MFZ Ovitor CS 320 FU User manual

EN

Control CS 320 FU / Rev.A 1.01 – 1

Operating Instructions

Control CS 320 FU

2 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 3

1. Contents

1. Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Information in this document . . . . . . . . . . . . 3

3. General safety instructions . . . . . . . . . . . . . . 3

4. Product overview. . . . . . . . . . . . . . . . . . . . . . 4

4.1 Product description...................4

4.2 Variants ...........................4

4.3 MotherboardCS320FU ...............5

4.4 Version CS 320 FU-I

Frequency converter incorporated in drive,

CS320controlinseparatehousing.......6

4.5 Version CS 320 FU-E

Frequency converter and CS 320 control

togetherinonehousing ...............6

4.6 Connection of Siemens G110 frequency

converter ..........................8

4.7 Connection of Siemens V20 frequency

converter ..........................8

5. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Safety instructions for installation ........9

5.2 Mains connection ....................9

5.3 Internal fuse protection...............11

5.4 Mainsvoltageselection ..............11

5.5 Supply to external devices

(only with 400 V / 3-phase connection) ...12

5.6 Connection of electronic limit position system

absolute value encoder (AWG) .........12

5.7 Mechanical limit switch (MEC) connection. 13

5.8 Connection of command devices........15

5.9 Lightgridconnection ................17

5.10 Connectionofclosingedgeprotective

device 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.11 Connectionlightbarrier1 .............19

5.12 Terminalassignment,relayoutputs ......20

5.13 Connectionofprogrammableinputs . . . . . 20

5.14 Safety input per EN 12453 ............23

5.15 Radioreceiver,pluggable .............24

5.16 CS radio ..........................25

5.17 Digital991 ........................25

5.18 Connection of external radio receiver ....26

5.19 Connection of frequency converter ......26

5.20 Connection of LCD monitor............27

5.21 Connection of MS BUS components .....27

5.22 Transmission system radio.............28

6. Initialisation. . . . . . . . . . . . . . . . . . . . . . . . . .28

7. Setting the limit positions . . . . . . . . . . . . . . .29

7.1 Checkingthedrive/traveldirection .....29

7.2 Settingthemechanicallimitswitches ....29

7.3 Settingtheelectronicendpositionsystem

usingthesettingbuttonsonthe

circuit board .......................29

7.4 Settingtheelectroniclimitpositionsystem

via the LCD monitor .................30

7.5 Settingtheintermediatepositionsofthe

electronic limit position system via

the LCD monitor ....................30

8. Programming . . . . . . . . . . . . . . . . . . . . . . . . .31

8.1 Overview of the LCD monitor ..........31

8.2 LCDmonitoroperatingmodes..........31

8.3 Expert menu.......................32

8.4 RESET............................32

8.5 RESETTING the controller with

LCDmonitor.......................33

8.6 RESETTING the controller without

LCDmonitor.......................33

8.7 RESETthefrequencyinvertersettings ....33

9. Frequency converter . . . . . . . . . . . . . . . . . . .34

9.1 General ..........................34

9.2 Adjustable values . . . . . . . . . . . . . . . . . . . 34

9.3 Traveldiagrams.....................36

9.4 Rated values for motor ...............37

10. Navigator (only LCD monitor) . . . . . . . . . . . .38

11. Functional overviews . . . . . . . . . . . . . . . . . . .40

11.1 Automatic mode....................40

11.2 Inputoperatingmode ................41

11.3 Explanations of the relay modes:........51

11.4 Explanations of the inputs: ............54

11.5 Diagnosisoperatingmode/errormemory . 58

12. Fault display and remedial measures. . . . . . .61

12.1 Fault display on the LCD monitor........61

12.2 ErrormessageviaLEDindicator ........65

13. Technical data . . . . . . . . . . . . . . . . . . . . . . . .67

13.1 Mechanical and electrical data .........67

13.2 Categoryandperformancelevelofthesafety

function per EN ISO 13849-1 ..........68

14. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

15. Manufacturer’s declaration . . . . . . . . . . . . . .70

16. Annex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

16.1 Safetycircuitmeasuringpoints .........71

16.2 Overview of the connections ...........72

Control CS 320 FU / Rev.A 1.01 – 3

EN

2 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 3

3. General safety instructions

WARNING!

Failure to comply with the documentation could

result in life-threatening danger!

Be sure to follow all the safety instructions in this

Be sure to follow all the safety instructions in this

document.

document.

Warranty

Thefunctionandsafetyoftheequipmentisonlyguaranteed

ifthewarningandsafetyinstructionsincludedinthese

operatinginstructionsareadheredto.

MFZ Antriebe GmbH + Co is not liable for personal injury or

damagetopropertyresultingfromthewarningsandsafety

advicebeingdisregarded.

MFZdoesnotacceptanyliabilityorwarrantyfordamagedue

to the use of non-approved spare parts and accessories.

Intended use

ThecontrollerCS320FUisdesignedexclusivelyfor

controllingdoorsystemsthroughdriveswithmechanicallimit

switches (MEC) or an electronic limit position system (AWG).

Thedoordrivesmustbedesignedforcontrolwithafrequency

inverter.

Target group

Onlyqualiedandtrainedelectriciansmayconnect,

programmeandservicethecontrol.

Qualiedandtrainedelectriciansmustmeetthefollowing

requirements:

− Knowledgeofthegeneralandspecicsafetyandaccident

preventionregulations,

− Knowledgeoftherelevantelectricalregulations,

− Trainingintheuseandcareofappropriatesafety

equipment,

− Capableofrecognisingthedangersassociatedwith

electricity.

Original operating instructions

− Copyright.

−No part of these instructions may be reproduced without

our prior approval.

− Subjecttoalterationsintheinterestoftechnicalprogress.

− Alldimensionsgiveninmm.

− Thediagramsinthismanualarenottoscale.

Key to symbols

WARNING!

Indicates a hazard with a medium level of risk which, if not

avoided, could result in death or serious injury.

CAUTION!

Indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

ATTENTION!

Indicatesanimminentdangerofdamageordestruction.

CHECK

Indicates a check to be performed.

REFERENCE

Reference to separate documents which must be complied

with.

Action request

−List, itemisation

➔Reference to other sections of this document

2. Information in this document

4 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 5

4 – Control CS 320 FU / Rev.A 1.01

Instructions regarding installation and connection

− ThecontrolisdesignedwithXtypeterminals.

−The system must be disconnected from the electricity supply

beforecarryingoutanyelectricalwork.Itmustbeensured

that the electricity supply remains disconnected for the

duration of the work.

− Localprotectiveregulationsmustbecompliedwith.

− Consultthemanufacturerbeforecarryingoutmodications

orreplacingthemainsconnectioncable.

− Ingeneral,anoriginalwiringharnessfrom

MFZGmbH&Co.KGshouldbeusedforestablishingthe

connectionbetweenthedoordriveandcontroller.Changes

orreplacementsshallonlytakeplacefollowingconsultation

with the manufacturer and approval by the same.

Information concerning operation

−Unauthorised persons (particularly children) should not be

allowedtoplaywithpermanentlyinstalledadjustingor

control devices.

−Keep remote controls beyond the reach of children.

Observethevalidstandardsandregulations!

4. Product overview

4.14.1 Product descriptionProduct description

ThecontrollerCS320FUisdesignedforuseinindustrial

areas and can be used with all door types in these areas.

This facilitates the speed-independent control of door drives.

It is possible to connect drives with mechanical limit switches

(MEC) or an electronic limit position system (AWG).

All the necessary command devices and safety elements can

be connected, set and evaluated.

ProgrammingtakesplaceviaapluggableLCDmonitor.

Alternatively, a service tool is available as an accessory.

The service tool consists of a stick and an app.

ThefollowingsuppliervariantsofthecontrollerCS320are

possible:

4.24.2 VariantsVariants

Housing variants:

− ControllerCS320FUinthe“standard”housing

− ControllerCS320FU-Einthe“combination”or“maxi”

housing

Variants of the pluggable LCD monitor:

−LCD monitor on the circuit board

− LCDmonitorinthehousingcover

− Hard-wiredLCDmonitor,pluggable(MSBUS)

Command device variants:

− 3-foldbuttonCSintegratedinthehousing

Optional:

− Housingwithout3-foldbutton

− HousingwithON/OFFkeyswitch

− Housingwithmainswitch

− Housingwithemergencystop

− Pluggablecomponents(circuitboard)

− Brakemonitoringmodule

−Week timer

−Radio receiver

− Radiotransmissionsystemforclosingedgeprotective

device and/or a safety element.

Theoperatinginstructionsdescribetheconnection

andprogrammingoptionsandvariantsoftheCS320

controller with connected LCD monitor and from software

versionV1.01a.

General safety instructions

4 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 5

EN

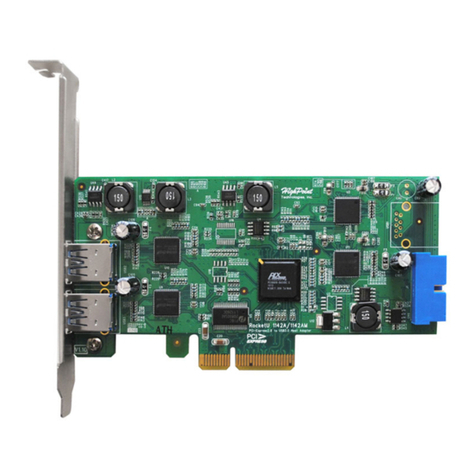

4.34.3 Motherboard CS320Motherboard CS320FUFU

Explanation:

X1: Mainsconnectionterminalstrip

X2: Motorterminalstrip

X3: Terminalstripforcommanddevices

X4: Terminalstripforsafetyelements

X5: Terminalstripforrelays

X6: ConnectorstripforinternalON/OFFswitch

X7: Connectorstripforinternal3-foldbuttonKDT

X8: ConnectorstripforLCDmonitor

(Beneath the LCD monitor)

X9: Connectorstripforradioreceiver

X10: Connectorstripforweektimer/brakemonitoring

module

X11: Connectorstripforelectroniclimitpositionsystem

(AWG)

X12: Connectorstripforexternalradioreceiver

X13: Connectorstripforinternal3-foldbuttonCS

X15: Terminalstripformechanicallimitswitches(MEC)

X16: ConnectorstripforBUSsystem(MSBUS)

X17: Plug-inconnectorRJforBUSsystem(MSBUS)

X18: Connectorstripforfrequencyconverter(interface)

X19: Terminalstripforsupplyingexternaldevices

230V/50Hz

X20: Connectorstripfortransmissionsystem

X21: Mainsvoltageselection

H1: Readyforoperation(green)

Lightsupwithpowersupply.

H2: Status indicator (red)

Lightsupwithfaultsorwithactuationofthesafety

equipment

S1: Programmingbutton(+)

(Beneath the LCD monitor)

S2: Programmingbutton(–)

(Beneath the LCD monitor)

S3: Programmingbutton(P)

(Beneath the LCD monitor)

F1: Fuseprotectionforexternaldevices230V/50Hz

(max. 1A slow-blow)

F2.1: Fuse protection for controller and drive L1 (max. 10 A)

F2.2: Fuse protection for controller and drive L2 (max. 10 A)

F2.3: Fuse protection for controller and drive L3 (max. 10 A)

Terminal strip for protective conductor (PE)

X10

B2

B1

W

V

U

1

2

3

4

5

6

7

8

X5

1

2

3

4

5

6

7

8

X15

1

2

3

4

5

6

7

8

9

10

X4

X7

X6

X12

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

F1

1

2

3

4

5

6

7

8

9

12

11

10

X9

X8

X20

S1

X13

X19

X3

X16

H1

H2

X11

X18

S2

S3

X2

X17

4.3 / 1

6 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 7

4.44.4 Version CS 320 FU-IVersion CS 320 FU-I

Frequency converter incorporated inFrequency converter incorporated in

drive, CS 320 control in separate housingdrive, CS 320 control in separate housing

X10

B2

B1

W

V

U

1

2

3

4

5

6

7

8

X5

1

2

3

4

5

6

7

8

X15

1

2

3

4

5

6

7

8

9

10

X4

X7

X6

X12

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

F1

1

2

3

4

5

6

7

8

9

12

11

10

X9

X8

X20

S1

X13

X19

X3

X16

H1

H2

X11

X18

S2

S3

X2

X17

B

C

A

4.4 / 1

A Frequency converter

B CS 320 control

C Housing

Siemens frequency converter

Type G110 230V/1~/0.75 kW incorporated in drive,

forSTAseriesforusewithspring-balancedsectionaldoors,

notincludingbrakemoduleorbrakeresistor

4.54.5 Version CS 320 FU-EVersion CS 320 FU-E

Frequency converter and CS 320 controlFrequency converter and CS 320 control

together in one housingtogether in one housing

X10

B2

B1

W

V

U

1

2

3

4

5

6

7

8

X5

1

2

3

4

5

6

7

8

X15

1

2

3

4

5

6

7

8

9

10

X4

X7

X6

X12

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

F1

1

2

3

4

5

6

7

8

9

12

11

10

X9

X8

X20

S1

X13

X19

X3

X16

H1

H2

X11

X18

S2

S3

X2

X17

A

B

C

D

4.5 / 1

A Frequency converter

B CS 320 control

C Brake module / brake resistor (under the PCB)

D Housing

Siemens frequency converter

TypeG110230V/1~/0.75kWin“Kombi”housing

for STA series,

notincludingbrakemoduleorbrakeresistor

TypeV20230V/1~/0.75kW in“Kombi”housing

TypeV20400V/3~/1.5kW in“Kombi”housing

TypeV20400V/3~/2.2kW in“Kombi”housing

for MTZ, MDF, SDO series,

includingbrakemoduleorbrakeresistor

Product overview

6 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 7

EN

X10

B2

B1

W

V

U

1

2

3

4

5

6

7

8

X5

1

2

3

4

5

6

7

8

X15

1

2

3

4

5

6

7

8

9

10

X4

X7

X6

X12

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

F1

1

2

3

4

5

6

7

8

9

12

11

10

X9

X8

X20

S1

X13

X19

X3

X16

H1

H2

X11

X18

S2

S3

X2

X17

B

C

D

E

F

X0

A

4.5 / 2

A Frequency converter

B Load contactor*

C PCB fuse protection

D CS 320 control

E Brake module / brake resistor (under the PCB)

F Housing

* Only version 230V/1~/1.5 kW und 400V/3~/4.0 kW

Siemens frequency converter

TypeV20230V/1~/1.5kW inMaxihousing

TypeV20400V/3~/3.0kW inMaxihousing

TypeV20400V/3~/4.0kW inMaxihousing

for MTZ, MDF, SDO series,

includingbrakemoduleorbrakeresistor

8 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 9

4.64.6 Connection of Siemens G110 frequencyConnection of Siemens G110 frequency

converterconverter

A

D

B

C

BU

RD

VT

BK

GY/PK

YE

PK

WH

BN

GN

4.6 / 1

Legend:

BK black PK pink

GN green RD red

GY grey VT violet

BU blue YE yellow

WH white BN brown

A Voltagesupply,230V/1~/N/PE

(suppliedthroughCS310/X2)

B Motor output, 230V/3~/PE

C Plug-inconnectionforFUdatacable

(differentcolourcodingforFU-IandFU-E)

D LED FU operation

4.74.7 Connection of Siemens V20 frequencyConnection of Siemens V20 frequency

converterconverter

A

D

C

F

BE

GN

WH

BN

YE

PK

4.7 / 1

Legend:

PK pink

GN green

YE yellow

BN brown

WH white

A Voltagesupply,230V/1~/N/PEor400V/3

(suppliedthroughCS310/X2)

B Motor output, 230V/3~/PE or 400V/3~/PE

C Plug-inconnectionforFU-Edatacable

D LED FU operation

E Brake module connection, DC+/DC-

(connection for brake resistor on brake module)

F Bridge(MUSTbeused)

Product overview

8 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 9

EN

5. Installation

5.15.1 Safety instructions for installationSafety instructions for installation

WARNING!

Life-threatening danger due to electric shock!

Beforeperformingwiringwork,alwaysdisconnectthe

Beforeperformingwiringwork,alwaysdisconnectthe

system from the power supply. Make sure that the power

system from the power supply. Make sure that the power

supplyremainsdisconnectedduringwiringwork.

supplyremainsdisconnectedduringwiringwork.

ATTENTION!

Property damage due to improper installation of

the controller!

Inordertoavoiddamagetothecontroller,observethe

followingpoints:

− Onlyqualiedandtrainedelectriciansmayworkon

electrical systems.

−Switch off the power supply to the system, check that it

isde-energisedandsafeguardagainstreconnection.

−Mains cables and control cables must be routed separa-

tely.

−The line types and cross-sections must be selected in

accordancewiththevalidspecications.

− Itisessentialtoobservethelocalprotectiveregulations.

− Observethespecicationsofthedoormanufacturerfor

installation.

Thefollowingpointsmustbecorrecttoguarantee

fault-freefunctioning:

− Thedoorisinstalled,fullyfunctionalanddesignedfor

power-driven operation.

− Thegearmotoristtedandreadyforoperation.

− Thecommandandsafetydevicesarettedandreadyfor

operation.

− ThecontrolhousingwiththeCS320FUcontrolleristted.

Observethevalidstandardsandregulations!

REFERENCE

The instructions from the respective manufacturer must be

observedfortheinstallationofthedoor,thegearmotorand

the command and safety devices.

5.25.2 Mains connectionMains connection

Prerequisites

Thefollowingpointsmustbecorrecttoguaranteethe

function of the controller:

− Themainsvoltagemustcorrespondwiththeinformation

on the type plate.

− Themainsvoltagemustbethesameastheinputvoltage

of the frequency converter.

− Theoutputvoltageofthefrequencyconvertermustbethe

sameasthesupplyvoltagefortheoperator.

− Themotorratingdataconguredmustcomplywiththe

data on the type plate.

−In the case of three-phase power, this must have a

clockwiserotatingeld.

− Withaxedconnection,anall-polemainswitchmustbe

used.

−With three-phase power, only triple block circuit breakers of

type C (max. 16 A) shall be used.

ATTENTION!

Malfunctions due to improper installation of the

controller!

− Theuseoffrequencyconvertersresultsinhigh-frequency

pulsatingdirectfaultcurrents/leakagecurrentsagainst

the protective conductor (PE). Any residual current device

(RCD) used must therefore be of type B+ (VDE 0100-

530, 531.3.2).

Werecommendusingaseparatefaultcurrentcircuit

breakerforeverydoororgatesystem.

− Beforeswitchingonthecontrolforthersttime,acheck

mustbecarriedoutaftercompletingthewiringtoensure

that all the motor connections on the motor and the

controlaresecurelyxed.Allcontrolvoltageinputsare

galvanicallyisolatedfromthesupply.

−The control and load lines of the connected drives must

bedouble-insulatedalongtheirentireroute.

10 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 11

Detailed circuit diagram for mains connection and

motor connection (230V / 1-phase / 0.75 kW)

X1

L

L

N

N

L1U

V

W

DC+ DC-

DC+ DC-

R+ R-

B1

B2

N

X21

F1

X19

F2.3

F2.2

F2.1

X11

X18

X2

A

C

B

3

M

230 V 50 Hz

/

/ /

1 N PE

5.2 / 1

Detailed circuit diagram for mains connection and

motor connection (230V / 1-phase / 1.5 kW)

N

L1

U

V

W

DC+ DC-

DC+ DC-

R+ R-

A

C

B

3

M

1L1 3L2 5L3

4T22T1 6L3

13N0

14N0

A1

A2

D

230 V 50 Hz

/

/ /

1 N PE

NL1PE

X0

5.2 / 2

Detailed circuit diagram for mains connection and

motor connection (400 V 3-phase / 1.5 kW / 2.2 kW)

V

X1

L2

L3

L1

N

W

U

L3

L1

L2

U

V

W

DC+ DC-

DC+ DC-

R+ R-

B1

B2

X21

F1

X19

F2.3

F2.2

F2.1

X11

X18

X2

A

C

B

3

400 V 50 Hz

/

/ /

3 N PE

M

5.2 / 3

Detailed circuit diagram for mains connection and

motor connection (400 V 3-phase / 4.0 kW)

L3

L1

L2

U

V

W

DC+ DC-

DC+ DC-

R+ R-

A

C

B

3

M

1L1 3L2 5L3

4T22T1 6L3

13N0

14N0

A1

A2

D

400 V 50 Hz

/

/ /

3 N PE

L3L2L1NPE

X0

5.2 / 4

Key:

A Brakeresistor(notforSTAandFDOrange)

B Brakemodule(notforSTAandFDOrange)

C Frequency converter

D Load contactor

M1: Motor

X1: Terminalblockformainsconnection

(with load contactor)

X1: Terminalblockformainsconnection

X2: Terminalblockformotor

X11: Connector strip for electronic limit position system

with safety circuit

X15: Terminalblockformechanicallimitswitches

(SafetycircuitatX2/B1-B2)

X19: Powersupplyconnectionforexternaldevices

Connection:

ConnectelectroniclimitpositionsystemtoX11,or

mechanicallimitswitchtoX15ofthecontroller.

Connectpowersupplyfrequencyinverter(A)toX2,orX10

of the controller.

Connectingthemotortothefrequencyconverter.

ConnectFU(C)datacabletoX18ofthecontrol.

Connect the control to the mains power supply.

Cablegroupsmustbesecuredclosetotheirrelevant

terminalsusingacabletie.

Check and compare technical data.

➔„13.Technicaldata“

Installation

10 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 11

EN

5.35.3 Internal fuse protectionInternal fuse protection

ThecontrollerCS320FUisequippedwithinternalfuse

protection (F2) at the mains input. The fuse elements are

equippedwithnefuses8A/T(5.2x20mm)inthefactory.

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

3

400 V / 50 Hz

/ N / PE

5.3 / 1

ATTENTION!

Malfunctions due to improper fuse protection of

the controller!

Internalfusemaximum10A/T!

The internal fuses do not replace fuse protection of the

supply cable. This shall be realised with max. 16 A and must

beconguredastripleblockcircuitbreakersoftypeC.

➔„5.2Mainsconnection“

5.45.4 Mains voltage selectionMains voltage selection

ThepositionofthebridgeconnectortoX21mustbeadjusted

tothesupplyvoltageandmotorvoltage.

PE

PE

PE

N

L3

L2

L1

X1

X21

3

400 V / 50 Hz

/ N / PE

F2.3

F2.2

F2.1

PE

PE

PE

N

L3

L2

L1

X1

X21

F1

X19

3

230 V / 50 Hz

/ PE

F2.1

F2.2

F2.3

AUF

ZU

PE

PE

PE

L

N

X1

X21

F1

X19

X11

X18

1

230 V / 50 Hz

/ N / PE

F2.1

F2.2

F2.3

5.4 / 1

PE

PE

PE

N

L3

L2

L1

X1

X21

3

400 V / 50 Hz

/ N / PE

F2.3

F2.2

F2.1

PE

PE

PE

N

L3

L2

L1

X1

X21

F1

X19

3

230 V / 50 Hz

/ PE

F2.1

F2.2

F2.3

AUF

ZU

PE

PE

PE

L

N

X1

X21

F1

X19

X11

X18

1

230 V / 50 Hz

/ N / PE

F2.1

F2.2

F2.3

5.4 / 2

12 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 13

5.55.5 Supply to external devicesSupply to external devices

(only with 400 V / 3-phase connection)(only with 400 V / 3-phase connection)

TheCS320FUhas2separatevoltagesuppliesforexternal

components,suchassignaldevices,lightbarriers,etc.

X19 230V/1~

X4 24V-DC

N

L3

L2

L1

X1

X21

X19

3

400 V / 50 Hz

max. 1A

230V-AC

max. 500mA

24V-DC

/ N / PE

X4

1

2

3

4

5

6

7

8

9

12

11

10

F1

-

+

L

N

5.5 / 1

NOTE:

UseoftheconnectionX19isonlypossiblewithasupplywith

400V / N / 3~.

TheconnectionX19isprotectedbythefuseelementF1

(max.1A/T).

5.65.6 Connection of electronic limit positionConnection of electronic limit position

system absolute value encoder (AWG)system absolute value encoder (AWG)

5.6 / 1

A

B

A: Absolutevalueencoderplug

B: AWGplug-interminal

Connector strip X11 (on connector A)

4 7

grey yellow

5 8

green pink

6 9

white brown

5.6 / 2 Cables with either numbered or

coloured wires are used for the AWG,

dependingonthedrive:

4(grey): Safetychaininput

5(green): RS485B

6 (white): GND

7 (yellow): RS485 A

8 (pink): Safety circuit output

9 (brown): 12V DC

Connector strip B (only absolute value encoder)

5.6 / 3

C: Thermal element in the drive

D: Emergencymanualactuation(emergencycrankor

emergencychain)

Installation

12 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 13

EN

NOTE:

In order to satisfy the requirements of EN 12453:2017 the

electronic end position system must comply as a minimum

withPL“c”withamin.category2perENISO13849-1.

In order to satisfy this requirement, it is only permissible to

use an absolute value encoder from MFZ (art. no. 97957) as

an electronic end position system.

5.75.7 Mechanical limit switch (MEC) connectionMechanical limit switch (MEC) connection

Alternatively to the absolute value encoder as an electronic

system, it is also possible to connect a mechanical cam limit

switch and evaluate this.

WithrstcommissioningandafteraRESET,theconnected

limit position system is automatically detected. With a

subsequentchange,therespectivelimitpositionsystemmust

beselectedviaaparametersettingintheINPUToperating

mode.

Series STA, MDF05, MTZ05

5.7 / 1 S1 S2 S3 S4 S5 S6

Series MDF20+, KD, MTZ20+

S1 S2 S3 S4 S5 S6

5.7 / 2

Mechanical limit switches

1

2

3

4

5

6

7

8

X15

S2

S5

S1

S6

5.7 / 3

Safety circuit

U

V

W

B1

B2

X2

S3

S4

S7

S8

5.7 / 4

14 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 15

Example of connection with 7-wire solution

1

2

3

4

5

6

7

8

U

V

W

B1

B2

X2

X15

S2

S5

S1

S6

S3

S4

S7

S8

5.7 / 5

Legend:

S1 Supplementary limit switch UP

S2 Limit switch UP

S3 Safety limit switch UP

S4 Safety limit switch DOWN

S5 Limit switch DOWN

S6 Supplementary limit switch DOWN

S7 Emergencyoperation(NC-contact)

S8 Motor thermal protection

NOTE:

In order to satisfy the requirements of EN 12453:2017 the

mechanical limit switches must have been approved as a

“reliablecomponent”inaccordancewithENISO13849-1.

Driveswithintegratedsafetycatchdevicemustnotbe

equipped with mechanical limit switches.

ATTENTION!

Property damage due to improper installation!

Connection as a 6-wire solution is prohibited and can lead

to destruction of the CS 320 circuit board.

ReferencepotentialonX2/B1-B2=24V-DC

ReferencepotentialonX15=12V-DC

1

2

3

4

5

6

7

8

S3 S4 S7 S8

S2

S5

S1

S6

U

V

W

B1

B2

X2

X15

5.7 / 6

Installation

14 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 15

EN

5.8 Connection of command devices

CAUTION!

Risk of injury due to uncontrolled door movement!

A CLOSE command in dead-man operation without a view

of the door is not permitted.

Install the command devices for the dead-man operation

Install the command devices for the dead-man operation

indirectvisualcontactwiththedoor,althoughoutside

indirectvisualcontactwiththedoor,althoughoutside

thedangerzonefortheoperator.

thedangerzonefortheoperator.

ACLOSEcommandwithoutvisualsightofthedoormay

onlybegivenviainput1/MOD32(X4/9-10).

If the command device is not a key switch:

Installitataheightofatleast1.5m.

Installitataheightofatleast1.5m.

Install it where it is inaccessible to the public.

Install it where it is inaccessible to the public.

Command devices (standard)

X3

A

B

C

D

E

5.8 / 1

Legend:

A Button / input DOWN

B Button / input impuls

C Button / input UP

(UP inside, with active two-way control)

D STOP button

E Emergencystopcommanddevice

UP / STOP / DOWN switch (6-wire solution)

X3

A

C

D

5.8 / 2

UP / STOP / DOWN switch (4-wire solution)

X3

A

C

D

5.8 / 3

IMPULS button

Selection of the function via IMPULS parameter

➔„11.2Inputoperatingmode“onpage41

B

X3

5.8 / 4

- UP switch

- STOP button

16 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 17

Cover keypad KDT

Push-button with NO / NC contacts.

Up to year of manufacture 12 / 2009.

X7X7

5.8 / 7

J

J Jumper(bridge)

The jumper must be connected if the KDT keypad is not

connected.

Cover keypad CS

Silicone keys with NO contacts.

From year of manufacture 01 / 2010.

X13

5.8 / 8

External radio receiver

1

2

3

4

5

6

7

8

9

10

X4 1

2

3

4

5

6

7

8

9

12

11

10

X19

X3

F1

24 V-DC

230 V-AC

*

5.8 / 5

*optionally,dependingonconnectionoftheradioreceiver

Key switch

A

C

X3

5.8 / 6

Legend:

A Button / input DOWN

C Button / input UP

(UP inside, with active two-way control)

Installation

16 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 17

EN

ON/OFF key switch

NCcontactforinterruptingthedoorfunction(optional).

This switch is part of the safety circuit.

X6X6

5.8 / 9

J

J Jumper(bridge)

The jumper must be connected if the key switch is not

connected.

5.95.9 Light grid connectionLight grid connection

Itispossibletoconnectupto2lightgridstotheCS320FU

Lightgrid1isconnectedtotheclosingedgeprotectivedevice

input.Lightgrid2isconnectedtoprogrammableinput2.

Light grid 1

ParameterSKS=MOD4

Theconnectioncable(A)ispluggable.

1

2

3

4

5

6

7

8

9

10

A

BK

BU

WH

BN

X4

GN

GY

11

12

5.9 / 1

Light grid 2

ParameterINPUT2=MOD12

Theconnectioncable(A)ispluggable.

1

2

3

4

5

6

7

8

9

10

A

BK

BU

WH

BN

X4

GN

GY

11

12

5.9 / 2

Legend:

BK Black

GN Green

GY Grey

BU Blue

WH White

BN Brown

R Receiver

T Transmitter

NOTE:

TheGridScan/ProlightgridsfromCedesareshownonan

exemplary basis in this manual.

TheGridScan/Prolightgridscorrespondto

− PerformanceLeveld,category2perENISO13849-1

−Protection level E per EN 12453:2017

Diagramsfromothermanufacturersoninquiry.

REFERENCE

For a precise description of the function and connection,

refertotheseparatedocumentationforthelightgrid.

18 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 19

5.10 Connection of closing edge protective

device 1

WithrstcommissioningandafteraRESET the system of

theclosingedgeprotectivedeviceisautomaticallydetected

andprogrammed.Ifnoclosingedgesystemisconnected,

the input is requested every time the power is switched on

againuntilaclosingedgesystemhasbeendetected.Witha

subsequentchange,therespectivesystemmustbeselected

viaaparametersettingintheINPUToperatingmode.Inthe

caseoflightbarrierswithatestfunction,thismustbe

set manually.

➔„11.2Inputoperatingmode“

Optoelectronic closing edge protective device (OSE)

ParameterSKS=MOD1

+

-

1

2

3

4

5

6

7

8

9

12

11

10

X4

WH

GN

BN

5.10 / 1

Legend:

WH White

GN Green

BN Brown

Electrical closing edge protection (8.2 kOhm)

ParameterSKS=MOD2

8k2

1

2

3

4

5

6

7

8

9

12

11

10

X4

5.10 / 2

Pneumatic closing edge protection (DW)

ParameterSKS=MOD3/testingautomaticallyactive

+

-

1

2

3

4

5

6

7

8

9

12

11

10

X4

5.10 / 3

Installation

18 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 19

EN

5.115.11 Connection light barrier 1Connection light barrier 1

Withrstcommissioningandafteraresetthelightbarrieris

automaticallydetectedandprogrammed.Ifnolightbarrier

system is connected, the input is requested every time the

powerisswitchedonagainuntilalightbarriersystemhas

beendetected.Withasubsequentchange,therespective

systemmustbeselectedviaaparametersettingintheinput

operatingmode.

Inthecaseoflightbarrierswithatestfunction,thismustbe

set manually.

➔„11.2Inputoperatingmode“

Light barrier 4-wire NC

withouttesting parameterLIGHTBARR1=MOD3

withtesting parameterLIGHTBARR1=MOD5

OUT

-

+

-

+

NC

1

2

3

4

5

6

7

8

9

12

11

10

X4

R

T

5.11 / 1

Light barrier MFZ 2-wire

withtesting parameterLIGHTBARR1=MOD1

2

1

2

1

1

2

3

4

5

6

7

8

9

12

11

10

X4

R

T

5.11 / 2

Light barrier 3 wire NPN

withouttesting parameterLIGHTBARR1=MOD2

withtesting parameterLIGHTBARR1=MOD4

OUT

-

+

-

+

NPN

1

2

3

4

5

6

7

8

9

12

11

10

X4

R

T

5.11 / 3

Light barrier 3 wire PNP

withouttesting parameterLIGHTBARR1=MOD3

withtesting parameterLIGHTBARR1=MOD5

OUT

-

+

-

+

PNP

1

2

3

4

5

6

7

8

9

12

11

10

X4

R

T

5.11 / 4

Legend:

R Receiver

T Transmitter

NOTE:

AlllightbarriersareactiveintheUPorDOWNdirection

dependingonthesetting.

➔„11.2Inputoperatingmode“(ParameterLBFUNC1)

20 – Control CS 320 FU / Rev.A 1.01 Control CS 320 FU / Rev.A 1.01 – 21

5.12 Terminal assignment, relay outputs

Four potential-free relay outputs are available, which can be

programmedwithavarietyoftypesoffunction.

➔„11.2Inputoperatingmode“

1

2

3

4

5

6

7

8

X5

5.12 / 1

- Relay 1

- Relay 2

- Relay 3

- Relay 4

Internal

relay switch

contacts

There are four potential-free relay outputs able to take a max.

load of 4A at 230 V/1~.

Thetypeoffunctiondependsontheparametersettingforthe

respectiverelayoutputintheINPUToperatingmode.

5.135.13 Connection of programmable inputsConnection of programmable inputs

ThecontrollerCS320FUhas3programmableinputs,for

which different functions can be selected.

Thetypeofwiringisdeterminedonthebasisofthe

parametersettingsfortheindividualinputs.

➔„11.2Inputoperatingmode“(ParameterINPUT1-3)

ATTENTION!

Danger of damage to the circuit board due to

incorrect connection!

Inputs 1, 2 and 3 have different reference potentials and

mustnotbeoperatedfromacommonpotential!

Input 1

OptionalwiringwithNO/NCcontacts.

Reference potential 24V-DC

➔„11.2Inputoperatingmode“(ParameterINPUT1)

*

X4

5.13 / 1

* optionally

Installation

Table of contents

Popular Controllers manuals by other brands

DEVI

DEVI DEVIlink CC installation guide

sirea

sirea MicroARM-A4 user manual

Angry Audio

Angry Audio BUTTON GIZMO Preliminary user guide

Samsung

Samsung MWR-WE13N Quick Reference Technical Handbook

BEIFANG VALVE ACTUATOR

BEIFANG VALVE ACTUATOR 920 Series instruction manual

Northern Lights

Northern Lights OGSC300 Operator's manual