Siral N2 Series Manual

IOM16 N2, N5070716

Page i of i

www.siral.us

TO PREVENT POTENTIAL INJURY OR DAMAGE TO PROPERTY, READ THIS MANUAL CAREFULLY AND

COMPLETELY.

Installation, Operation and

Maintenance Instructions

N2 to N5 Series

IMPORTANT SAFETY INSTRUCTIONS

Basic safety precautions should always be followed, including the following: Failure to follow instructions

can cause severe injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look

for one of the following signal words and be alert to the potential for personal injury.

WARNING warns about hazards that could cause serious personal injury, death or major property

damage and if ignored presents a potential hazard.

CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or

property damage and if ignored presents a potential hazard. It can also make consumers aware of

actions that are unpredictable and unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

WARNING - Read and follow all instructions in this IOM manual and on the equipment. Failure to

follow instructions can cause severe injury and/or death.

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable

local codes, regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn, and

cause death or serious property damage. To reduce the risk of electric shock, do NOT use an extension

cord to connect unit to electric supply. Provide a properly located electrical receptacle. Before working

on any electrical equipment, turn off power supply to the equipment.

WARNING – To reduce the risk of electric shock replace damaged wiring immediately.

WARNING – Ground all electrical equipment before connecting to electrical power supply. Failure

to ground all electrical equipment can cause serious or fatal electrical shock hazard.

WARNING – Do NOT ground to a gas supply line.

WARNING – To avoid dangerous or fatal electrical shock, turn OFF power to all electrical equipment

before working on electrical connections.

WARNING – Failure to bond all electrical equipment to system structure will increase risk for

electrocution and could result in injury or death. To reduce the risk of electric shock, see installation

instructions and consult a professional electrician on how to bond all electrical equipment. Also, contact

a licensed electrician for information on local electrical codes for bonding requirements.

CAUTION – Potential pinch point. Equipment connected to or driven by this device may start

unexpectedly and may cause personal injury or entrapment in linkage systems.

IOM16 N2, N5

070716 Page 1 of 23

www.siral.us

N2 - N5 Series

NOTICE: ALL N2 to N5Series actuators rotate CW to CLOSE the OUTPUT shaft out the bottom

of the actuator when viewed from ABOVE. On ALL N2 and N3 models, the CAM

shaft and the INDICATOR rotate CW to close as well.

TECHNICAL INFORMATION

N2V... N3V...

ACTUATOR SPECIFICATIONS

Supply Torque Output (lbf-in / Nm) 880 / 100 1770 / 200

12VAC

-

12VDC

Current Draw (Start / Run / LRA) 7.2A / 5.2A / 17.8A 7.2A / 5.2A / 17.8A

Speed (90°) DC, seconds 14 28

Motor - 12vdc Perm Magnet Brush Type 25W 25W

Duty Cycle (on/off / mod) 75% 75%

Motor Starts, per hour, Max 1200 1200

Motor Protection, Temp / Class 135°C / Class F 135°C / Class F

24VAC

-

24VDC

Current Draw (Start / Run / LRA) 4.2A / 3.2A / 11A 4.2A / 3.2A / 11A

Speed (90°) DC, seconds 14 28

Motor - 24vdc Perm Magnet Brush Type 25W 25W

Duty Cycle (on/off / mod) 75% 75%

Motor Starts, per hour, Max 1200 1200

Motor Protection, Temp / Class 135°C / Class F 135°C / Class F

120V

Current Draw (Start / Run / LRA) 1.16A / 0.93A / 1.47A 1.16A / 0.93A / 1.47A

Speed (90°) 60Hz / 50Hz, seconds 16 / 19 33 / 39

Motor - 120vac Split-Phase Cap TENV 40W 40W

Duty Cycle (on/off / mod) 25% / 75% 25% / 75%

Motor Starts, per hour, Max 1200 1200

Motor Protection, Temp / Class 135°C / Class F 135°C / Class F

230V

Current Draw (Start / Run / LRA) 0.54A / 0.42A / 0.66A 0.54A / 0.42A / 0.66A

Speed (90°) 60Hz / 50Hz, seconds 16 / 19 33 / 39

Motor - 230vac Split-Phase Cap TENV 40W 40W

Duty Cycle (on/off / mod) 25% / 75% 25% / 75%

Motor Starts, per hour, Max 1200 1200

Motor Protection, Temp / Class 135°C / Class F 135°C / Class F

All

Electrical Entry (2) 3/4" EMT or ABS gland

Control On/Off or Proportional

Ambient Operating Range -22°F to +125°F / -30°C to +52°C

Humidity Range 0-95% RH

Altitude Limit 9850 ft / 3000 m

Table of Contents

1 ................... Product Safety Information

2 ................... Product Specifications

3 ................... Shipping and Handling

3 ................... Installation Notices

3 & 8

................... Product Mounting and Setup

4 ~ 7................ Wiring Diagrams

8.................. Wiring Information and Control

9.................. Adjusting the actuator CW Stop Position

10 .................. Adjusting the actuator CCW Stop Position

11.................. Adjusting the actuator Auxiliary switch cams

12.................. Calibrating and Commissioning On/Off Models

13

.................. PCB Reference Data

14~18 ............... Calibrating and Commissioning Proportional Models

19.................. Mechanical Data

20.................. Component Identification

21&22

.............. Troubleshooting

IOM16 N2, N5

070716 Page 2 of 23

www.siral.us

1. Fully CLOSE the valve or damper to which the actuator is to be mounted.

• Keep in mind N Series actuators rotate CW (as viewed from above the unit) when driving CLOSED.

2. Assemble necessary linkage components and attach the actuator to the driven device.

3. Tighten mounting bolts, making sure actuator is centered on the device drive shaft.

4. Utilize the handwheel override to check for unobstructed manual operation from fully CW to fully CCW positions

BEFORE applying power to the unit.

Refer to your product part number to determine which wiring diagram to follow when wiring up the actuator. (Con’t pg 8).

WARNING – To avoid dangerous or fatal electrical shock, turn OFF power to all electrical equipment before

working on electrical connections.

1. This actuator is shipped in the FULLY CLOSED (CW) position (2 color position

indicator shows RED).

2. NOTICE: THIS ACTUATOR MUST HAVE WATER TIGHT EMT FITTINGS, WITH

CONDUIT DRAINAGE INSTALLED AND POWER SUPPLIED TO UNIT TO

KEEP THE HEATER WARM AT THE TIME OF INSTALLATION.

3. Storage: This unit should NOT be stored outside unless it is powered up

and has proper conduit terminations. When NOT powered up, it should be

stored in a clean, dry environment at all times.

4. This actuator has been factory calibrated to operate between 0° and 90°. Most

quarter-turn products will not require recalibration of these settings. If any

travel adjustment is necessary, please refer to pages 11-12 for instructions.

5. NOTICE: The standard N2 and N3 series actuator CANNOT operate with a

rotation greater than 95°.

Product Mounting and Setup

• These actuators are designed to be used between a horizontal and upright position. Do NOT mount the assembly with

the actuator top below a horizontal position.

• When installing conduit, use proper techniques for entry into the actuator. Use drip loops to prevent conduit condensate

from entering the actuator.

• Mechanical travel stops are factory calibrated for 90 degree operation. These stops are NOT designed to adjust

mechanical rotation by more than +/- 3 degrees, they are for positioning the handwheel only.

• Both NPT conduit ports MUST use proper equipment to protect the NEMA 4X integrity of the housing.

• The internal heater is to be used in ALL applications.

• Do NOT install the actuator outdoors or in humid environments unless it is powered up and the heater is functioning.

• Use proper wire size to prevent actuator failure (see chart on page 4 for proper wire sizing).

• All terminals accept 12-16AWG solid/stranded wire.

•NOTICE: Do NOT parallel wire multiple on/off actuators together without utilizing isolation relays. If this is

your intention, please contact HAYWARD FLOW CONTROL for a multiple actuator parallel wiring diagram.

Installation Notices:

Shipping and Handling:

The actuator is shipped from the

factory in its fully CW (CLOSED)

position. RED color in the

indicator window means fully CW,

while GREEN means fully CCW.

IOM16 N2, N5

070716 Page 3 of 23

www.siral.us

IOM16 N2, N5 070716

Page 4of 23

www.siral.us

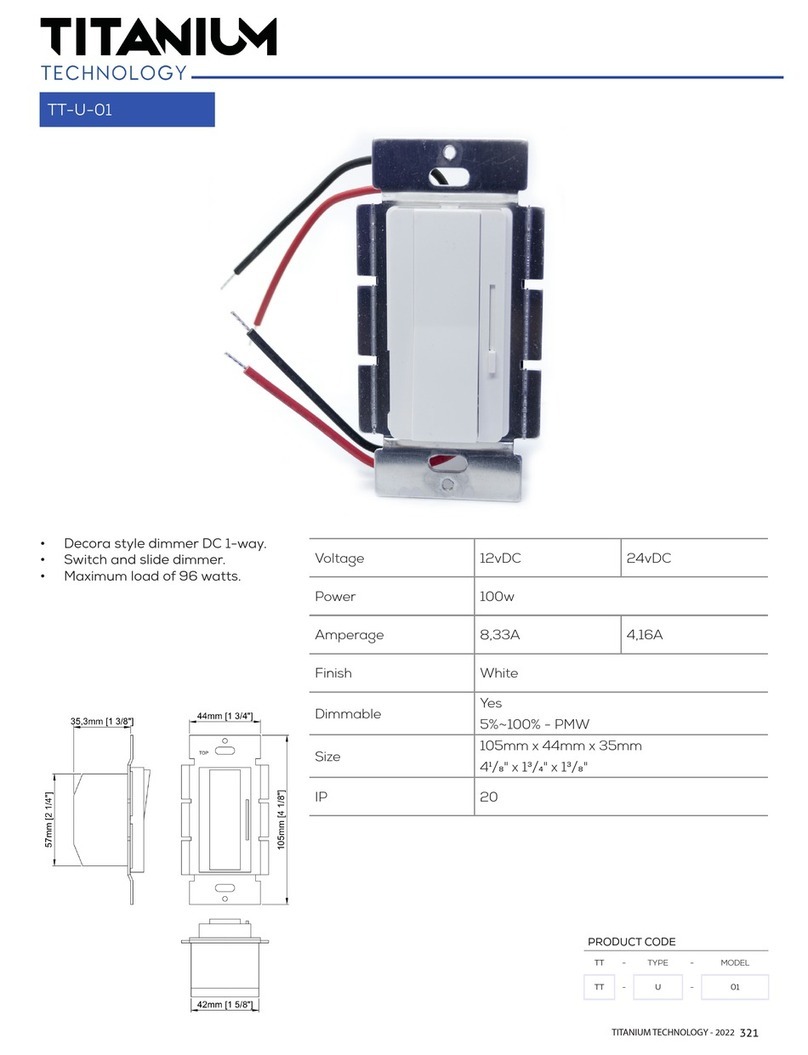

N2 & N5Series

24vdc on/off

24vac on/off

Terminals 7 & 8 may not exist or

may not be utilized in all models.

Terminals 7 & 8 may not exist or

may not be utilized in all models.

IOM16 N2, N5

070716 Page 5of 23

www.siral.us

N2 & N5Series

230vac on/off

Terminals 7 & 8 may not exist or

may not be utilized in all models.

Terminals 7 & 8 may not exist or

may not be utilized in all models.

120vac on/off

IOM16 N2, N5070716

Page 6of 23

www.siral.us

N2 & N5Series

24vdc proportional

24vac proportional

Terminals 7 & 8 may not exist or

may not be utilized in all models.

Terminals 7 & 8 may not exist or

may not be utilized in all models.

IOM16 N2, N5

070716 Page 7of 23

www.siral.us

N2 & N5 Series

120vac proportional

230vac proportional

Terminals 7 & 8 may not exist or

may not be utilized in all models.

Terminals 7 & 8 may not exist or

may not be utilized in all models.

GND Screw

ALL SWITCHES SHOWN WITH ACTUATOR

IN FULL CLOSED POSITION

6

5

4

3

2

1

Items within dotted line located inside actuator housing

SW1

SW2

SW3

SW4

Switch Stack

Detail

Feedback Return -

Feedback OUT +

Signal Return -

Signal IN +

L2

L1

230VAC

LINE IN

FIELD

CONTROL

DEVICE

GND

HEATER

D

C

B

ASW3

SW4 AUXILIARY SWITCH

(STANDARD)

AUXILIARY SWITCH

(STANDARD)

4060C-4006

OPEN COM*

OPEN*

CLOSED COM*

CLOSED*

* CONNECTIONS

OPTIONAL

ACC

ACL

AOC

4-20mA

input

impedance

250O

4-20mA

Field

impedance

= 500O

L1

L2

SI+

SI-

FB+

FB-

CW (RED)

CCW (GRN)

CW (RED)

CCW (GRN)

AOP

7

-

8

-

AIOCPU00-MXY334-Y2

OUT-

OUT+

IN-

IN+

N / COM

L / HR

1.00K

SW2

SW1

F.O.

F.C.

M

THERMAL

SWITCH

AIOCPU00-MXY334-Y2

OUT-

OUT+

IN-

IN+

N / COM

L / HR

1.00K

SW2

SW1

F.O.

F.C.

M

THERMAL

SWITCH

230V AC Motor

GND Screw

ALL SWITCHES SHOWN WITH ACTUATOR

IN FULL CLOSED POSITION

6

5

4

3

2

1

Items within dotted line located inside actuator housing

SW1

SW2

SW3

SW4

Switch Stack

Detail

Feedback Return -

Feedback OUT +

Signal Return -

Signal IN +

NEU

HOT

120VAC

LINE IN

FIELD

CONTROL

DEVICE

GND

HEATER

D

C

B

ASW3

SW4 AUXILIARY SWITCH

(STANDARD)

AUXILIARY SWITCH

(STANDARD)

4060C-4006

OPEN COM*

OPEN*

CLOSED COM*

CLOSED*

* CONNECTIONS

OPTIONAL

ACC

ACL

AOC

4-20mA

input

impedance

250O

4-20mA

Field

impedance

= 500O

HOT

NEU

SI+

SI-

FB+

FB-

CW (RED)

CCW (GRN)

CW (RED)

CCW (GRN)

AOP

7

-

8

-

AIOCPU00-MXY334-Y2

OUT-

OUT+

IN-

IN+

N / COM

L / HR

1.00K

SW2

SW1

F.O.

F.C.

M

THERMAL

SWITCH

AIOCPU00-MXY334-Y2

OUT-

OUT+

IN-

IN+

N / COM

L / HR

1.00K

SW2

SW1

F.O.

F.C.

M

THERMAL

SWITCH

120V AC Motor

WARNING – To avoid dangerous or fatal electrical shock, turn OFF power to all electrical equipment before

working on electrical connections.

1.

2.

3.

4.

5. N2 TO N5 Series actuators utilize a removable terminal block to facilitate ease of field

wiring and testing. To remove the terminal block from the PCB receiver, pull straight

OUT in a direction parallel to the PCB. In the photo at right, the RIGHT side of

the terminal block (between the PCB mounting screws) is pulled out to the RIGHT.

After wiring, reinsert the terminal strip into the receiver. This is a keyed pair and can

only be inserted ONE way. Screw terminals are rated to accept 14AWG down to

18AWG solid or stranded wire. TERMINAL NUMBERING HAS #1 AT THE BOTTOM.

(reference the correct wiring diagrams for numeric sequencing).

6.

6. Note that although terminals are labeled as 1-8 & A-D, not all terminals are used on

all models. Be sure to make field connections to the proper terminal

as identified by the LABEL and not the position!

7. Make the electrical connections per wiring diagrams found on pages 4~7.

8. Connect POWER and CONTROL to the correct terminals.

9. Terminals A~D on each actuator are for the (adjustable) aux switches. These are dry

type (volt free) Form A contacts rated 250VAC @ 10A Max.

Wire sizing data is provided in the table below to assist in the selection of the proper wire size for Siral N Series actuators

using various wire sizes over distance. Be make sure to reference the correct voltage and do not exceed the indicated

length of the wire run for each model.

MAX distance between Actuator and Power Supply (ft)

Actuator/

Voltage 12VAC/VDC 24VAC/VDC 120VAC 230VAC

5.2A 3.2A 0.93A 0.42A

18 - 39 712 2933

16 18 62 1120 4610

14 29 100 1809 7446

12 45 153 2766 11388

10 76 260 4702 19360

8133 388 7018 28896

AWG Amps

Wire Sizing Chart

NOTICE! - HRS Series actuators are fully assembled, calibrated and tested prior to leaving our factory. In

most cases, after you have mounted the actuator to your device, you should be able to operate the actuator

from fully CLOSED (CW) to fully OPEN (CCW) and back again, and nd that noadjustments are needed.

The assembly can be put into service immediately and should afford the end user years of service without

incident.However,shoulditbenecessarytomakeadjustmentstotheend-of-travelpositionstoovercome

any assembly related issues (i.e. valve shaft incorrectly timed to the drive stem), the procedures outlined

belowshouldbefollowedtoputtheassemblyintoservice.Notethatthereisamaximumadjustmentrange

of +/- 3° at each end of travel.

Pages 9~10 - Travel limits for CW (CLOSED) & CCW (OPEN) positions, N2 & N3

Page 11 - Auxiliary switch cams for CW & CCW positions, N2 & N3

(con’t from pg 3)

IOM16 N2, N5

070716 Page 8of 23

www.siral.us

CAUTION! - The mechanical stop screw limits handwheel operation ONLY and is NOT to be used as an

electrical travel limiting device.

WARNING – Serious Damage to the actuator will result if the motor is allowed to drive the gear train into the

mechanicalstop!!RemovepowerfromthisdeviceBEFOREmakinganytraveladjustments.

Loosen Mechanical Stop

1. BEFORE power is applied, use a 17mm wrench and a 5mm hex key

to loosen the RIGHT SIDE mechanical stop. This is the CW stop limit

adjustment. Turn the stop screw 5-6 turns CCW to allow electrical cam

stop adjustment without running into the mechanical stop screw.

2. Use the manual hand wheel to position the actuator to your required

CW position. This must be within +/- 3 degrees of the factory setting.

Adjust Cam 1

3. The lower cam is Cam 1, the CW end-of-travel adjustment. With the

actuator at its required CW position, with POWER OFF, use a 2.5mm

hex key to free up the cam set screw. Once it is free, rotate the hex

key to the RIGHT 10-15 degrees to reset the switch roller arm. Then

snug the set screw up against the camshaft (CW) until slight pressure

is felt. Now SLOWLY rotate the hex key pushing the cam to the LEFT

until you hear the “click” on the bottom switch, indicating that correct

adjustment has been achieved. Tighten the cam set screw.

4. Apply power to the actuator and drive CCW at least 15-20 degrees.

Then drive the actuator CW until the cam stops the electrical travel.

Check to be sure this is the correct CW position you require. Repeat

step 3 if further adjustment is needed.

Tighten Mechanical Stop

5. While holding the 17mm wrench on the RIGHT SIDE jam nut to prevent

the jam nut from locking, turn the 5mm hex key CW until the end of

the stop screw bottoms out against the internal stop boss. Then turn

the hex key ONE FULL TURN CCW before locking that adjustment

with the jam nut. This procedure assures that the actuator reaches

its end of travel electrically before there is any interference from the

mechanical stop.

6. This completes the CW position calibration.

This actuator has been factory calibrated to operate between 0 degrees and 90 degrees.

Most quarter-turn products will not require recalibration of these settings. Proceed ONLY if

adjustments are required.

CW Mechanical Stop

Cam 1

CW Mechanical Stop

Adjusting the actuator CW position

IOM16 N2, N5 070716

Page 9of 23

www.siral.us

CAUTION! - The mechanical stop screw limits handwheel operation ONLY and is NOT to be used as an

electrical travel limiting device.

WARNING – Serious Damage to the actuator will result if the motor is allowed to drive the gear train into the

mechanicalstop!!RemovepowerfromthisdeviceBEFOREmakinganytraveladjustments.

This actuator has been factory calibrated to operate between 0 degrees and 90 degrees.

Most quarter-turn products will not require recalibration of these settings. Proceed ONLY if

adjustments are required. Loosen Mechanical Stop

1. BEFORE power is applied, use a 17mm wrench and a 5mm hex key

to loosen the LEFT SIDE mechanical stop. This is the CCW stop limit

adjustment. Turn the stop screw 5-6 turns CCW to allow electrical cam

stop adjustment without running into the mechanical stop screw.

2. Use the manual hand wheel to position the actuator to your required

CCW position. This must be within +/- 3 degrees of the factory setting.

Adjust Cam 2

3. The second cam is Cam 2, the CCW end-of-travel adjustment. Once

the actuator is at its required CCW position, with POWER OFF, use

a 2.5mm hex key to free up the cam set screw. Once it is free, rotate

the hex key to the LEFT 10-15 degrees to reset the switch roller arm.

Then snug the set screw up against the camshaft (CW) until slight

pressure is felt. Then SLOWLY rotate the hex key pushing the cam to

the RIGHT until you hear the “click” on the second switch indicating

that correct adjustment has been achieved. Tighten the set screw.

4. Apply power to the actuator and drive CW at least 15-20 degrees.

Then drive the actuator CCW until the cam stops the electrical travel.

Check to be sure this is the correct CCW position you require. Repeat

step 3 if further adjustment is needed.

Tighten Mechanical Stop

5. While holding the 17mm wrench on the LEFT SIDE jam nut to prevent

the jam nut from locking, turn the 5mm hex key CW until the end of

the stop screw bottoms out against the internal stop boss. Then turn

the hex key ONE FULL TURN CCW before locking that adjustment

with the jam nut. This procedure assures that the actuator reaches

its end of travel electrically before there is any interference from the

mechanical stop.

6. This completes the CCW position calibration.

CCW Mechanical Stop

Cam 2

CCW Mechanical Stop

Adjusting the actuator CCW position

IOM16 N2, N5

070716 Page 10 of 23

www.siral.us

}

D

C

B

A

SW3 CW AUX

(Factory Set - Adj)

SW4 CCW AUX

(Factory Set - Adj)

}

}

Common Switch Terminal

Common

Fully OPEN (CCW)

Common

Fully CLOSED (CW)

Used by

Controller

-5°0°

CW CCW

85°

5°90°95°

WARNING – Serious Damage to the actuator will result if the motor is allowed to drive the gear train into the

mechanicalstop!!RemovepowerfromthisdeviceBEFOREmakinganytraveladjustments.

Cam 3

Cam 4

Adjust Cam 3

1. The THIRD cam is Cam 3, the CW auxiliary switch adjustment. Drive

the actuator to its CW position. Then use a 2.5mm hex key to free up

the cam set screw. Once it is free, rotate the hex key to the RIGHT 10-

15 degrees to reset the switch roller arm. Then snug the set screw up

against the camshaft (CW) until slight pressure is felt. Then SLOWLY

rotate the hex key and cam to the LEFT until you hear the “click” on

the third switch. Continue to rotate the cam between 3 and 5 degrees

to the LEFT to make sure the auxiliary cam switch changes state

before the actuator reaches its end of travel electrically. Tighten the

cam set screw.

Adjust Cam 4

1. The FOURTH cam is Cam 4, the CCW auxiliary switch adjustment.

Drive the actuator to its CCW position. Then use a 2.5mm hex key to

free up the cam set screw. Once it is free, rotate the hex key to the

LEFT 10-15 degrees to reset the switch roller arm. Then snug the set

screw up against the camshaft (CW) until slight pressure is felt. Then

SLOWLY rotate the hex key to the RIGHT until you hear the “click” on

the fourth switch. Continue to rotate the cam between 3 and 5 degrees

to the RIGHT to make sure the auxiliary cam switch changes state

before the actuator reaches its end of travel electrically. Tighten the

cam set screw.

Adjusting the actuator Auxiliary Switches

Auxiliary Switch Cam Mapping

IOM16 N2, N5

070716 Page 11of 23

www.siral.us

WARNING – Serious Damage to the actuator will result if the motor is allowed to drive the gear train into the

mechanicalstop!!RemovepowerfromthisdeviceBEFOREmakinganytraveladjustments.

IOM16 N2, N5

070716 Page 12of 23

www.siral.us

Calibration Procedure - On/Off Control:

1. Before making any changes in this section, keep in mind that this actuator has been fully calibrated to respond

between 0° and 90° degrees rotation. If NO changes to end stops are required, this unit is ready to be put into service

immediately. IF changes to the cam positions are required, refer to pages 9 ~ 11 before proceeding.

2. Apply correct power according to the actuator model, referring to wiring diagrams on pages 4~7.

3. Position the actuator to its full CCW (Open) and/or CW (Closed) positions and adjust the cams as necessary.

4. After making cam adjustments on either or both ends of travel, it is advisable to move off cam slightly, and then repeat

the drive command to assure the cam settings are correct.

5. Be sure the cam setscrews are snug (overtightening during calibration will make it difficult to make minor incremental

adjustments).

6. Unit is now calibrated and is ready to be put into service. No other calibration is necessary.

Calibration and Commissioning Procedure -

On/Off Control (All Models)

Commissioning Procedure - On/Off Control:

1. Utilize the handwheel or override shaft to rotate the actuator and damper, valve or other connected device through its

full travel from full CW to full CCW and back again to check for any possible interference. Do NOT utilize any mechanical

advantage devices to rotate the handwheel (pipes, wrenches, extension bars, etc.).

2. Manually position the actuator to its mid-stroke position.

3. Apply correct power to the unit.

4. Measure correct power and polarity on terminals 1 & 2 at the actuator terminal block.

5. Command the eld device to generate a CCW signal. The actuator rotates in a CCW direction (as viewed from above).

6. Measure terminals 2 and 6 (Run CCW) for correct voltage (matching that measured in step 4).

7. Actuator will stop when it reaches it’s full CCW position.

8. With eld command signal still present, measure terminals 2 and 5 and read voltage to match that measured in step 4.

9. Read continuity between terminals C & D to show the CCW Aux switch is closed.

10. Command the eld device to generate a CW signal. The actuator rotates in a CW direction (as viewed from above).

11. Measure terminals 2 and 4 (Run CW) for correct voltage (matching that measured in step 4).

12. Actuator will stop when it reaches it’s full CW position.

13. With eld command signal still present, measure terminals 2 and 3 and read voltage to match that measured in step 4.

14. Read continuity between terminals A & B to show the CW Aux switch is closed.

15. Generate a mid-position signal at the eld device to move the actuator off its full CW trip position.

16. Return Field control to automatic mode.

17. Actuator is now commissioned and operational.

IOM16 N2, N5

070716 Page 13of 23

www.siral.us

PCB Referance Data

All N2 & N5 Series utilize a main terminal

block where ALL field connections are

made. This is a 12 position removable

terminal block.

There are no other PCB’s installed inside a

120vac or 230vac On/Off actuator.

On N2 & N5 Series 24vac and 24vdc On/Off

units, a second PCB is installed which is the

logic and switching board controlling the

drive motor. There are no user adjustments

on this board. However there are interface

headers and set-up trimmers that are factory

set and should not be adjusted.

On N2 & N5 Series 120/230vac proportional

models, a logic/drive control PCB is installed

inside the enclosure.

And on N2 & N5 Series 24vac/vdc

proportional models, this logic/drive PCB is

installed inside the enclosure. AC models

also have a full wave bridge attached to the

top gear plate to provide the required DC

voltage for the drive motor.

IOM16 N2, N5

070716 Page 14of 23

www.siral.us

Calibration Procedure - Proportional Control (120/230vac Models):

After completing all mounting and wiring procedures and main power is available, it is now possible to commission

the actuator.

1. Before applying power or making any wiring connections:

2. Set the geartrain in the full CW position.

3. Set the #1 and #3 cams according to the on/off procedure.

4. Set the unit in the full CCW position.

5. Set the #2 and #4 cams according to the on/off procedure.

6. Set the geartrain back to the fully closed (CW) position.

7. Make your field wiring connections for power, control and feedback signals, referring to the correct wiring diagrams on

pages 4~7.

a. Connections are made ONLY TO THE MAIN TERMINAL BLOCK.

b. No connections are made to the proportional control board directly.

8. Set the jumper headers for correct signal IN and OUT. (ref pg 15)

9. Rotate the potentiometer pinion gear to its full CCW position, then back about 1.5~2 teeth CW before tightening the

two M3 setscrews on the sector drive gear.

10. Apply correct power according to the actuator model.

a. The red PWR LED will turn on.

11. Press the “Calibrate” black pushbutton on the Mod control board and hold it down for about three seconds, then

release.

a. The unit will run to its full CCW position, stop for a few seconds, then run back to its full CW position.

12. After a few seconds, the unit will complete the calibration routine and will return to active operation mode by

responding to the incoming 4-20mA control signals being sent to the actuator.

13. Slight adjustments may be made to the 4mA and 20mA trimmers to affect accuracy on the feedback signal as a

function of actuator position.

14. Unit is now calibrated and is ready to be put into service. No other calibration is necessary.

Alignment of the sector

and potentiometer gear

sets at actuator full CW

position. (ref step 9).

IOM16 N2, N5

070716 Page 15of 23

www.siral.us

Calibration Procedure - Proportional Control

(120/230vac Models)

FB Out

Connection

to Main Term

Block

Potentiometer

Connector

to

DECREASE

20mA

Feedback

Output

to

DECREASE

4mA

Feedback

Output

Power

Calibrate

On/Off

Control

DEFAULT

Signal IN

Connection

to Main Term

Block

L2 / Neu

L1 / Hot

Feedback Select

Input Select

2-10vdc TOP 2

4-20mA BOT 2

4-20mA TOP 2

2-10vdc BOT 2

DEFAULT

Make all connections to the MAIN terminal

block ONLY!

IOM16 N2, N5

070716 Page 16 of 23

www.siral.us

Calibration Procedure - Proportional Control (24vac/vdc Models):

After completing all mounting and wiring procedures and main power is available, it is now possible to commission

the actuator.

1. Before applying power or making any wiring connections:

2. Set the geartrain in the full CW position.

3. Set the #1 and #3 cams according to the on/off procedure.

4. Set the unit in the full CCW position.

5. Set the #2 and #4 cams according to the on/off procedure.

6. Set the geartrain back to the fully closed (CW) position.

7. Make your field wiring connections for power, control and feedback signals, referring to the correct wiring diagrams on

pages 4~7.

a. Connections are made ONLY TO THE MAIN TERMINAL BLOCK.

b. No connections are made to the proportional control board directly.

8. Set the DIP switches for correct signal IN and OUT. (ref pg 17)

9. Rotate the potentiometer pinion gear to its full CCW position, then back about 1.5~2 teeth CW before tightening the

two M3 setscrews on the sector drive gear.

10. Apply correct power according to the actuator model.

a. The blue LED D1 will turn on, and grn LED STA will turn on.

11. Press the “SET” black pushbutton on the Mod control board and hold it down for about three seconds, then release.

a. The grn STA LED will turn off and the unit will drive to the fully CW position and stop when the pre-set cam

positions are reached. There are NO LED indicators to advise when the actuator is running.

12. When the actuator stops, press the CLO pushbutton ONCE.

c. The actuator will drive to its full CCW (Open) position and stop when the pre-set cam postions are reached.

13. When the actuator stops, press the OP pushbutton ONCE.

14. The unit will start to respond to the incoming 4-20mA control signal being sent to the actuator.

15. Slight adjustments may be made to trimmer VR2 if necessary to tune the feedback signal.

16. Unit is now calibrated and is ready to be put into service. No other calibration is necessary.

Alignment of the sector

and potentiometer gear

sets at actuator full CW

position. (ref step 9).

IOM16 N2, N5

070716 Page 17 of 23

www.siral.us

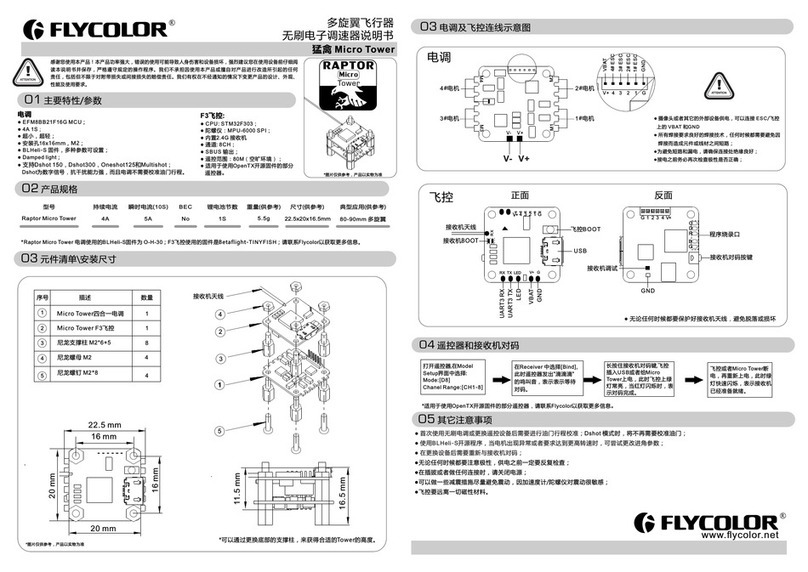

Calibration Procedure - Proportional Control

(24vac/vdc Models)

Limit Switch Harness

Connector

Red+

DC Motor

Connections

Blk -

Program

Port

FB Out Connector

Potentiometer

Connector

Option

DIP Select

Function DIP Select Signal IN Connector

Do NOT

adjust!

Do NOT

adjust!

to

DECREASE

LCD

Contrast (not

used)

to

DECREASE

current TRIP

setpoint (not

used)

Power

OP

CL

SET

OPEN

CLOSE

SET

CPU

Running

VR2

Trims Full

CCW FB

Out (20mA)

to

DECREASE

20mA OUT

Red+

24VDC

Blk -

Hot

24VAC

Com

Fault OUT

(Dry Contact)

DIP ON OFF FUNCTION

1 4-20mA 0(2)-10V Input

2 0-10V 2-10V/4-20mA

3 4-20mA 0(2)-10V Feedback

4 0-10V 2-10V/4-20mA

5 Mod On/Off Control

DIP FUNCTION

1 = Off, 2 = Off Fully CW upon loss of input signal

1 = Off, 2 = On Hold position upon loss of input signal

1 = On, 2 = On Fully CCW upon loss of input signal

3 = Off DA Mode (4mA = Closed CW)

3 = On RA Mode (20mA = Closed CW)

4 = Off Factory Function

4 = On Factory Function

1 2 3 4 5

ON

1 2 3 4

ON

On/Off

Control

DEFAULT

DEFAULT

Commissioning - Proportional Control Actuators

After completing all mounting and wiring procedures and main power is available, it is now possible to commission

the actuator.

1. Utilize the handwheel or override shaft to rotate the actuator and damper, valve or other connected device through its full

travel from full CW to full CCW and back again to check for any possible interference. Do NOT utilize any mechanical

advantage devices to rotate the handwheel (pipes, wrenches, extension bars, etc.).

2. Manually position the actuator to its mid-stroke position.

3. Apply correct power to the unit.

4. Measure correct power and polarity on terminals 1 & 2 at the actuator terminal block.

5. Command the eld device to generate a 20mA (10vdc) signal. The actuator OUTPUT shaft rotates in a CCW direction (as

viewed from above) and stops at the full CCW (Open) position.

6. Measure terminals 5 (+) and 6 (-) to read 20mA (10vdc).

7. Read continuity between terminals C & D to show the CCW Aux switch is closed.

8. Command the eld device to generate a 4mA (2vdc) signal . The actuator OUTPUT shaft rotates in a CW direction (as

viewed from above) and stops at the full CW (Closed) position.

9. Measure terminals 5 (+) and 6 (-) to read 4mA (2vdc).

10. Read continuity between terminals A & B to show the CW Aux switch is closed.

11. Generate a 12mA (6vdc) signal at the eld device to move the actuator to its mid-travel position.

12. Actuator stops at 50% travel, and feedback measuers 12mA (6vdc) +/- tolerance error if any (single decimal).

13. Return Field control to automatic mode. Actuator is now commissioned and operational.

IOM16 N2, N5

070716 Page 18 of 23

www.siral.us

N2 & N3 Mechanical Data

IOM16 N2, N5

070716 Page 19 of 23

www.siral.us

COVER REMOVAL CLEARANCE

COVER REMOVAL CLEARANCE

OUTPUT

SHAFT CW

MODEL

A

in/mm

A'

in/mm

B

in/mm

C

in/mm

D

in/mm

E

in/mm

F

in/mm

G

in/mm

H

in/mm

J

in/mm

K

in/mm

LWEIGHT

lbs/kg

N2V... 10.45/265 6/150 4.85/123 3.11/79 8.50/216 4.73/120 9.45/240 0.866/22 1.38/35

(4) M8

X 20mm

Deep

F07

2.756/70 4.7/120

12.5

turns

90°

24.5/11

N3V... 10.45/265 6/150 4.85/123 3.11/79 8.50/216 4.73/120 9.45/240 0.866/22 1.38/35

(4) M8

X 20mm

Deep

F07

2.756/70 4.7/120

12.5

turns

90°

24.5/11

DIMENSIONS

This manual suits for next models

3

Table of contents