Simon EA-K-30 Series User manual

BA_EA(230)-K-30-xxx_EN_12 www.simon-protec.com Date: 13.02.2019

BA EA-K-30/xxx-T(-DA) / EA230-K-30/xxx(-S) EN 1.2

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Copyright by SIMON PROtec Systems GmbH

Subject to technical changes and errors. All figures are exemplary.

Only valid with the supplementary sheet: “Safety Instructions and Warranty Conditions”!

Operating ManualValid for the following article numbers:

EA-K-30/xxx-T(-DA)

•M25315 (DA) 400 mm stroke

•M25316 (DA) 600 mm stroke

•M25317 (DA) 800 mm stroke

•M25318 (DA) 1000 mm stroke

•M25319 (DA) 1200 mm stroke

EA230-K-30/xxx

•M25140 300 mm stroke

•M25141 600 mm stroke

•M25142 800 mm stroke

•M25143 1000 mm stroke

EA230-K-30/xxx-S

•M25144 300 mm stroke

•M25145 600 mm stroke

•M25146 800 mm stroke

•M25147 1000 mm stroke

For further information please visit

our product website

short.simon-protec.com/eaken

BA_EA(230)-K-30-xxx_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Table of Contents

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 2

1. General ................................................................................................................................................................4

1.1 Foreword to this manual ....................................................................................................................................4

1.2 Intended use ....................................................................................................................................................4

1.3 EA-K-30 – Product description ...........................................................................................................................4

1.4 EA230-K-30 – Product description ......................................................................................................................4

2. Safety Regulations ...............................................................................................................................................5

2.1 Risk assessment .............................................................................................................................................. 5

2.2 Restrictor stay ..................................................................................................................................................5

3. Figures .................................................................................................................................................................5

4. EA-K-30 – Functions ............................................................................................................................................7

4.1 Soft-close range ...............................................................................................................................................7

4.1.1 Speed reduction ........................................................................................................................................7

4.1.2 Current reduction ......................................................................................................................................7

4.2 SIMON LINK ....................................................................................................................................................7

4.3 Configurable ranges ..........................................................................................................................................8

5. EA230-K-30 – Functions ......................................................................................................................................8

5.1 End position cut-off while closing ........................................................................................................................8

5.2 End position cut-off while opening ......................................................................................................................8

5.3 DIP switches ....................................................................................................................................................8

5.4 RESET ............................................................................................................................................................9

5.5 Teach-in run .....................................................................................................................................................9

5.6 Performing a teach-in run ..................................................................................................................................9

5.7 LED displays ..................................................................................................................................................10

6. Mounting ............................................................................................................................................................11

6.1 Mechanical connection .................................................................................................................................... 11

6.1.1 Mounting brackets ...................................................................................................................................12

6.1.2 Top bracket K-K50-OK ............................................................................................................................13

6.1.3 Inward opening bracket K-K30-AKI ...........................................................................................................14

6.1.4 Top bracket K-K-OK-SK ...........................................................................................................................15

6.1.5 Inward opening top/bottom hung window, mounting on a blind frame ...........................................................15

6.1.6 Outward opening top/bottom hung window, mounting on a blind frame .........................................................15

6.1.7 Inward opening top/bottom hung window, actuator mounted on the window sash ..........................................16

6.1.8 Inward opening bottom hung window, actuator K-K30-FLEX mounted on the window sash .............................16

6.1.9 Rotary window ........................................................................................................................................17

6.1.10 Calculating forces/stroke ........................................................................................................................18

6.1.11 Permissible pushing force on the chain ....................................................................................................18

6.2 EA-K-30 Electrical connection ..........................................................................................................................19

6.2.1 Supply ...................................................................................................................................................19

6.2.2 Supply / connection cable .......................................................................................................................19

6.2.3 Feedback signal – “F” contact ..................................................................................................................20

6.2.4 Feedback signal – dry contact .................................................................................................................20

6.2.5 Feedback signal – tandem port ................................................................................................................20

6.2.6 Single connection – dry contact ................................................................................................................20

6.2.7 Single connection – “F” contact ................................................................................................................ 20

BA_EA(230)-K-30-xxx_EN_12 www.simon-protec.com Date: 13.02.2019

Table of Contents

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 3

6.2.8 DUO operation / parallel connection .......................................................................................................... 21

6.3 EA230-K-30 Electrical connection ..................................................................................................................... 22

6.4 Single connection – standard variante (EA230-K-30 /xxx) .................................................................................... 22

6.4.1 Parallel connection (EA230-K-30 / xxx) ...................................................................................................... 23

6.4.2 Synchronous connection (EA230-K-30/xxx-S) ........................................................................................... 23

7. EA-K-30 – Technical Data .................................................................................................................................. 24

8. EA230-K-30 – Technical Data ............................................................................................................................ 26

9. Commissioning ................................................................................................................................................... 27

9.1 EA230-K-30 ................................................................................................................................................... 27

10. Troubleshooting ............................................................................................................................................... 27

10.1 EA-K-30 ....................................................................................................................................................... 27

10.2 EA230-K-30 ................................................................................................................................................. 27

11. Annex ............................................................................................................................................................... 28

11.1 Care and Maintenance .................................................................................................................................. 28

11.2 General business and delivery terms .............................................................................................................. 28

11.3 Company Addresses ..................................................................................................................................... 28

11.3.1 System manufacturer ............................................................................................................................ 28

11.3.2 Germany .............................................................................................................................................. 28

11.3.3 Switzerland .......................................................................................................................................... 28

11.3.4 Hungary ............................................................................................................................................... 28

12. Manufacturer's declaration ............................................................................................................................... 28

13. EC manufacturer’s declaration (distributor) ...................................................................................................... 28

General

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 4

Operating Manual

1. General

1.1 Foreword to this manual

This manual is intended for professional operation, installation

and maintenance by trained, knowledgeable and qualified

personnel (such as mechatronics engineer or electrician) and/

or qualified personnel who know how to install electrical

equipment.

Read this operating manual carefully and pay particular

attention to the hazard warnings. Store this operating manual

for future reference/maintenance. Please pay close attention

to the terminal assignment, the minimum and maximum

performance data (see “Technical Data”) and the installation

instructions. Incorrect use or improper operation/mounting

may cause loss of system functionality and damage to

property and/or people.

The following symbols can be found in this manual:

Operating procedures are marked this way.

Consequences are presented this way.

•Buttons or switches to be pressed/activated are shown

in bold.

• “Indicators” are placed in quotation marks.

1.2 Intended use

Opening units (actuators) are used for the power-operated

opening and closing of building covers that are installed in

walls or in roofs and are used for the ventilation of rooms or

for the removal of fire smoke.

See chapter 2.1 “Risk assessment” on page 5.

1.3 EA-K-30 – Product description

The EA-K-30/xxx-T(-DA) is an an electromotive chain

actuator that can be used in accordance with Chapter 1.2 of

this operating manual.

The technical features include:

• soft start

• intelligent, microprocessor-controlled overload cut-off

• low noise emission

• soft-close range

• configurable stroke and force

• double-sided connection option (EA-K-30/xxx-T-DA) for

the supply cable (with connector)

• DUO operation of two actuators1with a connection cable,

the power supply is looped through from one actuator to

the other

1.4 EA230-K-30 – Product description

The EA230-K-30/xxx(-S) is an electromotive chain actuator

that can be used in accordance with Chapter 1.2 of this

operating manual.

The technical features include:

• soft start

• low noise emission

•soft-close

• electronic zero point reset by means of a teach-in run in

the “CLOSED” direction

• stroke programming

• synchro operation of up to eight EA230-K-30/xxx-S

actuators

INFORMATION

An information text gives you additional hints!

ATTENTION

This warning notice alerts you to potential hazards that

may impact the product!

DANGER

This warning notice alerts you to potential hazards to your

life or health!

ENVIRONMENT NOTICE

This notice alerts you to potential environmental hazards!

1. A minimum of one actuator is required with a double-sided

connection – EA-K-30/xxx-DA.

Safety Regulations

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 5

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

2. Safety Regulations

See supplementary sheet “Safety Instructions and

Warranty Conditions”!

2.1 Risk assessment

2.2 Restrictor stay

3. Figures

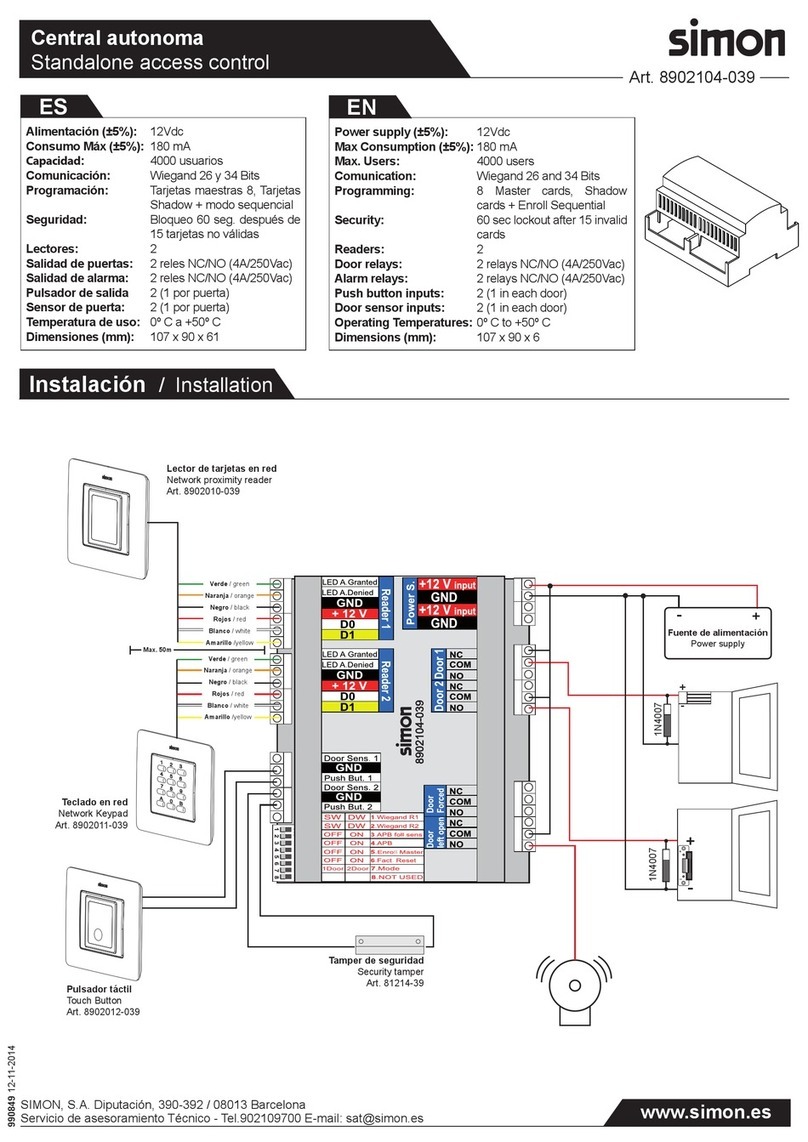

Figure 1: EA-K-30/xxx-T(-DA) chain actuator

Figure 2: EA230-K-30/xxx(-S) chain actuator

INFORMATION

Perform a risk assessment according to the application

(e.g. the mounted system).

Information can be found in the guidance sheet KB.01

“Power-operated windows” issued by the VFF (window,

door and facade manufacturers)

www.eurowindoor.eu/news-and-proceeding/

position-papers-and-publications/

ATTENTION

A restrictor stay with an adequate stroke must be installed

in bottom hung wings.

It is important to ensure that the fastening of the actuator

on the window or wing frame is designed to be permanent

and suitable for the actuator force specified on the type

plate.

46VWURNHPP /56VWURNHPP /66VWURNHPP/76VWURNHPPVWURNHPP

35

43,6

37

183,7

Connection

EA-K-30/xxx-T & EA-K-30/xxx-T-DA

Gear side

Supply cable / USB-300

Optional connection

Supply cable, only EA-K-30/xxx-T-DA

Chain side

37

43,6

234,3

468

VWURNHPP

/

624

VWURNHPP

/

727

VWURNHPP

/

824

VWURNHPP

35

DIP switches &

LED display

Figures

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 6

Figure 3: Top bracket K-K50-OK

Figure 4: Top bracket K-K-OK-SK

Figure 5: Inward opening bracket K-K30-AKI

Figure 6: Lower bracket K-K30-A

Figure 7: Lower bracket K-K30-K

Figure 8: Lower bracket – K-K30-FLEX

CDEF

CDEF

EA-K-30 – Functions

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 7

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

4. EA-K-30 – Functions

4.1 Soft-close range

4.1.1 Speed reduction

The actuator has a factory-activated speed reduction

function, the last 75 mm before reaching the “CLOSED” end

position (see Table 1: “Electrical properties” on page 24 and

Figure 10: “Configurable ranges” on page 8).

4.1.2 Current reduction

After reaching the last 75 mm before end position "CLOSED",

the soft-close current becomes active, 0.3 A by default. This

value can be increased to 1.0 A via SIMON LINK (when the

speed reduction function is deactivated).

4.2 SIMON LINK

The actuator has a configuration interface (gear side) on

which the following functions can be performed via SIMON

LINK:

• The stroke can be electronically limited from 100 mm on.

• Forces can be set in the “OPEN” and “CLOSED”

direction.

•Thesoft-close current can be adjusted.

• The speed reduction before the “CLOSED” end position

for the soft-close range can be set (see Figure 10:

“Configurable ranges” on page 8).

• The switching behaviour of the dry contact can be set.

• A detailed status message from the actuator and data

logger can be read.

Figure 9: Configuration interface for SIMON LINK

ATTENTION

In order to avoid damage to the window and actuator or

injuries to individuals, the cut-off current limit is

automatically reduced to 0.3 A when the speed reduction

function is activated; this corresponds to a force of

approx. 150 N. The cut-off current limit can be increased

to a maximum of 0.5 A (300 N) via SIMON LINK when the

speed reduction function is activated.

INFORMATION

You need a service cable (USB-300)

and the associated software (from

version 2.0.0) for configuration of the

actuator via SIMON LINK.

For more information visit

short.simon-protec.com/slen

ATTENTION

The cut-off of the actuator in the configuration is provided

by the USB-300 cable.

There must be no external power supply at this point in

time (EA-K-30/xxx-T-DA on the chain side).

gear side

connector for USB-300 cable

EA230-K-30 – Functions

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 8

4.3 Configurable ranges

Soft-close range: moves with the electronic zero point, the soft-close current ISC and the speed reduction can be configured via

SIMON LINK.

Reset range: the electronic zero point is reset when switching off via load in direction of the “CLOSED” driving direction within the

first 30 mm before the “CLOSED” end position.

Stroke: electronic stroke limitation depending on programming.

Figure 10: Configurable ranges

5. EA230-K-30 – Functions

5.1 End position cut-off while closing

The end position cut-off while closing occurs automatically

(load depending) and is not programmable. The electronic

switches off the actuator, when reaching a threshold value, if,

for example, the window is completely closed and moved into

the gaskets.

After the window is closed each time or the cut-off current has

been exceeded, the chain is extended slightly again to protect

the gaskets and the window.

5.2 End position cut-off while opening

The cut-off in the OPEN end position occurs automatically

and can be set with the DIP switches 1-2.

A teach-in run must be performed after setting the DIP

switches (three switch combinations for the STROKE setting).

5.3 DIP switches

(See Figure 2: “EA230-K-30/xxx(-S) chain actuator” on page 5.)

mechanical ]HUR

electronical ]HUR

mechanical “max”

30 mm 75 mm

reset

range

soft-closerange

electronical stroke

50 mm

stopping time 3 s stopping time 3 s

50 mm

before max. electr. stroke

stopping time 0 s

ATTENTION

The actuator must be de-energised before the DIP

switches can be changed. After setting the DIP switches, a

pause of approx. 5 seconds must be observed before the

drive can be supplied with power again.

DIP

switch 1

DIP

switch 2 Function

ON ON Maximum stroke

(delivery condition)

OFF ON STROKE reduced by 100 mm

ON OFF STROKE reduced by 200 mm

OFF OFF

RESET

(See chapter 5.4 “RESET” on

page 9)

EA230-K-30 – Functions

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 9

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

5.4 RESET

If necessary, release the connection between the chain

end piece and the top bracket.

Drive the actuator in the OPEN direction and extend the

chain by approx. 10 cm.

Disconnect the actuator from the power supply.

Check the communication cables in the case of actuators

connected in parallel (red/white).

Set both of the DIP switches 1 and 2 to OFF.

Wait for five seconds.

Drive the actuator in the OPEN direction.

The RESET procedure is performed, the orange LED

lights up continuously during this procedure. The

actuator immediately moves in the CLOSED direction

up to the end position, then approx. 5 cm back in

OPEN direction.

The orange LED flashes continuously after performing

the RESET process correctly.

Disconnect the actuator from the power supply again.

Set the DIP switches 1 and 2 to the desired setting.

Wait for five seconds.

Connect the chain end piece to the top bracket again.

Let the actuator perform a teach-in run

(see chapter 5.6 “Performing a teach-in run” on page 9).

5.5 Teach-in run

The actuators detect and store the distance between sash

and frame fully automatically during operation (when the

window is fully closed). The dimensional difference between

wing and frame is called overhang.

This teach-in takes place when the actuator fully closes the

window for the first time after a RESET.

5.6 Performing a teach-in run

Open the actuator slightly and then drive it in the

CLOSED direction and let it cut off in the end position.

If the teach-in process has worked correctly, the

actuator signals this by the flashing of the orange LED

(next to the DIP switches) for approx. 3 seconds.

If the orange LED does not flash as described, a RESET

must initially be performed (see chapter 5.4 “RESET“).

ATTENTION

The chain end piece must not be connected to the bracket

when performing the RESET process.

ATTENTION

The communication cables of the actuators must be

connected to each other during the RESET process in

synchronous mode (red with red and white with white).

ATTENTION

After RESET, e.g. after a stroke setting via the DIP

switches or after installation, you must perform a teach-in

run.

EA230-K-30 – Functions

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 10

5.7 LED displays

The EA230-K-30 has three status LEDs (see Figure 2: “EA230-K-30/xxx(-S) chain actuator” on page 5) with the following

meanings.

Red LED

Number

of

flashes Type of error Possible solution

1 Overload cut-off • Check the drives for correct installation

(mechanical/electrical);

• Is the force of the installed actuators adequate.

2Communication error (Synchro)

• Perhaps there are actuators connected that do not have a

common RESET.

• Check the red/white connection cable;

• Perform a RESET procedure for the interconnected

actuators.

3——

4Inconsistent DIP switch settings (Synchro)

• The DIP switch settings of the interconnected actuators do

not match.

• Check and correct the DIP switch settings.

5 Error during the RESET procedure • Repeat the RESET procedure.

6Cabling error (Synchro)

• The power input of the the interconnected actuators does

not match.

• Check and correct the connection of the actuators.

7Addressing error (Synchro)

• The assignment of the internal addresses of interconnected

actuators has failed.

• Perform a RESET procedure.

8Power supply error

• The supply voltage is not within the permissible range or is

not stable.

• Check the electrical connection;

• Check the supply voltage.

9Chain alignment error (Synchro)

• The chain position (STROKE) of the interconnected

actuators is not within the permissible range

• Perform a RESET procedure.

10 Memory error (Synchro)

• The storage process in the internal memory was not

successful.

• Repeat the RESET procedure.

11 Connection error

• A RESET procedure is performed at the same time in the

case of several non-synchronous actuators.

• Perform the RESET procedures individually.

Green LED

LED status Meaning

Continuously

lighting The voltage supply to the actuator is correct.

The actuator is closed correctly and the storage of the STROKES has been performed successfully.

Flashing The voltage supply to the actuator is correct.

The set STROKE has been reached. The number of flashes indicates the internal address to which the actuator

has been assigned during the RESET procedure in the case of synchronous actuators.

Mounting — Mechanical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 11

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

6. Mounting

See supplementary sheet “Safety Instructions and

Warranty Conditions”! 6.1 Mechanical connection

— Mechanical connection

You need different combinations of brackets for mounting the

actuator depending on the mounting position and the shape

of the window or building cover; the brackets (see page 6),

with the exception of the top bracket K-K50-OK, must be

ordered separately.

In order to ensure that the window is sealed securely,

check that the chain of the actuator is extended slightly

before mounting the actuator. However, the chain should

not extend more than 30 mm after mounting the actuator

otherwise the electronic zero point reset can no longer be

guaranteed (see Figure 10: “Configurable ranges” on

page 8).

Orange LED

LED status Meaning

Continuously

lighting

duration < 0.5 sec. Write process in the internal memory of the actuator is running.

Continuously

lighting RESET procedure is running.

Continuously

lighting for 3 sec. Teach-in procedure of the teach-in run has been completed correctly.

Flashing RESET procedure completed correctly. The number of flashes indicates the internal address to which the

actuator has been assigned during the RESET procedure in the case of synchronous actuators.

INFORMATION

Further information on mounting can be found in the

guidance sheet KB.01 “Power-operated windows” issued

by the VFF (window, door and facade manufacturers)

www.eurowindoor.eu/news-and-proceeding/

position-papers-and-publications/

DANGER

The system must be mounted by specialist

personnel (qualified electricians) only. All

relevant national safety regulations and

directives apply to mounting, installation and

commissioning.

Improper mounting can create a risk of

electric shock. All safety regulations must be

complied with. Follow the current assembly

instructions. Incorrect mounting can lead to

serious injury.

ATTENTION

Please note the static properties of the window frame

when mounting the actuator.

Use suitable fixings depending on the window material on

which the actuator is to be mounted. (The fixings are not

included in the delivery!)

Mounting — Mechanical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 12

6.1.1 Mounting brackets

Determine the mounting position of the brackets so that the chain of the actuator will not collide with the (window/wing) frame

in any opening position of the window and the position of the chain is in the centre of the window; centre line markings are

provided on the K-K-50-OK for this purpose (see Figure 14 on page 13). In parallel/duo operation the actuators should be

positioned in such a way that the chains are located on 1/4 of the edges (left/right) of the window sash.

Secure the brackets with screws that are suitable for the respective window or the desired surface (screws/fixings are not

included in the delivery), see Figures page 15 and page 16.

Insert the actuator in the support brackets and secure it with the two self-locking screws.

Figure 11: K-K30-K Figure 12: K-K30-A

Figure 13: K-K30-FLEX

Mounting — Mechanical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 13

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

6.1.2 Top bracket K-K50-OK Figure 14

Extend the chain approx. 10 cm and connect the chain end piece to the K-K50-OK (1). To do this, insert the fixing bolt from

the side with the logo (2) and secure it on the other side with the retaining ring (3).

Figure 15

Figure 16: Incorrect positioning of the K-K50-OK

ATTENTION

The top bracket must always be aligned in such a way

that the SIMON logo on the bracket is on the same side of

the chain as the SIMON logo on the chain exit.

INFORMATION

Centre line marking (see Figure 14) for aligning the

bracket on the middle of the wing (single variant) or at a

distance of 1/4 away from the edge (left/right) in parallel

operation.

SIMON

logos

centre line

marking

2

1

3

4

ATTENTION

The top bracket K-K50-OK must not be mounted turned,

otherwise its function can no longer be fully guaranteed

(see Figure 16: “Incorrect positioning of the K-K50-OK”).

INFORMATION

With the help of the alternative upper bracket K-K-OK-SK,

turned mounting with lateral force flow is possible (see

6.1.4 “Top bracket K-K-OK-SK” on page 15).

So nicht!

Not in this way!

Mounting — Mechanical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 14

6.1.3 Inward opening bracket K-K30-AKI

Figure 17

Extend the chain approx. 10 cm and connect the chain end piece to the K-K30-AKI (1). To do this, insert the fixing bolt from

the side with the logo (2) and secure it on the other side with the retaining ring (3).

Figure 18

ATTENTION

In the case of a compression force application (e.g. top

hung window),the mounting bracket must always be

aligned so that the SIMON logo of the bracket is on the

same side as the SIMON logo of the chain outlet.

INFORMATION

Window heights in a ratio of approx. 2 : 1 to the actuator

stroke (opening width) are possible for the inner hole

pairs (for the fixing bolt) depending on the quality and

shape of the window sash. This ratio changes to approx.

3 : 2 for the outer hole pair.

These are only approximate guideline values and must be

clarified before any mounting in case of doubt!

SIMON logos

1

2

3

4

Mounting — Mechanical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 15

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

6.1.4 Top bracket K-K-OK-SK

Figure 19

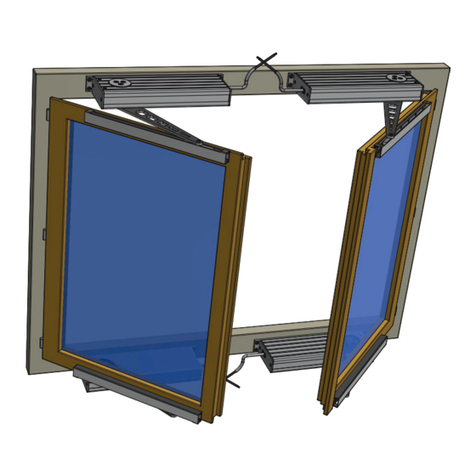

6.1.5 Inward opening top/bottom hung window, mounting on a blind frame

Figure 20: Inward opening bottom hung window

6.1.6 Outward opening top/bottom hung window, mounting on a blind frame

Figure 21: Outward opening top hung window

ATTENTION

The top bracket must always be aligned in such a way

that the SIMON logo on the bracket is on the same side of

the chain as the SIMON logo on the chain exit in the case

of top hung wing applications.

Note the resulting alignment of the actuator (see

Figure 19). The combination of actuator and bracket must

only be used in this alignment to one another. Any other

alignment will lead to the loss of the function of the

bracket.

min.

min. 39.5 mm*

plus pivoting range

depending on the wing height

min. 70.5 mm*

min.

61.8 mm

16.8

Mounting — Mechanical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 16

6.1.7 Inward opening top/bottom hung window, actuator mounted on the window sash

Figure 22: Inward opening bottom hung window, at the window sash

6.1.8 Inward opening bottom hung window, actuator K-K30-FLEX mounted on the window sash

Figure 23

min.

min.

ATTENTION

Position the actuator so that the chain is as far as

possible away from the window sash in order to avoid

damage to the window and the chain while opening it.

6min. mm

Mounting — Mechanical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 17

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

6.1.9 Rotary window

Figure 24: Mounted on a blind frame

Figure 25: Mounted on the window sash

ATTENTION

The chain actuator EA-K-30/EA230-K-30 must only be

mounted upright (with the actuator side at the top) on

DIN right windows!

Mounting — Mechanical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 18

Figure 26: K-K30-FLEX mounted on the window sash 6.1.10 Calculating forces/stroke

This calculation is only valid for wall windows mounted

vertically. A detailed calculation must be made for all other

mounting positions, which we will be pleased to assist you

with.

F := the force of the actuator [N]

S := the stroke of the actuator [mm]

H := the height of the window sash [mm]

W := the weight of the window sash [kg]

Required actuator force for the specified stroke:

F = (W / 2) x (S / H) x 10

= (W x S x 5) / H

Maximum possible actuator stroke for the specified force:

S = (2 x F x H) / (W x 10)

= (F x H) / (W x 5)

Figure 27

6.1.11 Permissible pushing force on the chain

Figure 28

height of the frame – H

weight of the

frame – W

force F

stroke S

bottom hung window

height of the frame – H

weight of the

frame – W

force F

stroke S

top hung window

250

200

150

100

50

force[N]

500 600

750

1000

0stroke [mm]

700 800700 900

static push force

dynamic push force

(eg. wind load)

650 850 950

300

550

400

450

1100

1050

1200

1150

pull force

Mounting — EA-K-30 Electrical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

Page 19

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

6.2 EA-K-30 Electrical connection

— EA-K-30 Electrical connection

6.2.1 Supply

The power supply must be designed for the actuator. The

voltage and current must correspond with the information on

the type plate. The supply cabling must be checked before

the initial commissioning, the cable cross section in particular

must be taken into account. The valid regulations regarding

minimum values for the cable sizing must be observed!

Sample calculation (this is only an approximate value and

does not replace an exact calculation):

The power is supplied to the EA-K-30/xxx-T on the gear side.

The power can also be supplied via the chain side on the

EA-K-30/xxx-T-DA (double-sided connection). The supply

voltage is relayed internally to the opposite connection point,

this can then be used to connect another actuator (see

chapter 6.2.8 “DUO operation / parallel connection” on

page 21).

6.2.2 Supply / connection cable

It is possible to supply power to the second actuator directly

through the first actuator (DA variant) in tandem / duo

operation. The supply cable can therefore be changed into a

connection cable.

Cut the second supply cable to the desired length (plus

approx. 3 cm).

Strip the cable over a length of 18 mm and remove 4 mm

of insulation from the 5 cores.

Screw the 5 cores into the connector and secure the

cable with a cable binder (e.g. 100 x 2.5) as traction

relief.

black

yellow

red

blue

brown

ATTENTION

Make sure that the loops of the supply cable are

adequately sized on moving parts, taking account of the

bending radii, in order to prevent the pinching or tearing of

the supply cable.

DANGER

Connect to the power supply (24 VDC) only after checking

the entire system.

INFORMATION

We recommend performing a trial run with a suitable

mobile power supply (incl. a control device, not just a

battery). This means that it is quick and easy to respond to

malfunctions.

ATTENTION

Do not earth the electrical connection.

The actuator must only be operated with a 24 VDC safety

extra-low voltage.

Unused cores must be insulated.

+

+

24V

INFORMATION

Size information for actuator cable (empirical formula):

Cable cross section [mm²] = single cable length [m]

x number of actuators

x current consumption

per actuator [A]

/ 73.

The DIN VDE 0100 and DIN VDE 0298 regulations

continue to apply.

Mounting — EA-K-30 Electrical connection

Operating Manual

Chain actuator – EA-K-30/xxx-T(-DA)

Chain actuator – EA230-K-30/xxx(-S)

BA_EA(230)-K-30-XXX_EN_12 www.simon-protec.com Date: 13.02.2019

info@simon-protec.com Issue: 1.2/01.2019

Page 20

Place the green connector and the cable binder in the

upper shell of the connector housing and screw the top

shell to the bottom shell.

6.2.3 Feedback signal – “F” contact

It is possible to create a classic “F” contact via the dry contact

by connecting the yellow core (NO2) to the blue (S) core (see

chapter 6.2.7 “Single connection – “F” contact” on page 20).

The alarm triggering of the contact must therefore be

activated in the “OPEN” and “CLOSED” end position via

SIMON LINK.

6.2.4 Feedback signal – dry contact

The normally open contact (NO1, NO2) is activated in the

CLOSED driving direction when the actuator is cut off in the

“CLOSED” end position, the message is stroke-dependent

and can be evaluated as a “CLOSED message”.

Other switching settings, such as in “OPEN” end position, can

be set via SIMON LINK.

6.2.5 Feedback signal – tandem port

6.2.6 Single connection – dry contact

Connect the cables according to the connection plan.

6.2.7 Single connection – “F” contact

Connect the cables according to the connection plan.

INFORMATION

The output of the dry contact occurs only on the gear side

of the actuator (see Figure 9: “Configuration interface for

SIMON LINK” on page 7).

ATTENTION

Only a cut-off signal (e.g. overload cut-off) is switched over

to the actuator connected in parallel. Monitoring of the

cables or function of the actuators connected in parallel

does not take place and therefore also does not lead to the

cut-off of the actuators connected in parallel.

ATTENTION

When not in use, the red wire (T) must be electrically

insulated. The red core must only be connected to the red

core of an actuator connected in parallel.

ATTENTION

When not in use, the red wire (T) must be electrically

insulated. The red core must only be connected to the red

core of an actuator connected in parallel.

The “F” contact (black) must not be earthed or clamped in

parallel!

volt-free contact

(max. 28 V / 1.0 A)

24V DC

T

NO1 S

OPEN: S = +

O = -

CLOSE: umpolen

actuator

NO2 O

tandem-port

(electr. insulate)

blue

brown

black

yellow

red

“F”-contact

(max. 1.0 A)

24V DC

blue

T

NO1 S

OPEN: S = +

O = -

CLOSE: pole change

actuator

brown

NO2 O

black

yellow

red

tandem-port

(electr. insulate)

This manual suits for next models

18

Table of contents

Other Simon Controllers manuals

Popular Controllers manuals by other brands

Marlec

Marlec Solar iBoost+ installation instructions

Sunlight Supply

Sunlight Supply Titan Controls Helios 2 instruction manual

Varian

Varian Turbo-V 300 ICE instruction manual

TRIAC

TRIAC 2R2500 Installation & maintenance manual

Siemens

Siemens SSC161.05U quick start guide

Honeywell

Honeywell Z74S-AN installation instructions