7

Installation & Setup Instructions

1. Install Dampers/Run Tubing

Dampers install directly into new or existing ductwork. Orient the tube connection port so it is pointing up-

stream (toward the equipment). Install one main tubing run for each zone. Use connection “T’s” for multiple

dampers in a zone. Arzel recommends using a different color tube for each zone. Note: Dampers should not

be concealed behind a permanent barrier such as drywall without an access panel.

2. Mount Control Panel

The control panel must be mounted vertically on an exterior wall to reduce noise. The wall must also

be located in a non-condensing area where temperatures will not normally exceed 140º F. DO NOT

MOUNT PANEL ON DUCTWORK OR THE HVAC EQUIPMENT. The best method is to attach a piece of

3/4” plywood to a stud wall or foundation. Hold the panel level on the wall and mark the positions of the

upper mounting holes. Drive two screws into the wall leaving the heads at least 1/2” out. Set the panel over

the screws. Drive two screws into the lower mounting holes. Tighten the upper screws.

Note: Prior to making electrical connections, touch a mechanical ground to discharge static electricity.

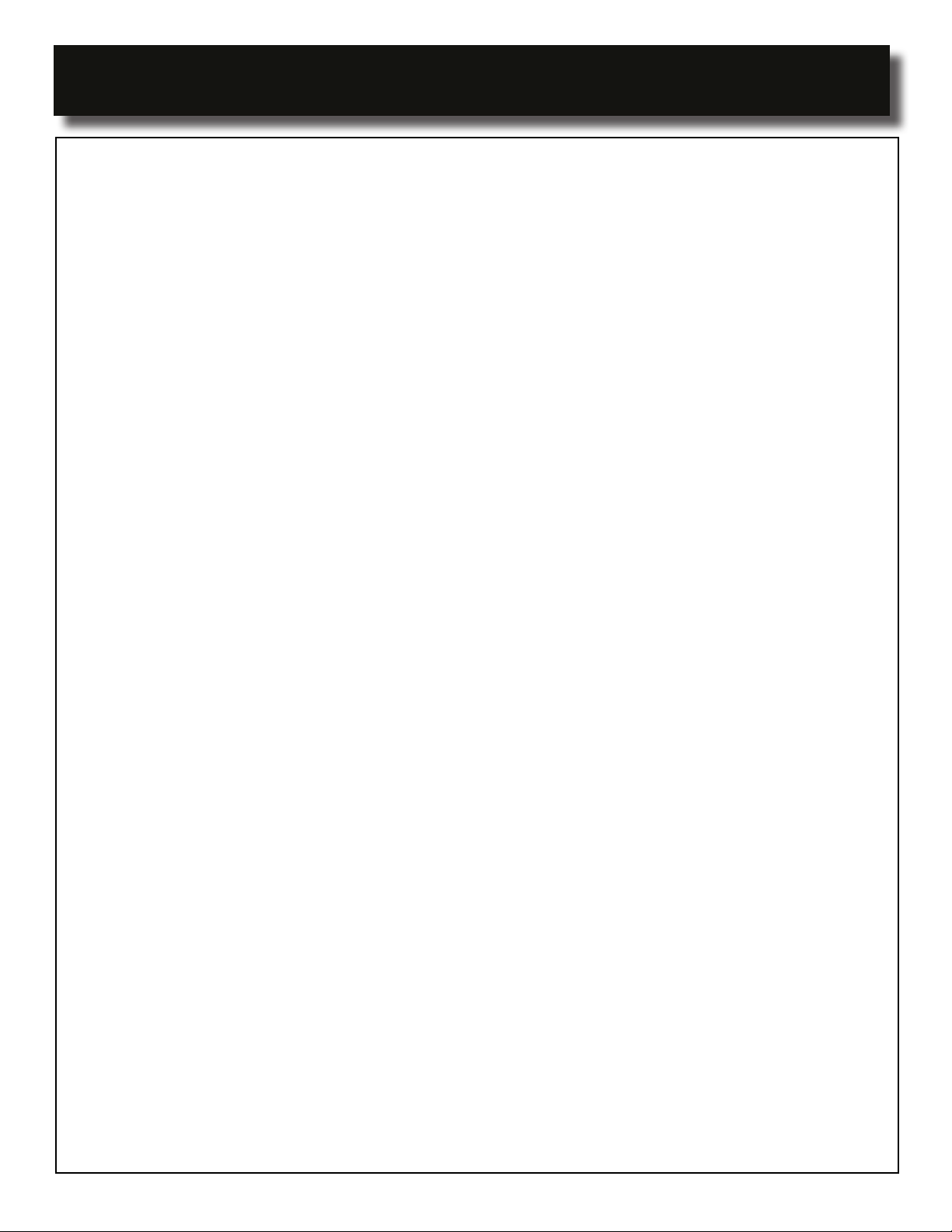

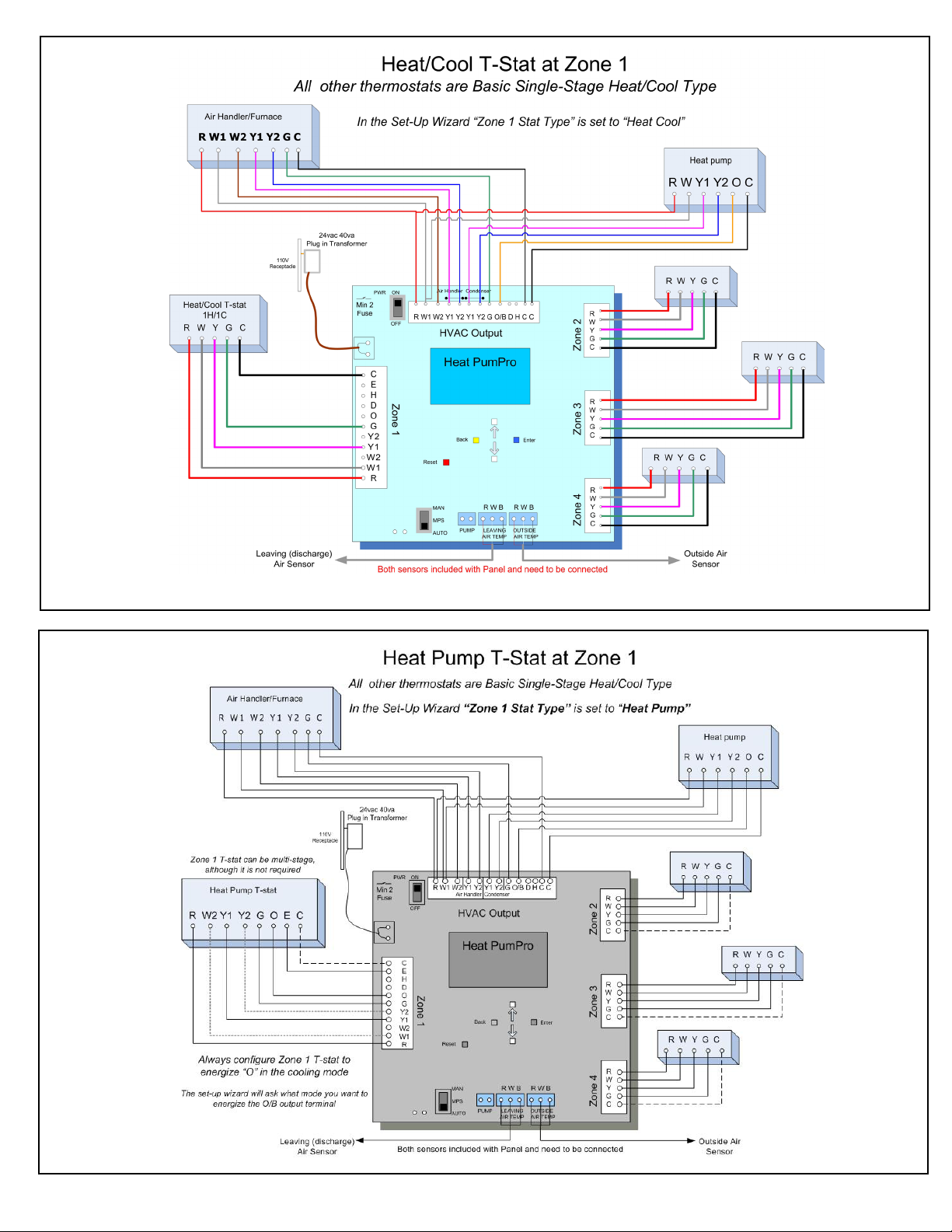

3. Connect Thermostats

Install a thermostat for each zone observing the terminal designations. Use 18 gauge, multi-conductor, solid

thermostat wire to connect the thermostats to the control panel. When using a heat pump thermostat in Zone

1, “O” must be set to energize for cooling calls. Zones 2, 3 and 4 must be non-heat pump models. Document

the location of each thermostat connected to each zone on the “Zone Layout” label on the side of the panel.

4. Connect Equipment

Use 18 gauge, multi-conductor, solid thermostat wire to connect the HVAC outputs located along the top of the

zone control panel to the HVAC equipment. Connect Y1, Y2 “Air Handler” to the blower or furnace controls

and the Y1, Y2 “Condenser” to the heat pump/air conditioner controls. The two “C” terminals are for connection

between the furnace/air handler transformer and the common circuit of the heat pump/air conditioner controls.

5. Connect Transformer

Use 18 gauge, 2-conductor solid wire to connect the R and C power input terminals to the mounting screws on

the 40VAC self-resetting, plug-in transformer supplied with the Arzel Zoning System. Plug in the transformer

to any standard 120VAC receptacle. Note: If you elect to not use the provided transformer your warranty

may be void. Additional surge protection is recommended.

6. Connect Sensors

1. Install the leaving air temperature sensor in the supply duct 12 to 18 inches from the plenum and

before any dampers.

2. Install the Outdoor Air Temperature sensor outdoors, preferably on the north side of the house,

not in direct sunlight.

3. Wires must be connected to corresponding terminals, R-red, W-white and B-black.

7. Turn on Panel and Run the Set-Up Wizard