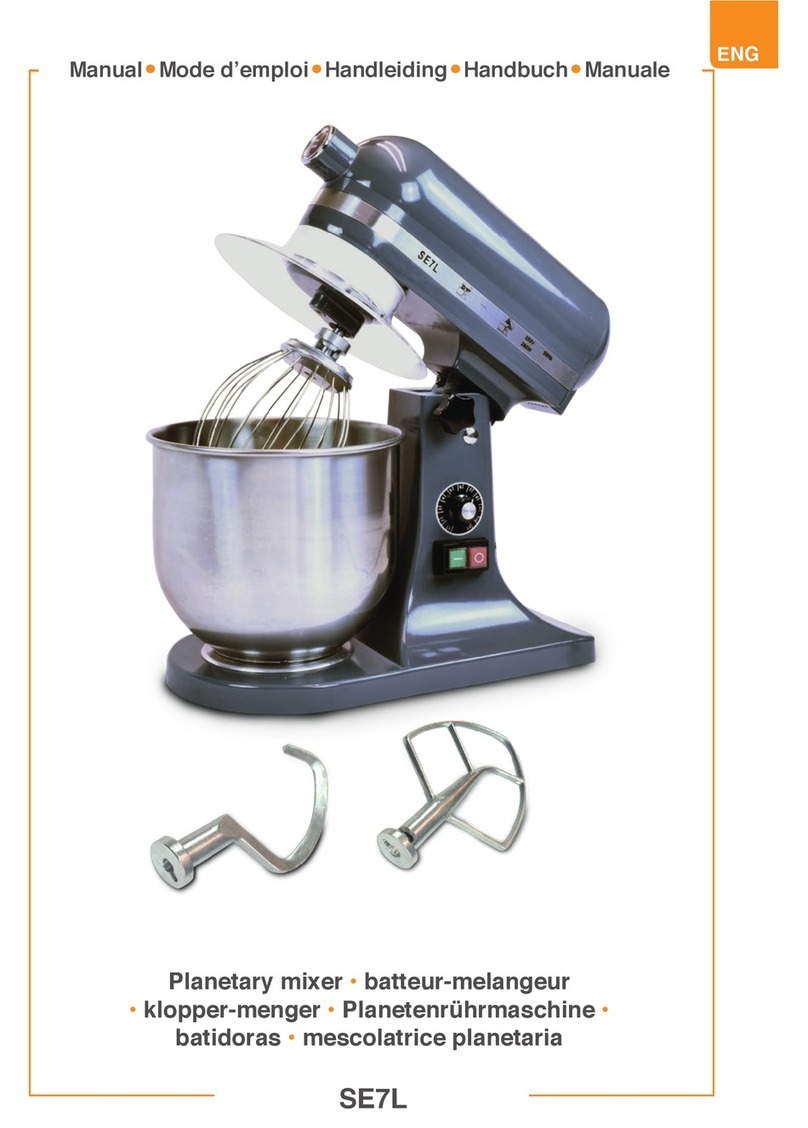

sinmag SM-500CSH User manual

OWNER’S MANUAL

SM-500CSH

(Planetary Mixer)

CONTENTS

1

Introduction••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••(2)

Installation & Commissioning•••••••••••••••••••••••••••••••••••••••••••••••••••(3)

Operation•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••(4)

Attention••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••(6)

Cleaning & Maintenance••••••••••••••••••••••••••••••••••••••••••••••••••••••••••(7)

Parts List••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••(8)

Electric Control Diagram••••••••••••••••••••••••••••••••••••••••••••••••••••••••(11)

INTRODUCTION

2

Brief introduction

The SM-500CHS planetary mixer has a total bowl capacity of 50 Litres,

combined with a 3 speed gearbox to ensure that all mixing requirements

can be met. They are produced to mix liquid ingredients, paste and viscid

ingredients, and dough.

Owners and operators should carefully read and familiarize themselves

with this entire manual before attempting to operate or service this machine.

Complying with this manual will ensure years of safe and trouble-free

operation.

All of the information, illustrations and specifications contained in this

manual are based on the latest product information available at the time of

printing. SINMAG reserves the right to make changes at any time without

notice. If questions arise during the operation or servicing, please contact

us before proceeding.

Specification

INSTALLATION AND COMMISSIONING

3

Installation

After uncrating your planetary mixer, inspect the machine for any damage

that might have occurred during shipment. Report any damage to us before

proceeding to operate this machine. Never attempt to operate this machine

with damaged or inoperable parts.

The following accessories are packed in the machine: One Dough Hook,

One Beater, One Whipping Ball.

Select a location for your mixer to allow sufficient room for operating,

cleaning and servicing the machine. The floor must be solid and level.

Commissioning

Check available voltage to your mixer. This mixer should have its own,

isolated electrical supply. Check your machine’s identification/electrical

plate to determine the appropriate breaker and wire size needed.

To ensure safety and years of trouble-free operation, the manufacturer

recommends that a licensed electrician check the electrical supply to

ensure that the proper breaker and wiring is being used.

After the machine has been connected to the electric supply, first of all

check the direction of rotation of agitator. When look from above, the

agitator should rotate clockwise. The arrow on the machine head indicates

the rotation direction of hook, beater or whipping ball. If the rotating

direction is wrong, please exchange any two of the electric cables to

reverse the rotating direction.

Then test the operation of the safety emergency stop button. The machine

must stop operating immediately. Test the operation of the microswitch

cut-out on the bowl safety cover. When the cover is lifted the machine must

stop immediately.

OPERATION

4

Operating Instructions

Tool Selection

Whipping ball: Light mixes such as whipped cream, mayonnaise, egg

white, pancakes and meringue.

Beater: Firm mixed such as light pastry, cakes, biscuits, icing, fillings and

mashed vegetables.

Hook: Heavy mixes such as dough and pastry.

Bowl Lift

Crank the lift level counterclockwise to lower the bowl. It is necessary to

lower the bowl change agitators, and to provide better access for filling and

emptying the bowl. To raise the bowl, crank the lift level clockwise until it

hits the upper stops.

Speed Control:

To change speeds, first TURN OFF MIXER, then move the shifter handle to

the desired speed. Number 1 is the slowest speed and number 3 is the

highest speed.

Slow Speed: or heavy mixtures such as dough, biscuits, etc.

High Speed: or fast, light work, such as whipping cream, beating eggs, and

mixing thin batters.

OPERATION

5

Operation Steps

1). Put the mixing materials into the bowl together with the agitator. Then fix

the bowl into the bowl bracket.

2). Lift the bowl to the topnotch by lift handle.

3). Fix the agitator onto the maxing head.

4). Place the shifter handle to the required speed, then turn on the machine.

5). Turn off the machine and lower the bowl by lift handle then take off the

agitator when mixing work is finished.

6). Take out the bowl together with agitator. Finally take out the mixed

materials.

ATTENTION

6

Working Safety

1). Disconnect from the power source when cleaning or servicing this

machine.

2). Never attempt to clean this machine while it is in motion, serious injury

could result.

3). Never place your hand or any kitchen utensil in the bowl whilst the mixer

is in operation.

4). Never operate this machine with safety covers removed or with safety

switches inoperative.

5). Many mixer operations may be started at the low speed then advanced

to a higher speed as the mixing progresses.

CLEANING AND MAINTENANCE

7

Cleaning and Maintenance

1).Clean the surface of the machine with dishcloth after operation everyday.

Use a damp cloth with a mild dish washing soap.

2).Wipe some lubricating oil on the bowl lifting gliding track. Lift the bowl up

and down for several times to full lubricate the track. If you are difficult to

lift the bowl, please scrape off the dough residue from the track then

wipe the lubricating oil. Please help to lift the bowl up and down to make

full lubrication when the bowl still has difficulty to be lifted up and down.

3).If it is still difficult to lift the bowl up and down by lift handle after the full

lubrication, please adjust the inner screw under the spring to strengthen

the strain of the spring as to strengthen the lifting force.

4).To check the gear oil level to avoid oil leak every month.

PARTS LIST

8

PARTS LIST

9

Parts List Parts Code Parts Name Specification

SM500C001 12402-320 Gear Shaft(13T)

SM500C002 15ZC401-6204-2RS Bearing

SM500C003 12402-340 Gear Wheel(20T)

SM500C004 12402-660 Block Ring

SM500C005 12402-330 Gear Wheel(30T)

SM500C006 12402-350 Gear Shaft(52T)

SM500C007 15ZC401-6204-2RS Bearing

SM500C008 15ZC401-6207-2RS Bearing

SM500C009 12420-190 Main Shaft

SM500C010 15ZC401-6206-2RS Bearing

SM500C011 12402-054 Ring Of Mainshaft

SM500C012 12402-300 Ring Of Gear Wheel

SM500C013 12402-290 Gear Wheel(45T)

SM500C014 12402-075 Shifting Block

SM500C015 12402-260 Gear Wheel(35T)

SM500C016 12402-200 Gear Cover

SM500C017 12402-210 Gear Wheel

SM500C018 12402-051 Oil Block Ring

SM500C019 12402-004 Gear Cover

SM500C020 12402-003 Bottom Cover

SM500C021 12402-520 Fixed Shaft

SM500C022 12402-500 Gear Wheel(21T)

SM500C023 Nut M16×1.5

SM500C024 Key 6×6×15

SM500C025 Ring Φ16

SM500C026 15YF402-62*35*10 Oil Seal

SM500C027 21402-001 Machine Head

SM500C028 21402-480 Internal Gear

SM500C029 15YF402-45*72*13 Oil Seal

SM500C030 12402-950 Conical Gear(30T) Φ71×32

SM500C031 12402-950 Conical Gear(30T) Φ71×32

SM500C032 15ZC201-6005-2RS Bearing

SM500C033 12402-700 Guide Rod

SM500C034 16WDKG Micro Switch

SM500C035 16JLJCQ Contactor

SM500C036 16JDQRHN10A-5 Thermal Relay

PARTS LIST

1

0

SM500C037 12402-012 Motor Belt Wheel

SM500C038 15PD402-800L Belt

SM500C039 21402-011 Big Belt Wheel

SM500C040 12402-031 Spring

SM500C041 12402-101 Spring

SM500C042 21402-037 Shifting Cover

SM500C043 16HTLTAD-Y-636 Micro Switch

SM500C044 12402-024 Plate

SM500C045 12402-036 Handle

SM500C046 12402-035 Shaft Of Handle

SM500C047 12402-025 Cover

SM500C048 16KGLK22-81R Stop Switch

SM500C049 15BSL22*250 Handle Wheel

SM500C050 15SBL2M*12 Handle

SM500C051 12402-910 Shaft Of Handle Wheel

SM500C052 21402-002 Frame

SM500C053 21402-005 Bowl Bracket

SM500C054 12402-029 Fixed Handle

SM500C055 12402-030 Pin

SM500C056 21402-170 Top Cover

SM500C057 21402-490 Safety Grid

SM500C058 12402-200 Bowl

SM500C059 21402-006 Base

SM500C060 17JD402 Foot Mat

SM500C061 16KGLK22-21G-N29 Start Button

SM500C062 21402-082 Beater

SM500C063 21402-083 Ball

SM500C064 21402-081 Hook

SM500C065 12402-280 Shifting Gear

SM500C066 12402-020 Ring

SM500C067 16402-380-50 Motor

ELECTRIC CONTROL DIAGRAM

1

1

Table of contents

Other sinmag Mixer manuals