INSTRUCTION'S

Sioux' Air Impact Wrench

No s. 313, 314, 303

OPERATION

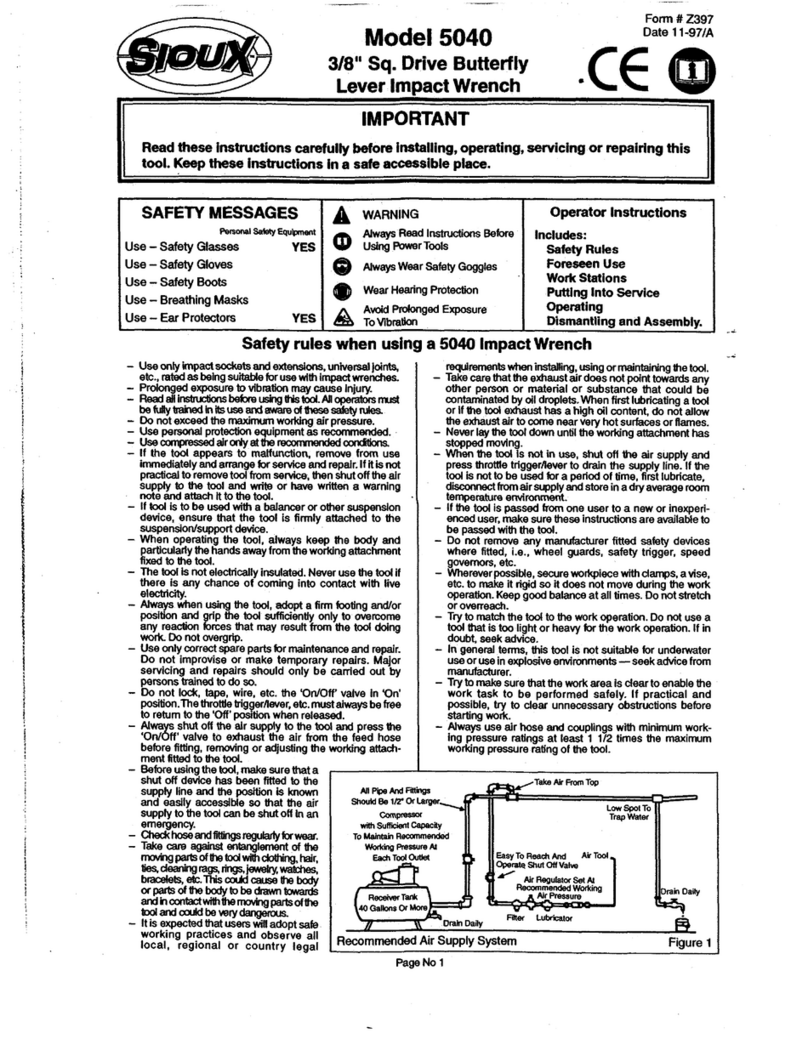

The efficiency of the Air Impact Wrench is dependent on the proper supply of clean dry air

at the proper pressure of 90 psi (6.33 KG/CM .2). The use of line filters, pressure regulators

and lubricators will insure maximum output and service of air tools. If no air filter is used drain

air tank frequently to prevent moisture from entering air tool.

HOSE AND HOSE CONNECTION

Hose and hose couplings should not be smaller than 7/32 (5.5 MM) inside diameter, 5/16 (7.94

MM) inside diameter hose is preferable. Smaller hose and those couplings will restrict the flow of

air and reduce the power of impact wrench. If quick couplers are used do not fasten them direct-

ly to the tool, use No. 1370 6 ft. leader hose between the tool and quick couplers.

LUBRICATION

Sioux has tested many oils and greases, many of which are good, but very few meet the special

requirements of air tools. In order that users of Sioux air tools get the best performance from the

tool, the following lubricants are recommended:

Sioux Air Motor Oil for air motors No. 288.

Sioux Special Grease Type A for hammer case No. 289.

HAMMER CASE

The hammer case mechanism is packed with Sioux Special Grease Type A. Every 40 hours of op-

eration add up to

Y4

oz. of Sioux Special Grease Type A. A 1

Y

oz. tube of grease, Cat. No. 289

is packed with each wrench.

AIR MOTOR

Air Line Lubricators are recommended and when used set flow of oil to deliver 2 to 4 drops per

minute to the air tool. When air line lubricator is not used, disconnect quick coupler and squirt

small amount of Sioux Air Motor Oil into leader hose every 4 hours. Daily before using, and after

each 4 hours of service, squirt a small amount of Sioux Air Motor Oil into leader hose.

POWER SELECTOR

The Sioux Air Impact Wrench is designed to operate at

90

lbs. per sq. inch at the tool. The power

selector, which is numbered

to 8, will adjust the torque output to the requirements of the user.

The impact wrench operates at full power when power selector is set at No.8.

LOSS OF POWER

1.

Hose too small. (See Hose and Hose Connec tion ) .

2. Excessive amount of moisture in air line. Drain compressor air tank and air line filter if used.

3. Loose, worn, or cracked sockets will rdeuce torque output. Use deep sockets rather than exten-

sion bar whenever possible.

4. Dirt or sludge in wrench. Disconnect leader hose and flush out air motor using a good grade

petroleum solvent. Squirt solvent directly into leader hose. Connect to supply line and depress

trigger and allow dirt and sludge to come out exhaust. Repeat if necessary. Lubricate the wrench

according to directions under Lubrication immediately.

FORM A1J-4I·67

SIOUX TOOLS INC.

SIOUX CITY, IOWA, U.S.A.

51102