INDCO BT Series User manual

OWNERSMANUAL

BT and BGF Series Mixers

TABLEOFCONTENTS:

Safety & General ................................................................................2

Operation ..............................................................................................3

Maintenance ........................................................................................4

Troubleshooting .................................................................................5-9

Parts List................................................................................................. 10-11

4040 EARNINGS WAY NEW ALBANY, IN 47150 P: 8129415954

F: 8129449742 INDCO.COM INFOINDCO.COM

Warranty

Our products are guaranteed against

defective materials and workmanship, we

will repair or replace such items as may

prove defective at our option. Warranty

period is one year on items manufactured

by INDCO. On items not manufactured by

INDCO, the manufactures warranty applies.

All component parts of our products are

covered by this warranty, except for normal

wear items such as belts or impellers. We

cannot be responsible for damage or

abuse to equipment caused by improper

installation or operation. Warranties

can also be voided by unauthorized

disassembly of equipment. For warranty

repairs, equipment is returned to INDCO

at the customer’s expense; we will repair

and return to customer at our expense.

Under no circumstances will we allow

labor charges or other expense to repair

defective merchandise. This warranty

is exclusive and is in lieu of all other

warranties, whether express or implied.

INDCO shall not be liable for any other

damages, whether consequential, indirect,

or incidental, arising from the sale or use of

its products.

Bracket

Mount

Mixers

Safety:

Please follow the below safety precautions. If there are any questions, please call INDCO at 800-942-4383. Please read this com-

plete manual before trying to operate your mixer. Failure to follow these instructions could result in serious bodily injury or death.

and other ojects clear of moving parts.

ELECTRIC MOTOR SAFETY:

Motors should be installed, protected and fused in accordance with latest issue of National Electrical Code, NEMA Standard

Publication No. MG 2 and local codes. Frames and accessories of motors should be grounded in accordance with National

Electrical Code (NEC) Article 430. For general information on grounding refer to NEC Article 250. Not all rotating parts are

standard connections. If environment has hazardous combustible fumes present, use only explosion-proof electric motors.

AIR MOTOR SAFETY:

The air motor is designed to be driven by compressed air and under no circumstances be driven with any other gases. Fluids,

particles, solids or any substance mixed with air, particularly combustible substances likely to cause explosions, must not drive air

motor.

thrust that could damage air motor.

damage.

clearances and rapid motor damage will result.

General:

INDCO bracket mount mixers are excellent for agitation of light to medium viscosity materials. The standard mounting bracket

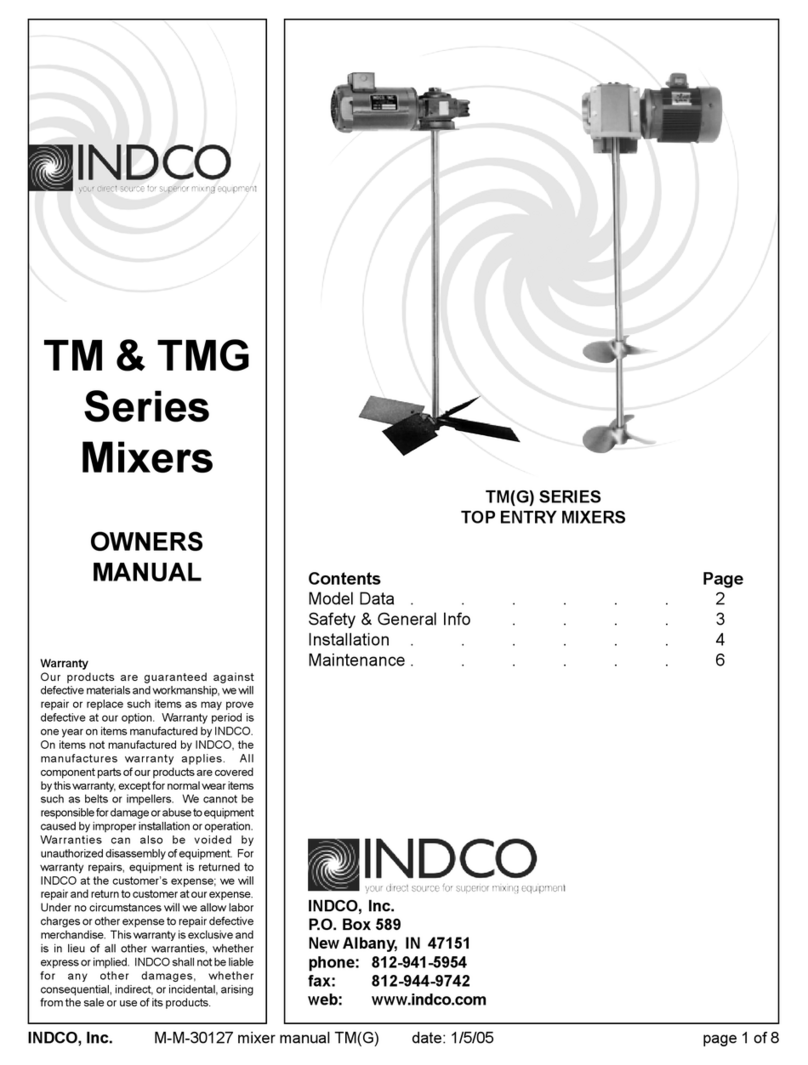

BT Series - DIRECT Drive

models run from 300 to 3000RPM.

BGF Series - GEAR Drive

run from 40 to 400RPM.

:

Before removing any packing, visually inspect the exterior of the shipment for any sign of damage. Should there be any

damage, bring it to the attention of the delivering UPS or truck line and note the same on the receiving ticket. Should there be

damage you must place a claim with the truck line. They are the only ones who will pay for the damage done and you are the

only one who can place that claim.

INSTALLATION:

Frame Bracket Assembly

range. Two hand-knobs tighten bracket assembly to side of container.

Impeller Shaft - BT Series

To install mixer shaft, back o the set screws as far as possible without removing them. Insert mixing shaft into the coupler as

Impeller Placement

For mixers with ONE impeller, mount it 1 to 2 impeller diameters distance o the bottom of mixing container.

For mixers with TWO or more impellers, mount the lowest impeller 1 to 2 impeller diameters distance o the bottom of mixing container.

situation. Experimenting with impeller placement may provide your best results.

motor~gearbox

mounting plate

frame bracket

(small)

- adjustable -

hand-knob

frame bracket

(large)

34” to 48”

container size

6”

8.5”

BT

Series

set screws

impeller shaft

coupler,

mounted to

motor shaft

Impellers - BT Series

The standard impellers are 3-bladed marine style. To install the propeller, back o the set screw(s) as far as possible without

Impellers - BGF Series

The standard impellers arefFolding type. To install follow same procedure as BT Series, above.

Impeller Shaft - BGF series

Tighten set-screws securely.

shaft

set screw

shaft

set screw

(both sides)

INSTALLATION, CONTINUED:

Impeller Shaft - BGF series

Tighten set-screws securely.

OPERATION:

Electric Power:

Once the electric motor has been wired, check rotation to be sure the mixer shaft is rotating in a clock-wise direction, looking

downward into the container.

Air Power:

Check to ensure the air valve is in the closed position, then connect air supply. Check rotation to be sure the mixer shaft is

rotating in a clock-wise direction, looking downward into the container.

Once the mixer is in the container, it is now safe to operate. Always start and stop mixer in slowest speed.

CAUTION:

ü Never run mixer without a propeller.

ü Never run propeller outside a container.

gear box

impeller shaft

impeller

motor

set-screws

2 @ 90° apart

Rotation:

clock-wise looking

downward into

tank

Apply “anti-seize”

material in the

shaft ~ hollow quill

area.

MAINTENANCE:

Maintaining your mixer is not dicult if you follow these guidelines:

- Check all set-screws and fasteners, tighten as needed.

- Check all wiring on a regular basis and repair as needed.

- Air motor powered units:

Lubrication

BGF Series Models with Gear Reducers

- Winsmith 917 & 920 Series

Factory Filled:

the oil plug provided and while the unit is oriented in its operating position.

correct grade based on actual ambient temperatures.

Oil Changing:

When changing oil for any reason, it should be remembered that oils of various types may not be compatible. Therefore, when

if necessary.

Initial Oil Change:

The oil in a new speed reducer should be changed at the end of 250 hour of operation.

Subsequent Oil Changes:

Under normal conditions, after the initial oil change, the oil should be changed after every 2,500 hours of operation, or every six

may be necessary to change oil at intervals of one to three months. Periodic examination of oil samples taken from the unit will

help establish the appropriate interval.

Synthetic Oils:

Synthetic lubricants can be advantageous over mineral oils in that they generally are more stable, have longer life, and operate

over a wider temperature range. These oils are appropriate for any application but are especially useful when units are subjected

to remove metal particles that accumulate during break-in. Subsequent oil changes should be made after 5000 hours operation if

units are operating in a clean environment.

Oil Temperature:

the application (loading, duration of service, ambient temp.). Excessive temperature can result from overloading due to original

Lubricants:

Below is just a few of the recommended lubricants that should be used in your speed reducer.

Part No. Description

N-AC980 Muer, metal

N-AC980 Muer, metal

N-AC990 Muer, metal

phase

Ambient Temp. 16 to 50°F 51 to 110°F 111 to 165°F

Max.Op.Temp. 185°F 200°F 200°F

ISO Visc.Grade 460 680 1000

AGMA Lub.No. #7 Comp. #8 Comp. #8A Comp.

Mobil Oil 600W 600W Super Extra Hecla

Shell Oil Omala 460 Omala 680 Omala 800

Sun Oil Sunep 1110 Sunep 1150 Oil 8 AC

3/4 HP

Air Motors

Electric Motors

1/2 HP 4 HP 1.5 HP

Part No. Description

phase

SWT-TOGGLE ON - OFF switch

SWT-GUARD Switch guard

phase

phase

SWT-DP-TOGGLE ON - OFF switch

SWT-GUARD Switch guard

phase

phase

SWT-DP-TOGGLE ON - OFF switch

SWT-GUARD Switch guard

phase

1 HP

Electric Motors

1.5 HP 3/4HP

Parts List - BT Series Mixer:

502

505

504

503

506

501

509

508

300

400

210

101 102

100

Parts List - BT Series Mixer:

ITEM DESCRIPTION PART NO. QTY.

100. Motor, air see ‘Parts List - Drive Motors’ 1

100. Motor, electric see ‘Parts List - Drive Motors’ 1

400. Impellers specify model 1~2

401. Set screw (not shown) specify model 2~4

500. Bracket Ass’y Complete, consisting of: BT-403 1

Parts List - BGF Series Mixer:

100

102101

204

200

202201

509

203

300

400

401

502

505

504

503

506

508

501

204

Parts List - BGF Series Mixer:

ITEM DESCRIPTION PART NO. QTY.

100. Motor, air see ‘Parts List - Drive Motors’ 1

100. Motor, electric see ‘Parts List - Drive Motors’ 1

500. Bracket Ass’y Complete, consisting of: BT-403 1

Bracket Mount - Toggle Clamp Adjustment

3. Clamp should be located so that the handle is vertical.

4. Use bolts to secure clamp (FIG B).

Fig A

FIG. A

FIG. B1 FIG. B1

Bracket Mount - Toggle Clamp Adjustment, Continued

clamping on cage with toggle handle in vertical position.

7. Release clamp and install remaining hardware.

1/8”

FIG. C

Bracket Mount - Toggle Clamp Adjustment, Continued

bracket mount has not yet been fastened and should look similar to the picture in FIG- D.

9. Secure the two halves together with the included hardware as shown. Note that the hardware should be located

utilizing the slotted portion of the bracket.

FIG. D

Bracket Mount - Toggle Clamp Adjustment, Continued

between the J hook and the tote wire frame as shown in order to secure properly

11. Cage style as shown below please follow the instructions for latch adjustment.

Tighten nut until desired

tension is obtained.

1/8”

After clamp tension

is obtained secure J-

Hook from rotation by

tightening lower nut.

Bracket Mount - Toggle Clamp Adjustment, Continued

13. Adjust bracket to set of mounting holes as shown.

Tighten nut until desired

tension is obtained.

1/8”

After clamp tension

is obtained secure J-

Hook from rotation by

tightening lower nut.

Bracket Mount - Toggle Clamp Adjustment, Continued

14. After frame and bracket have been located the J hook then needs to be adjusted.

15. Rotate latch in the up position as shown.

At the same time loosen the top nylock nut so

Tighten nut until desired

tension is obtained.

1/8”

After clamp tension

is obtained secure J-

Hook from rotation by

tightening lower nut.

TOTE RAIL

Bracket Mount - Toggle Clamp Adjustment, Continued

tension. Adjust the tension as desired to secure the latch to the tote frame.

1/8”

After clamp tension

is obtained secure J-

Hook from rotation by

tightening lower nut.

This manual suits for next models

1

Other INDCO Mixer manuals

INDCO

INDCO BM Series User manual

INDCO

INDCO TL Series User manual

INDCO

INDCO FGM 5 Gal Series User manual

INDCO

INDCO DL Series User manual

INDCO

INDCO TM Series User manual

INDCO

INDCO TMD Series User manual

INDCO

INDCO CB Series User manual

INDCO

INDCO CL Series User manual

INDCO

INDCO MX3 Series User manual

INDCO

INDCO FL Series User manual