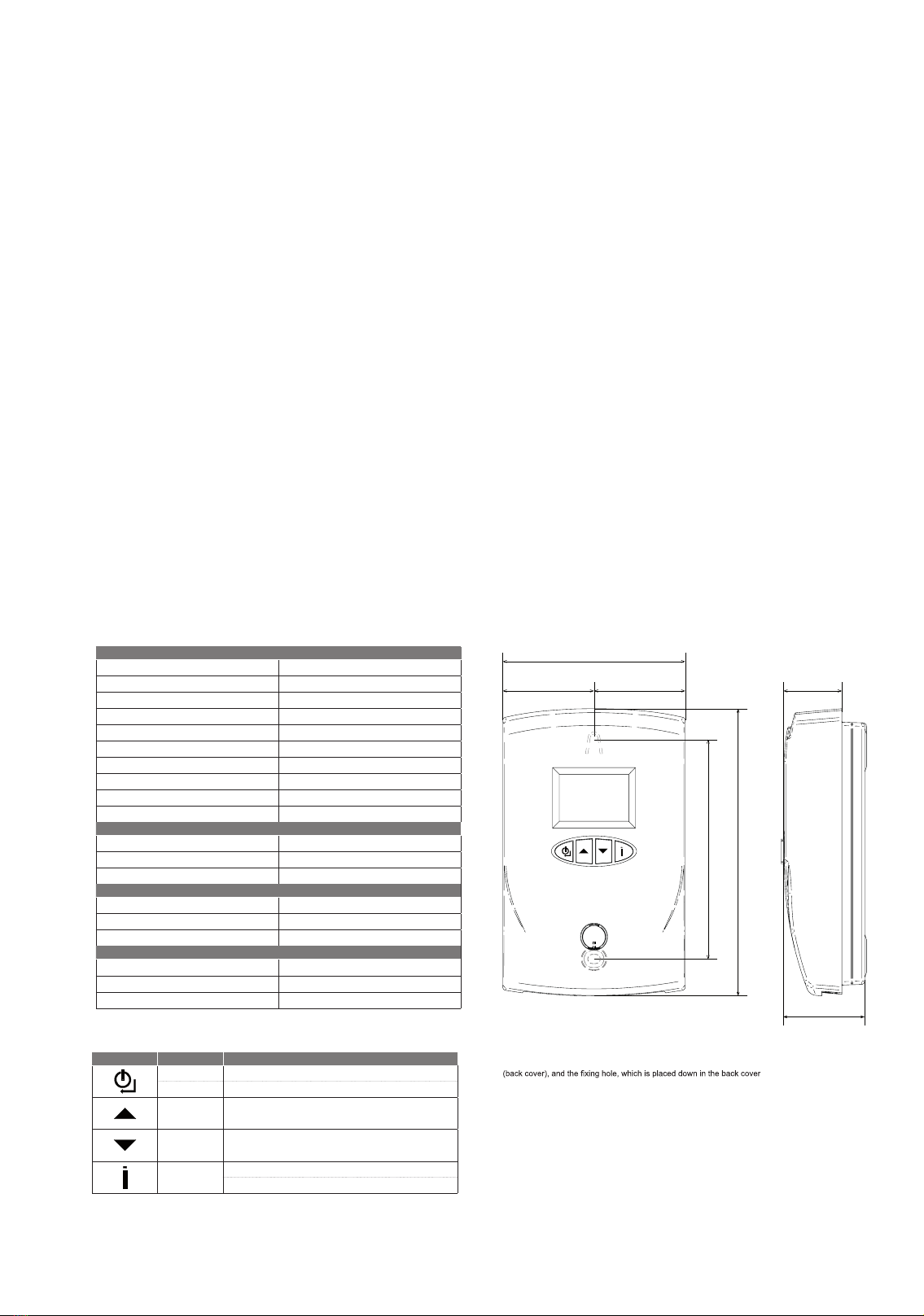

44

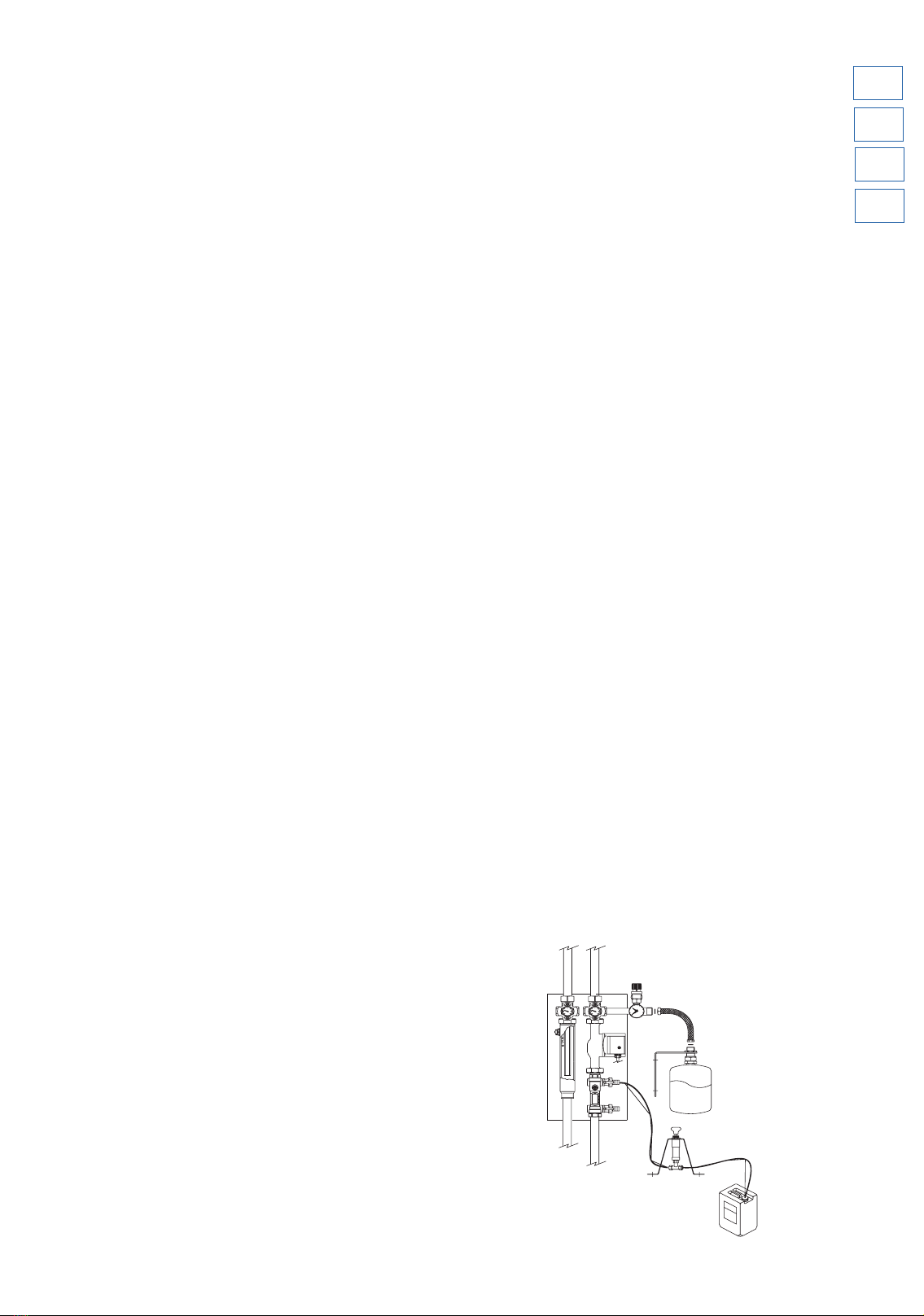

GI hydraulic unit.

Function of the buttons:

SERIGRAPHDESCRIPTION FUNCTION

ON/OFFTurn on or turn off the device

BACK Back to previous menu

INCREASE Go to next parameters or go to next value

DECREASEGo to previous parameter or go to previous value

INFO

Keep pressed for 1 sec.: Temperature information (S2, S3 - S1,S4)

Keep pressed for 10 sec.: Access to programming menu

GENERAL

Power supply 230 Vac +10% ÷ -15%

Frequency 50Hz +5% ÷ -5%

Range of working temperatures -20°C ÷ +60°C

Fuse 3,15AF (fast) 5x20

Varistor 300 Vac D7

SOLAR PUMP - P1 TRIAC (230 Vac) 0,5A – Cosφ 1

AUX 3 out - P1 PWM (230 Vac) 230Vac – 0,5A

AUX 2 out - P2 (230 Vac) 0,5A – Cosφ 1

AUX 1 out - Enabled thermostat /P20,5A – Cosφ 1

FREE CONTACT out - D1 (230 Vac) 230Vac – 0,5A

TEMPERATURE PROBE NTC

Range of correct work of the probes-40°C ÷ +105°C

Temperature in which the probe will indicate a fault -5°C>>T>>120°C

General tolerance on temperatures

(referred only to electronic board) ±1,5°C

TEMPERATURE PROBE PT1000

Range of correct work of the probes-40°C ÷ +250°C

Temperature in which the probe will indicate a fault -50°C>T>170°C

General tolerance on temperatures

(referred only to electronic board) ±1,5°C

ENVIRONMENTAL CONDITIONS OF USE

Ambient working temperature-20°C ÷ +60°C

Storage and transport temperature-30°C ÷ +60°C

Max. environment humidity (without any condensing) 95% a 40°C

TECHNICAL DATA

130 mm*

170 mm

108 mm

54 mm 54 mm 34 mm

48 mm

DIMENSIONS

The plastic box has protection rating IP20

*130 mm is the wheelbase between the holding hanger, which is set up in the front side of the device

.

S1

46

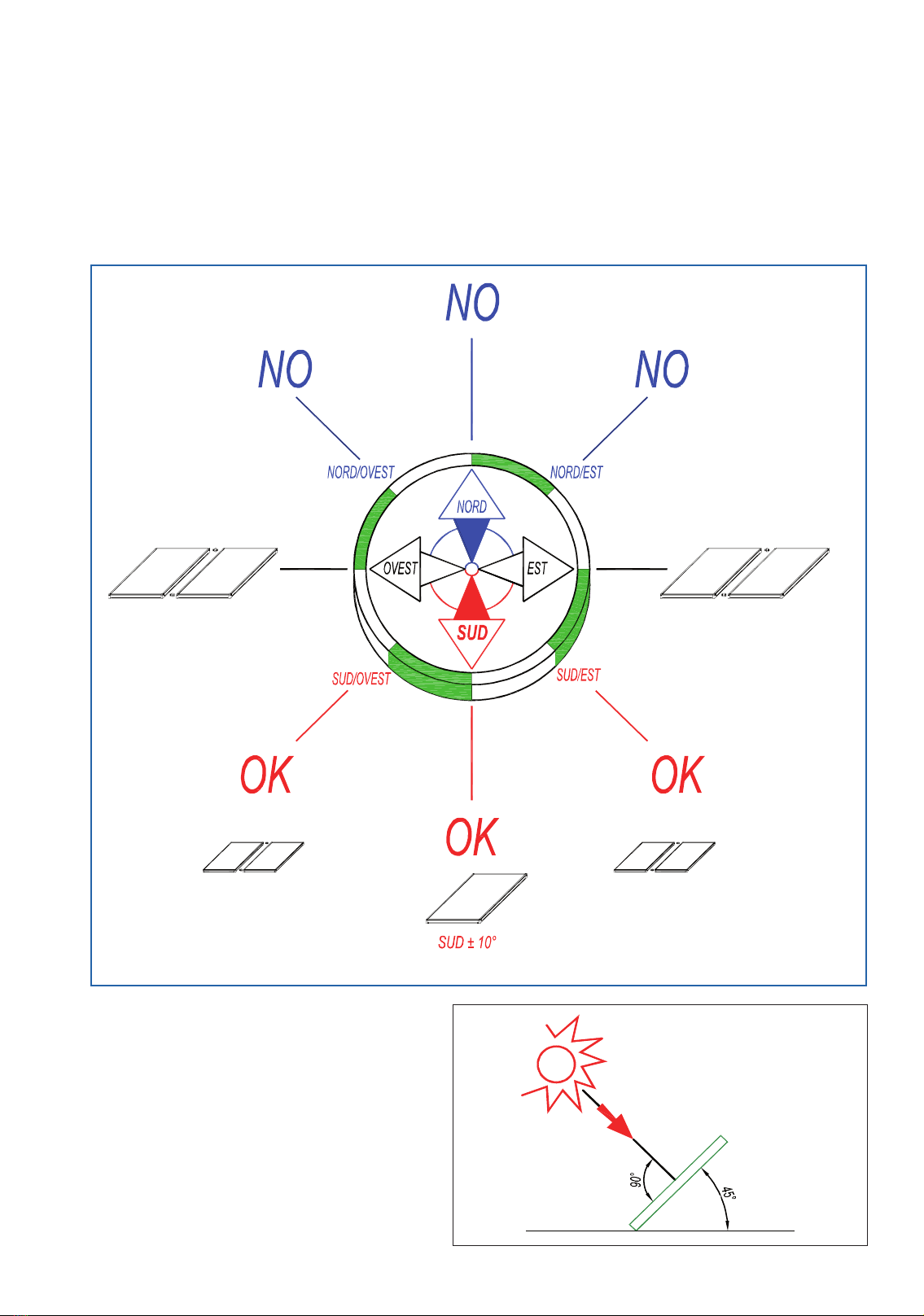

45° 45°

Pannello solare

220 220

540 162

48

TERMOSOLIS

“S1”

“S2”

DA RETE

ALL’UTILIZZO

DA RETE

S1

SB

S2

This manual suits for next models

1

Table of contents

Other Sime Inverter manuals

Popular Inverter manuals by other brands

Black & Decker

Black & Decker PI100BB instruction manual

Kraftixx

Kraftixx PPG 3500 Original operating instructions

Toshiba

Toshiba TOSVERT VF-AS1 Series instruction manual

Generac Power Systems

Generac Power Systems QT06030KVAN owner's manual

STORZ POWER

STORZ POWER SOL-ARK 12k installation manual

Selectronic

Selectronic LD700-24 operating manual