Sirocco Eco4 MKIII Guide

1

Model

Design options

Apex, Adjusta, Aleda, Black-Watch, Cristal, Contemporary, Fairfield,

Liberty, Caledonian, Lux, Ignite, Maine, Mystique, Pinnacle, Sirius

Westerly, Verto

Installation and User Instructions

Please ensure you read both the Fire and the Fascia instructions before starting the

installation.

All instructions must be handed to

user for safekeeping

This is not a DIY product and must be

installed by a Gas Safe registered

installer

Edition D 05/17

Country(s) of destination - GB/IE

Eco4

MkIII

2

INSTALLATION INSTRUCTIONS

These Notes Must Be Read Before Installation

This appliance is an Inset Live Fuel Effect appliance that provides radiant or combined radiant

and convected heat; it cannot and should not be used as the main heating source within a

property.

The appliance is designed to fit most types of fireplaces with a natural draught flue as listed

in the Installation Requirements.

The appliance must be installed by a competent person in accordance with the Gas Safety

(Installation and Use) Regulations 1998.

A Gas Safety Registered installer must be used for this purpose.

Read all these instructions before any installation takes place and in conjunction with the

appliance on site.

This appliance must be installed in accordance with the rules in force and only used in a

sufficiently ventilated space.

This appliance is factory set and tested for operation on the gas type, and at the pressure

stated on the appliance data plate.

After a new gas appliance (excluding flueless cookers) has been fitted, the Building

Regulations in England and Wales require that the installation must be notified to your Local

Authority. Your Gas Safe registered engineer needs to do this, failure to register the appliance

may affect your warranty

OPENING THE APPLIANCE

Stand the carton the right way up, open the box from the top.

Read all the instructions before continuing to unpack or install this appliance.

Remove the bags containing ceramic components such as coals or gravel etc. Remove the

cardboard packing pieces, and any other bags or boxes containing fittings or other parts.

When all loose parts have been removed, the appliance may be lifted from the outer carton.

Check that the components supplied correlate with the component checklist below.

If for some reason any of the listed components are missing or damaged do NOT commence

with this installation, in doing so will invalidate your warranty.

Please dispose of all the packaging materials at your local recycling centre.

3

CONTENT CHECK LIST

Quantity

Description

1

Firebox and Burner Tray

1

Decorative Trim/Frame

1

Fire Fret/Front

1

Fuel Bed

1

Cable fixing kit; 1 cable, 1 tensioner, 1 cable clamps, 3 fixing eyes.

1

Lengths of adhesive sealing strip.

1

Set of manufacturer’s instructions and warranty card.

3

Raw Plugs

INSTRUCTIONS CONTENT

Section

Contents

Page No

1

Important Notes

4

2

Installation requirements

5

3

Appliance Information

6

4

Ventilation

7

5

Site Requirements

7 to 9

5.1

Pre-Fabricated Flue box

9

6

Debris Space

10

7

Installation of appliance

10 to 12

7.1

Preparing the Opening

13 to 15

7.2

Fitting the Burner Tray

16 to 17

8

Fuel Bed

17 to 22

9

Fitting the Outer Frame/ Trim

22

10

Commissioning the Appliance

23

10.1

Operating the Appliance

23

10.2

Spark Failure

23

11

Setting Pressure

24

12

Spillage Monitoring System

25

13

Testing for Spillage

25 to 26

14

Briefing the Customer

27

15

Servicing

27

16

Cleaning the Coals

28

17

Troubleshooting Guide

29

18

User Instructions

29 to 32

19

Warranty Details

33

20

List of Spares

34 to 38

Contact details

39 to 41

4

Section 1: IMPORTANT NOTES

This fire is an Inset Live Fuel Effect Gas Fire providing radiant warmth. It is designed to

operate on Natural Gas or LPG.

It is the LAW that all gas appliances and fittings are installed by a competent person such as

a Gas Safe Registered fitter and in accordance with the Gas Safety (Installation and Use)

Regulations 1998, the relevant British Standards for Installation, Codes of Practice and in

accordance with the manufacturers’ Instructions.

The installation shall also be carried out in accordance with the following regulations:

The Building Regulations issued by the Department of the Environment, the Building

Standards (Scotland)

(Consolidation) Regulations issued by the Scottish Development Department.

BS 1251

BS 4543 part2

BS 5440 parts 1&2

BS 5871 part 3

BS 6461 parts 1&2

BS 6891

BS 8303

Failure to comply with these regulations could lead to prosecution and deem the warranty

Invalid.

This appliance must be installed in accordance with the rules in force and used only in a

sufficiently ventilated space.

Consult all instructions before installation and use of this appliance.

The appliance must be registered once commissioned with the regulatory governing body.

This appliance is free from any asbestos material. Refractories and coal bed are constructed

from ceramic fibre.

Note - For Republic of Ireland, reference should be made to the relevant standards

governing installation, particularly in regard to flue sizing and ventilation. See

IS813, ICP3, IS327 and any other rules in force.

5

Section 2: INSTALLATION REQUIREMENT

This appliance MUST NOT be installed into a bathroom or shower room, or where steam may

be present.

An extractor fan must not be fitted in the same room or space as the appliance as this can

affect the safety of the appliance.

The fire has been designed to fit into a fireplace or builders opening conforming to BS 1251

(and meeting certain dimensional requirements), or a suitable flue box complying with the

constructional requirements of BS 715.

A natural draught flue system is required, and if previously used for solid fuel or oil burning,

the flue and chimney must be swept prior to appliance installation.

The flue must be checked before installation by using a smoke pellet or similar to ensure

proper draw and that leakage is not evident at any joints. Repair and re-test as necessary

before the appliance is installed.

Any flue box used must be installed onto a suitable non-combustible insulating surface at

least 12mm thick, covering the entire base area of the box.

The flue must have an effective height of at least three metres, as measured from the hearth

to the top of the flue.

Any flue damper plates or restrictors must be removed and no other restriction fitted to the

flue. Where removal is not practical, the restriction must be fixed in the fully open position.

The flue must be connected to only one fireplace, and the flue must not vent more than one

appliance.

There must be no opening in the flue apart from the one that the appliance is installed into,

and the one venting the gases into the air. A suitable terminal may be fitted, such as class

GC1, as regulations allow.

Some of our appliances have been tested for use in a pre-cast block flue complying with BS

1289.

In accordance with BS1289 part 1, pre-cast flues built with directly plastered faces (front or

rear) are not correctly installed as to ensure proper operation with any type of gas fire.

Depending on the flue construction, on occasions the temperature reached can cause

cracking of the surface plaster through no fault of the appliance.

An air gap or some form of insulation material should be installed to prevent normal flue

temperatures from damaging wall surfaces.

This appliance is suitable for use with a surrounding area or back panel of 150C minimum

rating.

Table of contents

Popular Fireplace Accessories manuals by other brands

Town & Country Fireplaces

Town & Country Fireplaces 22150051 instructions

Travis Industries

Travis Industries 33 DVI installation instructions

Lopi

Lopi Hearthview 864 user manual

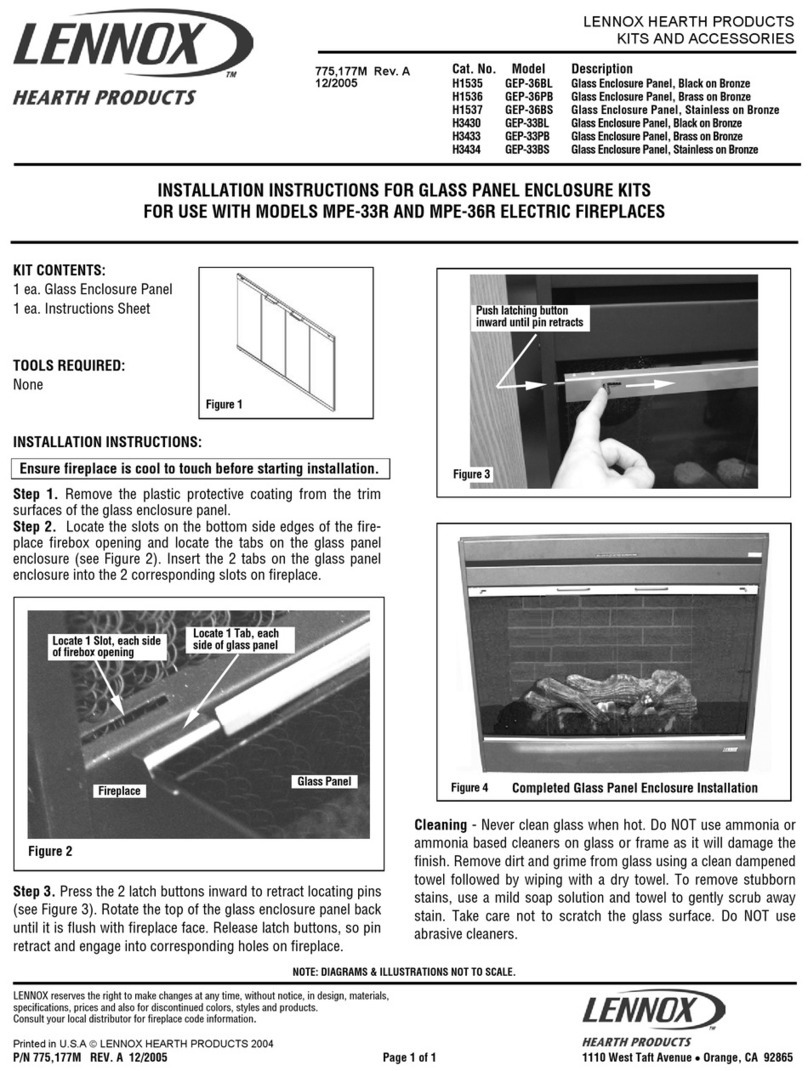

Lennox Hearth Products

Lennox Hearth Products LENNOX MPE-33R installation instructions

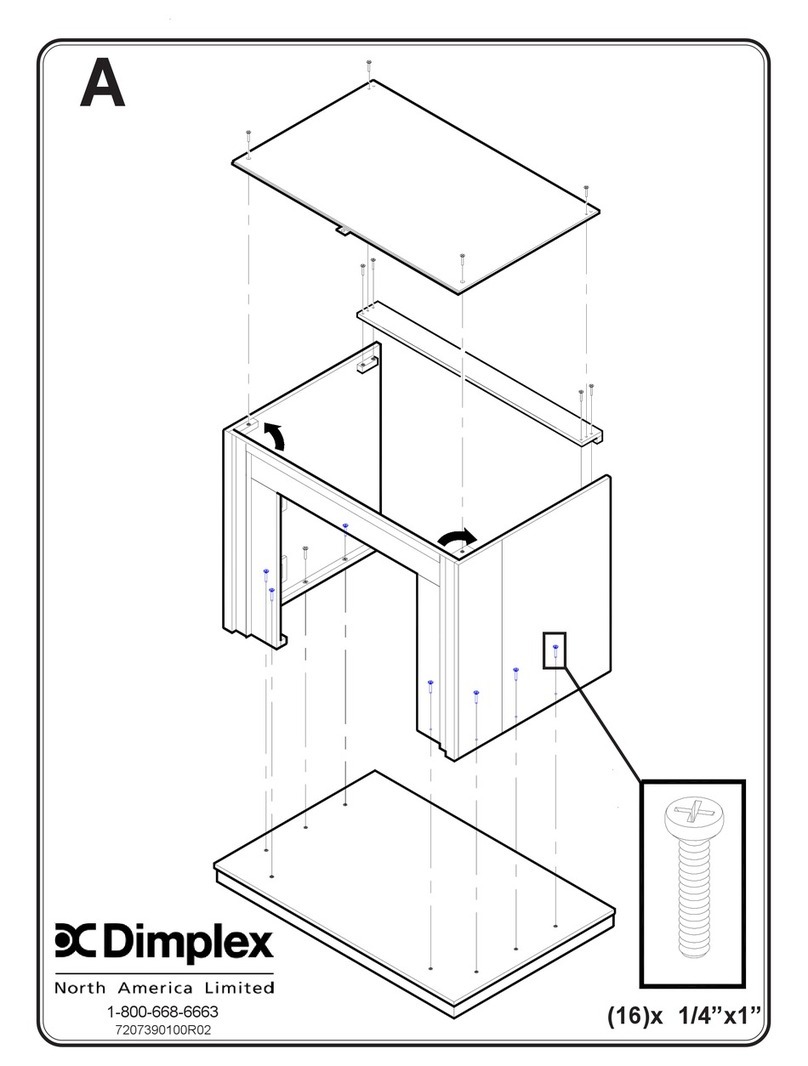

Dimplex

Dimplex DFP6776C install guide

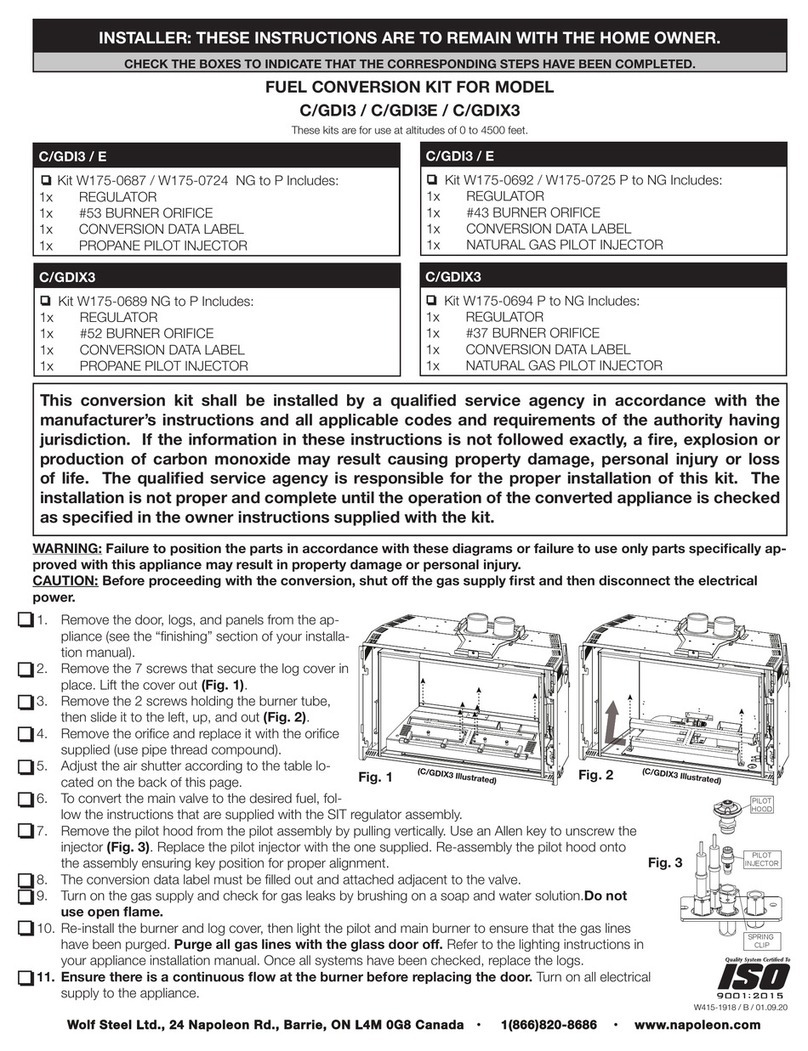

Napoleon

Napoleon W175-0689 instruction manual

Travis Industries

Travis Industries 95400424 installation instructions

Osburn

Osburn ZERO CLEARANCE KIT installation instructions

Majestic

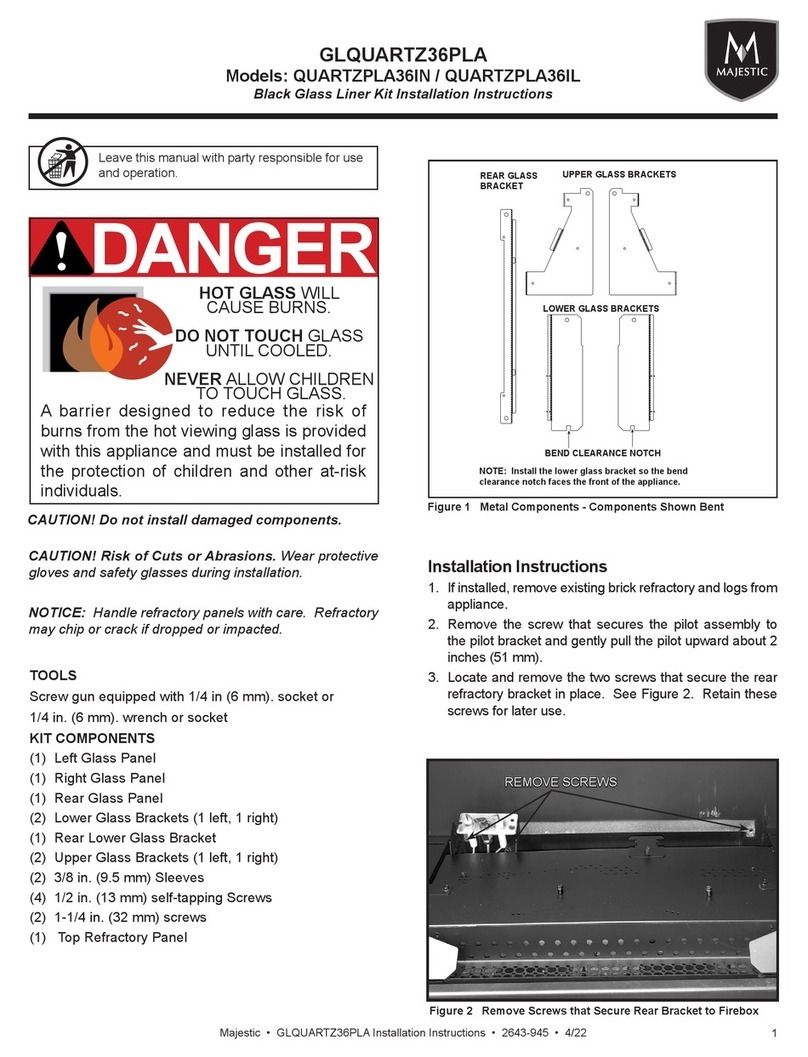

Majestic QUARTZPLA36IN installation instructions

Napoleon

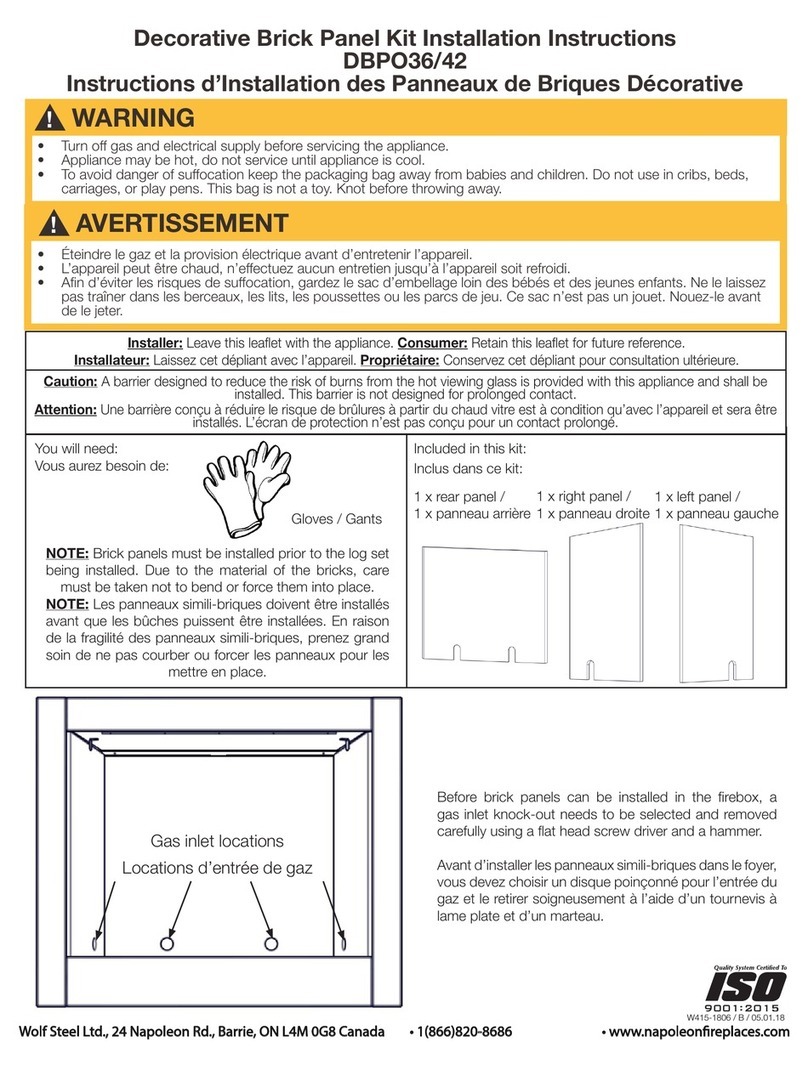

Napoleon DBPO36 installation instructions

Dimplex

Dimplex SMP-130-E install guide

Empire Comfort Systems

Empire Comfort Systems LS50TINF installation instructions