SJE Rhombus VFDC-4100 User manual

This manual explains the features and operations of the VFDC-

4100 controller which is specifically designed for Pressure Booster

Pump Systems. The VFDC-4100 controller is capable of maintaining

a constant discharge pressure by adjusting the speed of up to 4

Variable Frequency Drives (VFDs), one VFD and up to 3 across the

line (ATL) starters, or one Jockey pump and up to 3 main pumps.

WARNINGS

Failure to read and understand the information provided in this manual may result in personal injury or death, damage to

the product or product failure. Please read each section in its entirety and be sure you understand the information provided

in the section and related sections before attempting any of the procedures or operations given.

Failure to follow these precautions could result in serious injury or death.

Keep these instructions with warranty after installation. This product must be

installed in accordance with National Electrical Code, ANSI/NFPA 70 so as to

prevent moisture from entering or accumulating within the controller housing.

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing this product.

A qualified service person must install and service this product

according to applicable electrical codes and electrical schematics.

EXPLOSION OR FIRE HAZARD

Do not use this product with flammable liquids. Do not install in

hazardous locations as defined by National Electrical Code,

ANSI/NFPA 70.

• Do not install in area with: excessive or conductive dust, corrosive or

flammable gas, moisture or rain, excessive heat, regular impact shocks

or excessive vibration.

• Do not place in water or let water leak onto the controller.

• Do not allow debris to fall inside the unit during installation.

• Double-check all the wiring before turning on the power supply.

• Do not touch live wires.

• Stay as far as possible from high-voltage cables and power equipment.

• Leave a minimum of 10 mm space for ventilation between the top and

bottom edges of the controller and enclosure walls.

SJE-Rhombus VFDC-4100 Controller User Manual 1

Table of Contents

Chapter 1

1.1 Controller Description........................................................................ 2

1.2 Controller Outline Dimension ............................................................ 3

Chapter 2

2.1 Description of Functions.................................................................... 4

2.2 Security.............................................................................................. 5

2.3 Default Values ................................................................................... 6

2.4 Function Keys & Icon Descriptions ................................................... 8

2.5 Description of LCD Screen................................................................ 9

Chapter 3

3.1 Security............................................................................................ 10

3.2 Details of Setup Menus ................................................................... 10

3.3 Setup Menu Display & Input Method............................................... 14

Chapter 4

4.1 Triplex VFD Power Circuit Schematic (VFD) .................................. 16

4.2 Triplex Controller Circuit Schematic (VFD) ..................................... 17

4.3 Triplex VFD Power Circuit Schematic (1VFD+ATL)........................ 18

4.4 Triplex Controller Circuit Schematic (1VFD+ATL)........................... 19

Chapter 5

5.1 Troubleshooting............................................................................... 20

Chapter 6

6.1 Fault Alarm Display & Corrective Actions ....................................... 21

6.2 Alarm Data Screen.......................................................................... 22

6.3 Operation Data Log Screen & Run Times ...................................... 22

ModBus Communication Functions & Adress Code........................ 24

2SJE-Rhombus VFDC-4100 Controller User Manual

Chapter 1

1.1 Controller Description

<Front View>

<Rear View>

LCD Screen

LED Indicators

Push Buttons

CN2 Sensor Terminal

CN10 COMM Port

CN7 Fault Inputs

CN8 Low Suction/Set

Pressure 2

CN1 Annalog Speed

Refs.

CN3 Transistor outputs

CN5 Relay outputs

CN4 DC Input Power

SJE-Rhombus VFDC-4100 Controller User Manual 3

1.2 Controller Outline Dimensions in inches.

Chapter 2

2.1 Description of Functions

LCD Display

The LCD Display is a user friendly operator interface with 240 x 64 pixels resolution; it allows the user to quickly view the

system status and log.

Multiple Pumps Parallel Operation

The controller is able to control up to four (4) pumps utilizing all VFD’s, or one VFD with up to 3 ATL (across the line)

starters for the lag pumps.

Lead/Lag Operation

A fully automatic lead/lag operation based on the variation of the system discharge flow allows you to significantly reduce

your energy cost and consistently maintain the system pressure. While the lead pump is operating, the system will

sequentially start and stop lag pump(s) based on variation of the system pressure.

Across The Line (ATL) Pump Operation

When enabled and utilized, this function allows for multiple pumps to be controlled in a true PID pressure control system,

while only needing one VFD. When the output of the lead pump (VFD) is at 100%, the controller changes that pump over

to direct (ATL) operation and switches on the first lag pump using the VFD. In the same way, lag pump 2 and 3 can be

added as needed for heavy flow conditions. The pump being controlled by the VFD will always be varying its speed as

needed to maintain the set pressure.

Automatic Re-Start

Should the system shutdown by a sudden power loss, it will automatically restart when the power is restored. No manual

reset is required. The system automatically returns to the running condition programmed and stored in the system memory.

Lead Pump Alternation

When selected as set time based, the alternation will occur when the total operating time of the lead pump reaches to

the alternation time; the system automatically selects the next pump in sequence to be the lead pump. This function is

designed to reduce the system life cycle cost. The system make all pump operate for equal period of time as to prevent

the over-use of a particular pump resulting in high parts wear of the pump. The alternation may also be cycle based

rather than time based.

Faulty Pump(s) Skip Function

The system automatically skips any pump sending a fault signal to the controller, and immediately changes the operating

sequence to the functioning pumps. The faulty VFD/Pump will continue to report its fault until maintenance personnel can

diagnose and repair the fault condition. A fault can be any of the following: VFD fault, starter overload trip (when using

starters) or HAND/OFF/AUTP (HOA) selector switch is not in the AUTO position.

Dry Run Prevention

The system automatically stops the running pump(s) upon the detecting a Low pressure signal (Low Water). This

function prevents the pump(s) from dry running that may result in damage to the pump(s).

Program

Used to program the set pressure to change based on a time/day/month basis.

Dual Set Pressures

An additional SET PRESSURE is available in the PRESSURE menu and can become the active set pressure by

activating input 018 on CN8. This function can be useful for systems with large fluctuations in suction pressure or large

variations in demand flow.

Alarm Display and Logging

The system displays alarm conditions on the LCD monitor, and records the condition in a log that is date and timed

stamped.

Operating Data Display and Storage

The semi-permanent operating data recording and storage for each pump allows efficient pump maintenance.

4SJE-Rhombus VFDC-4100 Controller User Manual

Freeze Prevention

When this function is enabled the lead pump will automatically start at the VFD minimum output for 30 seconds and then

shift to the next pump when the temperature is under 32 deg. This will occur when all pumps are stopped for more than

30 seconds at the same time.

Idle Prevention

If the lead pump does not run for the set time, corrosion of some parts may occur. In order to prevent this, the system

will automatically run the lead pump at the minimum operating speed for 60 seconds and then starts the next pump in

sequence. The same process will be repeated if the succeeding lead pump does not run during the set time.

Password

If the password function is enabled, a pop-up window will appear when you press the MENU button. You must enter your

password to access the setup screens. This is to prevent access to the input values by an unauthorized person. You can

change or disable the user password if you wish, however once enabled you must remember the value to gain access to

the setup menu.

Communication

It is possible to monitor the system remotely when connected via the RS-485 port. See page 24 for details.

PID Control

The microprocessor based controller is programmed to perform adjustable Proportional, Integral and Derivative control to

provide consistent and reliable pressure control.

LCD Screen Saver

The back light of the LCD display is programmed to automatically fade out if the keypad is not used for a set time. This

function allows for maximum life span of the LCD monitor. This function can be disabled if desired.

Jockey Pump Function

The role of the Jockey pump is to maintain constant pressure during low flow conditions. When utilized, the jockey pump

is typically much smaller than the main pumps and is well suited to handle variations in flow at a low flow rate. When flow

demand exceeds the capacity of the Jockey pump and the main pumps are called to run, the Jockey will turn off after a

programmable delay time, minimizing wear on the small pump.

Pre-Charge Function

In systems that drain out when not running, the pre-charge function allows for filling the piping system without causing

damage. This function allows for the lead pump to run at a low preset speed for a preset time prior to switching over to

full automatic operation. This greatly reduces water hammer to the piping system.

SJE-Rhombus VFDC-4100 Controller User Manual 5

2.2 Security

The security system is designed to prevent access by unauthorized persons to the setup menu without entering a user

password. If this function is turned on in the protect menu you will be required to enter the password to gain access to

the setup screens. When you press the [Menu] button, the password pop-up window will appear. You must enter your

user password to access the setup menu screens.

Set the password in the password function under the protect menu item by using the up/down & right/left key and press

the enter button. The password must consist of 4 numbers.

After entering the password, and exiting the setup menu, access to the setup screens will be locked. The password will

then need to be re-entered to access the setup screens.

6SJE-Rhombus VFDC-4100 Controller User Manual

2.3 Default Values

Menus Setup Menus Default Input Range

YEAR 2004 0000 ~ 9999

MONTH 1 1 ~ 12

DATE 1 1 ~ 31

DATE WEEKDAY 0 MONDAY ~ SUNDAY

TIME HOUR 0 0 ~ 23

MINUTE 0 0 ~ 59

SECOND 0 0 ~ 59

LEAD PUMP PUMP 1 1 ~ 4

PUMP 1 USED USED, NOT USED, JOCKEY

PUMP PUMP 2 USED USED, NOT USED

SET UP PUMP 3 NOT USED USED, NOT USED

PUMP 4 NOT USED USED, NOT USED

SET PRESSURE 60 PSI 2 PSI ~ 650 PSI

SET PRESSURE 2 60 PSI 2 PSI ~ 650 PSI

HIGH PRESSURE LIMIT 95 PSI 3 PSI ~ 719 PSI

PRESSURE LOW PRESSURE LIMIT 15 PSI 1 PSI ~ 649 PSI

SET UP START LEAD PRESSURE -3 PSI -65 PSI ~ 65 PSI

START LAG PRESSURE -7 PSI -65 PSI ~ 65 PSI

STOP LAG PRESSURE 3 PSI -0 PSI ~ 65 PSI

P VALUE 60 0 ~ 200

I VALUE 30 0 ~ 200

D VALUE 1 0 ~ 200

CYCLE TIME 120 Msec. 50 ~ 999 M.SEC.

ALTERNATION 24 HOURS 0 ~ 999 HOURS

FRICTION 0.0 PSI 0 ~ 650 PSI

CONTROL RUN DELAY 1 SECONDS 0 ~ 10 SECONDS

SET UP STOP DELAY 1 SECONDS 0 ~ 999 SECONDS

JOCKEY STOP DELAY 5 SECONDS 0 ~ 999 SECONDS

OPERATION TYPE VFD VFD, 1VFD+ATL

LOW SUCTION TMR 30 SECONDS 10 ~ 999 SECONDS

LOW SUCTION RST AUTO AUTO, MANUAL

LOW SUCTION RST TMR 30 SECONDS 10 ~ 9999 SECONDS (2.78 HOURS)

LOW PRESSURE STOP TIME 10 SECONDS 10 ~ 999 SECONDS

INITIALIZE YES, NO

SENSOR SENSOR VALUE 200 PSI 29 PSI ~ 720 PSI

SET UP SENSOR OFFSET 0 PSI -72 PSI ~ 72 PSI

VFD STOP TIME 30 SECONDS 0 ~ 60 SECONDS

VFD MINIMUM RATE 40% 10 ~ 90 % (of VFD DISP. TYPE)

VFD STOP RATE 60% 20 ~ 90 (of VDF DISP. TYPE)

VFD VFD DISP. TYPE 100% 100%, 60Hz, 50Hz

VFD AUTO RESET 5 0 ~ 20

PIPE FILL OFF ON, OFF

PIPE FULL RATE 45% 10 ~ 90% of VFD DISP. TYPE or VFD

PIPE FILL TIMER 30 SECONDS 5 ~ 600 SECONDS

SJE-Rhombus VFDC-4100 Controller User Manual 7

2.3 Default Values con’t.

Menus Setup Menus Default Input Range

IDLE PREVENTION NOT USED USED, NOT USED

PROTECT FREEZE PREVENTION NOT USED USED, NOT USED

PASSWORD USE NOT USED USED, NOT USED

PASSWORD 1234 0000 ~ 9999

RETURN TO MAIN SCREEN 120 SECONDS 10 ~ 300 SECONDS

LCD BACK LIGHT TIME 120 SECONDS 10 ~ 998 SECONDS (999 TO DISABLE)

DATA LOG 60 SECONDS 0 ~ 999 SECONDS (16.65 MIN)

TEST CODE 0 0 ~ 9999 (NOT USED)

RELAY OUTPUT 1 STOP AVAILABLE SETTINGS FOR OUTPUTS:

RELAY OUTPUT 2 RUNNING NOT USED, PUMPS STOPPED, PUMPING,

SYSTEM RELAY OUTPUT 3 ALARM GENERAL ALARM, LOW SUCTION, P1-P4

RELAY OUTPUT 4 NOT USED VFD RUN, P1-P4 ALT RUN, BUZZER,

RELAY OUTPUT 5 NOT USED LOW PRESSURE, HIGH PRESSURE,

DIGITAL OUTPUT 6~13 NOT USED VFD1-4 FLT/HOA, SENSOR FAULT

LANGUAGE ENGLISH ENGLISH, ESPANOL

PRESSURE UNIT PSI PSI, BAR

SCHEDULE OPERATION NOT USED NOT USED, TIMELY, WEEKLY, MONTHLY

PROGRAM 00:00:00~00:00:00 NOT USED 0 PSI ~ 650 PSI

TUESDAY NOT USED 0 PSI ~ 650 PSI

FEBRUARY NOT USED 0 PSI ~ 650 PSI

PARITY NONE EVEN, ODD, NONE

BAUDRATE 9600 9600, 14400, 19200

COMM NODE 1 1~31

SET DATA BITS 8

STOP BIT 1 1,2

ALARM DATA 32 MOST RECONT ALARMS SAVED SEE CHAPTER 6

OPERA DA OPERATION DATA SELECTION RUN LOG RUN LOG, PUMP RUN TIMES

Total 2000 lines of data saved.

(Refer to Chapter 6)

8SJE-Rhombus VFDC-4100 Controller User Manual

J

“Pump Setting” - “Pump 1”

When you set “Jockey Pump”

The VFD faulted while operating

the pump.

“Pump Setting” - “Pump 1 ~ 4”

Set to “USED” when the pump is

available for use.

“Pump Setting” - “Pump 1 ~ 4”

Set to “NOT USED” when the pump is

NOT available for use.

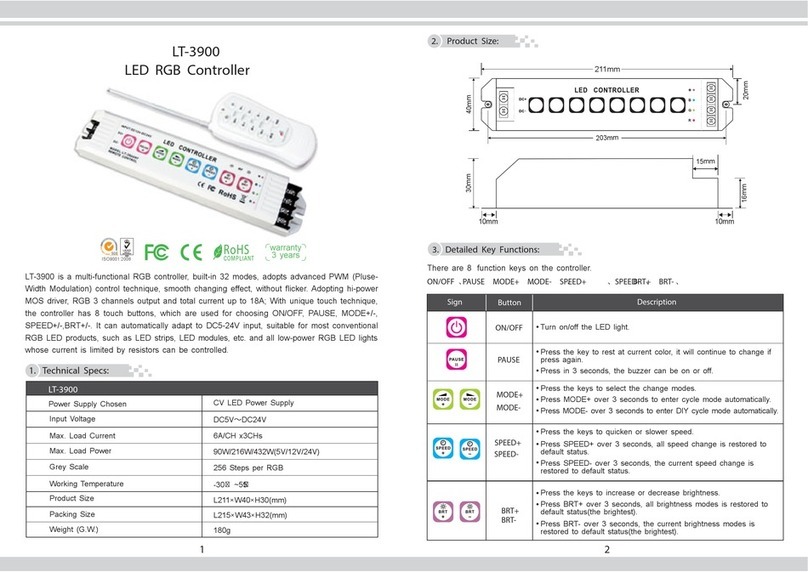

2.4 Function Keys & Icon Description

2.4.1 Function Description

LCD Screen/LED Indicators/Keypad

1. LCD: Displays on the screen the operating status and setting.

2. LED: Displays the operation, alarm, operating pump, etc.

Four PUMP LED displays the operation of each pump.

LED Off: PUMP stopped

LED On: PUMP running

3. Function Keys

2.4.2 Description of Icon

Menu Navigation and Data Entry

Pressing the menu button will enter the main setup menu items. The system will ask for a password if enabled. Using

the arrow buttons, navigate to the item desired, and press enter. Navigate with the arrows and enter the item of choice to

display its value. Enter to change the value using the arrow buttons and again press the enter button to accept the new

value, or press esc. to exit without saving. Press the esc., enter and arrow buttons as desired to move up, drill down,

and navigate the screen as needed.

WARNING:

Certain settings will not change when system is in “AUTO” mode. For these, set the HOA switches to “OFF” to make changes.

RESET

Used to clear faul codes

after the fault condition is

removed. (Some Faults may

require you to cycle power.)

ESC

Press to move up in

the menu structure or

cancel an entry without

saving.

ENTER

Press to accept a value

or navigate down within a

menu item.

Navigation Buttons

MENU

Used to access the main setup screen.

System may ask for a password

if enabled.

SJE-Rhombus VFDC-4100 Controller User Manual 9

2.5 Description of LCD Screen

2.5.1 Opening Screen

Opening Screen: when the controller power is turned on, the opening screen will be displayed for 3 seconds.

2.5.2 Main Screen

1. Opr. Pre = current discharge pressure & Set Pre = set pressure (Target pressure)

2. Alarm & Time Display: Display of the current time and alarm list if an alarm is active.

3. Auto/Stop Display: Display of the operating condition of the system.

“AUTO” – Is in AUTO if any of the HAND/OFF/AUTO selector switches in AUTO position (Input CN7)

“STOP” - is displayed if none of the HAND/OFF/AUTO selector switches are in AUTO position

4. VFD Output Frequency Display: Display of the output value of the VFD running.

The VFD output display can be configured in percentage (%) or in frequency (50Hz or 60Hz).

5. Pump Status Display: Idle, Running, VFD Fault, or Jockey.

6. Pump Number: Display of the total pumps and Lead pump and numbers.

The Lead pump is labeled “L”, the other pumps are labeled “P”.

PRESSURE BOOSTER

CONTROLLER

PCB-4000 VER 1.05

1. Current & Set Pressure Display

2. Alarm & Time Display

6. Pump Number Display

5. Pump Status Display

4. VFD Output Frequency Display (0-100% = 0-60Hz)

3. Auto/Stop Display

L = Lead Pump

10 SJE-Rhombus VFDC-4100 Controller User Manual

Chapter 3

3.1 Security

The security system is programmed to prevent access by unauthorized persons to control setup without User Password.

<PASSWORD INPUT>

<Password Input Screen>

When you press the [MENU] button, the password pop-up window will appear as shown in the figure above. You must

enter your user password “1234” to access the menu items screen.

• Set the password by using the Up/Down & Right/Left Key and press the Enter button.

• The password must consist of 4 numbers.

• The default User Password is 1234.

NOTE: After entering the password, access to the setup screen will be granted until the LCD backlight timer times

out. The password will then need to be re-entered to access the setup screens. If you don’t give any controls on the

Setup Menu Screen, it will automatically return to the Main Screen. It is strongly recommended to change the password

after the initial access. If you set the system control to factory default setting, the password is initialized to the default

password “1234”. NOTE: The password feature is disabled by default.

INPUT PASSWORD !

0 0 0 0

04. 12. 01 Ver 1.03

3.2 Details of Setup Menus

3.2.1 Date/Time Setup: Current Time Setup

Menus Setup Menu Contents Input Range

YEAR Current Year Display 0000 ~ 9999

MONTH Current Month Display 1 ~ 12

DATE Current Date Display 1 ~ 31

DATE/TIME DAY Current Day Display MONDAY ~ SUNDAY

HOUR Current Hour Display 0 ~ 23

MINUTE Current Minute Display 0 ~ 59

SECOND Current Second Display 0 ~ 59

The time and date does not change should you set the set system to factory default.

3.2.2 Pump Setup

Menus Setup Menu Contents Input Range

LEAD PUMP Lead Pump Selection 1 ~ 4

PUMP 1 Used, Not used or Jockey Used, Not Used, Jockey

PUMP PUMP 2 Used or Not Used Used, Not Used

SETUP PUMP 3 Used or Not Used Used, Not Used

PUMP 4 Used or Not Used Used, Not Used

The lead pump must be set to a pump that is USED and not the Jockey pump.

If PUMP1 is set to JOCKEY, the Jockey pump will always start first and cannot be the LEAD PUMP. The jockey pump

is not included in the lead lag sequencing. The jockey pump will operate alone unless the set pressure cannot be

maintained. Then the lead pump and subsequent pumps will start based on lead/lag sequencing. The jockey pump will

stop after the lead pump starts and a preset delay times out (JOCKEY STOP DELAY).

SJE-Rhombus VFDC-4100 Controller User Manual 11

3.2.3 Pressure Setup

Menus Setup Menu Contents Input Range

SET PRESSURE Target pressure for the pump system discharge 2 PSI ~ 650 PSI

SET PRESSURE 2 To change the set pressure to this alternate 2 PSI ~ 650 PSI

value, a dry contact must close between G-COM

and 018 on the CN8 terminals.

HIGH LIMIT ALARM If the discharge pressure exceeds this value, the 3 PSI ~ 719 PSI

controller will shutdown the pumps after a delay.

LOW LIMIT ALARM If the discharge pressure drops below this value, 1 PSI ~ 649 PSI

PRESSURE the contoller will shutdown the pumps after a

delay.

SETUP START LEAD PRESSURE If the set pressure is 60 PSI and start lead -65 PSI ~ 65 PSI

pressure at -3 PSI, the lead pump will start

when the operating pressure drops below 57 PSI.

START LAG PRESSURE If the set pressure is 60 PSI and start lag -65 PSI ~ 65 PSI

pressure is -7 PSI the lag pump(s) will start when

if lead pump is operating full speed (100% and

the system pressure drops below 53 PSI.

STOP LAG PRESSURE If the set pressure is 60 PSI and the stop lag 0 PSI ~ 65 PSI

pressure is 3 PSI the lag pump will stop if it is

operating at minimum speed (example 50%)

and the current pressure is over 63 PSI.

3.2.4 Control Setup

Menus Setup Menu Contents Input Range

P P Value Setup of PID (Proportional) 0 ~ 200

I I Value Setup of PID (Integral) 0 ~ 200

D D Value Setup of PID (Derivative) 0 ~ 200

CYCLE TIME Sampling time of PID Control 0 ~ 999 m.sec

ALTERNATION Shifts the lead to the next available pump in the 0 ~ 999 HOURS (set to 0 for

sequence.

lead. Change every cycle, set

to 999 for no alternation)

FRICTION PSI offset allowance for friction loss 0 PSI ~ 900 PSI

RUN DELAY Delay time for pumping output to start 0 ~ 999 SECONDS

STOP DELAY Delay time for pumping output to stop 0 ~ 999 SECONDS

CONTROL JOCKEY STOP DELAY TIME Delay time after the main pump starts 0 ~ 999 SECONDS

SET UP OPERATION TYPE Sets the operation type. VFD = multiple VFD VFD, 1VFD+ATL

control system (1 VFD for each pump.)

1VFD+ATL = Single VFD control system

(combination of 1 VFD and starters)

LOW SUCTION TMR Delay time before stipping the pump due to low 10 ~ 999 SECONDS

suction pressure

LOW SUCTION RST Method used to reset the low suction shut AUTO, MANUAL

down valve

LOW SUCT RST TMR When low scution rest is set to auto, this is the 10 ~ 999 SECS (2.78 hrs)

time the controller will wait before attempting

to reset.

LOW PRESS STOP TIME Delay time before stopping the pump due to low 10 ~ 999 SECONDS

pressure fault.

INITIALIZE All parameters are set to factory defaults YES, NO

(except data setup)

12 SJE-Rhombus VFDC-4100 Controller User Manual

3.2.6 VFD Setup

Menus Setup Menu Contents Input Range

VFD STOP TIME Time delay for when the last pump stops after 0 ~ 60 SECONDS

the speed drops to the VFD minimum rate.

VFD MINIMUM RATE VFD minimum speed output 10 ~ 90%

VFD STOP RATE The last pump stops when its speed is less than 20 ~ 90%

this set value and the VFD STOP TIME is done.

VFD DISP. TYPE Display the VFD output value on the main screen. 100%, 60Hz, 50Hz

VFD VFD AUTO RESET Reset times after an alarm happened while the 0 ~ 20

VFD was operating.

PIPE FILL Enable or disable the pipe fill function. ON, OFF

PIPE FILL RATE The preset speed the pump will run on start up 10- 90% or VFD min speed

slowly fill the pipes. Runs for the PIPE FILL

TIMER or the SET PRESSURE is reached.

PIPE FILL TIMER The length of time the pump will run. If the set 5 ~ 600 SECONDS

pressure is reached during this time, the

system will switch to PID immediately.

3.2.7 Protect Setup

Menus Setup Menu Contents Input Range

IDLE PREVENTION When set to USED, if the lead pump has not ran USED, NOT USED

for 10 days, the system will automatically run the

lead pump at the minimum operating speed for 60

seconds. Then it will switch lead pump. The same

process will be repeated if the succeeding lead

pump does not run for 10 days etc.

PROTECT FREEZE PREVENTION When set to USED, the lead pump will automatically USED, NOT USED

start the VFD minimum output for 30 seconds and

then shift to the next pump when the temperature

is under 32 deg. This will occur when all pumps are

stopped for more than 30 seconds at the same time

PASSWORD USE See password section for description USED, NOT USED

PASSWORD 0000 ~ 9999

3.2.5 Sensor Setup

Menus Setup Menu Contents Input Range

SENSOR TRANSDUCER TYPE Range Setup of Sensor 29 PSI ~ 720 PSI

SETUP SENSOR ADJUST Sensor Offset Value -72 PSI ~ 72 PSI

SJE-Rhombus VFDC-4100 Controller User Manual 13

3.2.8 System Setup

Menus Setup Menu Contents Input Range

RETURN MAIN SCREEN Returns to the main screen after set time if user 10 ~ 300

does not use any key controls

LCD BACK LIGHT TIME After the set time, LCD back light automatically turns 10 ~ 999

off. This can be disabled by setting value to 999.

DATA LOG Sets the sampling rate for the Operation data log 10 ~ 999

SYSTEM TEST CODE Internal code to check the system. 0 ~ 9999

SET UP RELAY OUTPUT 1-5 Relay output 1-5 allows for up to 5A @ 250V

DIGITAL OUTPUT 6-13 Digital output is transistor out. High = 5V Low = 0V

Available settings for outputs are: NOT USED,

PUMPS STOPPED, PUMPING, GENERAL ALARM,

LOW SUCTION, P1-P4 VFD RUN, P1-P4 ATL RUN,

BUZZER, LOW PRESSURE, HIGH PRESSURE,

VFD 1-4 FLT/HOA, SENSOR FAULT

LANGUAGE Language selection English/Espanol

PRESS UNIT Unit of measure for analog input PSI/BAR

3.2.9 Communication Setup (RS-485)

Menus Setup Menu Contents Input Range

PARITY Select parity mode EVEN, ODD, NONE

COMM BAUDRATE Transmission speed 9600, 14400, 19200

SETUP NODE Network node address 1~31

DATA BITS 8

STOP BIT 1,2

3.2.10 Communication Setup

Menus Setup Menu Contents Input Range

SCHEDULE OPERATION This function allows the set pressure to be NOT USED, TIMELY, WEEKLY,

00:00:00 ~ 00:00:00 adusted based on a schedle. If on certain days MONTHLY

PROGRAM of the week, you wanted the set pressure to be

TUESDAY different, you would set schedule operation to

FEBRUARY WEEKLY then set the pressures for the days of

the week.

14 SJE-Rhombus VFDC-4100 Controller User Manual

3.3 Setup Menu Display & Input Method

Example for the Data Setup Change

<Fig 1> Menu Setup Screen

<Fig 2> Data Setup Change Screen

<Fig 3> Date Setup Change Screen

1. The display will change to <Fig 2> if you press the enter button after selecting the Date/Time on the Menu Setup

<Fig 1>.

2. Moved to the set position which needs to be changed: Year/Month/Day/Week by Right & Left key. Press the Enter

key and edit when flashing.

3. Change the value by using the Up/Down keys.

4. Save the changed value by pressing the Enter key.

5. Exit to the main screen by pressing the ESC key.

DATE/TIME PUMP SET PRESSURE

CONTROL SENSOR VFD

PROTECT SYSTEM PROGRAM

COMM SET ALARMS DATA LOG

DATE & TIME SETUP (4.0/RUN)

2005 / 12 / 22 [WED]

11 : 00 : 00

DATE & TIME SETUP (4.0/RUN)

2005 / 12 / 22 [WED]

11 : 00 : 00

SJE-Rhombus VFDC-4100 Controller User Manual 15

Example for the Pressure Setup Change

<Fig 1> Main Screen

<Fig 2> Menu Setup Screen

<Fig 3> Pressure Setup Change Screen

<Fig 4> Pressure Setup Change Screen

<Fig 5> Pressure Setup Change Screen

<Fig 6> Pressure Setup Change Screen

DATE/TIME PUMP SET PRESSURE

CONTROL SENSOR VFD

PROTECT SYSTEM PROGRAM

COMM SET ALARMS DATA LOG

DATE/TIME PUMP SET PRESSURE

CONTROL SENSOR VFD

PROTECT SYSTEM PROGRAM

COMM SET ALARMS DATA LOG

PRESSURE SETUP (60.0/RUN)

SET PRESSURE 60 PSI

HIGH PRE. LIMIT 150 PSI

LOW PRE. LIMIT 20 PSI

Press the “MENU” button.

Use the UP/DOWN and RIGHT/LEFT keys to go to the Pressure

Menu.

Press “ENTER” button to open the Pressure Menu.

Moved to the set position which needs to be changed using the UP/

DOWN key. Press “ENTER” key.

Use the UP/DOWN and RIGHT/LEFT keys to edit.

Save the changed value by pressing the Enter key.

Exit to the main screen by pressing the ESC key.

PRESSURE SETUP (60.0/RUN)

SET PRESSURE 60PSI

HIGH PRE. LIMIT 150 PSI

LOW PRE. LIMIT 20 PSI

PRESSURE SETUP (60.0/RUN)

SET PRESSURE 65PSI

HIGH PRE. LIMIT 150 PSI

LOW PRE. LIMIT 20 PSI

16 SJE-Rhombus VFDC-4100 Controller User Manual

Chapter 4

4.1 Typical Triplex VFD Power Circuit Schematic (OPER TYPE =VFD)

SJE-Rhombus VFDC-4100 Controller User Manual 17

RS-485

CN10

+-

4.2 Typical Triplex Controller Circuit Schematic (OPER TYPE = VFD)

4.3 Typical Triplex VFD Power Circuit Schematic (OPER TYPE = 1VFD+ATL)

18 SJE-Rhombus VFDC-4100 Controller User Manual

Table of contents

Languages:

Other SJE Rhombus Controllers manuals