Sino Instruments HS602 User manual

User manual

HS602

Intelligent Pressure Calibrator

2

The operating instructions are parts of the products and must be kept in

the immediate vicinity of the instrument and readily accessible to skilled

personnel at any time.

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

The manufacturer's liability is void in the case of any damage caused

by using the product contrary to its intended use,non-compliance with

these operating instructions,assignment of insufciently qualied skilled

personnel or unauthorised modications to the instrument.

HUAXIN reserve the rights to change the contents or form of these

operating instructions at any time without prior notice having been

given.

Claim

In order to protect your ordering products,your own and others safety,Please

read this manual carefully before your operation. And pls place this manual

near the operation site for the operator reference.The consequence would be

incurred by the non-observance are marked.

Disassembling the inner components may take toll or completely

damage the equipment.Only the qualified technician could make a

repairment. Any abnormal happened to the equipment,pls call our

service staff to make a repairment under their instruction.

Please don't disassemble & repair the equipment by yourself.

Safety information

Warning

1

To avoid over pressure damges,don't apply pressure that exceeds the

limits listed in the pressure specication table.

This action might injure the product and inuce the performance.

Pay attention to the range

Don't beat and shock

2

3

3

Other power supply will damage to the product, and even may cause

the re or an electric shock.

The calibration should be carried out under a standard calibration

condition,such as the standard gauge must be accuracy 3 times of

HS602,ambient temperature (20±2)℃.

Only use the special adapter or battery

The calibration should be carried out under a standard calibration condition

Symbols

Labelling,Safety Marks

Symbols used on the product and in the menu

Symbol Meaning Symbol Meaning

Indicates warning Conforms to European

Union directives

Indicates important

information

Conforms to standard of

PCEC

Intelligent Pressure Calibrator

Model:HS602 NO.1401118104

Voltage:8.4DCV Range:(0-10)bar

Date:2014.1 Accuracy:±0.5%F.S

Huaxin Instrument(Beijing)Co.,Ltd

Product name

Model

Voltage

Date of manufacture Accuracy

Manufacturer

Pressure range

No.

6

7

That will damage the item by using the wrong medium.

Pay attention to the medium of the item

That will damage the item,and even may cause the re or an electric

shock.

Don't immersed in water or exposed to water or getting wet

5

4

4

Claim

Safety information

1. Summary - 1 -

2. Technical Spec - 2 -

3. Working Principle - 4 -

4. Install Operation - 4 -

4.1. Basic structure - 4 -

4.2. Button& terminal Introduction - 5 -

4.3. Display - 6 -

4.4. Installation method - 6 -

4.5. The gauge type - 6 -

4.6. Change the original pressure unit - 7 -

4.7. Temperature modication display - 8 -

4.8. DC24V output setting - 10 -

4.9. COM Communication setting - 10 -

4.10. Digital display setting - 11 -

4.11. Factory reset - 12 -

5. Calibration step - 12 -

5.1. Pressure Low point, High Point Calibration - 12 -

5.2. Clear two point modication value - 14 -

5.3. Clearing clear zero value - 15 -

5.4. Current measurement calibration - 15 -

5.5. Voltage measurement calibration - 17 -

6. HART - 18 -

6.1. Using HS602 Calibrated HART Pressure transmitter - 18 -

6.2. Connection - 19 -

6.3. Operation step - 19 -

7. Field instrument testing - 21 -

7.1. Using storing function calibrate pressure transmitter in the eld - 21 -

7.2. Basic Setting - 21 -

5

7.3. Starting testing - 22 -

7.4. Data browsing - 22 -

8. Maintenance - 23 -

8.1. Maintenance and instruments - 23 -

8.2. Attention items - 23 -

9. Accessories List - 24 -

10. Standard - 24 -

11. Support - 24 -

1

1.Summary

Pressure range up to 2500bar

High accuracy up to 0.025%F.S

Current measurement (0-25)mA

Accuracy ±(0.02%RD+0.005%F.S)

Voltage measurement (0-25)V

Accuracy ±(0.02%RD+0.005%F.S)

Pressure switch test

HART Communication capability

Advanced temperature compensating

24vdc power for Pressure transimtter testing

Large,easy to read display with 6-digit resolution

RS232 communication with PC

With Max and mix values function

Zero point,full scale calibration function

Nine pressure units selectable

Equipment with rugged ABS plastic

Rechargeable lithium battery or charger

Data storing function

Large LCD with white backlight,dual readout

Light weight,small size,easy operation

HS602 Intelligent pressure calibrator is a high-precision single-range

digital pressure gauge with hart function. it is composed of high-precision

measurement chips,DC24V power supply,rechargeable battery protection

circuit,hart communication modules and intelligent digital pressure module

and so on.

This unit can be used for real-time measurement of pressure value and the

calibration of the pressure transmitters,differential pressure transmitters,

pressure transducers and pressure gauges,etc.

Characteristics

2

Model

HS602 Intelligent Pressure

Calibrator

Accuracy

±0.025% F.S, ±0.05% F.S

Electric signal

Current measurement:(0-25)mA

Accuracy:±(0.02%RD+ 0.005%F.S)

Voltage measurement:(0-25)V

Accuracy:±(0.02%RD+ 0.005%F.S)

DC output:DC24V(≤30mA)

Accuracy:±1%F.S

Gauge types

Gauge pressure

Compound pressure

Absolute pressure

Differential pressure

Work medium

Oil, water&noncorrosive gases

Over pressure alarm

120%Full Scale

Display

Description:6 digits big LCD

with blacklight

Display rate:Less than 0.025%

of full scale is 150ms,more than

0.025% of full scale is 1s

Numeral display height:16.5mm

(0.65")

Pressure unit

psi,bar, mbar,kgf/cm2,Pa,kPa,

MPa,mmH2O,mmHg

Temperature

Compensated temperature:

-10°C to 50°C

Operating temperature:

-10°C to 50°C

Humidity:<95%

Storing temperature:-20°C to 70°C

Pressure connection

1/4NPT male,M20×1.5 male

Other connections customized

Power

Battery:One piece 7.4Vdc

rechargeable lithium battery&charger

Battery life:80 hours

Housing

Case material:Plastic

Wetted parts:316 stainless steel

Dimension:Φ95mmx49mm

Total height:166(mm)

Weight:0.75kg

Data storing

Storage capacity:calibration record

of 30pcs gauge under test

Communication

RS232

Certicate

CE .....................

EX .....................

ISO 17025 lab calibration

certicate(optional)

2.Technical Specication

3

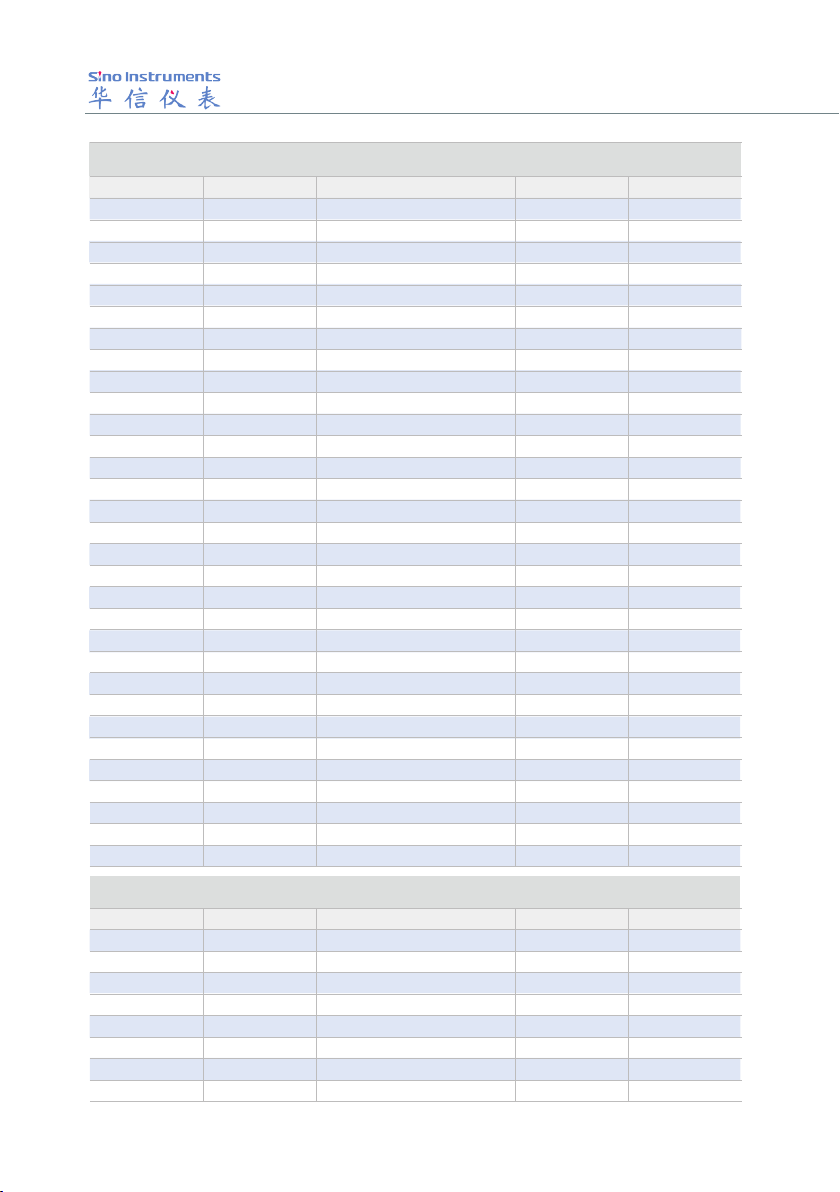

Pressure ranges selection sheet

Compound pressure

Gauge pressure

No. Range (bar) Accuracy ( % FS) Media Pressure Type

HS602-1 (-1-0) 0.025,0.05 G G

HS602-2 (0-0.4) 0.025,0.05 G G

HS602-3 (0-0.6) 0.025,0.05 G G

HS602-4 (0-0.7) 0.025,0.05 G G,A

HS602-5 (0-1) 0.025,0.05 G G,A

HS602-6 (0-1.6) 0.025,0.05 G,L G,A

HS602-7 (0-2) 0.025,0.05 G,L G,A

HS602-8 (0-2.5) 0.025,0.05 G,L G,A

HS602-9 (0-3.5) 0.025,0.05 G,L G,A

HS602-10 (0-4) 0.025,0.05 G,L G,A

HS602-11 (0-6) 0.025,0.05 G,L G,A

HS602-12 (0-7) 0.025,0.05 G,L G,A

HS602-13 (0-10) 0.025,0.05 G,L G,A

HS602-14 (0-16) 0.025,0.05 G,L G,A

HS602-15 (0-20) 0.025,0.05 G,L G,A

HS602-16 (0-25) 0.025,0.05 G,L G,A

HS602-17 (0-35) 0.025,0.05 G,L G,A

HS602-18 (0-40) 0.025,0.05 G,L G

HS602-19 (0-60) 0.025,0.05 G,L G

HS602-20 (0-70) 0.025,0.05 G,L G

HS602-21 (0-100) 0.025,0.05 G,L G

HS602-22 (0-160) 0.025,0.05 G,L G

HS602-23 (0-200) 0.025,0.05 G,L G

HS602-24 (0-250) 0.025,0.05 G,L G

HS602-25 (0-350) 0.025,0.05 G,L G

HS602-26 (0-400) 0.025,0.05 G,L G

HS602-27 (0-600) 0.025,0.05 G,L G

HS602-28 (0-700) 0.025,0.05 G,L G

HS602-29 (0-1000) 0.025,0.05 G,L G

HS602-30 (0-1600) 0.1,0.2 G,L G

HS602-31 (0-2500) 0.1,0.2 G,L G

No. Range Accuracy Media Pressure Type

HS602-32 (-0.025-0.025)0.05 G D,G

HS602-33 (-0.05-0.05)0.025,0.05 G D,G

HS602-34 (-0.1-0.1) 0.025,0.05 G D,G

HS602-35 (-0.25-0.25)0.025,0.05 G D,G

HS602-36 (-1-1) 0.025,0.05 G D,G

HS602-37 (-1-6) 0.025,0.05 G,L G

HS602-38 (-1-10) 0.025,0.05 G,L G

HS602-39 (-1-25)0.025,0.05 G,L G

Remark:G=Gauge pressure A=Absolute pressure D=Differential pressure

4

3.Working Principle

4.Install Operation

The tested pressure signal acts on the pressure sensor,the signal of pressure

sensor change into electrical signal.the current and voltage measurement

signal will be led into via the terminal on the panel,after the A/D conversion

and the sampling-processing by microprocessor,the final result would be

displayed on the LCD screen.

4.1 Basic structure

Current,Voltage,Double

Switching Value Input

Battery&Charging protecting

DC+5V,3.3V

DC24V Output

Display Button

LCD display

A/D Converter

HART

RS232

Pressure Sensor

CPU

Model

Screen

Buttons

Pressure range

Male thead

RS232 port

Adapter

socket

Label

1/4 NPT(or customized)

(X-XX)bar

5

1.Back cover insert 13.Cover battery plate

2.Front cover 14.Lock nut

3.Key-press panel 15.Press cover

4.Button switch 16.Hole press cover

5.Power strip 17.Support pad for sensor

6.Front view window 18.Reinforcing pad for sensor

7.LCD 19.Sensor

8.PCB 20.O-ring 9×1.8

9.Plugging terminal panel 21.High pressure sealing

10.Terminal board 22.Check ring 19

11.Back cover 23.O-ring 16×1.8

12.Li-ion battery pack 24.Sensor connector

4.2 Button&terminal Introduction

Connection terminals:

Including terminals for current measurement,voltage measurement,

DC24V output, pressure switch value measurement and a public terminal.

Connect terminals as below;

Light up the display screen.

Starting unit is kPa, press this key to switch unit circularly among

mmHg、mmH2O、bar、mbar、psi、kgf/cm2、MPa and Pa.

Press this key to clear current value as zero drift value.then this gauge

would be already in a clearing zero status when you start it up again.

Press this key for zero point and full scale calibration and linear

revision to insure the accuracy.( Do not use the key if there is no

necessary calibration equipments available)

Starting function is measurement for press,current, temperature.

press this key to switch circularly and then choose the measuring

function your demand.

MEASURE

CAL

ZERO

UNIT

LIGHT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

6

4.5 The gauge type

4.3 Display

1

2

Connect gauge under test and HS602

on the pressure comparator.

According to calibration regulation,

make HS602 as standard gauge to

nish the whole calibration process.

4.4 Installation method

SW1:Measuring Pressure switch.

SW2:Measuring Pressure switch.

GND:This is a public terminal.

V:(0 ~25)V,Accuracy:±(0.02%RD+0.005%FS).

mA:(0 ~25)mA,Accuracy:±(0.02%RD+0.005%FS).

24V:DC24V output(≤30mA) accuracy:±1%FS.

RS232 communication port.

DC8.4V Charging inputDC8.4V.

The HS602 screen denitions:

PC icon:the mark of PC connection

Battery icon:indicates state of charge.

Only be seen when there is low power

Pressure display:displays measuring

pressure value

Pressure units:displays selected

pressure units

Electricity reading:displays measuring

electricity value,sw1 value,and menu

Electricity units:displays measuring

current/voltage units

Menu reading:displays measuring sw2

value and menu

HART :shows the communication status

7

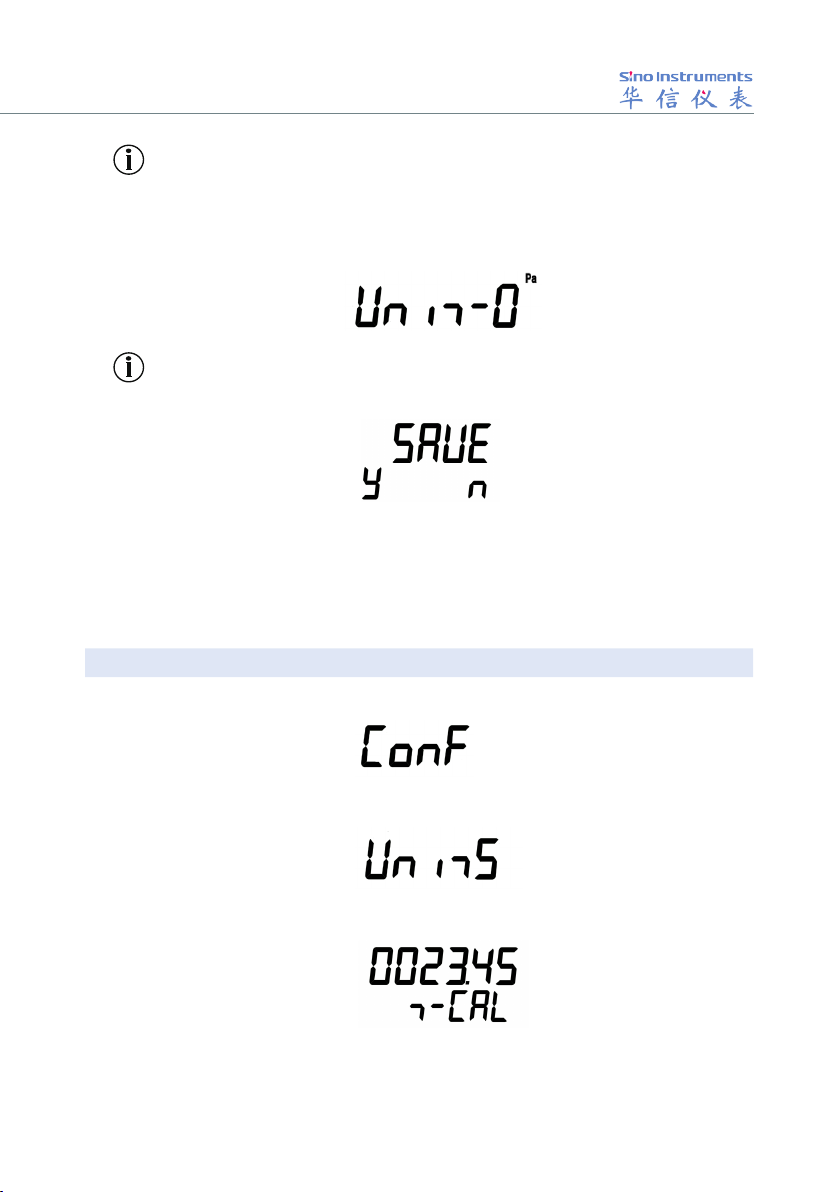

4.6 Changing the original pressure unit

(1) In Measuring interface,Press CAL;enter into basic setting interface.

No.1:Gauge pressure No.2:Gauge pressure

Rang: ≤±

100kPa

No.3:Differential pressure

2

3

1

4

5

Connecting pressure generator

Open to air

Connecting pressure generator

High pressure

Low pressure

1

3

2

4

5

(2) Press CAL,enter into the Unit interface.

(3) Press CAL,enter into the Unit choose interface(Unit ashing).

8

At this time, the unit displayed is client measuring interface unit.maybe

that is not match with the unit kPa in above pic.

Remark:The displayed unit:Pa,kPa,MPa.

Remark

(4) Press Zero and choose the Unit you need (if you choose the unit Pa).

(5) Press CAL,enter into the save interface.

(1) In Measuring interface,press CAL,enter into basic setting interface.

(6) If press LIGHT,save the setting,and then return unit selectable

interface. that means the pressure unit modied well.

(7) Press LIGHT three times continuously.then back to the measuring

interface.

4.7 Temperature modication display

(2) Press CAL,enter into the Unit interface.

(3) Press ZERO three times enter into temperature interface below.

(4) Press CAL,enter into data modied interface.

The rst character(“-”)located in activated interface (No ashing).

9

(6) Press CAL,next character located in activated interface(Flashing).

When decimal point bit ashing, press ZERO for setting decimal point.

When the number ashing,press LIGHT for decreasing number from 9 to

0,press ZERO for increasing number from 0 to 9.

After selecting your number, repeat step(6).

(7) Repeat step(6),until the last bit.

(5) If you want to modify the activated value,press ZERO and display“-

”(ashing),if you don't need modify activated values,pls enter into next

step directly.

(Minus)

(8) Press CAL, enter into the save selecting interface.

(9) Press LIGHT twice continuously and back to the measuring interface.

Press LIGHT for save the settings,if not,press ZERO.

10

4.8 DC24V output setting

(1) In measuring interface,press CAL,enter into basic setting interface.

(3) Press ZERO continuously until it get into “DC 24V” measurement

interface below.

(2) Press CAL,enter into the Unit interface.

(4) Press CAL,switching ON/OFF.

(5) Press LIGHT twice continuously and back to the measuring interface.

4.9 COM Communication setting

(1) In measuring interface,press CAL enter into basic setting interface.

(2) Press CAL,enter into the Unit interface.

11

4.10 Digital display setting

(1) In measuring interface,press CAL,enter into basic setting interface.

(3) Press ZERO,and select the menu,enter into setting interface below.

(3) Press ZERO,and select the menu,enter into setting interface below.

(2) Press CAL,enter into the Unit interface.

(4) Press CAL,switching ON/OFF.

ON-1 (Automatic)and ON-2 (Semi-automatic),OFF means to close.

(5) Press LIGHT twice continuously,and back to the measuring interface.

(4) Press CAL,switching circularly4、5、6 bit.

12

(1) In measuring interface,press CAL,enter into basic setting interface.

(2) Press CAL,enter into the Unit interface.

(3) Press ZERO continuously and then enter into factory reset interface.

(4) Press CAL,enter into the Save interface.

If press LIGHT,it can resume to default setting. It will get back to

factory reset interface and cancel the operation if you press ZERO.

If the item could not work by error operation,that could restore factory

reset.

(5) Press LIGHT twice continuously.and back to the measuring interface.

4.11 Factory reset

(5) Press LIGHT twice continuously.and then enter into measuring interface.

The calibration should be carried out under a standard calibration

condition,such as the standard source must be accuracy 3 times,ambient

temperature (20±2)℃.

5.1 Pressure Low point, High Point Calibration

(1) Pressure input add low point standard pressure.

(2) Waitting for pressure stability.

(3) In measuring interface,press CAL,enter into basic setting interface.

5.Calibration step

13

(4) Press ZERO,enter into pressure low point, high point calibration

interface.

(5) Press CAL,enter into pressure low point calibration(Press CAL,

enter into pressure high point calibration) interface.

(6) Press CAL,enter into low point calibration data modify interface.

(7) Refer "4.7(7) step of Temperature displaying modied".and amend low

point pressure data(If the gauge had stored data,that do not nead amend,then

press CAL directly).

(8) Press CAL input the last a character,waiting for standard pressure

stability and then press CAL,enter into save interface.

(9) Press LIGHT,save low point calibration data and return low point

calibration interface.

14

(12) Waitting for pressure stability.

(14) Refer"4.7(7) step of Temperature displaying modified".and amend

high point pressure data(If the gauge had stored data,that do not need

amend,then press CAL directly).

(13) Press CAL,enter into high point calibration data modify interface.

(15) Press CAL input the last a character,waiting for standard pressure

stability and then press CAL,enter into save interface.

Press LIGHT,save high point calibration data and return high point

calibration interface.

(16) Press LIGHT twice continuously.and then back to measuring interface.

(1) In measuring interface,press CAL once time,and then press ZERO

once time,that will display below.

5.2 Clear two point modication value

(10) Press ZERO,enter high point calibration interface.

(11) Pressure input add high point standard pressure.

15

(1) In measuring interface,press CAL once time,and then press zero

twice,that will display below.

(2) Press CAL once time,and then press ZERO twice,that will display

below.

(2) Press CAL once time,that will display below.

(3) Press CAL once time,that will display below.

(3) Press CAL once time,that will display below.

(4) Press LIGHT three times,saving and returning measuring interface.

(4) Press LIGHT three times,saving and returning measuring interface.

5.3 Clearing clear zero value

5.4 Current measurement calibration

(2) In the measuring interface,press CAL, enter into the setting interface.

(1) Contacting the standard current with current input circuit.

(3) Press ZERO continuously for four times,until entering into current

measurement calibration menu.

Table of contents