Be sure to comply with the precautions below. Not complying might result in

injury or death.

WARNING

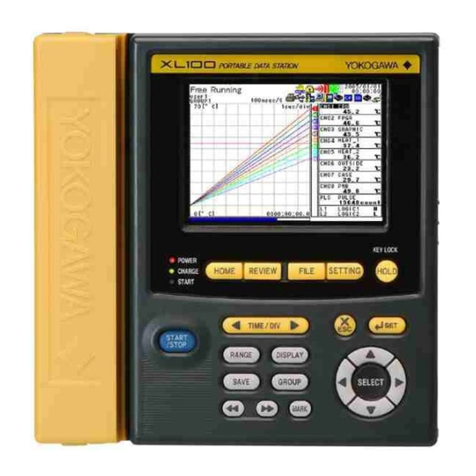

Use the Correct Power Supply

Before connecting the power cord, ensure that the source voltage matches the

rated supply voltage of the instrument and that it is within the maximum rated

voltage of the provided power cord.

Use the Correct Power Cord and Plug

To prevent electric shock or fire, be sure to use the power cord supplied by

YOKOGAWA. The main power plug must be plugged into an outlet with a protective

earth terminal. Do not disable this protection by using an extension cord without

protective earth grounding.

Connect the Protective Grounding Terminal

Be sure to connect the protective earth to prevent electric shock before turning ON

the power. The power cord that comes with the instrument is a three-prong type

power cord. Connect the power cord to a properly grounded three-prong outlet.

Do Not Impair the Protective Grounding

Never cut off the internal or external protective earth wire or disconnect the wiring

of the protective earth terminal. Doing so poses a potential shock hazard.

Do Not Operate with Defective Protective Grounding or Fuse

Do not operate the instrument if the protective earth or fuse might be defective.

Also, make sure to check them before operation.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors.

Operation in such an environment constitutes a safety hazard.

Do Not Remove Covers

The cover should be removed by YOKOGAWA’s qualified personnel only. Opening the

cover is dangerous, because some areas inside the instrument have high voltages.

Ground the Instrument before Making External Connections

Securely connect the protective grounding before connecting to the item under

measurement or to an external control unit. If you are going to touch the circuit,

make sure to turn OFF the circuit and check that no voltage is present.

Precautions to Be Taken When Using the Modules

• Do not apply input voltage exceeding the maximum input voltage, withstand

voltage, or allowable surge voltage.

• To prevent electric shock, be sure to furnish protective earth grounding of the

instrument.

• To prevent electric shock, be sure to fasten the module screws. Otherwise, the

electrical protection function and the mechanical protection function will not be

activated.

• Avoid continuous connection under an environment in which the allowable surge

voltage or greater voltage may occur.

• Be careful not to exceed the maximum input voltage of a module in the following

cases.

• When the probe attenuation is 1:1.

• When the module input coupling is set to AC.

A DC voltage at the same electric potential as the probe input is applied to the

module input.

Safety Precautions