TABLE OF CONTENTS

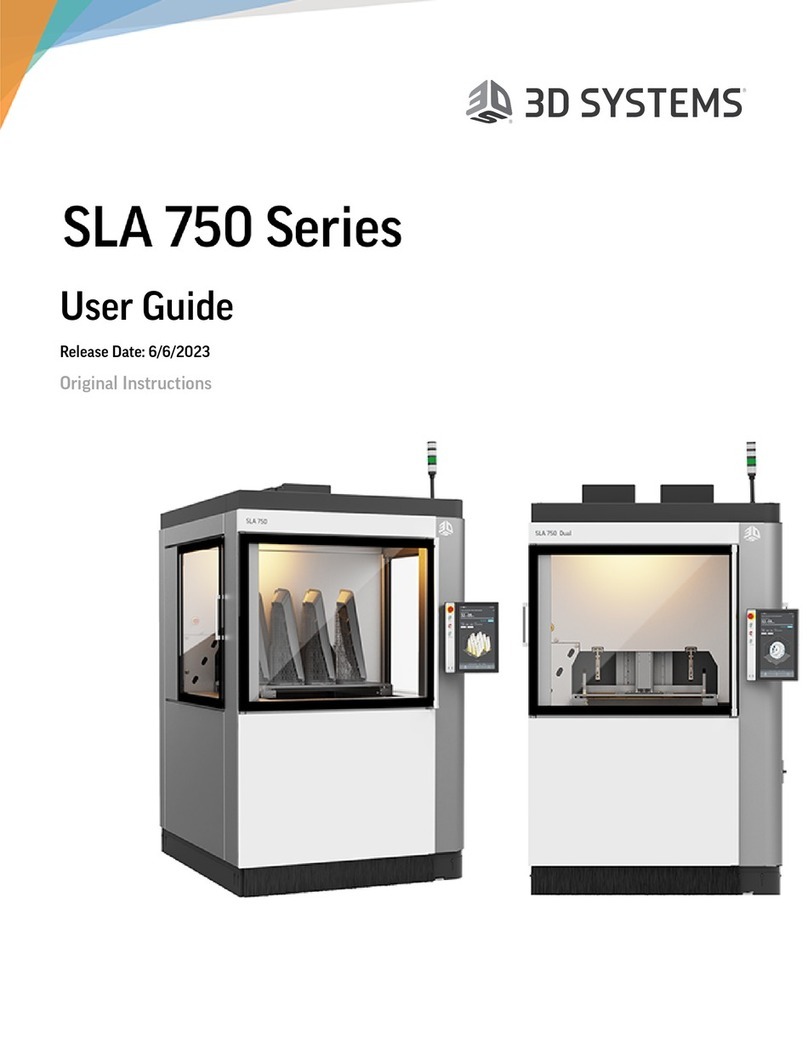

1 POSTCURE 1050 INTRODUCTION ................................................................................................... 1

2 POSTCURE 1050 SAFETY ................................................................................................................... 2

2.1 PostCure 1050 Safety Switches ....................................................................................................................................................3

2.2 PostCure 1050 Material Handling and Safety ............................................................................................................................ 3

2.3 PostCure 1050 Environmental Safety ..........................................................................................................................................3

2.4 PostCure 1050 Electrical Safety ....................................................................................................................................................4

2.5 PostCure 1050 Emergency Shutdown .........................................................................................................................................4

2.6 PostCure 1050 First Aid and Protective Equipment .................................................................................................................. 5

2.7 PostCure 1050 Safety Notice ........................................................................................................................................................6

2.8 PostCure 1050 Label Installation Diagram .................................................................................................................................6

3 POSTCURE 1050 OVERVIEW ............................................................................................................. 9

3.1 PostCure 1050 Components ........................................................................................................................................................ 9

3.2 PostCure 1050 Curing Chamber ................................................................................................................................................11

4 POSTCURE 1050 SPECIFICATIONS AND REQUIREMENTS ...........................................................13

5 POSTCURE 1050 SYSTEM SETUP ....................................................................................................14

5.1 Power on PostCure 1050 ............................................................................................................................................................ 14

5.2 PostCure 1050 3D Connect ........................................................................................................................................................ 14

6 POSTCURE 1050 OPERATION .........................................................................................................15

6.1 PostCure 1050 User Interface ....................................................................................................................................................15

6.1.1 PostCure 1050 Status ........................................................................................................................................................ 16

6.1.2 PostCure 1050 Materials ...................................................................................................................................................16

6.1.3 PostCure 1050 Settings .....................................................................................................................................................28

6.2 PostCure 1050 Cure a Printed Part ........................................................................................................................................... 36

6.2.1 Drying Parts Inside PostCure 1050 ..................................................................................................................................44

6.2.2 PostCure 1050 Cure an SLA Print Platform .................................................................................................................... 44

6.3 PostCure 1050 Firmware Update .............................................................................................................................................. 44

6.4 PostCure 1050 Clean Resin Spills ...............................................................................................................................................48

6.5 PostCure 1050 Power Off Machine ........................................................................................................................................... 48

7 POSTCURE 1050 PREVENTATIVE MAINTENANCE ........................................................................ 50

7.1 Cleaning the PostCure 1050 .......................................................................................................................................................50

7.2 PostCure 1050 Remove-Replace LED Bars ............................................................................................................................... 53

7.3 PostCure 1050 Remove-Replace Chamber Fan ....................................................................................................................... 56

3D Systems, Inc. i p/n 40-D177, Rev. A