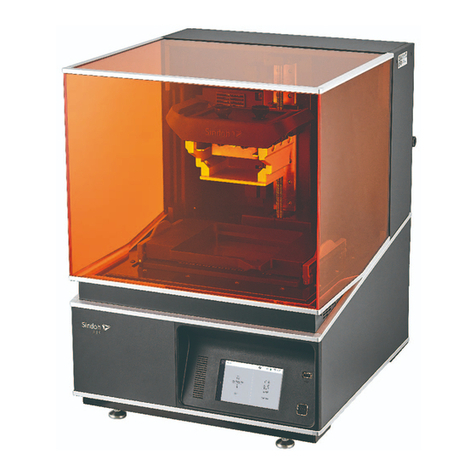

Sindoh DP201 Series User manual

DP200

/

DP102

DP201

/

DP202

2X

/

2X DP303

1X

/

1X DP302

3DWOX 1

Read the User Manual before operating the product,

and keep the manual at a convenient place near the

product.

3DWOX Desktop Manual

3dprinter.sindoh.com

2

Contents

1. Basic UI Elements -------------------------------------------------------------------------------------------------------------- 4

2. Functions and Information -------------------------------------------------------------------------------------------------- 6

2.1 Loading ----------------------------------------------------------------------------------------------------------------------------- 6

Detail description ----------------------------------------------------------------------------------------------------------------- 6

2.2 Profile Value Setting ------------------------------------------------------------------------------------------------------------- 6

Detail description ----------------------------------------------------------------------------------------------------------------- 6

2.3 Custom Profile ------------------------------------------------------------------------------------------------------------------ 11

2.4 Filament Information Indicator ---------------------------------------------------------------------------------------------- 13

Detail description --------------------------------------------------------------------------------------------------------------- 13

2.5 View Mode Selection Button------------------------------------------------------------------------------------------------- 13

Detail description --------------------------------------------------------------------------------------------------------------- 14

2.6 Moving a model ---------------------------------------------------------------------------------------------------------------- 14

2.7 Adjusting Model Size ---------------------------------------------------------------------------------------------------------- 15

2.8 Model Rotation ----------------------------------------------------------------------------------------------------------------- 15

2.9 Print ------------------------------------------------------------------------------------------------------------------------------- 15

2.10 Standard Menu Bar ------------------------------------------------------------------------------------------------------------ 15

2.11 Select a Cartridge -------------------------------------------------------------------------------------------------------------- 16

2.12 Equal Distribution -------------------------------------------------------------------------------------------------------------- 18

2.13 Merge & Split -------------------------------------------------------------------------------------------------------------------- 19

Merge ---------------------------------------------------------------------------------------------------------------------------- 19

Split -------------------------------------------------------------------------------------------------------------------------------- 19

Detail description -------------------------------------------------------------------------------------------------------------- 19

3. Printing (basic functions) ------------------------------------------------------------------------------------------------- 26

3.1 Loading 3D Model Files ------------------------------------------------------------------------------------------------------ 26

3.2 Basic Parameter Setting ------------------------------------------------------------------------------------------------------ 26

3.3 Slicing ----------------------------------------------------------------------------------------------------------------------------- 26

3.4 Print -------------------------------------------------------------------------------------------------------------------------------- 27

USB Thumbdrive---------------------------------------------------------------------------------------------------------------- 27

Network Connection ----------------------------------------------------------------------------------------------------------- 27

Local Network Usage---------------------------------------------------------------------------------------------------------- 28

4. Advanced Features ---------------------------------------------------------------------------------------------------------- 30

4.1 Support Edit Function --------------------------------------------------------------------------------------------------------- 30

Support Editing View Mode ------------------------------------------------------------------------------------------------- 30

4.2 3D Model Analysis Function ------------------------------------------------------------------------------------------------ 33

Select 3D Model ---------------------------------------------------------------------------------------------------------------- 33

Under Analysis menu, select Thickness / Overhang. ----------------------------------------------------------------- 34

Analysis Control Window ---------------------------------------------------------------------------------------------------- 34

Thickness Analysis Function ------------------------------------------------------------------------------------------------ 34

Overhang Analysis Function ------------------------------------------------------------------------------------------------ 35

3

4.3 Function to Calculate Optimal Printing Direction ---------------------------------------------------------------------- 35

Estimated Printing Error Surface ------------------------------------------------------------------------------------------- 35

Overhang Surface ------------------------------------------------------------------------------------------------------------- 35

Amount of Support ------------------------------------------------------------------------------------------------------------- 35

4

1. Basic UI Elements

Reference

-

Font used in the printer GUI and the user manual is the “NANUM” font provided by NAVER.

After installation is complete, double click on the icon created on your desktop, a screen similar to the following

appears. Explanation is as follows.

1 2 3 4

5

6

7

8

9

10

11 12

13

14

15

No. Name Explanation

1 Standard menu bar Most program functions are available in this menu bar. Opening files,Loading

preset values, Exporting program values and more functions available.

2 3D view Displays a reconstructed 3D model loaded on the program.

3 Select view angles You may look at the three-dimensional view from the front, back, left, right,

up, and down based on the selected angle.

4 Printer Domain In 3D view, displays actual printer domain showing the location and size of

the model.

5 View Mode Selection

button

On the screen 3 types of viewing modes are available. 3D Model Viewer,

Support Edit Viewer, Layer Viewer are available.

6 Position button Moves model in direction of 2 axes.

7 Scale button Changes the model’s size. (zoom or change length)

8 Rotation button Rotates object on set angles based on 3 axis.

9 Print button Connects to a printer to print a sliced model over the network.

10 Layer Color button Select colors to print by layers.

11 Printer frontal indication Indicates the front of the printout.

5

No. Name Explanation

12 3D model 3D model data displayed on the screen.

13 Import button (LOAD) Loads printable 3D data into program.

14 Settings button Settings for values necessary for slicing.

15 Filament information

indicator

Shows information on filaments inside the printer. Easily informs user of

filament material, color and remaining quantity.

2X and 2X DP303 display two bars when both cartridges are loaded.

16 (2X/2X DP303)

No. Name Explanation

16 Select a Cartridge

button

It is enabled only for the 2X and 2X DP303. Loaded cartridges will be displayed .

If two or more objects are loaded, additional lines with cartridge selection options

will be displayed.

Cartridges can be selected and printed according to each mesh or object.

6

2. Functions and Information

2.1 Loading

Loads a printable 3D model and displays it on the screen.

Currently supported file formats are ply, obj, stl (binary, ascii, amf)

Detail description

1Click on the Import button located left of screen.

2After selecting file, 3D model file is displayed as if it’s on the printer bed.

2.2 ProleValueSetting

Slicing and printing require variety of parameter values. From the material of the filament, to the height of the

sliced layers, and to the printing speed, various parameters should be configured.

Detail description

1Click on the Settings button located on left bar.

2According to selected mode a window will pop up, user can input desired profile.

7

Easy Mode

-

Easy mode can be set for printing speed-quality, material, support pattern, and inside filling.

-

For the 2X and 2X DP303, Cartridge No. is enabled.

Advanced Mode

-

This enables the user to change profiles to modify output values as he/she desires.

-

Custom profiles (= user-defined profiles) can also be edited in the advanced mode. (See 2.3 Custom Profile.)

Basic

<This applies to the default profiles of the slicer program.>

-

For the DP 201, DP 201 bed temperature and material settings are disabled.

8

-

For the 2X or 2X DP303, two cartridges will be on the list, and each cartridge can be set individually.

-

sign marked values are synchronized for two cartridges. Individual values cannot be set independently.

-

Support type can be selected or disabled.

-

Profile selection bar: The user may choose either a default profile or a custom profile.

-

Reset button: Clicking the “Reset” button will restore the current setting before the new setting is saved

(before the “OK” or the “Apply” button is clicked).

However, the “Creation Position” in the “Support” tab and the “Bed Fixation Type” in

the “Bed Fixation” tab will be retained even after the “Reset” button is clicked.

-

OK button: This will save all the setting values and close the dialog box.

-

Apply button: This will save the setting values without closing the window.

-

Cancel button: This will close the dialog box without saving the setting values.

<This applies to custom profiles (not the default profiles of the slicer program).>

-

“Edit” button: If the user clicks this button, the changes in the “Edit Custom Profile” will be saved,

and the user will return to the advanced mode, where the changes will also be reflected.

If the user does not save the changes in the “Edit Custom Profile”, the changes will not be reflected

in the advanced mode.

-

The other settings will be identical to those of the default profile.

Quality / Infill

-

Sets values for thickness and infill rate of external walls and bottom/top surface of the model .

-

sign marked values are synchronized for two cartridges.

Individual values cannot be set independently.

9

Speed

-

It controls the printing and travel speeds.

-

If you print large object with a high “Fill Density”, please reduce the “Travel Speed”.

Retraction / Cooling

-

Sets control values for the retraction of filament and nozzle cooling fan.

Multi Nozzle

-

It is enabled only for the 2X or 2X DP303.

-

It is a window to set profile when using multiple nozzles.

-

For outputting a large printout with the multi-nozzle, set the lowering bed value to be larger (0.8 mm

recommended) than the default value (0.2 mm).

Wipe Tower

-

It is enabled only for the 2X and 2X DP303. This feature is recommended for use when printing

on one layer with two cartridges.

1. While using other nozzle, wipe off any leaking filament residue from the waiting nozzle to maintain a

smooth output surface.

2. When the nozzle is replaced, the filament is first output to the Wipe tower to compensate for

the filaments leaked from the nozzle.

10

-

The Wipe Tower is divided into an Inner tower and an Outer tower, and one cartridge can be used in the

tower of each part.

For example, if you set the outer cartridges to (1) as shown, the inner tower will automatically be set to

cartridge (2).

-

In order to ensure a stable Wipe tower output, please enlarge the tower raft and tower size according

to the size of the shape you want to output.

-

Select [Advanced Mode]-[Enable Wipe Tower] and [Layer Viewer] to show the Wipe Tower.

Shape Error Correction

-

Shape error correction provides functions to correct mesh errors. (Ex: Printing along the mesh surface).

Support

-

It is used to set the position and pattern of support.

Bed Adhesion

-

It tab enables setting according to assigned fixing type.

-

Please set the bed adhesion type to [Brim] if the flexible filament is used to print a model with narrow

bottom. Otherwise, the output will not stick to the bed or warp.

-

In outputting a printout of large volume with a filament made of ABS material, the printout and the raft may

separate from each other because the printout is shrunk during the outputting. In such case, decrease the

“First Layer Airgap” or increase the “Flow Compensation” ([Basic]) before outputting the printout.

11

2.3 CustomProle

Clicking [Profile] - [Custom Profile] will open the [Custom Profile List] window.

Only custom profiles that are exclusive of the slicer program’s default profiles will be listed.

If the user has not created a custom profile, the list will be empty.

* Name: This is the profile name input by the user for profile creation.

* Description: This is the description of the profile input by the user.

- The description may be edited by double-clicking the button on the [Custom Profile List] window.

(Enter after editing) The changes will be saved when the user clicks the “OK” or “Apply” button.

* [New] button: This button enables the inputting of a new custom profile.

- When this button is clicked, the [Add Custom Profile] window will appear.

* [Edit] button: This button enables the editing of an existing custom profile.

- When editing, the user should select one custom profile at a time.

- When this button is clicked, the [Edit Custom Profile] window will appear.

* [Delete] button: This button enables the deletion of an existing custom profile.

- A deletion will only be saved when the user clicks the “OK” or “Apply” button.

- The user may select and delete multiple profiles at a time.

12

1Clicking the [New] button → [New Custom Profile] window

- This window is for the creation of a new custom profile.

* Name (required value): Input a profile name with a maximum length of 30 characters.

- The symbols ?, “, *, \, /, |, :, <, >, [ , and ] cannot be entered in the custom profile name.

* Description (optional value): Input a profile description with a maximum length of 300 characters.

* Profile (required value): Select the profile number to be imported.

- The user may copy not only a default profile but also a previous custom profile that he/she has created.

- The list of default profiles varies depending on the model.

e.g., In the case of the DP200, when no custom profile is defined, only the “Sindoh PLA” and the

“Sindoh ABS” will be listed.

- In the case of tthe 3DWOX 1, 2X/2X DP303 and 1X/1X DP302 model, the [New Custom Profile] window

will show the “ETC” profile.

In profile editing, if the user selects a Sindoh profile, he/she can select only profile values within the

limits given by Sindoh.

However, if the user selects “ETC”, he/she can select a wider range of profile values.

<“Import Profile” function>

- Clicking the “Import Profile” button at the bottom of the profile window will show a pop-up window

for the selection of a profile from exported profiles. The user may create a custom profile by selecting

a profile of *.ini format to be imported.

13

2Clicking the [Edit] button → [Edit Custom Profile] window

- This window is for editing and saving existing profile values.

- Clicking the [Reset] button will reset the setting values before they are saved (before the “OK” or

“Apply” button is clicked).

- In the case of the 3DWOX 1, 2X/2X DP303 and 1X/1X DP302 1 model, the “Filament” and the

“Material” fields of the [Default Setting] will show the “ETC” profile.

The user should select the “ETC” material if he/she uses a material that is different from those

provided by Sindoh.

*[OK] button: This will save all the setting values and close the dialog box.

*[Cancel] button: This will close the dialog box without saving the setting values.

* [Save Profile] button: This will save the profile setting values without closing the window.

2.4 Filament Information Indicator

Printer automatically reads condition of filament in printer and displays on screen.

Detail description

Current default printer

name

In open

material

mode

Current quantity, condition

and remaining material

of filament inside the printer

<DP200/DP102, DP201/DP202,

3DWOX 1,1X/1X DP302 >

<2X/2X DP303 > <3DWOX 1,

2X/2X DP303,

1X/1X DP302>

2.5 View Mode Selection Button

At the top right hand side of the viewer, you will see buttons as shown on the left. Clicking the button

on the screen will display three types of view modes to be selected. (From the top, Normal View,

Support Edit View, Layer View ) Once selected, the selected view type is highlighted for the user.

14

Detail description

3D Model Viewer

This mode renders the 3D model loaded and displays it on the screen.

In this mode user is able to change position, angle and size of the 3D model and print it out.

Support Edit Viewer

When the model contains a slant surface, s support is needed at the bottom of the model to ensure

good printing output. Hence, in this mode user is given the accessible views to position the support

at the right location.

Layer Viewer

This mode slices the 3D model to print. Pressing this button allows user to slice 3d model parallel to

the printer bed by reflecting parameter values, and to display the layers.

2.6 Moving a model

Moves the model on screen in directions of x and y axes.

Moves (in mm) a selected model in two axes.

Applies values to model. (Equivalent to Enter key)

Place the selected model in the center of the bed.

Moves the selected model to the location where it was initially loaded.

15

2.7 Adjusting Model Size

Scale and length of selected model on screen can be adjusted.

Size of scale can be controlled in direction of three axes.

Size of length can be controlled in direction of three axes.

Expansion and contraction on the x,y,z directions at the same ratio.

Adjust model to maximum printable size.

Reset to original size.

2.8 Model Rotation

Selected model can be rotated in the direction of the three axes.

Enter the angle to rotate in three axes.

Restore the model’s original direction when it was initially loaded.

Apply the entered value to the model (Same as the Enter Key)

IIf the model’s angle is tilted, this will automatically adjust the angle so that the

model is adhered to the flat surface of the bed.

2.9 Print

Connect to a printer to print a sliced model over the network

2.10 Standard Menu Bar

Contains File, Settings, and Network printer related functions and located at the top of the program window.

16

2.11 Select a Cartridge

-

It is enabled only for the 2X or 2X DP303. When two models or a model consisting of two or more meshes

is loaded, it may print with a different cartridge by specifying the cartridge number for each mesh or object.

-

Press the button to check the filament amount of each cartridge.

1When the Layer Color is off, [Select a Cartridge]

To print Mesh 1 with Cartridge 1 and Mesh 2 with Cartridge 2, select the cartridge for each Mesh as shown

above.

2When the Layer Color is on, [Select a Cartridge]

If the Layer Color is activated, a 3D model cannot be right-clicked. (To delete or move object.)

For DP200/DP102, DP201/DP202, 3DWOX 1 and 1X/1X DP302

-

Pause the printing on the desired layer. Unload the cartridge, replace it, and continue printing.

17

For 2X and 2X DP303

1The Layer Color is a function to specify different cartridges for different layers. Move the left-side slider to

show slider positioned layer and the layer number. Position the slider at cartridge change desired layer

and press the [Add] button in the bottom.

2Then, another tab is created to replace cartridges by layer. Move the slider, and press the [Add] button to

add more Layer Color.

▼

18

0th to 69th layers are printed by cartridge 1 and 69th to 230th layers are printed by cartridge 2.

If the boundary cross-sectional area of the layer color is small, increase the infill density of the internal

filament for ensuring durability.

2.12 Equal Distribution

Enter desired number of layers, and press the [Equal Distribution] button to divide all layers evenly.

19

2.13 Merge & Split

It is not applicable if the [Layer Color] is enabled.

Merge

Merge is a function to align the axis with respect to the origin.

Ctrl + Select (left-click) two or more objects. Then, right-click and click merge object to merge the selected

objects. After merging them, it can be checked with Select a Cartridge. Individual meshes can be assigned to

different cartridges.

Split

Right-click and click Split to split the merged object.

Detail description

File

Loads 3D model (equivalent to Load button)

Load G-code and the model to show the print path

Save the loaded model to another type of file or name

Save G-code after slicing the loaded model

MODE

3DWOX offers users two types of different modes for slicing.

“EASY MODE” offers a predefined setting for a fast and easy print, “ADVANCED MODE” allows users to

set each and every detailed value for user preference, to achieve desired printouts.

20

Profile

There are many profile-related functions. For custom profiles, see “2.3 Custom Profile.”

Setting

This enables the designation of various setting values needed for slicing.

Printer Setting (DP200/DP102, 3DWOX 1)

-

Printer Model: A connected default printer appears on the screen.

-

Number of Nozzles: The number of nozzles of the device is displayed

-

Bed Heating Function: Only select when bed heating function is available. When left unchecked, G-code

for bed heating will not be created.

-

Slicing Origin Point Correction (based on the equipment’s origin point): Place the 3D model on the

bed based on the equipment’s origin point (0,0).

-

Origin Correction (Bed center): Automatically controls model to be always positioned in center of printer

bed.

-

Maximum Printing Size: Insert maximum printable size of the connected printer.

-

E-mail: Sends the printing status to the entered e-mail address.

Under “email,” input the recipient email address(es) and select the number of times to send the

notification emails. Additional recipient addresses can be added by using “;.”

The maximum number of notification emails that can be sent is 10.

An email notification, an email will be sent out for the user to see if the email notification is working properly

by default. So the email will be sent out one more time than the number that the user entered. However,

the number of email that is sent will not exceed 10 times.

(When user selects 10 times, the notification email will be sent out 10 times)

Other manuals for DP201 Series

1

This manual suits for next models

9

Table of contents

Other Sindoh 3D Printer manuals

Sindoh

Sindoh 3DWOX 5X User manual

Sindoh

Sindoh A1 Series User manual

Sindoh

Sindoh A1 Series User manual

Sindoh

Sindoh DP201 Series User manual

Sindoh

Sindoh 3DWOX-1 User manual

Sindoh

Sindoh DP200 Series User manual

Sindoh

Sindoh 3DWOX 2X User manual

Sindoh

Sindoh 3Dwox DP200 Troubleshooting guide

Sindoh

Sindoh 5X Series User manual

Sindoh

Sindoh A1SD Series User manual