Sit 501 EFD User manual

501 EFD

Electronic Flame

Failure Device

SIT Group

501 EFD

DESCRIPTION

FEATURES

SEQUENCE OF

OPERATIONS

TECHNICAL

DATA

INSTALLATION

DESCRIPTION

The 501 EFD automatic direct burner

ignition (DBI) unit has been designed for

atmospheric and fan assisted burners

which require non volatile lock-out.

This SIT Flame Failure Device is a solid

state controller based on the well known

and proven rectification effect of flame

ionization.

A suitable design and a special compo-

nents selection has allowed SIT to obtain

a wide temperature range from -20 to +

80 °C.

Applications

The 501 EFD provides automatic ignition

control with non volatile lock-out for

intermittent operation in accordance

with EN 298 for:

- Atmospheric burners

- Fan-assisted boilers,

including dynamic air check

FEATURES

Basic features include

- Compact design

- Remote, manual reset function

- Multiple plug-in connectors

- Well established electronic

technology for high reliability

- Atmospheric burner applications

- Trial for ignition after flame loss

- Permanent lock-out visualization, also

without thermostat input

- Wide range of operating ambient

temperature

Options available

- Contact for flame indication

relay from the power

supply line

- Fan output and air pressure

switch check

- Potted version

- Single electrode (for ignition

and flame detection)

- Different flame current

sensitivity

can be provided upon request

- Fast-on connectors

- Several pre-purge and safety

timings can be tailored to the

application

SEQUENCE

OF

OPERATIONS

Normal operation (atmo-

spheric or fan assisted)

During the waiting or purge

time, Tw or Tp, the circui-

try verifies that there is no

parasitic flame signal pre-

sent. If the unit is used in a

fan assisted application,

the air pressure switch is

verified to be in the N.C.

(normally closed) or “no

flow” position. Upon powe-

ring the fan, the unit will

not begin the operating

sequence until the N.O.

(normally open) or “flow”

position is activated on the

air pressure switch. After

the scheduled waiting time

Tw, or purge time Tp, the

built-in ignitor and the gas

valve are energized. This

commences the safety

time, Ts. The ignition spark

will ignite the gas and the

flame will be sensed by the

HV electrode (single probe

model) or the detection electrode (dual probe model). Upon sen-

sing the flame, the HV spark will be suppressed and the gas valve

will remain energized. On units with a flame relay, the flame detec-

ting connection will be powered when the flame is established. When

the thermostat is satisfied, the valve and fan are de-energized and

the control returns to the standby mode.

Behaviour under abnormal conditions

- if the air proving switch is in the N.O. (normally open) or “flow”

position at startup, upon a request for heat, the unit will remain in

a waiting mode with the fan de-energized

- if air flow is not proven by the airflow switch after energizing

the fan, the unit control will remain in the waiting mode with

the fan energized until the air flow is sensed

- upon flame failure during normal operation, the unit will maintain

the power to the fan and start again the ignition sequence with

a waiting time (or purge time) followed by a safety time

- if flame is not established and sensed during the beginning of Ts,

the spark will be suppressed shortly before the programmed end

of the safety time to permit the sensing of extremely weak

flames. This time is referred to as Tc (check time). If no flame is

sensed during any part of the safety time, the unit will lockout

Resetting the unit

To reset the unit the external reset switch is depressed. If a first

reset is not successful, wait at least 10 seconds before the next

attempt. Before starting, check if control is locked-out. If locked-

out, depress the reset button; After a manual reset an extended

pre-purge waiting time will occur.

TW TS TW

MV

HV

TC

TS

ATMOSPHERIC

D B I APPLICATION

FAN-ASSISTED

D B I APPLICATION

TC

TP TS TP TS

P

MV

HV

TECHNICAL

DATA

AMBIENT TEMPERATURE

-20 to + 80 °C

HUMIDITY

95% max at 40 °C

SUPPLY VOLTAGE

230 Vac -15%, +10%, 50-60 Hz

POWER CONSUMPTION

10 VA

ELECTRICAL RATINGS

valve output: 230 Vac, 0,5 A, cosf=0,6

fan output: 230 Vac, 0,5 A, cosf=0,6

flame relay output: 230 Vac, 0,5 A, cosf=0,6

alarm output: 230 Vac, 0,5 A, cosf=1

ELECTRICAL CONNECTIONS

high voltage probe: fast-on 2,8X0,5 mm

connectors: - STELVIO/STOCKO multiple plug-in connectors, or

- fast-on connectors 6,3 X 0,8 mm.

PROTECTION CLASS

IP 00 (fast-on)

IP 20 (connectors)

TIMING

minimum waiting time Tw: 1,5-3-5-7-10-30 sec.

minimum pre-purge time Tp: 1,5-3-5-7-10-30 sec.

maximum safety time Ts: 5-7-10 sec.

FLAME SENSING

minimum flame current: 0,5 µA

recommended flame current: > 1 µA

FUSING

internal: 2 A, non replaceable

external: 1,6 A fast. The 501 FFD should be

externally fused to proctet the unit

IGNITION

Integral electronic spark generator.

ignition voltage: 15 KV at 30 pF load

repetition rate: 15 Hz +/- 20%

max. lenght of the cable: 2 m.

spark gap recommended: 2-4 mm.

MOUNTING

No restriction for mounting position.

T1

T2

T3

T4

T5

T6

T7

T8

T9

T11

T12

Fast-on 6,3 x 0,8

Ø4,6

85

85

132

T13

T14

T15

T16

100

T10

37

42

HIGH VOLTAGE COIL

NN

230 VAC LINE

VAC NEUTRAL

GROUND

N

N

HV

BURNER ION

N

T1 T2 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14

T16 T15

T3

N

MV 2

P

MV 1

FL

HV

P

RS

230 VAC LINE

230 VAC NEUTRAL

GROUND

N

N

WIRING DIAGRAM

STELVIO/STOCKO plug-in connectors fast-on connectors

INSTALLATION

General Notes

Before installing the 501 EFD read and

follow the instructions carefully. Failure

to follow the instructions could cause

damage to the ignition module or the

appliance in which it is installed. Make

sure the ratings given in

the technical data match

the specifications of the

appliance.

The person installing or

replacing the ignition

module must be a trained,

experienced technician.

When the installation is

complete, make sure that

the ignition module operates properly in

accordance to the normal operating

sequence.

To ensure reliable long term operation,

mount the 501 EFD in a low ambient

temperature and low heat radiation

position in the appliance. High tempera-

tures could reduce product life.

For safety, connect a high limit ther-

mostat in series with the power supply

of the unit to de-energize the 501 EFD

in case of excessive temperatures. To

suppress radio frequency interference

the 501 EFD and spark electrode

cabling should be mounted in a shielded

environment.

Installation

The module should be mounted in such

a way that it is not subjected to exces-

sive heat, moisture, dust, grease or

oil. It also should not be subjected to

water or steam cleaning. The control

should be mounted and shielded in a

way that it will not get wet.

Excessive heat can damage the module

and shorten the operating life of the

control. For applications that operate

at high temperature, some insulation,

shielding and forced air circulation may

be necessary to keep the control ope-

rating properly.

Wiring

The module should be mounted close

enough to the burner to allow short

direct routing of the high voltage cable.

Use a suitable high voltage cable that

conforms to national standards such as

EN60335-1. The cable must not run in

continuous contact with a metal surfa-

ce or the spark voltage will be reduced.

The necessary connections between

the ignition control module and external

loads should be made using thermopla-

stic insulated wire with a minimum

rating of 105°C.

Disconnect power before making any

wiring connections to prevent electrical

shock or equipment damage.

Refer to the wiring diagram for detailed

information on the exact connectors.

The unit should be protected by an

external quick acting fuse of appropria-

te ratings to prevent problems due, for

example, to short circuit or faulty

loads.

Note that a common ground is requi-

red between the burner and the

ground terminal on the control module.

Only one wire must connect the modu-

le ground terminal to the appliance

common ground point.

The external loads and the burner

must be connected to the same com-

mon ground point.

High voltage and probe electrodes

should be mounted at the burner with

a spark gap set according to the elec-

trical specifications data.

Flame check

The minimum flame ionization current

is 0.5µA. For a stable flame detection

this current under normal conditions

should be higher than 1µA. To measu-

re the ionization current connect a DC

microammeter in series with the flame

detection probe.

If the flame current is insufficient,

check that the flame detection probe is

fully in the flame.

Note that the flame detection is affec-

ted by the polarity of the connection to

the main supply. For safety reasons,

the flame is detected only with the cor-

rect line polarity connected to the con-

trol. Otherwise the unit will go to

lockout at the end of the safety time,

even if the burner is lit.

With single probe unit, to check the

flame level measure the DC voltage

between the probe and the ground with

a flame present. Connect the positive

lead to the probe and the negative to

the ground. The voltage should be

greater (more negative) than -25V.

Note however that the input impedan-

ce of the suitable voltage meter must

be more than 100MΩ.

501 EFD

SIT La Precisa

Viale dell'Industria 31/33

35129 PADOVA - ITALY

Tel. 049/8293111 - Fax 049/8070093 - Telex 430130 SITEC I

9.955.552 3/95

Table of contents

Popular Fireplace Accessories manuals by other brands

Town & Country Fireplaces

Town & Country Fireplaces 22150051 instructions

Travis Industries

Travis Industries 33 DVI installation instructions

Lopi

Lopi Hearthview 864 user manual

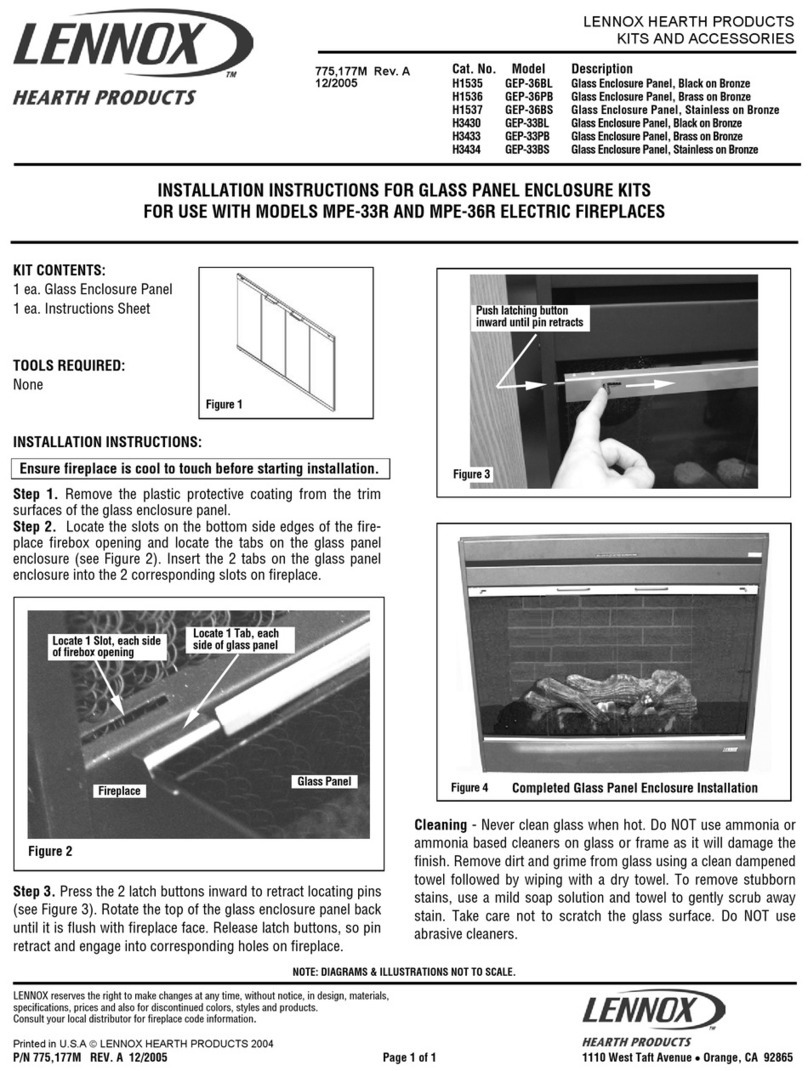

Lennox Hearth Products

Lennox Hearth Products LENNOX MPE-33R installation instructions

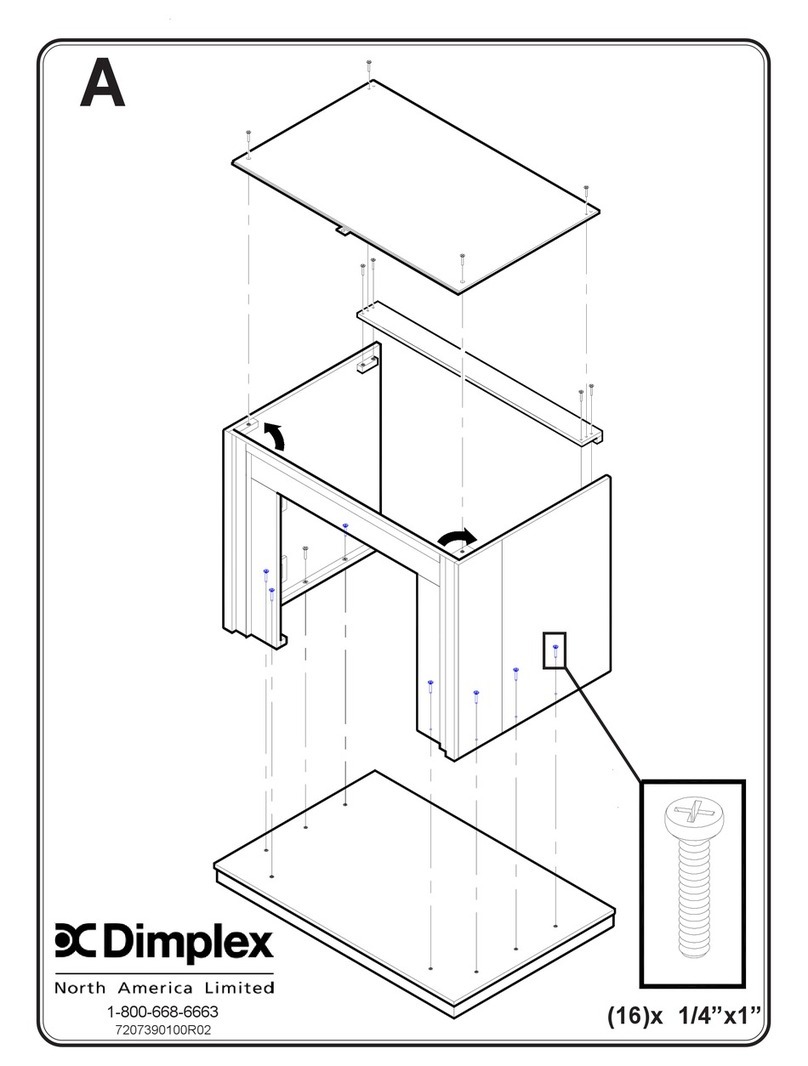

Dimplex

Dimplex DFP6776C install guide

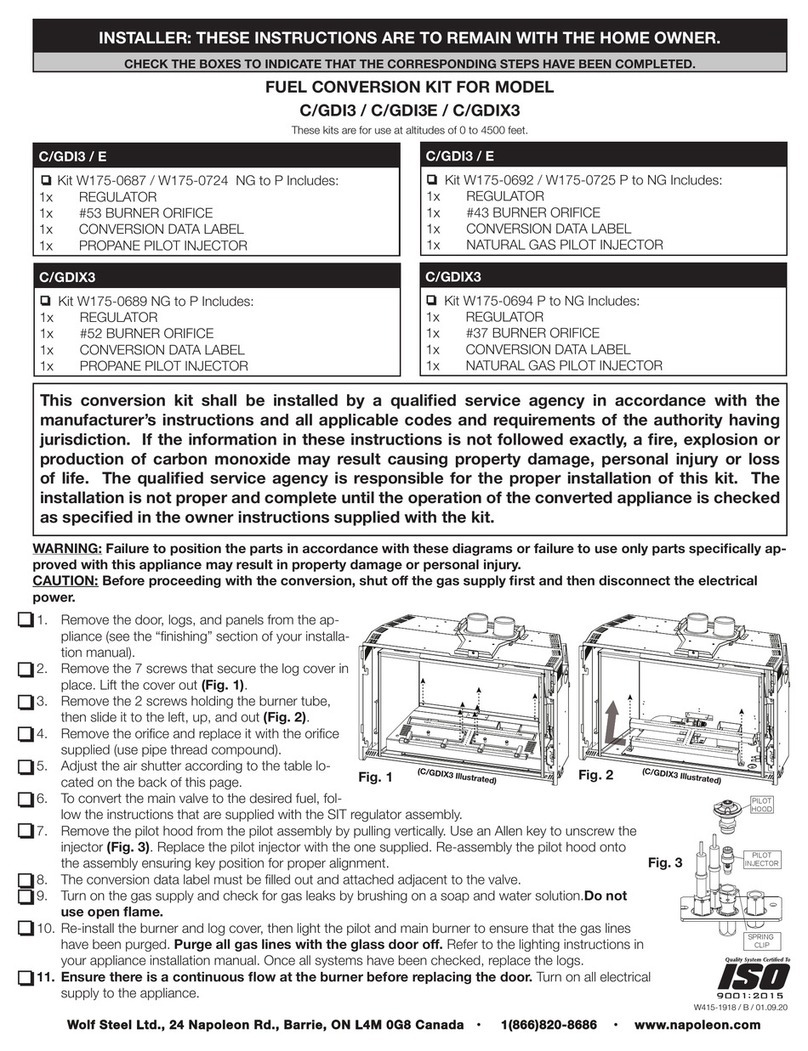

Napoleon

Napoleon W175-0689 instruction manual

Travis Industries

Travis Industries 95400424 installation instructions

Osburn

Osburn ZERO CLEARANCE KIT installation instructions

Majestic

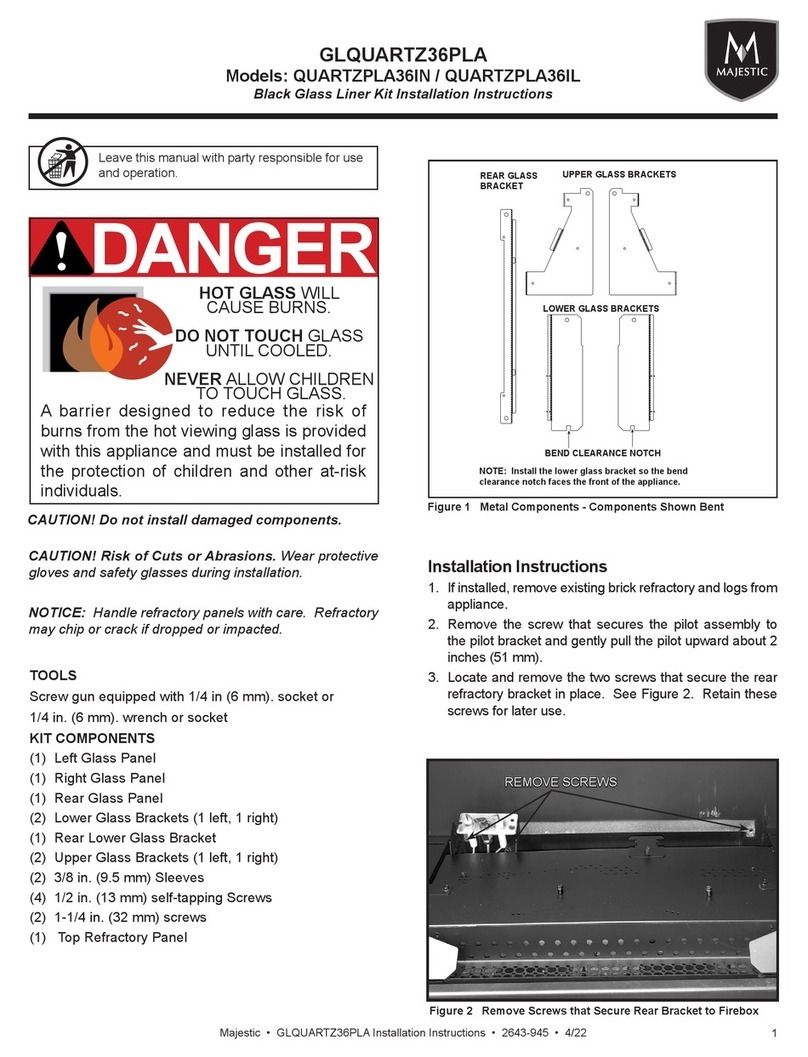

Majestic QUARTZPLA36IN installation instructions

Napoleon

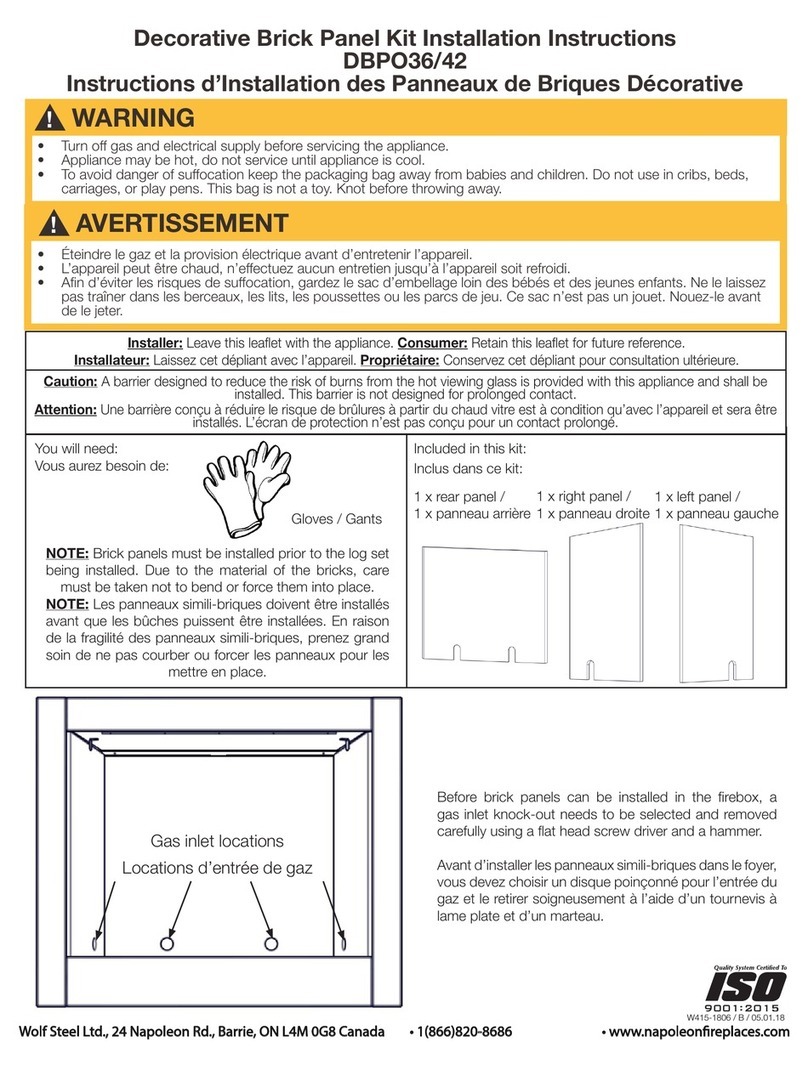

Napoleon DBPO36 installation instructions

Dimplex

Dimplex SMP-130-E install guide

Empire Comfort Systems

Empire Comfort Systems LS50TINF installation instructions