7

2

19/04/2018 Rev:2.0.0

English

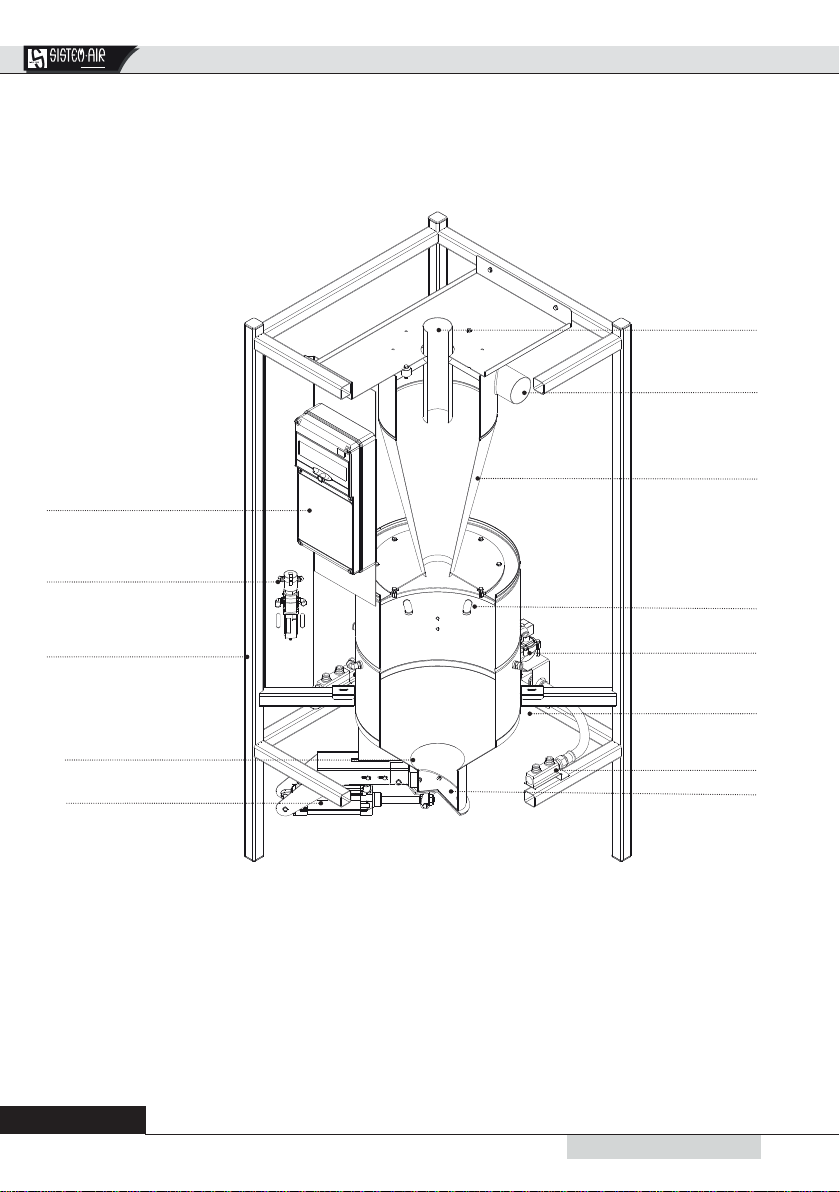

Dust separators for industrial use can be used in countless applications, thanks to their versatility and

compatibility with the other components of a centralized industrial vacuum system.

In particular, the special Auto Jet Turbix separator is a unique product of its kind: the presence of the

cone with cyclonic effect allows it to have an extraordinary ability to eliminate dust, preventing it from

clogging the central vacuum unit filter, while the automatic exhaust device makes it suitable for the as-

piration of large volumes of material without needing continuous emptying of the collection vessel. The

presence of the nozzles that discharge compressed air into the collection cylinder represent a further

advantage in the automatic emptying, making the separator suitable for use even in the case of aspira-

tion of very light and voluminous materials.

The AUTO Jet separator has been designed and constructed according to the criteria imposed by cur-

rent regulations and the community directives, without neglecting fundamental elements such as func-

tionality and practicality of use.

The main technical characteristics can be listed as follows:

• Load bearing structure in epoxy powder coated steel

• Cylindrical shell in AISI 304 stainless steel

• Pneumatic linear actuator

• Possibility to connect 8 compressed air nozzles

• Control panel for the blowing, powder filling and dust discharge systems.

The pneumatic actuator allows the opening of the discharge door even in the presence of strong

depressions inside the separator, in order to allow the discharge of the material in any situation.

To facilitate the discharge of any type of collected material, even the lightest and most voluminous ones,

the separator is equipped with 8 nozzles that allow the discharge of compressed air when the lower

door is opened.

The shape of the cone allows the cyclonic separation of the collected material to be carried out,

guaranteeing a great effectiveness in eliminating dust, even fine ones, withoutusing a filter. Maintenance

will also be greatly reduced on the plant filter.

Rotating the material inlet fitting through 360 °, it is possible to rotate the inlet of the collected material by

unscrewing the fixing screws of the cone with predefined progressive angles of 45 ° each.

The separator with automatic drain is made of stainless steel: this material makes it suitable for the

aspiration of liquids, but also of incandescent particles. By accurately adjusting the timing of the

discharge, in case of entry of liquid and solid materials during the same suction cycle, it is possible to

avoid the formation of wet sediments which then solidify, becoming difficult to dispose of.