9

112"

Twin Hammer

Pistol

Grip

Operator Instructions

Includes

-

Foreseen Use,Work Stations, Putting Into Service,

Operating,Dismantling,Assemblyand Safety Rules.

ManufacturerISupplier

SiouxTools, Inc.

250 Snap-on Drive

P.O. Box 1596

Murphy,NC 28906

U.S.A.

Tel

No. 828-835-9765 Fax No. 828-835-9685

Air Pressure

ProductNetWeight

5.0

Ibs

2.3

Kg

RecommendedWorking

Maximum

RecommendedUseOf

BalancerOr Support

NO

6.2

bar

90

PSI

6.2

bar

90

PSI

SAFETY MESSAGES

Personal

Safety

Equipment

Use

-

Safety Glasses

YES

Use

-

Safety Gloves

Use

-

Safety Boots

Use

-

BreathingMasks

Use

-

Ear

Protectors

YES

A

WARNING

Q

;!::;:;;

'g;;;;:;;

Always

Wear

Safety

Goggles

@

Wear

Hearing

Protection

Avoid

Prolonged

Exposure

To

Vibration

_1_

Safety rules when using

IW50HAP-

4F/IW50HAP-4P

ImpactWrenches

-Use only impact sockets and extensions, universal

joints, etc. rated as being suitable for use with impact

wrenches.

-

Prolonged exposureto vibration may cause injury.

-Read all instructions before using this tool. All

operators must be fully trained in its use and aware of

these safety rules.

-

Do not exceedthe maximumworking air pressure.

-

Use personal protection equipment as recommended.

-

Some dust created by power sanding, sawing, grinding,

drilling, and other constructionactivities contains

chemicalsknownto cause cancer,birthdefects andother

reproductiveharm.

-Use only compressed air at the

,

recommendedconditions.

1

-If the tool appears to malfunction,

remove from use immediately and

arrange for service and repair. If it is

not practical to remove tool from

service, then shut off the air supply

to the tool and write or have written a

warning note and attach itto the tool.

-

If tool is to be usedwith a balancer or

other suspensiondevice, ensure that

the tool is firmly attached to the

suspension/support device.

-When operatingthe tool, alwayskeep

Important

Read these instructions carefully before installing, operating,

servicingor repairingthistool.Keepthese instructionsina safe

accessibleolace.

-

-

ProductType

112''Twin Hammer Pistol

cycles

per

M,n.

Grip ImpactWrenches

ModelNoINos

IW5OHAP-4F

(Ring)

IW~OHAP-4~

(pin)

Test Method:

Tested in accordancewith Pneurop

test code PN8NTC1 and IS0Standard

3744

Serial No.

RecommendedHose Bore

Size

-

Minimum

318

ins

10

mm

VibrationLevel 3.17 Meters

/

Sec2

RecommendedMax.

Hose Length

30Ft 10M

Test Method:

Tested inaccordance with IS0

standards8662 Parts

1

&

7

Noise Level:

Sound Pressure Level 97.2 dB(A)

Sound Power Level 110.2 dB(A)

the bodyand particularlythe handsaway fromthe work-

ing attachment fixed to the tool.

-The tool is not electrically insulated. Never use the tool

if there is any chance of coming into contact with live

electricity.

-Always when usingthe tool, adopt a firm footing and/or

position and grip the tool sufficiently only to overcome

any reaction forces that may result from the tool doing

work. Do not overgrip.

-Use only correct spare parts for maintenance and

repair. Do not improvise or make temporary repairs.

Major servicing and repairs should only be carried out

by persons trained to do so.

-

Do not lock, tape, wire, etc. the 'On/OffVvalve in 'On'

position.The triggerllever, etc. must always be free to

All

Pipe

And

Fittings

Should

Be

112"

Or

Larger

Easy

To

Reach

And

Air

Tool

!

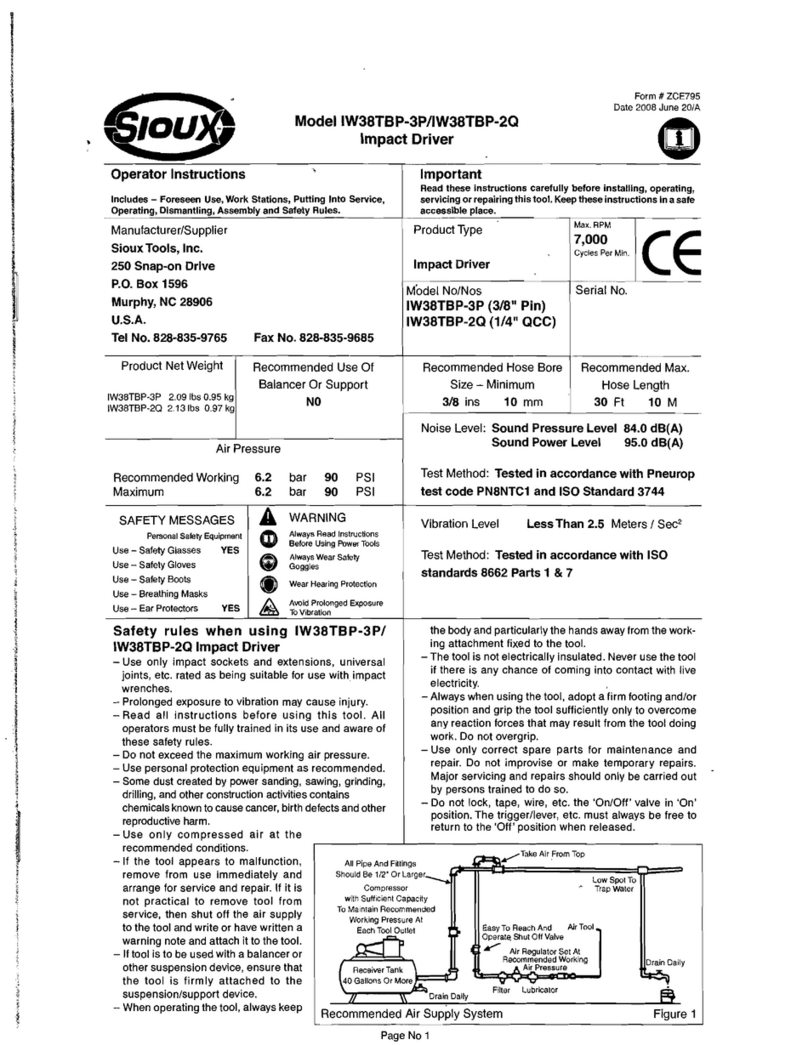

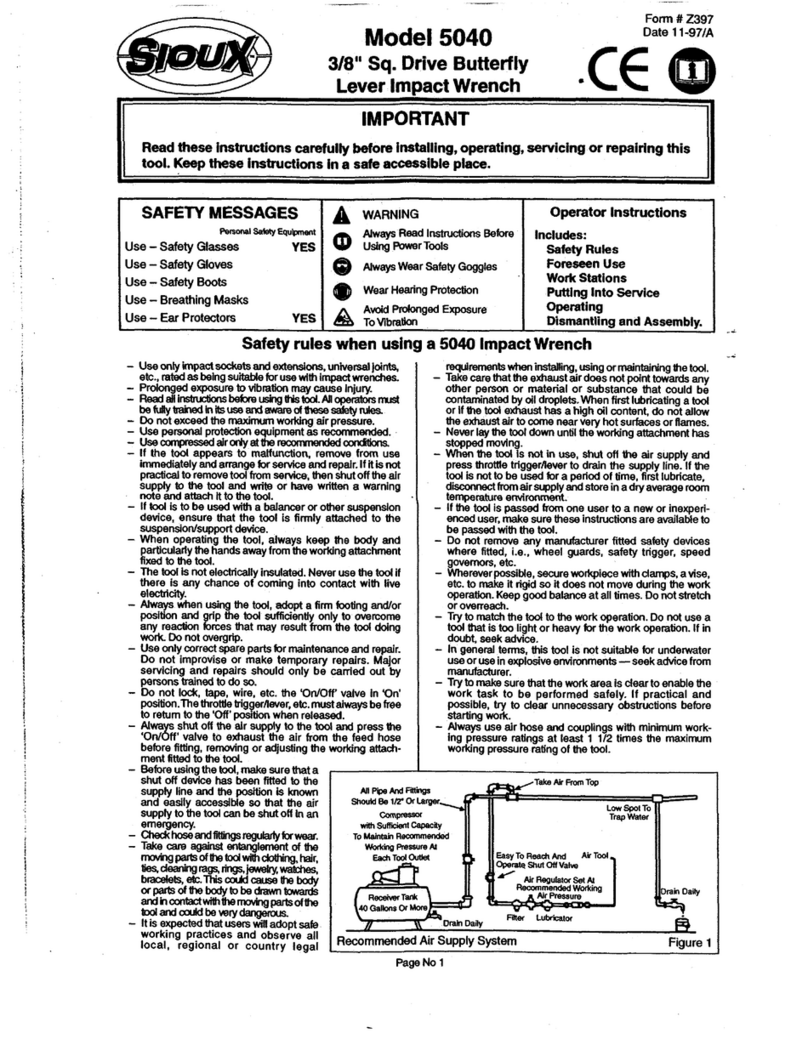

RecommendedAir Supply System Figure

1

Page No

1