ForeseenUse

Of

TheTool

-

5040

Theimpact

wrench

isdesignedfor the tighteningandImningof threadedfastenerwithinthe range as specifiedby

the

manufacturer.

Itshould

only

beusedinconjunction

with

suitableimpacttype

3W

squarefemaledrive nut runningsockets. Onlyusesockets

whii

are

of theimpact

type.

Itisallwedto

use

suitableextensionbars, universaljoints andsocket adaptorsbeWnthe squareoutput drive ofthe ratchetwrench

and

the

female squaredrive

of

the socket.

Do not use the tool for any other purpose than

that

sptxified without consulting the manufacturer or the manufacturet's authorized

supplier.To do

$0

may

be

dangemus.

Neveruseanimpactwrench asa hammer todislodge orstraightencmssthreadedfasteners. Neverattempttomodifythe toolfor other

usesandnever modifythetdfor

even

itsrecommendeduseas a nutrunner.

Work Stations

The

toolshoutdonlybeusedas a handheld,handoperatedtool.

lt

is

alwaysrecommendedthat

the

toolisusedwhenstadngona

solid

floor.

It

canbeusedinotherpositions,

but

beforeanysuchuse, the operatormustbeina securepositionhavinga firm gripandfooting

andbe aware thatwhen looseningfastenersthe tdcanmequitequicklyaway from the fastener beingundone.An allowancemust

always

be

madefor this rearwardmovement

so

asto avoid

the

possibilityof hand'amhdy entrapment.

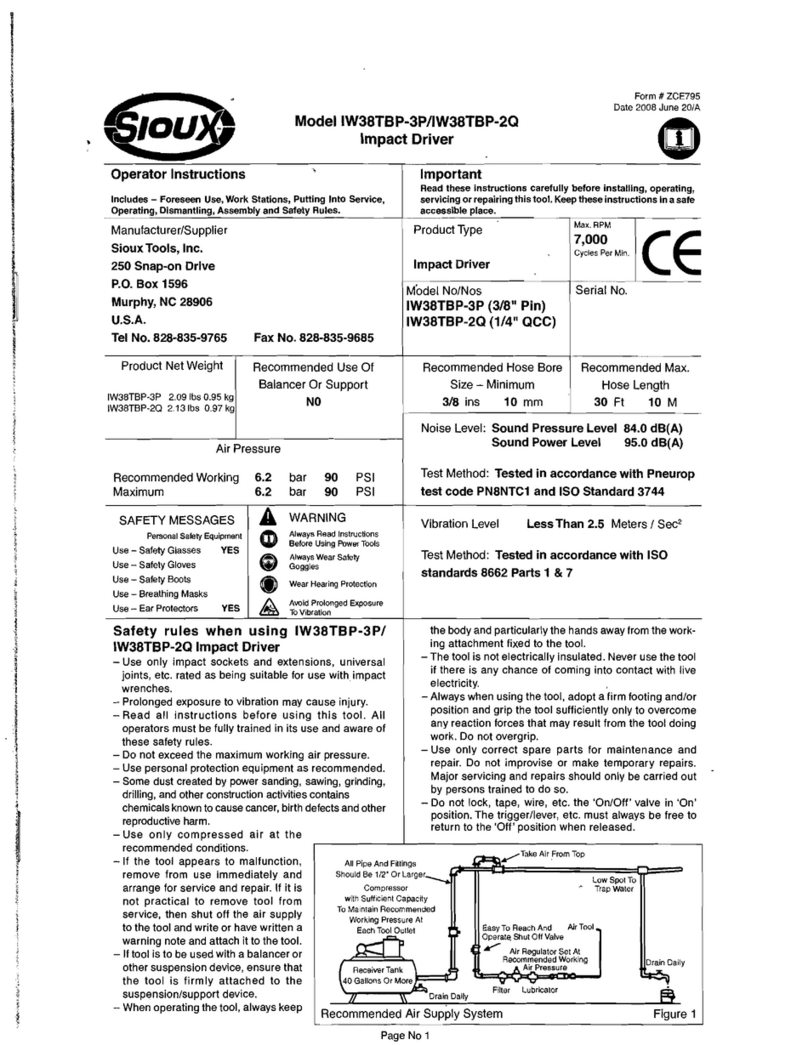

PuttingInto Service

Air

Supply

Usea cleaniubtkatedairsupplythatwillgivea measuredair pressureatthetoolof

!XI

PSIG

(6.2

bar)whenthetoolisrunningwiththe

tri~erflW8rfullydepressed. Userecammendedhose Size andlenath.Itisrecommendedthatthetool isconnectedtothe air supplyas

s&minfigure

1.

Do

notconnectthetooltothe air linesystemwithzutincorporatinganeasytoreachandoperateairshutoff valve.-he

airsupply should

be

lubricated.It

is

stronglyrecommendedthat anair filter, regulator,lubricator

(FRL)

is

us&

as shownInFigure

I

as

thii

willsupplyclean, lubricatedair atthe correct pressureto the tool. Detailsof such equipment can

be

obtainedfrom your supplier. If

suchequipmentisnotused, thenthetoolshouklbelubricated

by

shuttingoff

the

airsupplytothetd,depressurizingthelinebypressing

--

the trigger on the td.Diinnectthe air line and pour into the

hose

adaptor a teaspoonful (5ml) of a suitable pneumatic motor

lubricatingoilpreferablyincorporatinga rust inhibiior. Reconnecttoolto air supply and runtdslowly for a few secondsto albw airto

circulatethe oil. Iftool isusedfreauentlv. lubricateon

daii

basisand

if

tool startstoslow orlosemwer.

It

is

recommendedthatWnt tight& &the threadedfasiener assemblybechecked with a torquewrench.

Itisrecommendedthat

the

air pressureat the tool while the tool istunningis

90

PSU6.2

bar.

Operating

Theoutput of the impactwrench inprimeworkingconditionisgoverned

by

mainlythree factors:

a) theinputair pressure;

b) the time the impact wrench isoperatedon the jomt. Normaitime forjoints of average tension requirement

3

to

5

seconds;

c) thesettingof the air regulatorfor aghnjoint at a givenpressureoperatedfora giventime.

The air regulator

(47)

canbe usedto regulatethe output of the impact wrench if no other means of control is available. It is strongly

recommendedthatanexternalpressureregulator, ideallyasparl

of

a

filterlregulatorflubricator

(FRL), isusedtocontrolairinletpressure

so

thatthe pressurecan

be

setto help controlthe tensionrequidtobeappliedtothe threadedfastenerjoint.

There is

no

consistent, reliabletoqueadjustmenton animpact wrench of this

type.

However, the air regulator canbe usedto adjust

tomue to the awmximate tiahtness of a

known

threaded

ioint.

To set the tool to the desired tome. select a nut or screw of known

tightnessof the&me size, t6read pitchandthreadcondiikas those on the job.Turn air regulatoitolow position, applywrenchto nut

andgraduallyincreasepower(turnregulatortoadmitmomair) untilnutmovesslightlyinthedirectionitwas originallyset.Thetdisnow

setto duplicatethattightness, noteregulatorsetting for future use. When tighteningnutsnot requiringcriticaltoquevalues, runnut up

flushandthentightenanaddiionalonequarlertoonehalf turn(&it additionalturningisnecessaryifgasketsarebeingclamped).For

additionalpower neededon disassembly work, turn regulatorto itsfully open position.This impactwrenchisrateda

3/8"

bolt size.

Ratingmustbedowngradedforspring

U

bolts,tiebolts, longcapscrews, doubledepthnuts, badlyrustedconditionsandspringfasteners

as

they absorbmuchof the impactpower. Whenposdtie,clamporwedge the boltto preventspringback.

Soakrustednutsinpenetratingoilandbreakrustsealbeforeremovingwith impactwrench. Ifnutdoes notstartto moveinthreetofive

seconds usea largersize impactwrench. Do not use impact wrenchbeyondratedcapacityas thiswilldrasticallyreducetool liie.

NOTE: Actualtoqueona fastenerisdirectlyrelatedtojoint hardness,toolspeed, conditionof socketandthetimethetoolisallowedto

immct.

usethe simplestpossibletool-to-sockethook up. Everyconnectionabsohenergyandreducespaver.

Thedirectionof mtationof

thii

tool

Is

contmlled

by

the throttlelever.

Be

surethat itis

known

whii

side

ol

the lever hasto

be

pressedto

give the requireddirectionof mtatiinbeforeapplyingthe impactwrenchto thejoint to befastenedor loosened.

For bestresuns:

I)

Always

use

the correct

size

impact

type

socket.

2)

Useextra

deep

socketsinplaceof

extension

barswherepossible.

3)

Do notuseoversized, worn

or

crackedsockets.

4)

Holdthewrenchso

the

socket

fits

squarelyon the fastener.Holdthe wrench firmly, but not too tightly, pressingslightlyforward.

Dismantling

&

Assembly Instructions

Disconnecttool fromair supply.

Pryoff rubbernoseguard

(I)

frommotorhousing

(5).

Removeoilerscrew

(3)

andO-ring

(4)

anddrainoilfromthe frontendintoa suitable

container. Gripthetoolinaviselocatingonthesquaredriveof

the

anvil

(12).

Unscrew

2

screws(50)andremove

2

lock

washers

(49)

and

retainerplate

(48).

Pulloutair regulator

(47)

completewithO-ring

(46)

beingcarefulnotto loseball

(44)

andspring

(45).Tap

pin

(36)

with

asuitablepunchas

fas

aspossibleoutof theassembly,butstillallow the assemblyto mtate. Itisnownecessarytogripthe lengthof the

pindriventhroughtheassembly andpullitouttaking carenotto deformit.

Lift

Offcollar

(37)

andpullout inletbushing

(43).

O-rings

(41)

and

(42)

mayberemovedfrom the stem on inletbushing

(43).

Unscrew

2

capscrews

(39)

and

2

cap screws

(40)

andremovetogether

with

4

lockwashers

(38)

to release

bat#

cap

(30)

andgasket

(29)

fromthe assembly. At thisstage, removethrottlelever

(7)

together with

2

throttiePins

(6).

Fmmbackcapassemblypulloff

2

plungers

(31)

andremove

2

Springs

(32)

and

2

valves

(33).

Itisthenpossibleto lever

out

2

valve seats

(34)

and

2

springs

(35)

takingcareto protect

the

eyesasthe springscanflyoutwhen released. Pullout mtorpin

(22)

andextracttheayemblycomprising

of

retainingring

(28).

rearendplate

(26).

bearing

(27),

mtor

(24),6

mtorblades

(23)

andcylinder

(25).

Noteatthis tlmethe way thecylinder

(25)

irremovedandnotethat itmustbereassembledinthesameway with thechamferonthe

outsidediametertoendface atthefmntendof

the

tool. Removemtor blades

(23)

frommtor

(24),

takeoffretainingring

(28)

andpullmtor

(24)

through rearendplate

(26)

andbearing

(27)

assembly. Usinga suitablepunch, bearing

(27)

may beremovedfromrear

end

plate

(261,

Pulloutfront endplate

(21)

completewithO-ring

(20)

andcarefullypryoffthe O-ring,Removebearing

(17)

andoilseal

(18)

from

front endplate

(21).

Removeretainingring

(19)

frommotorhousing

(5)

and

take

out

the

completehammermechanism.Take off O-ring

(15)

fromcage

(16)

toremovehammer

(14).

2

cagepins

(13)

andanvil

(12).

O-ring

(10)

maybelevered

off

andO-ring

(I

1)

removedfrom

anvil

(12).

oil

seal

(2)

may be

hooked

outof andanvilbushing

(8)

pressedoutof motor housing

(5).

Page

No

2