SIXTY82 M29S LENGTH 300 Product information sheet

1

The new original

ORIGINAL USER MANUAL –PART 1

GENERAL REQUIREMENTS

2

NB! PART 1 is inseparable connected with

the applicable user manual PART 2

March 2019

Manufacturer:

SIXTY82 B.V.

Amperelaan 9

9207AM Drachten

The Netherlands

Phone +31 (0)88 1342200

Email info@sixty82.nl

3

Content

1. INTRODUCTION

2. SCOPE

3. IDENTIFICATION

4. LIMITATIONS OF USE

5. SAFETY INSTRUCTIONS

5.1 ELETRICAL POTENTIAL BONDING

6. TRANSPORT AND STORAGE

7. APPROVED ACCESSORIES

8. COATINGS AND SURFACE TREATMENTS

9. SLINGING METHODS

10. ASSEMBLY INSTRUCTIONS

10.1 ASSEMBLY

10.2 DISASSEMBLY

10.3 ATTACHING LOADS

11. INSPECTIONS

11.1 GENERAL

11.2 INSPECTION LEVELS

11.3 INSPECTION FREQUENCY

12. MAINTENANCE AND DISCARD CRITERIA

12.1 DISCARD AND REJECTION CRITERIA

12.2 GENERAL

12.3 MAIN CHORDS

12.4 BRACES

12.5 CONNECTORS

12.6 PINS

13. LEGISLATION

14. GUARANTEE

15. DISCLAIMER

16. CE DECLARATION OF CONFORMITY

4

1. INTRODUCTION

BEFORE using SIXTY82 truss, read this manual carefully and pay

attention to the information provided. Use this manual to

familiarise yourself with the products, its proper use and safety

regulations.

DANGER: Indicates a hazardous situation

which, if not avoided, will result in death or

serious injury. This signal word is to be limited

to the most extreme situations.

WARNING: Indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

NOTICE: address practices not related to

personal injury.

SAFETY NSTRUCTIONS: is used for a lists of

steps, procedures or instructions that might

otherwise substitute a DANGER, WARNING or

CAUTION notification.

This manual shall be inseparably used in conjunction with a PART

2 manual and vice versa. The PART 2 manuals contains product

specific requirements regarding legislation, set-up, dismantling,

allowable loading and any other information not referred to in

Part 1. PART 2 is always seperseding PART 1.

Make sure manuals are available at all times for all

users and all employees.

For the ease of reading, truss elements are referred to as

„trusses“.

2. SCOPE

The intended use of trusses is to be repeatedly assembled and

disassembled in order to carry loads in temporary or permanent

installations.

Trusses can be considered as lifting accessories or construction

products.

If used as lifting accessories, trusses are subjected to the

European Machine Directive 2006/42/EC. They are statically

tested with 1,5x the maximum load during its general approval

test

Trusses under the intended use are not subject to the scope of

the European Construction Products Regulation 305/2011/EC.

If the application does so, contact the manuafacturer for the

required CE Declaration of performance. NB! Due to the

requirements additional cost will be applicable to the product.

It shall be noted that it is the sole reponsibility of

the user to check with local authorities if the

legislation used by SIXTY82 is accepted in the

country of use.

3. IDENTIFICATION

SIXTY82 products can be recognised by the specific ID-tag on all

trusses as well as the embossed logo on each coupler.

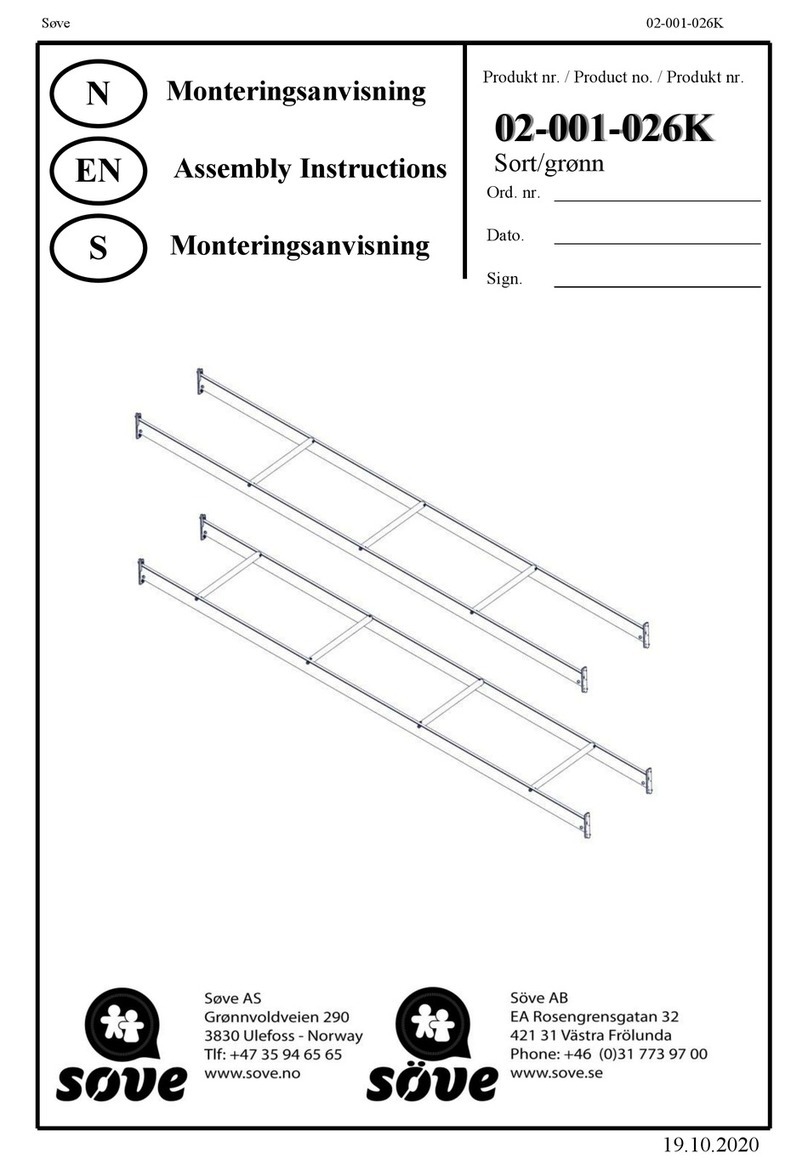

To identify individual parts, see figure 3.1

B10102018001-

Fig. 3.1

5

Fig 3.2

Fig 3.2

4. LIMITATION OF USE

•Trusses must be used within

the limits of the structural

report.

•Loadingfigures mentioned are only valid for static loads.

•Self-weight is

already taken into account.

To meet BS, ANSI and EN standards for truss elements in

repetitive

use, all loadings as mentioned in the loading tables shall be

multiplied with 0.85.

All other structures made of truss need

dedicated structural

reports.

Some products within our range fit with those of other brands.

Nevertheless, trusses can differ considerably depending on their

design, layout and manufacture (e.g. material properties, alloy,

diameter, thicknes, layout of the bracing, system tolerances,

etc.) SIXTY82 provides comprehensive technical support and

structural data for all trusses.

The structural integrity of an assembled structure of different

brands and legal compliance is the sole responsibility of the user.

Their combined use must always be certified by a structural

engineer on a case by case basis.

SIXTY82 cannot accept responsibility for products manufactured

by third parties.

Trusses are not particularly designed for lifting

people!

Adequate load-reduction and safety

precautions, according to local legislation, must be

taken when

people are lifted.

Trusses can be used in environmental

conditions varying from -

20°C up to +80°C.

However, if trusses are used bellow 0°C special attention must be

taken. The open heel of the welds of some of our trusses and

capillary working of pin holes can cause water intrusion inside

the truss chords and diagonals. If temperatures are bellow 0°C,

captive water caused by intrusion or condensation will freeze

and can cause damage to the truss members.

To avoid this effect SIXTY82 can provide the same trusses with

100% circumferential welded diagonals as well as drainage

holes.

Special attention must be taken when trusses are used in

aggressive environments or its near

vicinity.Thealuminium alloys

used might not be particular suitable

for this environment.

Direct contact with concrete

shall be avoided by means of a

sealant. A special instruction form is available.

The alloy used has good properties in a salt water environment

however, it can cause oxidation on the surface. Regular cleaning

with fresh water or a dedicated protection is advised.

The material used for the connectors is especially vulnerable for

salt water. It is advised to anodise, coat or treat it with a sealant

in such a way that no salt water particles can contact the

material.

All bolts and nuts used in the line of forces, shall be

fastened by

meansofa torquewrench. Whenboltsare

connectedtothreaded

aluminiumcomponentsthetorque

settingare M12 >15Nm, M16

> 25Nm.

5. SAFETY INSTRUCTIONS

For health and safety reasons, people handling truss should wear

adequate Personal Protection Equipment like, but not limited to,

gloves, sound protection, hard heads and safety shoes.

The noise levels during

assembly and disassembly can exceed 80 dB.

Elements

weighting 20 kg or more shall be carried by at least 2

persons.

Persons whohaveto

be on the construction side shall be instructed

and informed about correct use and possible

dangersbefore use.

In case of an accident, damaged or malfunction, trusses shall be

marked, taken out of service and offered for inspection to a

qualified person in order to establish their structural integrity for

re-use. The trusses shall be identified accordingly, and records of

identification numbers and photo’s shall be kept.

Examples of accidents or malfunction can be:

•Truss is dropped to floor from height;

•Truss is lifted with missing pins in joints which might

cause overloading;

•Truss was subject to shock loads;

•Truss was torqued during e.g. lifting.

6

Always wear hard heads, safety shoes, sound

protection and protective gloves when moving,

sembling, disassembling or transporting truss

elements.

Assembled trusses and structures must be checked on their

structural stability and strength by a chartered engineer.

Do not mix structural data from different

standards without knowing their respective safety

principles like Load Resistance Factor Design or

Allowable Stess Design methodology.

Do not use of damaged or malfunctioning parts.

5.1 ELECTRICAL POTENTIAL BONDING

The user needs to ensure that truss systems that might

develop dangerous touch voltages in the event of an electrical

fault are incorporated into a common potential equalisation

system. This applies to all elements made of electro

conductive material which have equipment placed on, or

attached to, them or across which wires and cables run that,

in the event of damage, could make electrical contact with

metal parts. The connections can be made with clips, pipe

clamps, screw joints or special single-pole locking connectors.

The common potential equalisation system must be connected

to the earth wire of the electrical power supply system. For cable

lengths of up to 50 metres, 16 mm2Cu is considered the

standard value for an adequate cross-section. For cable lengths

of up to 100 metres, the standard value is 25 mm2Cu. In truss

tower systems, the potential equalisation connection can be

made by means of a potential equalisation connection point

provided by the manufacturer at the tower base. Since the

wheels or rollers used in tower systems with „sleeve blocks“

insulate the movable part of the truss construction, the latter

must be provided with a separate potential equalisation

connection.

Grounding trusses is extremely important as

very often audience and installers will come in

direct contact while the fixtures suspended are

electrically charged.

6. TRANSPORT AND STORAGE

Always wear hard heads, safety shoes, sound

protection and protective gloves when moving,

assembling, disassembling or transporting truss

elements.

Treat the truss with care. Don’t drop, drag or throw

them. Prevent damage from sharp edges such as

the forks

of a forklift. Use dedicated dollies as

means

for transportation and storage.

Avoid verticaltransportationor stocking for reasons of falling.

Avoid physical contact with unprotected steel at all

times.

Makesuretrusses cannotmove

or shakeduringtransport.Due to

the softness

of the aluminium the abrasive working of moving or

shaking can lead to severe damage.

7. APPROVED ACCESSORIES

For an

overview of approved accessories, we refer to our

brochure or our website: www.sixty82.com.

It is of great importance that accessories never damage

the truss.

Special

attention shall be taken at using clamps

and hooks. It

might very well be that their inside

radius does not

meet the tube size it needs to be

connected to. This can lead to severe damage.

8. COATINGS AND SURFACE

TREATMENTS

Coatings and surface finishes shall only be applied after

consultation with the coating or finish manufacturer or other

parties qualified to evaluate the possible effects of the coating

or surface finish on the structural properties and load - bearing

capabilities of the truss. Only use curing process of tempratures

of 200dgr or lower for per period of 10 minutes.

Records shall be kept detailing the application of any coating or

surface finish with particular attention to processes requiring the

application of heat.

Chemical removal of coatings and surface finishes shall be

carried out only after consulting with the chemical manufacturer

to ensure that the chemical will not affect the mechanical

properties of the aluminium.

The use of Abrasion-blasting shall be treated with great care. It

is adviced not to be used on aluminium less than or equal to 3

mm thick.

9. SLINGING METHODS

There are many ways of slinging a truss. At all times strength and

stability must be guaranteed. However, the correct way depends

on many aspects and the application.

Based on loading a truss to its maximum, it is advised

to sling trusses as per instruction given. These methods:

•Guarantee strength when attached in the node or

directly next to the end brace. (within 50mm)

•Guarantee that the hanging point is above the truss

centre of gravity

•Give redundancy in case one sling fails

•Minimise the horizontal compression of main chords

Slingingshallbeapplied solely at themain chords, not at

the couplers or internal braces unless approved by a

chartered engineer.

Slingingshallbeappliedatnodepoints,asideendbraces

or aside horizontal cross braces.

Slinging equipment shall be made from non-

abrasive and fire-retardant materials.

7

Pic. 9.1

Pic. 9.2

Pic. 9.7

Pic. 9.8

Ladder truss needs special attention for slinging.

Stabilisation of the top chord is vital for the load

capacity. Only the bottom chord shall be loaded.

Other load applications need structural analysis

before use.

Pic. 9.3

Pic. 9.4

Pic. 9.5

Pic. 9.6

Pic. 9.9

Pic. 9.10

Pic. 9.11

Pic. 9.12

Pic. 9.13

Pic. 9.14

Pic. 9.15

The use of slinging devices with a soft cover is advised. Direct

contact between a steel wire rope and the truss chord should be

avoided because of the abrasive surface of the steel wire rope.

For stability reasons it is advised to wrap at least 2 main

chords.

Trusses can be suspended from either the top or bottom

chords. The best method depends on the application.

Suspending or supporting has the same effect on a truss.

If the truss is not supported in the node point, the main

chords will be subject to an additional local bending moment.

This effect shall be considered in the structural analysis and

could lead to reduction of the load capacity!

For optimum performance, suspensions shall be attached

into the node points. If not, the truss might be subject to a

substantial reduction of its load capacity. Slinging to all main

chords doesn't change this. The correct load can only be

determined by studying each load case individually. This

should be done by a chartered engineer.

ADVICED SLINGING METHODS

8

Fig. 9.4

10. ASSEMBLY & DISASSEMBLY

INSTRUCTIONS

Trusses and truss constructions shall be assembled by some

competent person or sufficiently instructed personnel under

supervision of a competent person. Before assembly, use and

disassembly, the competent person is responsible for, but not

limited to:

•follow up of all instructions as stated in this manual

and the applicable Part 2.

•instruction to those assembling the trusses and correct

suspension of trusses and loads.

It is advised to physically show how to assemble and disassemble

trusses, how to orientate couplers and which tools to use.

Trusses with a conical coupler only allow the pin to be placed

from the outside inwards. Make sure that the conical hole in the

connector is correctly placed. The larger side of the hole need to

face outwards. See fig 10.1

Fig. 10.1 Fig. 10.2

When two trusses with conical connector are assembled a gap

between them can be seen. This is on purpose and has no

negative influence on strength and function. See fig 10.2

All bolts and nuts used in the line of forces, shall be

fastened by

means of a torque wrench. When bolts are

connected with

threaded aluminium components the torque

settings are M12 >

15Nm, M16 > 25Nm.

A competent person shall check prior to use if all trusses are

connected properly before applying loads.

For trusses with end braces it does not matter if the diagonals do

not follow the alternating zig-zag pattern.

Fig 10.4

10.1 ASSEMBLY

1. Slide two trusses towards each other.

2. Look if the pin holes are more or less alligned.

NB! With conical truss there is always a small difference in

allignment. This is done on purpose in order to maintain the

functionality of the conical connection system.

3. Guide the truss by its end in case the holes do not align.

Never use brute force.

4. Drive the pin through the pin holes preferably by using a

red-copper hammer. Rubber/ plastic hammers do not work

properly as they absorb to much energy.

Tip! Place the pin in such a way that the hole for the R-clip is

perpendicular to the length of the truss. This allows easy

mounting of the R-clip.

5. Put the R-clip in place.

6. Sling the truss by means of appropriate methods described.

7. Before loading, check if all connections are made.

8. Attach loads as per instruction given in chapter 8.3

9. Lift the truss 1 meter and check all connections. Correct

where needed.

10. Lift the truss to trim height. Avoid „bumping“ during the

lifting operation as it will lead to an increase of forces in the

truss and load.

10.2 DISASSEMBLY

1. Lower the truss till working height.

2. Remove the loads.

3. Inspect the truss for any default. Mark them accordingly

and take them out of service.

4. Lower the truss till floor level.

5. Detach the slings or lifting accessories.

6. Remove the R-clips.

7. Drive the pins out by means of a firm hit.

8. Check components on any default. Mark them accordingly

and take them out of service.

10.3 ATTACHING LOADS

Make sure:

Loads to be equally divided over both bottom or top chords.

Loading a truss on one side lead to internal torsional forces

which are not considered in the data provided.

Fig. 10.5

Fig 10.6

9

.

Fig 10.7

11. INSPECTION

SIXTY82 encourages careful documented inspection by

a

competent person at least once a year or as often if the

circumstances or intensity of use

requires so.

If the truss is used as lifting equipment, the inspection interval

should be according

to the machine directive (EC 2006/42) and

local

legislation or as often as needed

If the structural element is used as permanent load bearing

element in permanent buildings, they are subject to the EU

Construction Product Regulation 305/2011/EC.

The inspection interval

should be according to the building code

and local

legislationor as often as needed.

SIXTY82 trusses need to be checked and

inspected

visually for damage or any other aspect,

that might

negatively affect the safety, prior to each time of

use.

11.1 GENERAL

Responsibility and liability for the safe use of

truss elements, lies

predominantly with the user

itself.

The open heel in the bracing welds in the M29 and

M39

series are

part of the design and TÜV approved.

Inspectthetruss elements, rigging wearand

accessorieson visual

wear or damage of any kind

before assembling or using the truss

at

any time! For inspection criteria see Table 1.

Do not use damaged trusses, couplers and pins.

11.2 INSPECTION LEVELS

INITIAL INSPECTIONS

When first acquired, whether they are new or used,

structural

elements should be inspected in accordance

with Table 1, and a

record of the inspection

needs to be

maintained.

REGULAR INSPECTIONS

Regular visual inspections should be carried out in

accordance

with Table 1. Regular inspections should

be performed by a

competent person and should be

carried out prior to each

incident of use.

PERIODIC INSPECTIONS

Periodic visual inspections should be carried out in

accordance

with Table 1 and a record of the inspections needs to be

maintained. Periodic inspections should be performed

by a

competent person and should be conducted at least once each

year or in accordance with an

inspection routine established by a

qualifiedperson.

Trusses which are subject to any accident

must be inspected

according to the requirements per periodic inspection and in

accordancewithtable1.

11.3 INSPECTION FREQUENCY

TRUSSES IN REGULAR SERVICE

Trusses in regular service should be

subjected to regular and

periodic inspections.

PERMANENT INSTALLATIONS, STATIONARY

Periodic inspections should be carried out on all

trusses that are

permanently installed in a

stationary (not moving) configuration.

The frequency of inspections should be determined on the basis

of the

prevalent conditions.

PERMANENT INSTALLATIONS, MOVING

Periodic inspections should becarriedout every

three months, or

in accordance with an inspection

routine established by a

qualified person, on all

trusses that are installed in a permanent

configuration where movement of the truss system is an integral

part of use.

RECORDS

Records of initial inspections and periodic inspections

should be

kept by the owner for each truss and should be signed and dated

by the

personcarryingout the inspections.

10

12. MAINTENANCE AND DISCARD

CRITERIA INTRODUCTION

Apart from the normal requirements with regard due

to care in

utilization, professional assembly, dismantling,

transport and

storage of truss elements, regular

inspections are vital. A critical

visual check of the

individual elements before each use,

independent of

the respective field of utilization, shall be

performed.

Regular inspections of the trusses should be

carried out at least once

a year by a competent person and

documented in written form. If

thetrussis used intensively, regularinspections should be

performed

at shorter intervals. If deficiencies are

noted during an inspection of

the truss that

preclude further safe use, the truss must

be taken out

of service and scrapped. Identification of the deficiency cannot be

considered sufficient in

most cases. Disposal via the

manufacturer/supplier

or a metal recycling company is the only safe

way of

protecting othersfrom risks generated by defective

material.

The discard criteria provided by shall be incorporated fully into the

inspection.

Due to the fabrication, the trusses can have some dimensional

deviation from the theoretical dimensions given. These deviations

are within limits as given in EN 1090-3.

12.1 DISCARDANDREJECTIONCRITERIA

Trussesareconsideredtoberejected formserviceif they display one

or more of the criteria

mentioned inthis manual.

In case of doubt the manufacturer/supplier or an

expert

should be asked for their opinion.

12.2 GENERAL

Although aluminium may not develop corrosion the way many steel

alloys do ambient

influences can impact on aluminium corrosively.

Careshould be takenwith trusses thatare placed outdoors for a long

time, in particular in areas with a

high level of industrial pollution,

near salt water, near

tram lines, near swimming pools. Trusses

should be checked individually before each use as to

whether the

expected pollution has had a corrosive

effect.

If any part of a truss shows significant

visible damage

or is suspected of containing a

damaged element

(visible or not), the truss should be taken out of service

and marked

accordingly. A qualified person should

carry out an

assessment of the truss elements.

•

Repairs should be carried out and warranted by

either the

manufacturer or a suitably qualified

person to be approved by the

manufacturer.

•

Regularly smooth thesurface ofcoupling parts. Use a

finesandpaper

or conventional abrasive materials

•

Keep them slightly lubricated with oil, silicone spray

or similar

lubrication. Any lubricant used should not

be “sticky”, thus

preventing the gathering of dirt, dust

or small parts of debris.

•

Prevent painting the inner surface of the connector and pin holes

.

This has a negative

effect on the fit.

•

Remove any kind of debris from trusses and its components. Do not

use any abrasive

methods other than abrasive cloth or sandpaper

grain 240 or higher.

12.2.1 GENERAL discard criteria

•

Weldswhich have cracks or other irregularities.

•

Missing identification stickers (name of the manufacturer, type and

dateof production).

•

Lasting (3D) deformation of the stacking system parts by rotation,

bending or torsion or other deformation

with resultant deviation

from the original shape.

Fig. 9.1 Table 1

Part Initial Regular Periodic Chords Diagonals Connectors Welds Fasteners Geometry ID-TAG

Chapter 11.2 Chapter 11.2

Chapter 11.2

Missing parts

Dents

Bends

Holes (1)

Incorrect repair

Abrasion

Corrosion

Missing members

Flatness (2)

Deformation

Excessive wear

Cracks

Correct grading (3)

Twisting

Squareness

Bending

Sweep

Camber

Inspection level

Items to be inspected

11

Damaged or worn material shall be clearly marked

and immediate taken out of service.

12.3 MAIN CHORDS

If one or more main chord extrusions shows

cracks, or if one or more

main chord extrusions is

deformed

by more than 5% of their

respective diameter

from the original centre line , the truss is unfit

for further use. The same applies if the ends of the main chord of a

truss are

deformed inthe area around the connector, connecting the

truss to another element will only be possible by

exerting

considerableforce.

Further signs of a discard condition are:

•

Scratches, cuts or signs of attrition on the surface of

the

main extrusions that reduce the cross-sectional

area of

the tube.

•

Indentations in the main tube to a

depth of more than

1mm and a length of more than

10mm, irrespective in

whichdirection.

•

Holes which appear after the truss is brought into use.

•

The remaining (plastic) deformation of the main

chord to

an oval shape or indentation of the tube.

12.4 BRACES

If one or more diagonal braces, end braces or cross

braces are

broken or no longer exists, the truss is not usable. The same applies

for laterally displaced braces

ter from the

centre line. Further signs

of a discard condition are:

•

Scratches, cuts or signs of wear on the surface of the

braces that reduce the cross-sectional area of the

braces

by more than 10%.

•

Indentationsin the braces to a

depthof more than 0,5 mm

and a length of more

than 10 mm, irrespective in which

direction.

•

Holes which appear after the truss is

brought into use.

•

The remaining (plastic) deformation of a brace to an

oval

shape or indentation of the brace tube.

12.5 CONNECTORS

Signs of a discard condition are:

•

Cracked or partially broken welding seams between

the

main tube and the connector.

•

Oval signs of wear in the drill holes.

•

Rotational displacement for the drill holes for the bolt

holesin a connector orbetween two adjoining

connectors

by more than 2°.

•

Deflection of the main chord ends.

•

Signs of wear on the connector or the connector that

reduce the cross-sectional area.

•

Deformation or distortion in the main chord area

next to

the welds of the connector.

•

Overloadingby excessive force causes buckling.

•

Overloading through excessive tensile force can

cause

diminution of the main tube next to the welds.

•

Each scratch, cut or hammer stroke indentation

on the

connector to a depth of more than 1mm andthat is longer

than 10 mm, independent of the

direction.

•

Excessive corrosion in the connector.

For systems that have remained assembled for more

than one year

indoors or for 2 months outdoors,

new, galvanized bolts should be

used or stainless

-steel

versions in order to prevent possible

dangers by galvanic

corrosion.

12.6 PINS

Pinsundergowearwheninsertedandremoved

frequently,inparticular

by hammer strokes. They can

be regarded as consumer goods.

Pressure areas and deformations in the bolts are

indications of a

massiveoverload. If a bolt shows such a change, it may not be used any

longer.

Further signs of a discard condition:

•Cuts, indentations, scratches and other damages on

the

smooth surface of the pin.

•Burrs, mushroom heads and other protruding, sharp

or

pointed edges at the narrower end of the pin.

•Deformationthroughhammeringwhichcauses

•wear on the cross-hole or damage to a screw thread.

•Attrition of the zinc coating on any part of the bolt,

causing

this to corrode.

•No self-locking nuts may be used if the nylon safety

mechanism is clearly damaged by wear.

NEVER RE-ZINC PLATE STEEL PINS AS THEY ARE

MADE OF HIGH GRADE STEEL. HYDROGYNE

EMBRITTLEMENT MIGHT OCCUR.

13. LEGISLATION

For fabrication and use the following standards are applicable.

MANUFACTURING

EN 1990

Eurocode 0 Basis of structural design

EN 1991 all parts

Eurocode 1 Actions on structures

EN 1993 all parts

Eurocode 3 Design of steel structures

EN 1999 all parts

Eurocode 9 Design of Aluminium structures

EN 1090-1

Execution of steel and aluminium structures-part 1:

Requirements for conformity assessment of

structural components.

EN 1090-3

Execution aluminium structures: technical

requirements for aluminium structures.

ANSI E1.2-2006

Entertainment Technology: Design, Manufacture

and Use of Aluminium Trusses and Tower

EN 17115

Entertainment technology: Specifications for

design, manufacture of aluminium and steel trusses

EN 10042:2005

Arc welded joints in aluminium and its weldable

alloys - Guidance on quality levels for

imperfections.

EN ISO 3834-1 & 3

Quality requirements for welding - Fusion welding

of metallic materials - Part 1: Guidelines for

selection and use Part 3: Standard quality

requirements

EN 754 (all parts)

Aluminium and aluminium alloys - Cold drawn

rod/bar and tube

EN 755 (all parts)

Aluminium and aluminium alloys - Extruded

rod/bar, tube and profiles

12

EN 515:1993

Aluminium and aluminium alloys - Wrought

products - Temper designations

EN 573 (all parts)

Aluminium and aluminium alloys - Chemical

composition and form of wrought products

EN 10204:2004

Metallic products - Types of inspection documents

2006/42/EC

European Machine Directive

USE

BS 7906-2

Code of practice for use of aluminium and steel

trusses and towers / England

LOLER

Safe use of lifting equipment, lifting operations and

lifting equipment regulations / England

DGUV 17/ BGVc1

Staging and Production Facilities for the

Entertainment Industry/ Germany

IGVW SQP1

Code of practice for event technology- Provision

and Use of Truss Systems/ Germany

BS 7906-2

Code of practice for event technology- Provision

and Use of Truss Systems/ Germany

14. GUARANTEE

1. For a period of 12 month we undertake to repair, free of

charge any damage attributable to faulty materials or

workmanship, provided that the appliance is forwarded,

freight paid, to our works or one of the SIXTY82 contract

service organisations.

2. Extended warranty can be obtained by registering your

products at www.sixty82.com

3. The guarantee - period begins with the day of the delivery,

proven by a purchase receipt like an invoice or delivery note

or their copies.

4. The guarantee only is applicable for new equipment.

5. The guarantee does not cover damage due to transport

damage, negligent handling, overload or parts subject to

normal wear and tear. Nor damages that originate from a case

of misuse because of non-observance the instructions in this

manual.

6. The fitting of replacement parts not supplied by us or

modifications of our design by third parties also invalidates the

guarantee.

7. Guarantee repairs do not renew nor extend the guarantee-

period.

15. DISCLAIMER

Sixty82 has made every effort to ensure the accuracy of this

manual, no liability will be accepted for errors. Sixty82 reserves the

right to change or alter their products and documentation without

prior notice.

No part of this manual may be reproduced in any form or by any

means without written permission.

In case of a claim under the guarantee, a malfunction or spare part

requirements please contact your point of sale or Sixty82.

16. CE DECLARATION OF CONFORMITY

13

Table of contents

Popular Construction Equipment manuals by other brands

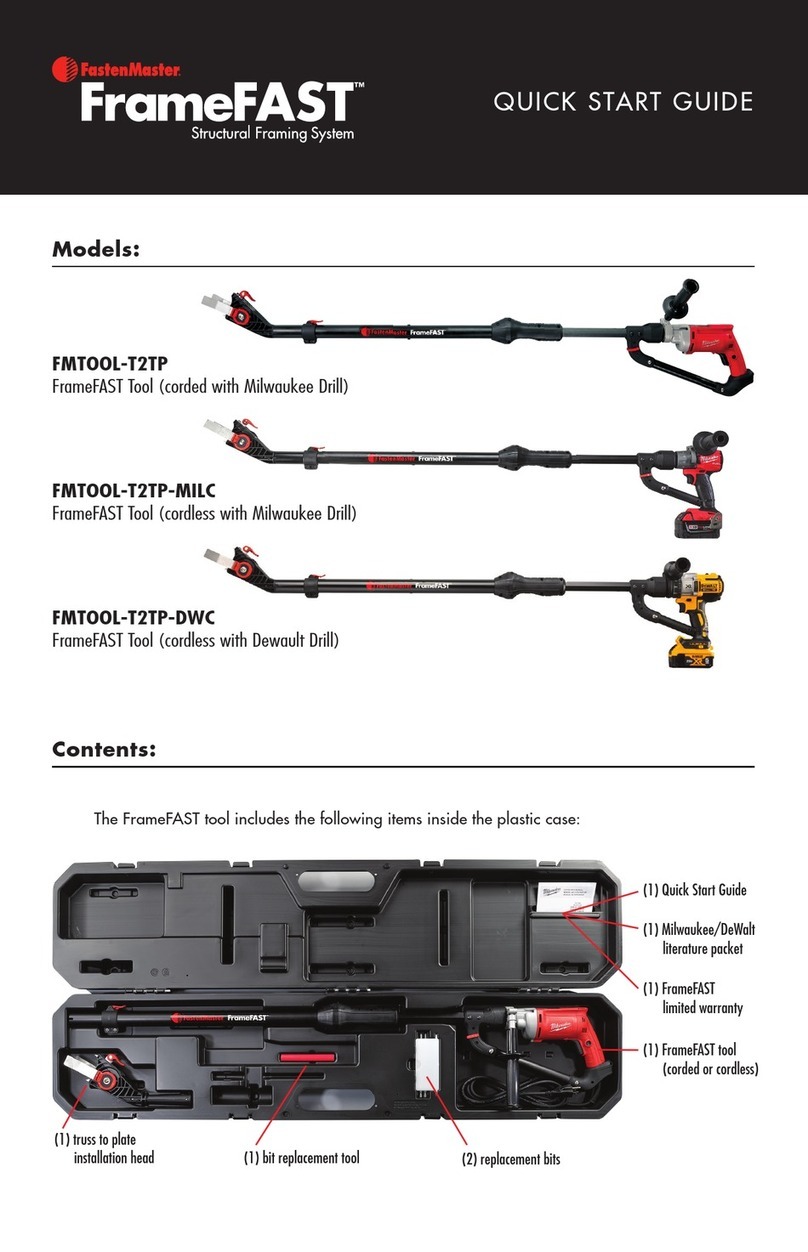

FastenMaster

FastenMaster FrameFAST FMTOOL-T2TP quick start guide

MULTIQUIP

MULTIQUIP Mikasa Series manual

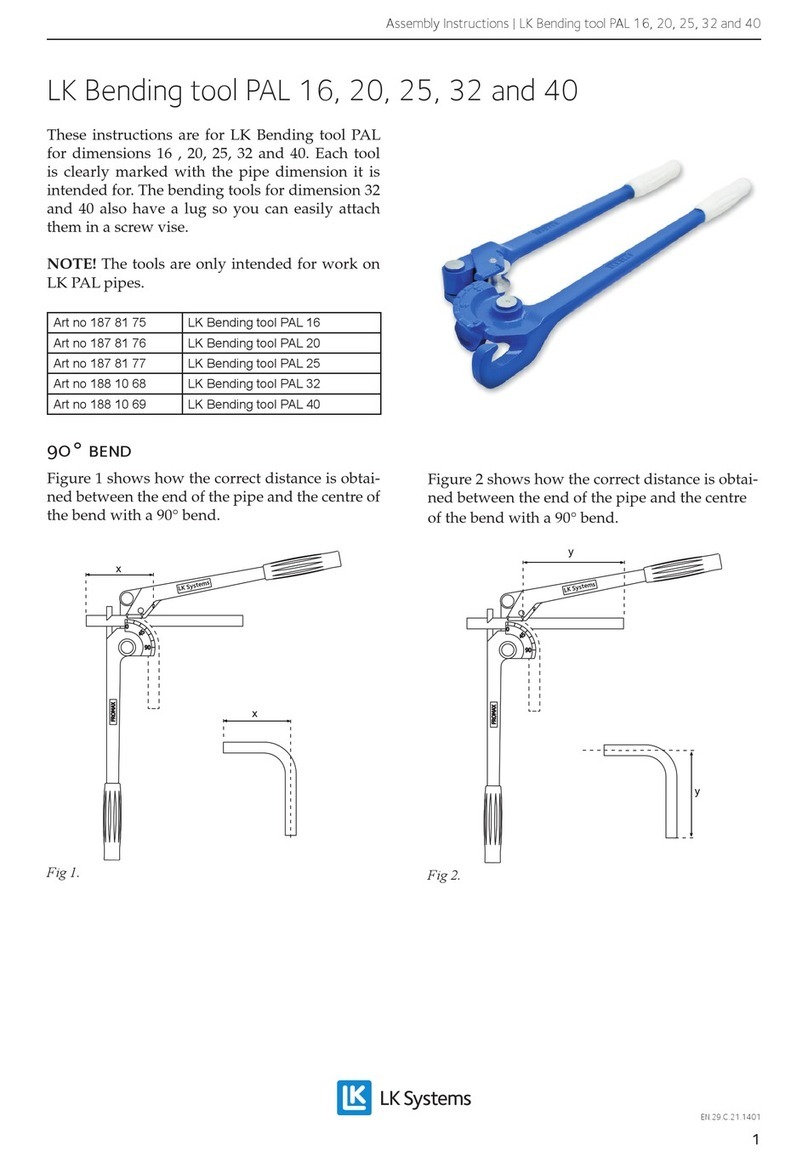

LK Systems

LK Systems PAL 16 Assembly instructions

Atlas Copco

Atlas Copco FlexiROC T30 R Operation

Fayat Group

Fayat Group BOMAG BW 80/90 AD-5 Service manual

Parkside

Parkside PFMR 1400 C2 Operation and safety notes