8 |Installation | M5000 Series User Manual

Flush-mounting the display

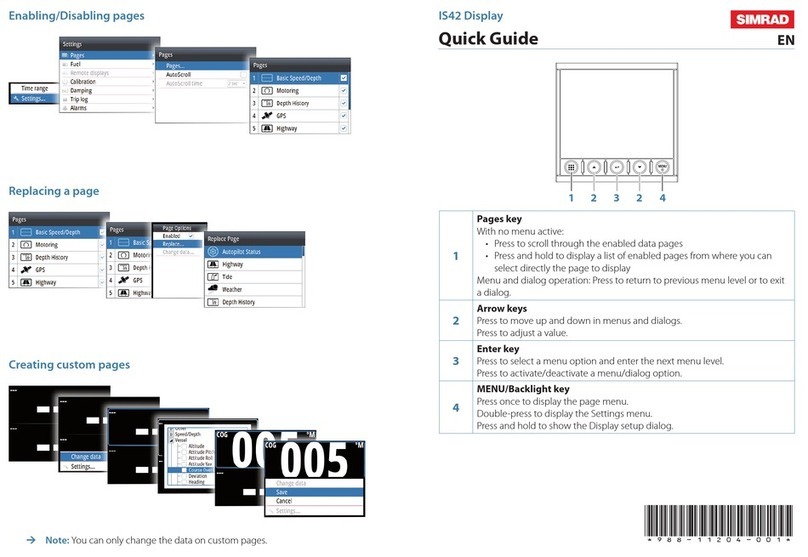

¼Note: The following guidelines and warnings apply:

Hard materials e.g. GRP, Acrylic, hardwoods

2.3 - 2.5 mm (3/32")

Important drill bit size selection information

Front mount screw recommendations

Soft materials e.g. Plywood

1.9 - 2.3 mm (5/64")

Max 5.5 mm

(0.22”)

1. Fit the supplied M4 machine screws,

washers, and plastic spacers to each of

the four threaded ttings on the back

case of screen. Hand tighten only.

REMOVESHADED AREA

*988-10455-001*

NOTE:

DONOT SCALE

PRINT 1:1

IMPORTANT.Donotuse this template if it has been rescaled

bycopyingor prin ng. If this is not the original, or is a print

fromale, please check the dimension lines below are to

scalebeforeuse.

IMPORTANT.Nepasu lisercegabarit s’il a été photocopié ou

impriméenformat réduit ou agrandi. Si ce gabarit n’est ni un

originalniune version imprimée d’un chier PDF, veuillez

vérierqu’ilest à l’échelle avant de l’u liser.

IMPORTANTE.nousar la plan lla si hay peligro que la escala

originalexactase ha alterado por copias o procesos de

impresiónimprecisos.Si esto no es el original, o un PDF, veri

carquelas líneas abajo están a la escala antes de usar.

WICHTIG.DiesenVordruck nicht verwenden, wenn er durch

KopierenoderDrucken im Maßstab verändert wurde. Sollte

esnichtdas Original oder ein PDF-Ausdruck sein, müssen

untenstehendeZeilenvor erwendung an den rich gen

Maßstabangepasstwerden.

BELANGRIJK.Gebruikdeze mal niet indien de schaal is veran-

derddoordathet is gecopieerd of gedrukt. Indien deze mal

niethetorigineel of een print van PDF is, controleer dan of de

onderstaandelijnende juiste schaal zijn voordat u ze gebrui-

kt.

IMPORTANTE.Nãou lize este gabarito se a escala do mesmo

versidoalterada por cópia ou impressão. Se não for o

originalouuma cópia impressa de um arquivo PDF, verique

aslinhasabaixo, para acertar a escala antes da u lização.

VIKTIGT.Användinte denna mall om den skalats om genom

utskri ellerkopiering.Om de ainteär originalet eller en

utskri frånenPDF, kontrolleraa linjerna nedan stämmer

medskalaninnan det används.

IMPORTANTE.Nonu lizzare questo modello se è stato

ridimensionatocopiandoloo stampandolo. Se questo non è

l’originaleola stampa di un le PDF,vericare se le linee che

seguonodevonoessere dimensionate prima di essere u lizza-

te.

TÄRKEÄÄ.Äläkäytä tätä kaaviota,jos sen mi akaavaon

muu unutkopio-idessatai tulostaessa. Jos tämä ei ole alku-

peräinentaiPDF tuloste tarkista rajat mi akaavasta alla

ennenkäy öä.

注意:请尽量不要使用本安装挖孔尺寸模版图的复印件。

如果使用复印件,则在使用之前请确认其比例一定要与原

件大小必须一致。

중요: 복사나 출력으로 크기가 조정 된 경우 이 템플릿을

사용하지 마십시오. 원본이 아니거나 인쇄물이면,

사용하기 전 아래 치수선의 눈금을 확인 해 주십시오.

注:このテンプレートは印刷やコピーによって縮尺が変

わっていることがありますので使用しないで下さい。テ

ンプレートがオリジナルのものでない場合には、下の寸

法線を使って縮尺を確認してください。

ВНИМАНИЕ: Не используйте эту инструкцию, ес

ли она была изменена в размерах при копирова

нии или распечатке. Если вы используете не ор

игинал, а распечатку из файла, убедитесь в соо

тветствии размеров линейки в нижней части и

нструкции с действительными размерами.

Checkdimensions before cutting

12"

300mm

L

C

L

C

192.5mm (7.58")

186.0mm (7.32")

192.5mm (7.58")

186.0mm (7.32")

200.0mm (7.87")

117.5mm (4.63")

111.0mm (4.37")

130.0mm (5.12")130.0mm (5.12")

117.5mm (4.63")

111.0mm (4.37")

200.0mm (7.87")

385.0mm (15.16")

372.0mm (14.65")

400.0mm (15.75")

235.0mm (9.25")

222.0mm (8.74")

260.0mm (10.24")

ZM-16

Marine Monitor

B&G

2. Tape appropriate mounting

template in place on dash, and

ensure cutout lines are level relative

to a reference point on dash.

3. Drill top and bottom mounting

screw holes using an appropriate

drill bit for the surface material:

• Soft materials e.g. Plywood - 1.9 - 2.3

mm (5/64”)

• Hard materials e.g. GRP, Acrylic,

hardwoods - 2.3 - 2.5 mm (3/32”)

4. Drill cutout corners with a small

pilot drill bit followed with 13 mm

drill bit. Complete cutout with

jigsaw or similar tool.