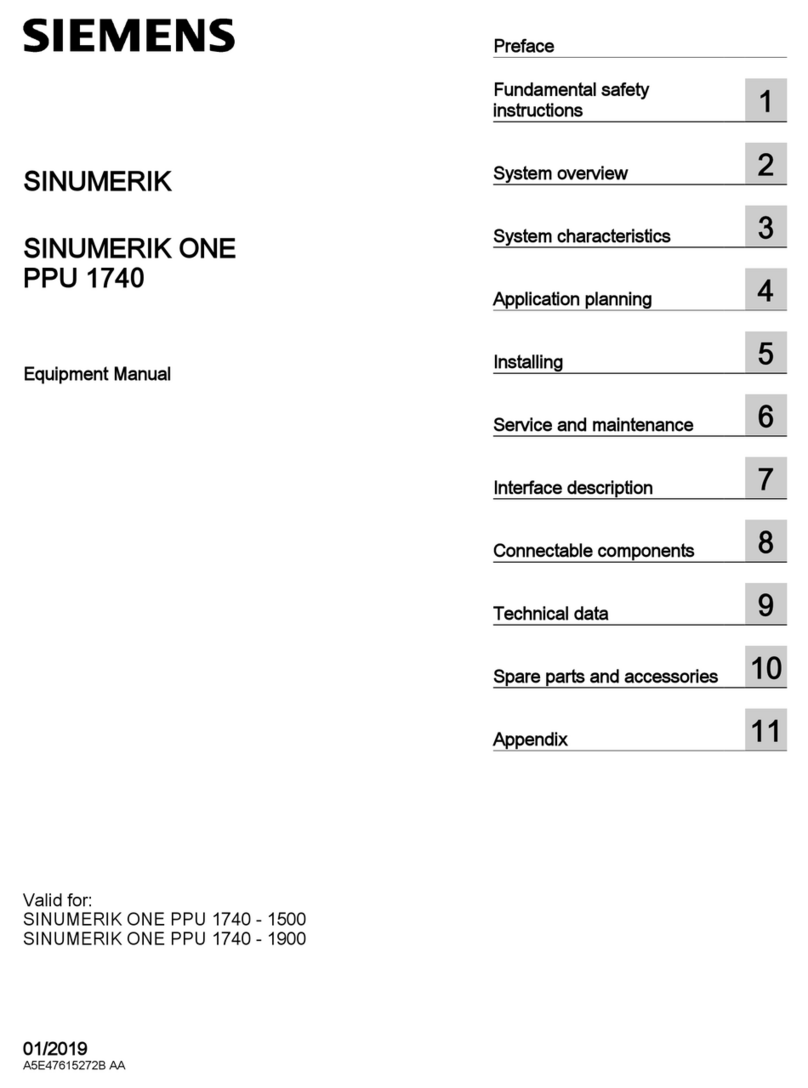

Table of contents

3RW51 Soft Starter

Manual, 06/2019, A5E37108631002A/RS-AB/002 5

7.6 Soft Torque .............................................................................................................................91

7.7 Additional parameters.............................................................................................................93

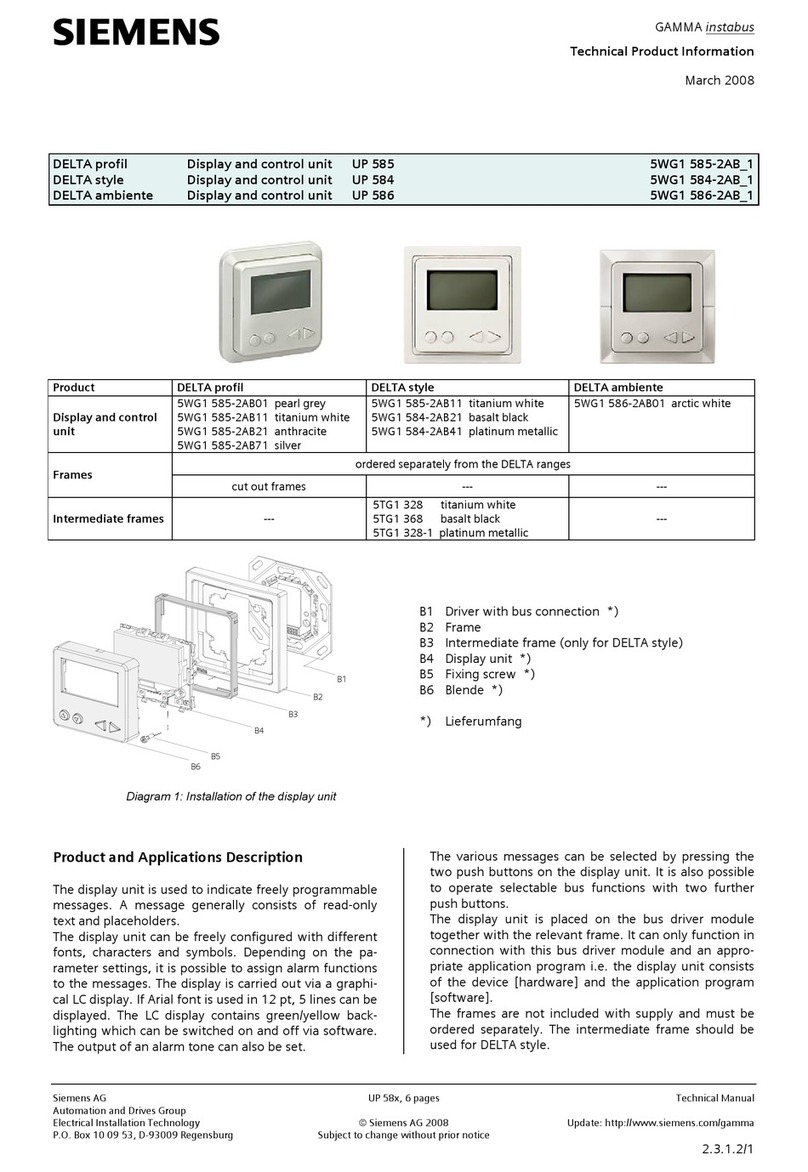

7.8 3RW5 HMI Standard...............................................................................................................94

7.8.1 Design of the 3RW5 HMI Standard ........................................................................................94

7.8.2 3RW5 HMI Standard menu.....................................................................................................95

7.8.3 Setting station address via 3RW5 HMI Standard ...................................................................99

7.9 3RW5 HMI High Feature ......................................................................................................100

7.9.1 Design and operator controls of the 3RW5 HMI High Feature.............................................100

7.9.2 Main menu of the 3RW5 HMI High Feature with the 3RW51 soft starter.............................103

7.9.3 Parameterizing the 3RW5 HMI High Feature .......................................................................107

7.9.4 Monitoring .............................................................................................................................108

7.9.4.1 Monitoring the measured values of the 3RW51 soft starter with the 3RW5 HMI High

Feature..................................................................................................................................108

7.9.4.2 Monitoring the process image of the 3RW51 soft starter with the 3RW5 HMI High

Feature..................................................................................................................................109

7.9.5 Parameterizing analog output AQ via the 3RW5 HMI High Feature ....................................109

7.9.6 Overview ...............................................................................................................................111

7.9.7 Defining the local access protection (PIN)............................................................................113

7.9.8 Micro SD card .......................................................................................................................115

8 Messages & diagnostics ........................................................................................................................ 117

8.1 Diagnostics options...............................................................................................................117

8.2 LED display...........................................................................................................................117

8.2.1 Overview of the device LEDs of the 3RW51 soft starter ......................................................117

8.2.2 Status and error displays ......................................................................................................118

8.2.3 LED STATE / OVERLOAD ...................................................................................................119

8.2.4 Overview of LEDs on 3RW5 HMI Standard..........................................................................120

8.2.5 Overview of LEDs on 3RW5 HMI High Feature ...................................................................121

8.3 Warnings and remedial measures ........................................................................................122

8.4 Faults and remedial actions of the 3RW51 soft starter.........................................................123

8.5 Faults and remedial actions on the 3RW5 HMI High Feature ..............................................126

8.6 RESET MODES....................................................................................................................127

8.7 Diagnostics via the 3RW5 HMI High Feature module ..........................................................128

8.7.1 Diagnostics of the 3RW51 soft starter with the 3RW5 HMI High Feature............................128

8.7.2 Diagnostics of communication with the 3RW5 HMI High Feature........................................130

8.7.3 Execute HMI diagnostics with the 3RW5 HMI High Feature ................................................131

8.7.4 Logbooks ..............................................................................................................................132

9 Maintenance and servicing .................................................................................................................... 133

9.1 Maintenance and repairs ......................................................................................................133

9.2 User test................................................................................................................................134

9.3 Firmware update...................................................................................................................137

9.4 Perform the firmware update using micro SD memory card (3RW5 HMI High feature).......138

9.5 Restore factory setting..........................................................................................................139

9.5.1 Restoring the factory settings via 3RW5 HMI High Feature.................................................140

9.5.2 Restoring the factory settings with the reset button via 3RW5 HMI High Feature ...............141