SIS SIS8300-KU User manual

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 1 of 92

SIS8300-KU

10 channel

125 MSPS 16-bit

MTCA.4 Digitizer

User Manual

SIS GmbH

Harksheider Str. 102A

22399 Hamburg

Germany

Phone:

++49 (0) 40 60 87 305 0

Fax:

++49 (0) 40 60 87 305 20

http://www.struck.de

Version: SIS8300KU-M-x002-1-V101.doc as of 09.03.2017

Struck Documentation

SIS8300-KU

µTCA 16-bit Digitizer

Page 2 of 92

Revision Table:

Revision

Date

Modification

0.01

24.10.2016

Based on SIS8300L2-M-x00D-1-V110 (Firmware: V100D)

0.02

25.10.2016

Chapter "Functionality" updated

Chapter "Block diagram" updated

Chapter "Platform Management" MMC scheme updated

Chapter "MGT clock" scheme updated

Chapter "Frontpanel" sketch updated

Chapter 5.1 changed from Harlink to "RJ45 In-/Outputs" and updated

Chapter "Board Layout" print and used connector table updated

Chapter "Firmware Options register" updated

Chapter "RJ45 connector... register" updated

Chapter "SIS8900 RTM LVDS ... register" updated

Chapter "Ordering Options" updated

Chapter "Zone 3 connector schematic" updated

0.03

09.11.2016

Chapter "Functionality" updated

0.04

12.12.2016

Register description update

0.05

Block diagram update

0.06

15.12.2016

Chapter "Overall Clock distribution" updated

Chapter "Interlock" updated

Chapter "SIS8900 RTM LVDS ... register" updated

1.00

13.01.2017

First official release

Based on firmware sis8300KU_x001

1.01

09.03.2017

Release related to firmware sis8300KU_x002 (IP sis8300KU_x802 )

Added feature in firmware:

-FPGA Boot SPI Flash interface to update the FPGA Boot Flash via PCIe

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 3 of 92

- Table of contents

-Table of contents............................................................................................................................................. 3

1Introduction..................................................................................................................................................... 5

1.1 Related documents .................................................................................................................................. 5

2Design............................................................................................................................................................. 6

2.1 Functionality ........................................................................................................................................... 6

2.2 Block Diagram........................................................................................................................................ 6

2.3 Platform Management............................................................................................................................. 7

2.3.1 E-Keying ......................................................................................................................................... 7

2.3.2 MMC sensors.................................................................................................................................. 8

2.3.3 MMC firmware upgrade.................................................................................................................. 8

2.4 SPI Connectivity ..................................................................................................................................... 9

2.5 JTAG Connectivity ............................................................................................................................... 10

2.6 ADC Temperature Sensors.................................................................................................................... 10

2.7 DAC...................................................................................................................................................... 11

2.8 Clock Distribution................................................................................................................................. 12

2.8.1 Overall Clock Distribution............................................................................................................ 12

2.8.2 DAC Clock.................................................................................................................................... 13

2.8.3 µRTM Clock Overview................................................................................................................. 13

2.8.4 TCLK Clock Overview................................................................................................................. 13

2.8.5 AMC_TCLK on Zone 3................................................................................................................ 14

2.8.6 MGT Clock ................................................................................................................................... 15

3Jumper/Connector Pin Assignments ............................................................................................................. 16

3.1 CON100 JTAG ..................................................................................................................................... 16

3.2 J604 Watchdog Reset............................................................................................................................ 16

3.3 J32 AVR JTAG..................................................................................................................................... 17

3.4 J33 ATxmega128 Debug....................................................................................................................... 17

4LEDs............................................................................................................................................................. 18

4.1 Module Management LEDs .................................................................................................................. 18

4.2 Front Panel LEDs.................................................................................................................................. 18

4.3 SMD LEDs............................................................................................................................................ 19

5Front panel .................................................................................................................................................... 20

5.1 RJ45 LVDS In-/Outputs........................................................................................................................ 21

5.2 SMA Clock Input................................................................................................................................. 22

5.3 SFP Card Cage...................................................................................................................................... 22

6Board Layout ................................................................................................................................................ 23

7Firmware Description ................................................................................................................................... 24

7.1 ADC Sample Logic............................................................................................................................... 24

7.2 Memory Interface.................................................................................................................................. 25

7.2.1 Memory Write Interface................................................................................................................ 26

7.3 Memory buffer ...................................................................................................................................... 27

7.4 Address Map ......................................................................................................................................... 28

7.5 Register description............................................................................................................................... 30

7.5.1 Module Id. and Firmware Revision register.................................................................................. 30

7.5.2 Serial Number register .................................................................................................................. 30

7.5.3 User Control/Status register ......................................................................................................... 31

7.5.4 Firmware Options register............................................................................................................. 32

7.5.5 ADC Temperature Sensor interface register ................................................................................. 33

7.5.6 Firmware Options register............................................................................................................. 34

7.5.7 ADC Acquisition Control/Status register..................................................................................... 35

7.5.8 ADC Sample Control register ....................................................................................................... 36

7.5.9 MLVDS Input/Output Control register ......................................................................................... 37

7.5.10 RJ45 Connector Input/Output Control register ............................................................................. 38

7.5.11 SFP1 Link Control/Status register................................................................................................. 39

7.5.12 SFP2 Link Control/Status register................................................................................................. 40

7.5.13 Port12 Link Control/Status register............................................................................................... 41

7.5.14 Port13/14/15 Link Control/Status register..................................................................................... 42

Struck Documentation

SIS8300-KU

µTCA 16-bit Digitizer

Page 4 of 92

7.5.15 DAC Trigger Control register ....................................................................................................... 43

Synch-Mode = 1: Both DACs are triggered synchronous with DAC1 “Start-logic” ................................... 43

7.5.16 Clock Distribution Multiplexer control register............................................................................ 44

7.5.17 Clock Distribution AD9510 Serial Interface (SPI) interface register............................................ 46

7.5.18 Clock Multiplier IC SI5326 SPI interface register....................................................................... 48

7.5.19 Clock Synthesizer IC Si5338A I²C interface register.................................................................... 49

7.5.20 FPGA Boot SPI Flash interface..................................................................................................... 50

7.5.21 DAC Control register .................................................................................................................... 51

7.5.22 DAC Data register......................................................................................................................... 52

7.5.23 RTM I2C interface register ........................................................................................................... 53

7.5.24 ADC Serial Interface (SPI) interface register................................................................................ 54

7.5.25 ADC Input Tap delay register ....................................................................................................... 55

7.5.26 DAC Trigger and DAC_CLK prescaler setup register.................................................................. 56

7.5.27 DAC RAM endpoint register ........................................................................................................ 57

7.5.28 Trigger registers ............................................................................................................................ 58

7.5.29 Memory Sample Start Block Address / Actual Sample Block Address registers.......................... 61

7.5.30 Sample Block Length register....................................................................................................... 62

7.5.31 Ringbuffer Delay register.............................................................................................................. 62

7.5.32 SIS8900 RTM LVDS Test Input/Output Control register............................................................. 63

7.5.33 Read DMA System Destination address (lower 32bits)................................................................ 65

7.5.34 Read DMA System Destination address (upper 32bits)................................................................ 65

7.5.35 Read DMA Card Memory Source address.................................................................................... 65

7.5.36 Read DMA Transfer length........................................................................................................... 66

7.5.37 Read DMA Control....................................................................................................................... 66

7.5.38 Readout DMA Sample byte swap ................................................................................................. 67

7.5.39 Write DMA System Source address (lower 32bits) ...................................................................... 68

7.5.40 Write DMA System Source address (upper 32bits) ...................................................................... 68

7.5.41 Write DMA Card Memory Destination address............................................................................ 68

7.5.42 Write DMA Transfer length.......................................................................................................... 69

7.5.43 Write DMA Control ...................................................................................................................... 69

7.5.44 Write DMA maximal number of Outstanding Requests ............................................................... 69

7.5.45 DAQ Done DMA Chain Control................................................................................................... 70

7.5.46 IRQ Enable.................................................................................................................................... 70

7.5.47 IRQ Status..................................................................................................................................... 71

7.5.48 IRQ Clear...................................................................................................................................... 71

7.5.49 IRQ Refresh .................................................................................................................................. 71

7.5.50 Memory test mode register............................................................................................................ 72

7.6 External register interface ..................................................................................................................... 73

7.7 User Blockram DMA Interface............................................................................................................. 75

7.8 User Interrupt Interface......................................................................................................................... 76

8µRTM management ...................................................................................................................................... 77

9FPGA Firmware upgrade.............................................................................................................................. 78

9.1 JTAG Firmware Upgrade procedure..................................................................................................... 78

9.1.1 Use of Xilinx Vivado Hardware Manager..................................................................................... 78

9.2 Linux tool ‘flashupdater’....................................................................................................................... 80

9.3 Linux tool ‘ipmitool’............................................................................................................................. 80

9.4 Linux workaround for PCIe-Hot-Plug .................................................................................................. 81

10 Appendix................................................................................................................................................... 82

10.1 Power Consumption.............................................................................................................................. 82

10.2 Ordering options.................................................................................................................................... 82

10.3 SFP+ Accessories.................................................................................................................................. 82

10.4 Zone 3 connectors J30 and J31 ............................................................................................................. 83

10.4.1 J31 connector pin assignments...................................................................................................... 83

10.4.2 J30 connector pin assignments...................................................................................................... 83

10.5 Note on AC/DC input stage selection ................................................................................................... 85

10.5.1 Interlock ........................................................................................................................................ 87

10.6 Zone 3 connector schematic.................................................................................................................. 88

10.7 MMC Readme file................................................................................................................................. 89

11 Index ......................................................................................................................................................... 90

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 5 of 92

1 Introduction

The SIS8300-KU is a 10 channel 125 MS/s digitizer with 16-bit resolution according to the

MTCA.4 standard.

SIS8300-KU

Note: While the SIS8300-KU is Kintex Ultrascale based you will find many Virtex 5/6 references in

the firm- and software for historical reasons (i.e. remnants from the SIS8300_V2 and SIS8300L2

designs).

As we are aware, that no manual is perfect, we appreciate your feedback and will incorporate proposed

changes and corrections as quickly as possible. The most recent version of this manual can be obtained

from our Dokuwiki at www.struck.de/dokuwiki. Please direct account requests to info@struck.de.

1.1 Related documents

A list of available firmware designs can be retrieved from http://www.struck.de/SIS8300firm.html

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 6 of 92

2 Design

The central building block of the SIS8300-KU card is a Xilinx Kintex Ultrascale FPGA. It holds the 4

lane PCI Express interface and is in control of all active components.

2.1 Functionality

The key properties of the SIS8300-KU card are listed below.

AMC .4 µTCA for Physics Board

4 Lane PCI Express Gen3 Interface

Dual zSFP+ Card Cage for optional Multi Gigabit Link

Xilinx Kintex Ultrascale FPGA

DDR4 Memory Interface

4 x 4Gbit default DDR4 memory size

ATxmega128A1U Microcontroller IPMI

External Clock and Trigger Inputs

Front panel digital I/O (4in/4 out) on RJ45 Connectors

µRTM ADC Analog Inputs, I²C-Bus, DAC Analog Outputs

10 ADC Channels 125MS/s, 16-Bit

2 DAC Channels 250MS/s, 16-Bit

Clock distribution with phase shifting

4 M-LVDS µTCA Ports

2 µTCA Clocks

White Rabbit Option (depends on assembly)

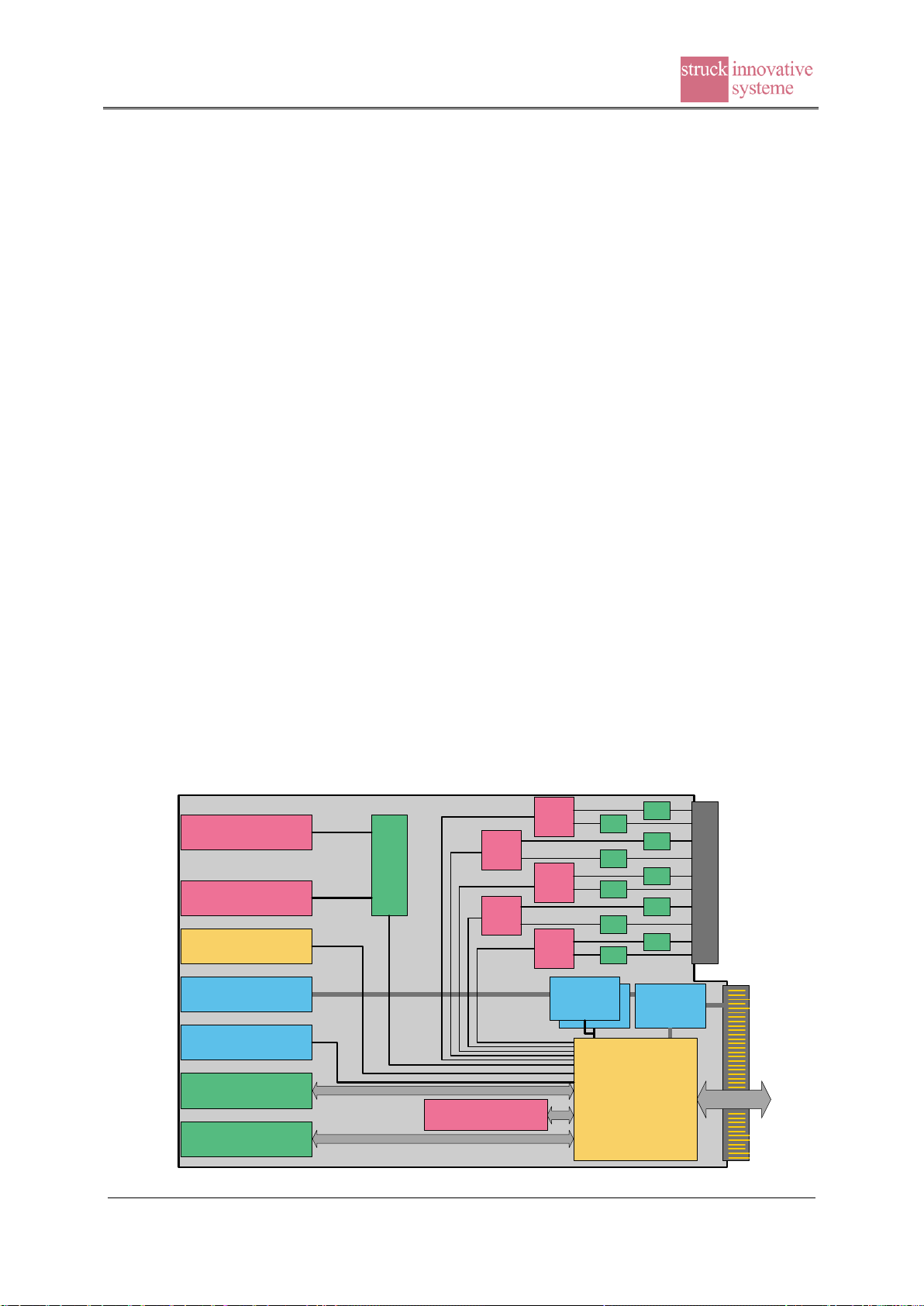

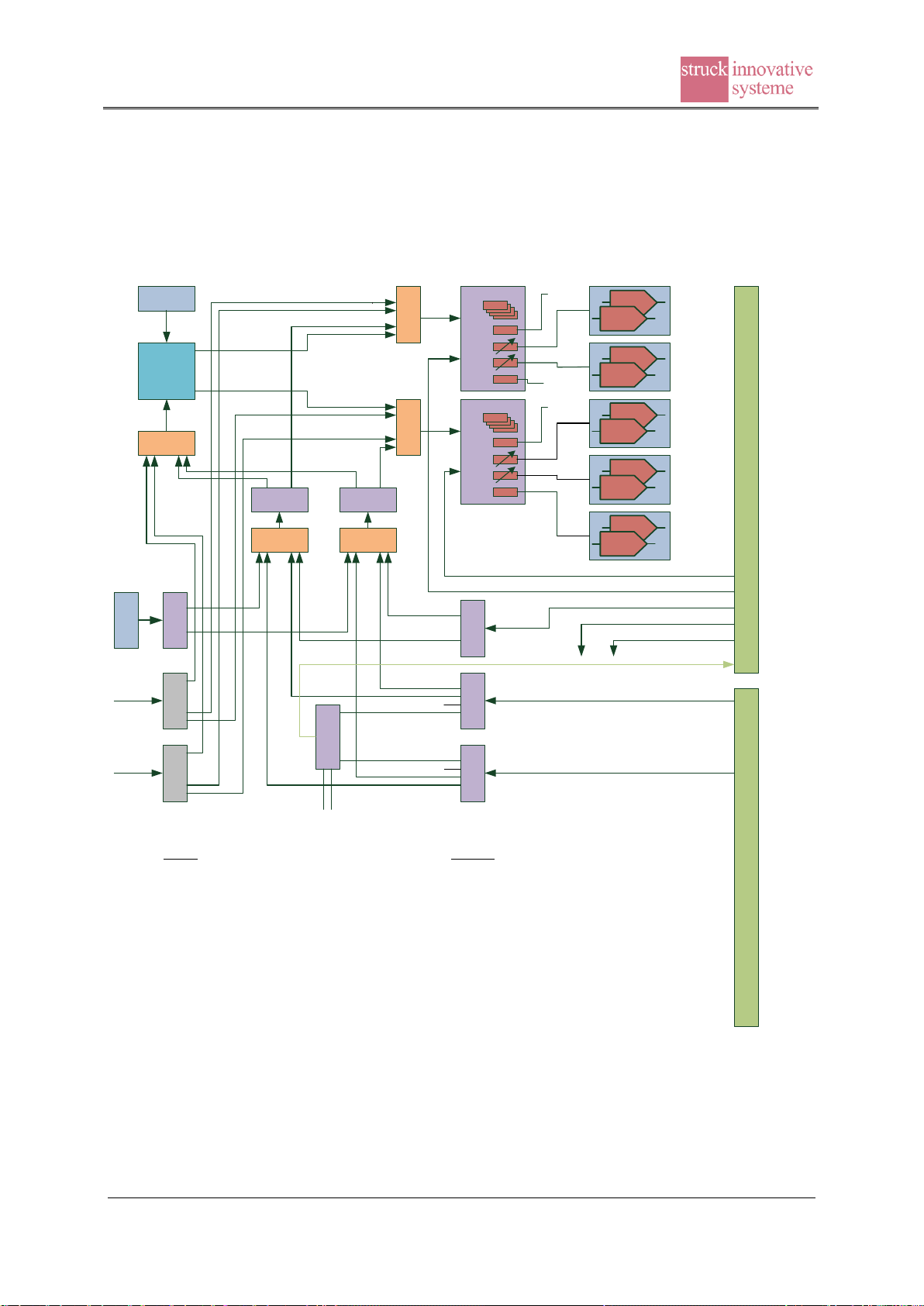

2.2 Block Diagram

A simplified block diagram of the SIS8300-KU is shown below.

SFP+

2 Ch DAC Out

Digital I/O

Kintex

Ultrascale

FPGA

SERPROM IPMI

SFP+

Ext Clock,

SMA

Dual

ADC

Ext Clock, Trigger,

LVDS

DDR4 Memory

IS

Clock

Distribution

IS

IS

Dual

ADC

Dual

ADC

Dual

ADC

Dual

ADC

IS

IS

IS

IS

IS

IS IS

LEDs/Switch SERPROM

BS

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 7 of 92

2.3 Platform Management

The Module Management Controller (MMC) functionality of the SIS8300-KU is implemented in an

Atmel ATxmega128A1U-CU microcontroller. The management code is based on the DESY MMC

V1.00 management software solution(*). It can be upgraded in two different ways (please refer to

section 2.3.3).

(*) The DESY Module Management Controller (MMC) software is licensed to Struck Innovative

Systeme GmbH under DESY LV92. Please, refer to the readme file in the appendix of this manual

also.

The MMC scheme of the SIS8300-KU is illustrated below.

Zone 3 ConnectorAMC Connector

FPGA

I2C Isolation

Control

SIS8300-KU

+3.3V / +12V

Power

Supplies

MMC

ATxmega128

FRU EEPROM

JTAG

Front

Panel

Temp.

Sensors Unique

ID Serial

Port

Power

Switch

I2C

Isolator

Driver

x

Power Control

and Monitoring

Management Bus

Isolation Control

Hot-plug and Status

Local I2C Bus

Debug

Management Bus

Presence Detect

Geographic Address

TCLK / ILOCK

Isolation Control

Power Control

and Status

JTAG

Isolator

Optional

AMC_TCLK

ILOCK

JTAG Isolation

Control

FPGA

User IO

Bus

Presence Detect

2x

EEPROM

FPGA Configuration

Upload

FPGA Config

Select

RTM I2C Bus

FPGA

User IO

FPGA

User IO

2.3.1 E-Keying

An Electronic Keying mechanism is used to provide correct connection and setup of point-to-point

fabrics and clocks for AMC modules in example. E-Keying information of the SIS8300-KU is stored

in the MMC as FRU information. It will be communicated to the MCH at power up. E-Keying entries

in the FRU information of the SIS8300-KU match the FPGA design at shipment version and are fixed.

If you change the FPGA design and/or make a custom FPGA design it can be necessary to change part

of the FRU information also.

The use of incorrect FRU information can result in unexpected behaviour.

Please contact us in case you need detailed information on SIS8300-KU E-Keying.

More information on this issue is planned for future additions to the documentation.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 8 of 92

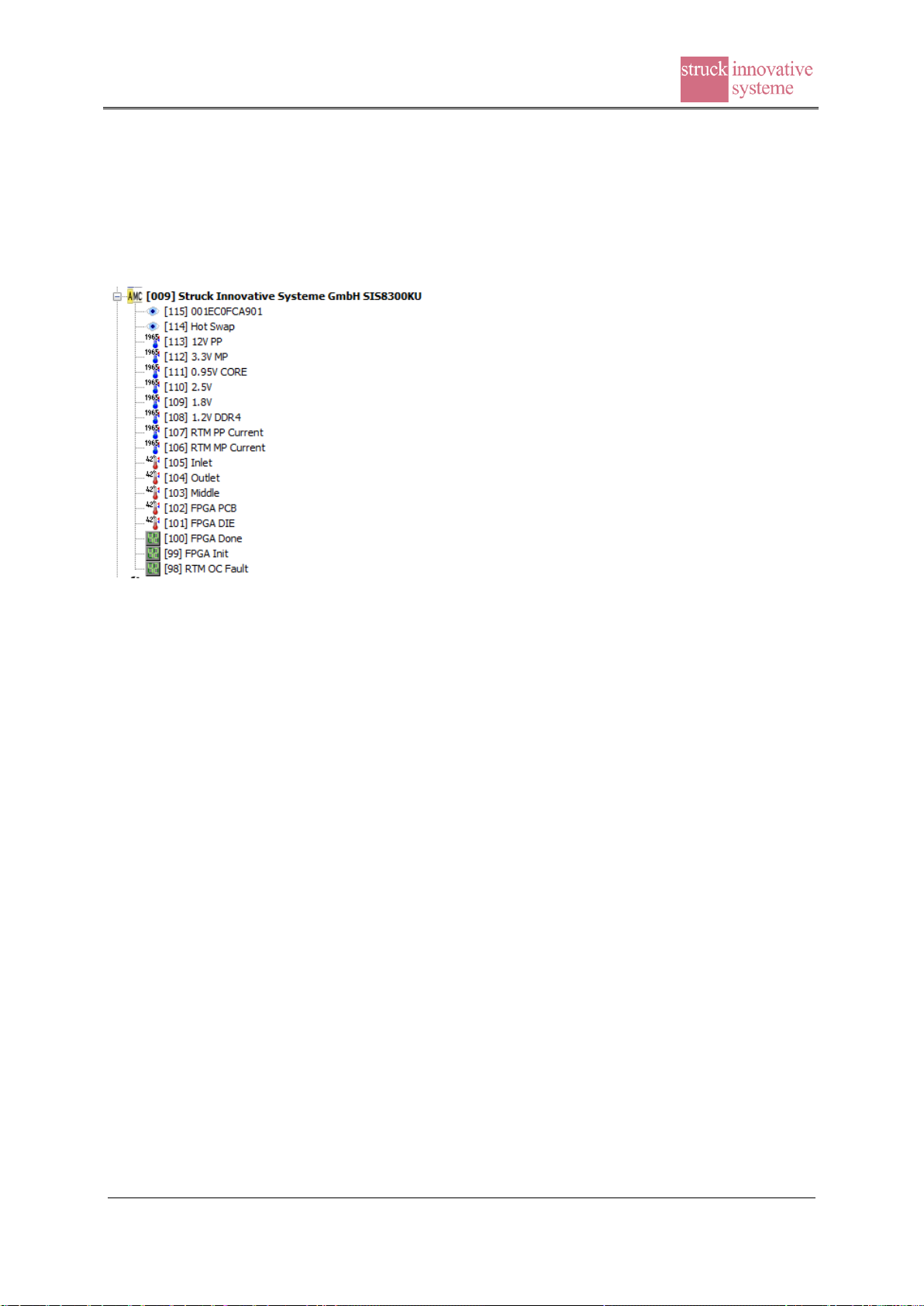

2.3.2 MMC sensors

Different sensors are connected to the MMC. They are giving information about temperatures,

voltages, currents and states. An additional memory with unique ID is available for board

identification purposes.

An overview of all existing SIS8300-KU MMC sensors –as seen with NATView- is illustrated below.

Note: On SIS8300-KU further temperature sensors exist, please see section 2.6.

2.3.3 MMC firmware upgrade

The MMC firmware can be upgraded in field over connector J32 or can be uploaded via

IPMI.

To upgrade in field you need an AVR programming tool, i.e. AVR JTAGICE mkII. After

connecting to connector J32 (please refer to section 3.3) the MMC can be upgraded using

Atmel-Studio software.

The more comfortable means for an upgrade is the upload of the MMC code over IPMI.

This can be done with the LINUX software ipmitool.

Syntax:

ipmitool -I lan -H <IP-MCH> -P "" -B 0 -b 7 -T 0x82 -t <Slot>

hpm upgrade SIS8300KU_VersionID.hpm

Slot: 0x72 (1st slot), 0x74 (2nd slot), 0x76 (3rd slot), ...

for example:

ipmitool -H 192.168.115.62 -P "" -B 0 -b 7 -T 0x82 -t 0x74 hpm upgrade SIS8300KU_VersionID.hpm

ipmitool -H 192.168.115.62 -P "" -B 0 -b 7 -T 0x82 -t 0x74 mc info

To verify, that the MMC was upgraded successfully, mc info can be read to check the MMC

code version.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 9 of 92

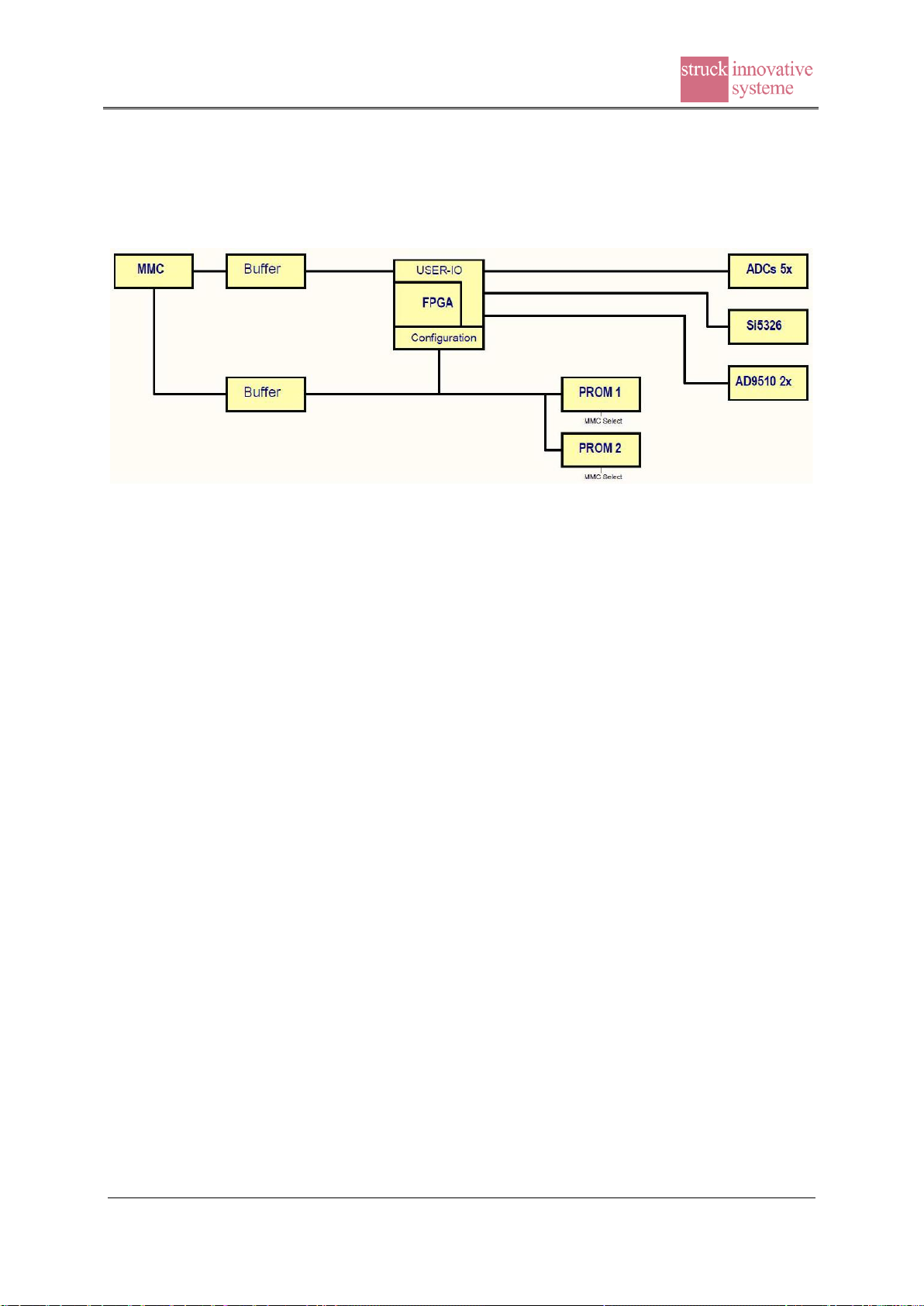

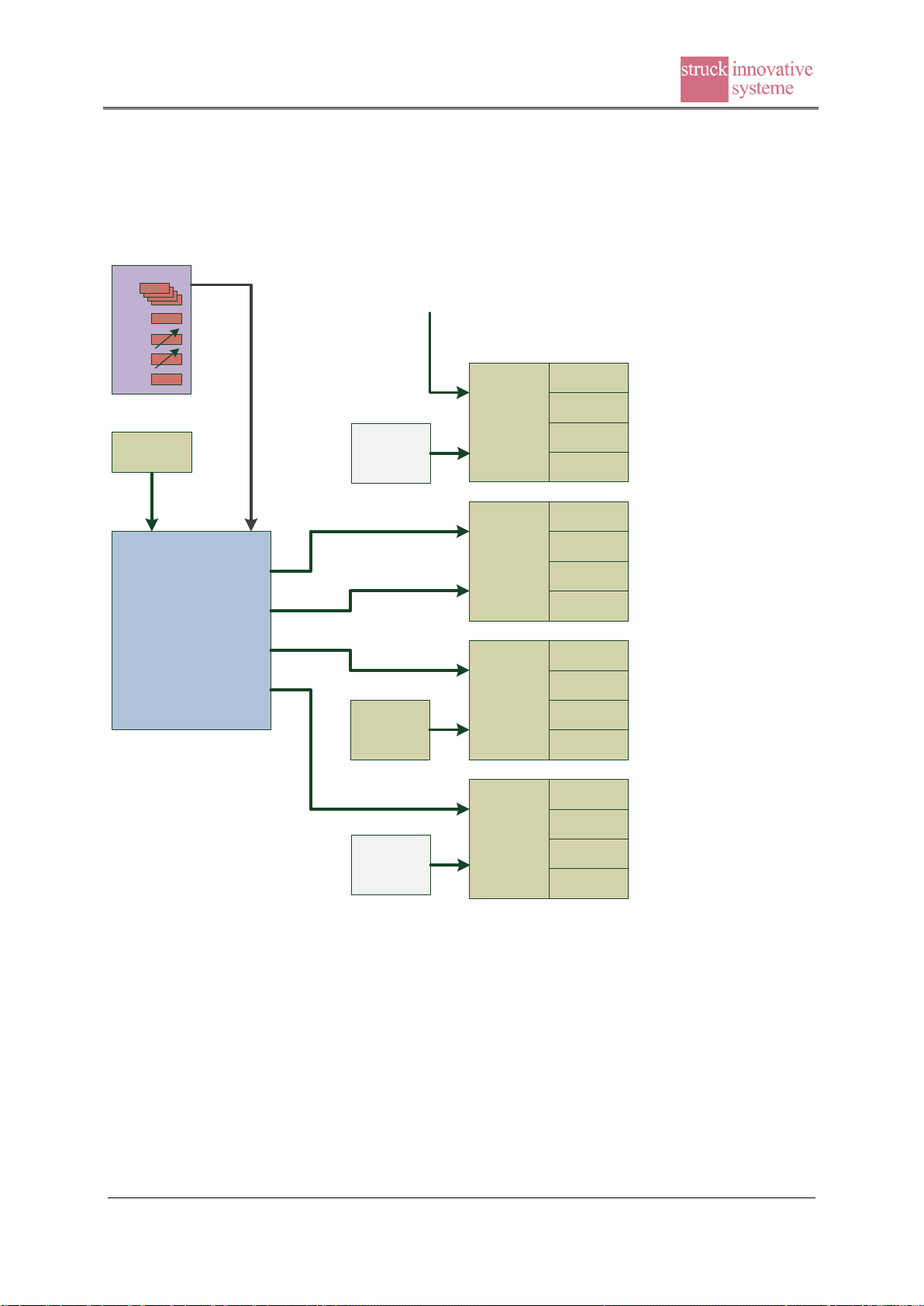

2.4 SPI Connectivity

The SPI bus connectivity scheme of the SIS8300-KU is illustrated below.

The SIS8300-KU has two SPI EEPROMs, that can hold FPGA configuration data. So it is

possible to choose from two firmware designs for the configuration of the FPGA. The

selection of the SPI EEPROM is under control of the MMC and can be changed per IPMI

command.

The ipmitool command line to set one of the Flashes as boot file source looks like:

ipmitool -I lan -H <IP-MCH> -P "" -B 0 -b 7 -T 0x82 -t <Slot>

raw 0x30 0x01 <Flash>

Flash: 0x00 (Basic-FLASH), 0x01 (Second-FLASH)

Slot: 0x72 (1st slot), 0x74 (2nd slot), 0x76 (3rd slot), ...

Verification:

ipmitool -I lan -H <IP-MCH> -P "" -B 0 -b 7 -T 0x82 -t <Slot>

raw 0x30 0x00

Result:

00 : Basic-FLASH selected

01 : Second-FLASH selected

IPMI raw command to reset the FPGA:

ipmitool -I lan -H <IP-MCH> -P "" -B 0 -b 7 -T 0x82 -t <Slot>

raw 0x30 0xFF

The user has to take special care to avoid concurrent access to the SPI EEPROM from

different sides (via PCIe and IPMI).

The SPI EEPROMs can be flashed via a JTAG-Programmer, PCIe or IPMI with appropriate

tools. Please refer to section 9 for more information about flashing the SPI EEPROM.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 10 of 92

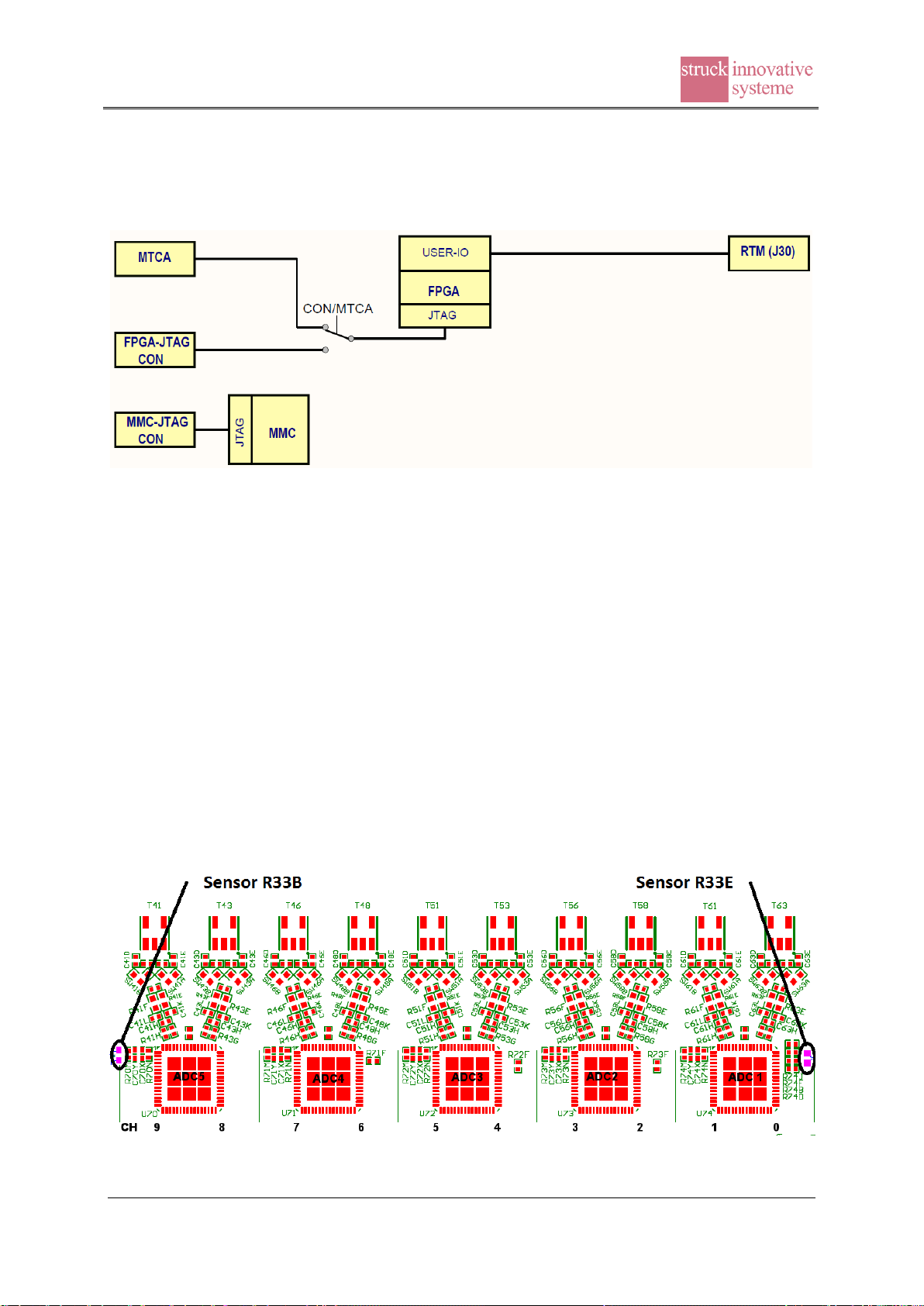

2.5 JTAG Connectivity

The JTAG connectivity scheme of the SIS8300-KU is illustrated below.

JTAG connection to µRTM can be realized in FPGA firmware but is a optional feature for

future.

Switching connection of FPGA hardware JTAG port between MTCA (AMC Backplane) and

on board JTAG connector (illustrated switch CON/MTCA) can be made via IPMI command.

IPMI command ... (not implemented yet, please request us for more information)

Upon power up the switch CON/MTCA connects the JTAG connector to the JTAG port of

the FPGA hardware.

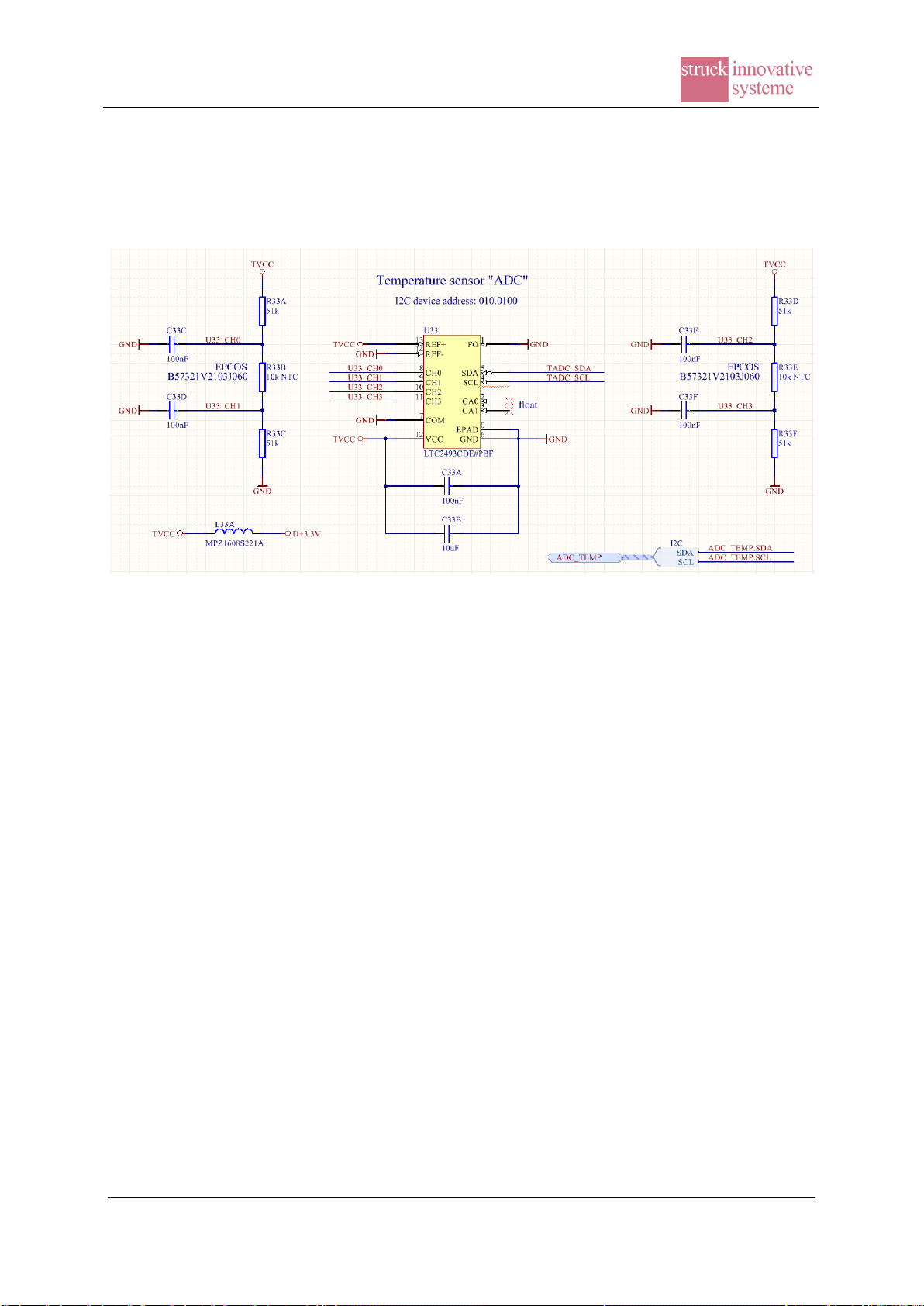

2.6 ADC Temperature Sensors

Two thermistor based sensors are used to measure the temperature at the beginning and the

end of the row of the 5 digitizer chips.

The location of both sensors on the bottom side as seen from the top is shown below.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 11 of 92

The sensor signals are measured by the 24-bit ΣΔ-ADC LTC2493, which is connected to the

Kintex Ultrascale FPGA via an I²C interface.

The schematic of the ADC temperature sensor circuitry is illustrated below.

Note: please refer to section 7.5.5 for a description of the I²C interface register

Please refer to device datasheet for additional information on the LTC2493 chip.

A software example can be found on the Struck product DVD under:

sisdvd_xxxxxx\sis8xxx and DWC\sis8300L\software\tests\adc_temp

2.7 DAC

A part of the SIS8300-KU versions comes with the 250 MSPS MAX5878 dual DAC chip.

The dual DAC can be used to control the Vectormodulator on the DWC8VM1

Downconverter/Vectormodulator RTM over the Zone 3 connector for example. The two DAC

channels can be routed to two front panel SMA outputs also (stuffing option). The table in

section 10.2 (ordering options) lists a number of DAC configurations of the SIS8300-KU.

Modules configured as DAC to FP outputs route the two DAC outputs over signal

conditioning stages to the two front panel SMA connectors. The default range of the DAC

outputs over the SMA connectors is -1V,…,+1V into a 50 Ω load.

On modules configured with DAC to Z3, the outputs of the DAC are directly connected to the

Zone 3 connector without any additional components. Since each DAC channel outputs two

complementary currents, appropriate signal conditioning has to be done on the µRTM.

Refer to the datasheet of the MAX5878 for further information.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 12 of 92

2.8 Clock Distribution

2.8.1 Overall Clock Distribution

The clock distribution scheme of the SIS8300-KU is illustrated below.

ADC

ADC

ADC

ADC

ADC

ADC

ADC

ADC

ADC

ADC

ΔT

ΔT

AD9510

ΔT

ΔT

AD9510

FPGA

CLK05

Ch0

Ch1

Ch9

RTM_CLK1

RTM_CLK0

ADCLK925

µRTM

RTM_CLK2

ADCLK944

EXTCLKA

SMA

TCLKB

Backplane

MUX BMUX A

ADCLK925 ADCLK946 ADCLK946

Quartz

ADCLK925ADCLK925

MUX D MUX E

MUX C

SI5326

EXTCLKB

RJ45

TCLKA

3

2

0

1

1

3

2

0

3

2

0

1

3 1 2 0 3 1 2 0

#1

#2 FPGA

CLK69

AMC_TCLK

ADCLK944

Quartz

(optional)

RTM_CLK4

RTM_CLK5

to FPGADAC Clock

DS25CP152

select

enable

under MMC Control

7

6

5

4

4

5

6

1

2

1

2

RJ45

CLK

7

1

1

2

Inputs:

MUX D àAD9510-#2_CLK1

RTM_CLK1 àAD9510-#2_CLK2

MUX E àAD9510-#1_CLK1

RTM_CLK0 àAD9510-#1_CLK2

Outputs:

AD9510-#2_OUT7 àFP_RJ45_E

AD9510-#2_OUT6 àADC4_CLK

AD9510-#2_OUT5 àADC5_CLK

AD9510-#2_OUT4 àFPGA_CLK69

AD9510-#2_OUT3 àN/A

AD9510-#2_OUT2 àN/A

AD9510-#2_OUT1 àFPGA_MGT_CLK

AD9510-#2_OUT0 àDIV1_OUT0 (DAC_MUX)

AD9510-#1_OUT7 àADC1_CLK

AD9510-#1_OUT6 àADC2_CLK

AD9510-#1_OUT5 àADC3_CLK

AD9510-#1_OUT4 àFPGA_CLK05

AD9510-#1_OUT3 àN/A

AD9510-#1_OUT2 àN/A

AD9510-#1_OUT1 àN/A

AD9510-#1_OUT0 àDIV0_OUT0 (DAC_MUX)

Depending from ordering options a 114.285 MHz clock will be populated. This external

reference is required for the SI5326 to perform jitter attenuation. Please refer to the SI5326

datasheet and section 10.2.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 13 of 92

2.8.2 DAC Clock

The DAC clock scheme of the SIS8300-KU is illustrated below.

FPGA DAC

DAC MUX

BUFFER

0

1

ΔT

ΔT

AD9510

#1

#2

ΔT

ΔT

AD9510

2

µRTM

3

RTM_CLK4

DIV0_OUT0

DIV1_OUT0

FPGA_FB

FPGA_CLK

DAC_CLK

16 DATA

DAC_SELIQ

0

0

2.8.3 µRTM Clock Overview

The µRTM clock overview table is shown below.

Clock

Usage

RTM_CLK0

Ultra low jitter clock 1 ADC group 1

RTM_CLK1

Ultra low jitter clock 2 ADC group 2

RTM_CLK2

Clock switch yard

RTM_CLK3

Not used

RTM_CLK4

DAC Clock

RTM_CLK5

Connected to FPGA via clock buffer

2.8.4 TCLK Clock Overview

An overview on the TCLK clocks is shown in the table below.

Clock

Usage

TCLKA

MUX switch yard and Zone 3 AMC_TCLK

TCLKB

MUX switch yard and Zone 3 AMC_TCLK

TCLKC

Not used, can be 100 Ω terminated if needed

TCLKD

Not used, can be 100 Ω terminated if needed

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 14 of 92

2.8.5 AMC_TCLK on Zone 3

The AMC_TCLK signal can be derived from TCLKA or TCLKB. Selection and output

control of AMC_TCLK switch is under control of MMC. Currently the state of both signals

can be read from SIS8900 RTM LVDS Test Input/Output Control register, please refer to

section 7.5.32.

The TCLKA or TCLKB selection and switch output control can be made per IPMI command:

<IPMI> raw 0x30 0x03 0xEC

(E=1/0: TCLK active/deactivated, C=0/1: select TCLKA/TCLKB)

The status can be read back with the command:

<IPMI> raw 0x30 0x02

After power up TCLKA is selected per default.

AMC_TCLK signal is available for SIS8300-KU with Zone 3 class compatibility A1.1CO

and A1.0C only. Please refer to section 10.4.2.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 15 of 92

2.8.6 MGT Clock

The MGT (Multi Gigabit Transceiver) clock scheme of the SIS8300-KU is illustrated below.

PCIe 1 (Port 5)

PCIe 0 (Port 4)

SFP (L2)

SFP (L1)

clock from AMC Backplane

(FCLKA)

LLL (user links, Port 14)

LLL (Port 13)

LLL (Port 12)

Gbe (Port 0)

Gbe (Port 1)

SI5338A

Programmable

Quad Output

PLL

controlled via I2C

from FPGA

125 MHz

25 MHz

quartz

PCIe 3 (Port 7)

PCIe 2 (Port 6)

MGT

REFCLK0

LLL (low latency link, Port 15)

MGT

REFCLK1

MGT

REFCLK0

MGT

REFCLK1

MGT

REFCLK0

MGT

REFCLK1

MGT

REFCLK0

MGT

REFCLK1

227-2

227-3

227-0

227-1

226-2

226-3

226-0

226-1

225-2

225-3

225-0

225-1

224-2

224-3

224-0

224-1

IN1-2 IN5-6

C0

C1

C2

C3

ΔT

ΔT

AD9510

#2

DIV1_OUT1

oscillator

100 MHz

oscillator

(assembly option)

x MHz

WR - PLL

(assembly option)

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 16 of 92

3 Jumper/Connector Pin Assignments

The following subsections describe jumper and connector pin assignments.

3.1 CON100 JTAG

The SIS8300-KU’s on board logic can load its firmware from two SPI EEPROMs (Basic

FLASH and Second FLASH), via the JTAG port on connector CON100, PCI Express, MTCA

or via the MMC.

Hardware like the XILINX HW-USB-JTAG in connection with the appropriate software will

be required for in field JTAG firmware upgrades.

CON100 is a 2mm (i.e. metric) 14 pin header that allows you to reprogram the firmware of

the SIS8300-KU board with a JTAG programmer. The pin out is shown in the schematic

below. It is compatible with the cable that comes with the XILINX HW-USB-II-G-JTAG

platform cable. CON100 can be found at the right bottom side of the board.

Note: The board has to be powered for reprogramming over JTAG

3.2 J604 Watchdog Reset

J604 can be found next to the left upper edge of U500 (largest chip on the card with green

heat sink). With J604 closed the boards watchdog reset is connected to the reset logic. J604

should be opened for JTAG firmware programming.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 17 of 92

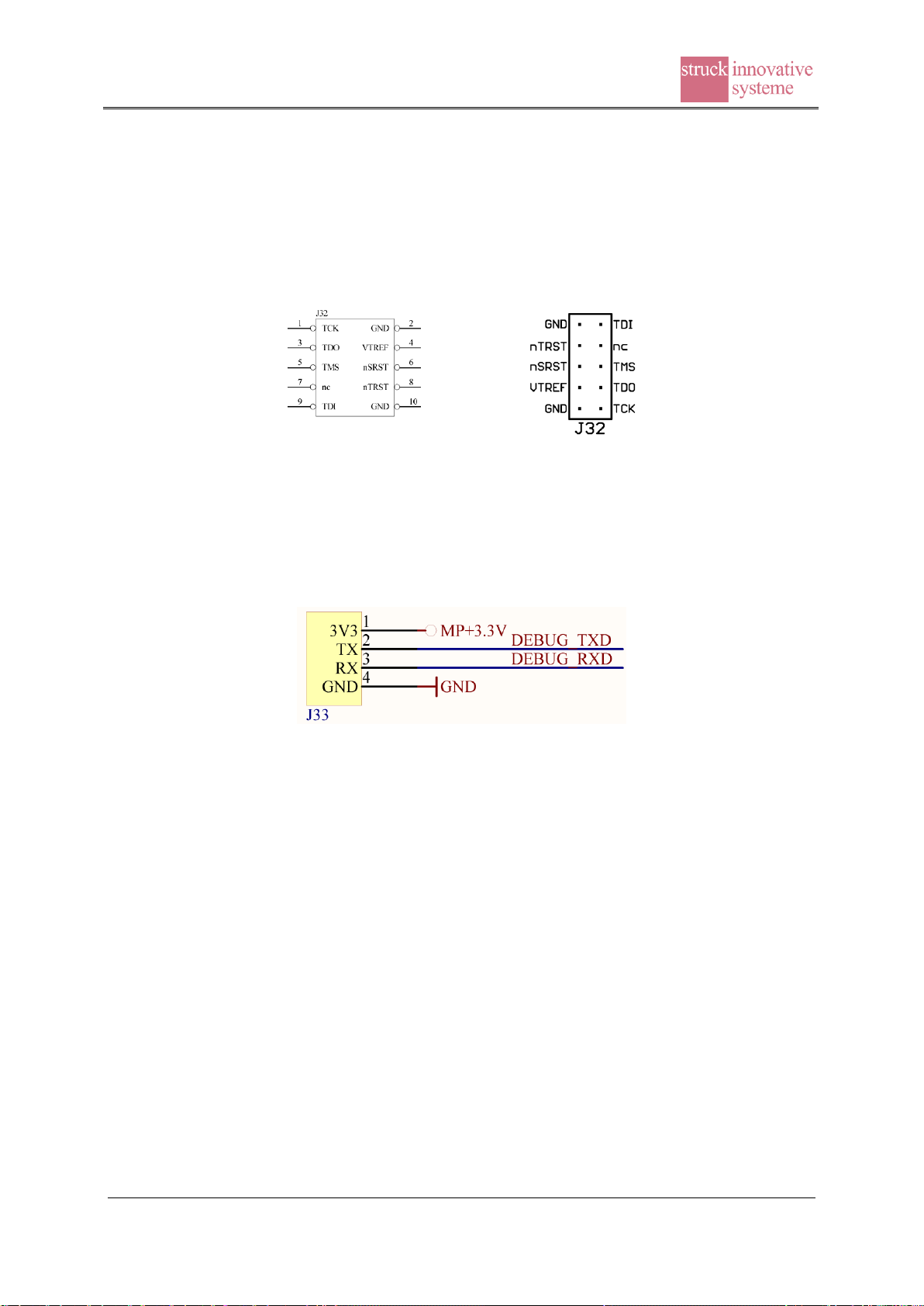

3.3 J32 AVR JTAG

This 10-pin header is used to connect to the JTAG of the Atmel ATxmega128 microcontroller

providing the IPMI/MCH functionality of the SIS8300-KU. J32 can be found at the left

bottom side of the board. The pin out is shown in the schematic below.

3.4 J33 ATxmega128 Debug

This 4 pin socket strip grants access to the debug port (PE2 and PE3) of the ATxmega128

microcontroller. It was designed in to facilitate Struck in house microcontroller software

development.

Note: Due to a lack of coding there is no protection against a wrong polarity connection. This

connector is reserved for Struck in house purposes only.

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 18 of 92

4 LEDs

4.1 Module Management LEDs

Three right angle front panel LEDs (blue, red, green, not labelled) show the hot-swap status

and general module information about failures and out of service status.

The front panel Hot Swap handle has to be used for module insertion and extraction.

To insert the card, the Hot Swap handle must be pulled. The Hot Swap handle can pushed in

once the module is properly seated in the carrier backplane connector to initiate the MCH to

bring the module into operational state.

Typical module insertion process (module handle pushed in)

blue

red

green

Status

On

Off

Off

Module management controller start, activation process begins

Blink

Off

Off

Module activation process in progress, wait for payload power

Blink

On

Off

Payload power present, MMC waits for onboard Power Good

Off

Off

On

Power Good, FPGA loaded (done signal), module operational

Typical module extraction process (module handle pulled out)

blue

red

green

Status

Blink

Off

On

Module still operational, deactivation process begins, wait ...

Blink

On

Off

Payload power off, Module deactivation process in progress

On

Off

Off

Module deactivation finished and safe for extraction

Note: do not remove module before Hot Swap handle is pulled and the blue LED is solid on

4.2 Front Panel LEDs

The SIS8300-KU has additional 4 circular green front panel LEDs and 4 right angled green

LEDs next to dual SFP card cage. The function of the LEDs are shown in the table below.

LED name

Function in base design

A

PCI Express Access

U

User LED

L1

PCIe Link up

L2

ADC Sampling active

R (L1)

SFP Link 1 receiver loss of signal

T (L1)

SFP Link 1 transmitter fault

R (L2)

SFP Link 2 receiver loss of signal

T (L2)

SFP Link 2 transmitter fault

Note: if SIS8300-KU is in operational state and no SFP modules are present in SFP card cage

associated LEDs (R and T) are lit permanently

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 19 of 92

4.3 SMD LEDs

A number of surface mount red LEDs are on the SIS8300-KU to visualize part of the board

status.

LED designator

LED comment

Function

D20A

S1

Firmware dependent

(Optical Link 1 up)

D20B

S2

Firmware dependent

(Optical Link 2 up)

D20C

S3

Firmware dependent

D20D

S4

Firmware dependent

D20E

S5

Firmware dependent

D20F

S6

Firmware dependent

D20G

S7

Firmware dependent

D20H

S8

Firmware dependent

D21D

READY

FPGA ready

D10A

+12V

Payload power present

D10B

MP+3.3V

Management power present

Struck Documentation

SIS8300-KU

MTCA.4 Digitizer

Page 20 of 92

5 Front panel

A sketch of the SIS8300-KU front panel view (with front panel I/O option) is shown below.

Table of contents

Other SIS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Trotec

Trotec BM12 operating manual

Endress+Hauser

Endress+Hauser TopClean S CPC 30 operating instructions

Max Machinery

Max Machinery 234 Series instruction manual

Rotronic

Rotronic HygroPalm Series instruction manual

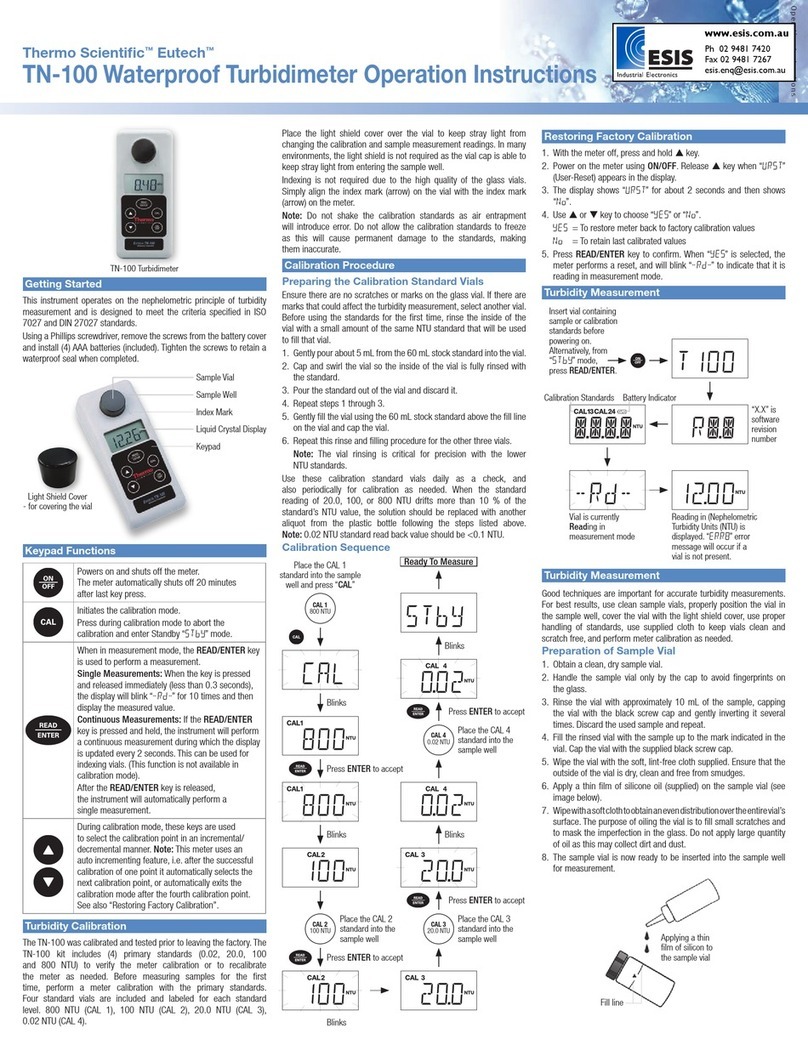

Thermo Scientific

Thermo Scientific Eutech TN-100 Operation instructions

Burkert

Burkert SE30 Ex Namur operating instructions