skeletal dynamics DISTAL ELBOW SET User manual

As described by:

Jorge L. Orbay, M.D.

Miami Hand & Upper

Extremity Institute

Miami, Florida

SURGICAL TECHNIQUE GUIDE

DISTAL ELBOW SET

proximal ulna plate

Indications for Use

The proximal ulna plates are intended for xation of fractures, fusions, osteotomies

and non unions of the ulna, particulary in osteopenic bone.

Please refer to the Distal Elbow Plating Set Instructions for Use to review the warnings, precautions and contraindications for this system.

DISTAL ELBOW SET

proximal ulna plate

1

2

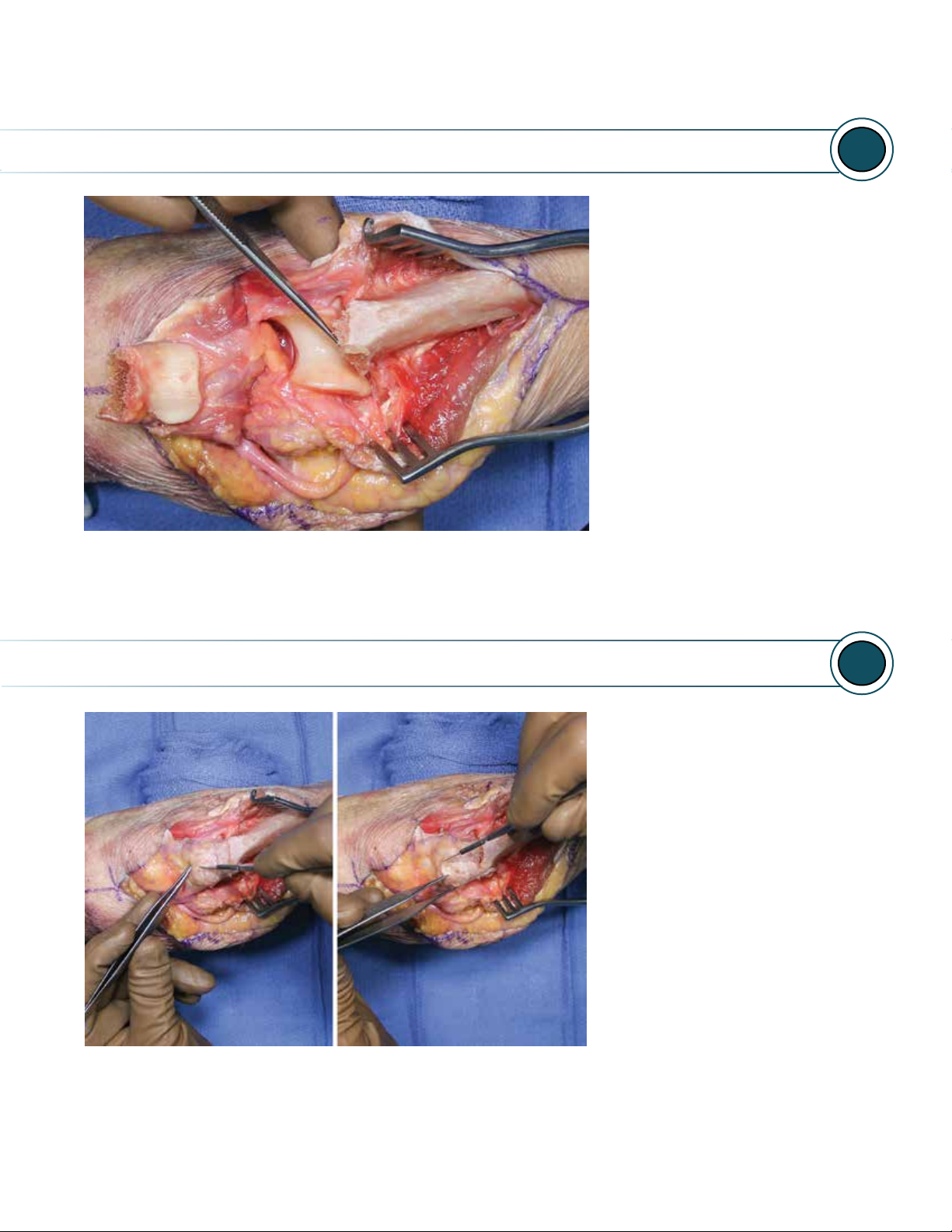

SUPERFICIAL EXPOSURE

Locate the ulnar nerve.

Release and protect the

nerve, considering the

possibility of transposition.

With the elbow exed 900,

make a posterior incision

extending distally, curving

around the olecranon and

over the subcutaneous

border of the ulna.

NOTE:

The incision can be curved

slightly lateral or medial to

the tip of the olecranon

based on your preferred

method.

Warning:

Take care to avoid injury to

the ulnar nerve.

DISTAL ELBOW SET

proximal ulna plate

RELEASING THE ULNAR NERVE

4

3 DEEP EXPOSURE

ACCESSING THE JOINT

Expose the proximal ulna

sub-periosteally.

For olecranon fractures,

enter the joint through the

fracture plane by releasing

the capsular attachments

on the proximal fragment as

needed.

The articular surfaces can be

evaluated at this time.

5

6

Debride the fracture site.

NOTE:

It is necessary to remove

callus, clot and brous tissue

in order to achieve a proper

reduction.

DEBRIDING THE FRACTURE

DISTAL TRICEPS RELEASE

Starting distal to proximal,

split the triceps insertion

longitudinally for approximately

1 cm.

Elevate the triceps along a

narrow longitudinal strip to

provide space for the “Home

Run” (HR) tab.

7

8

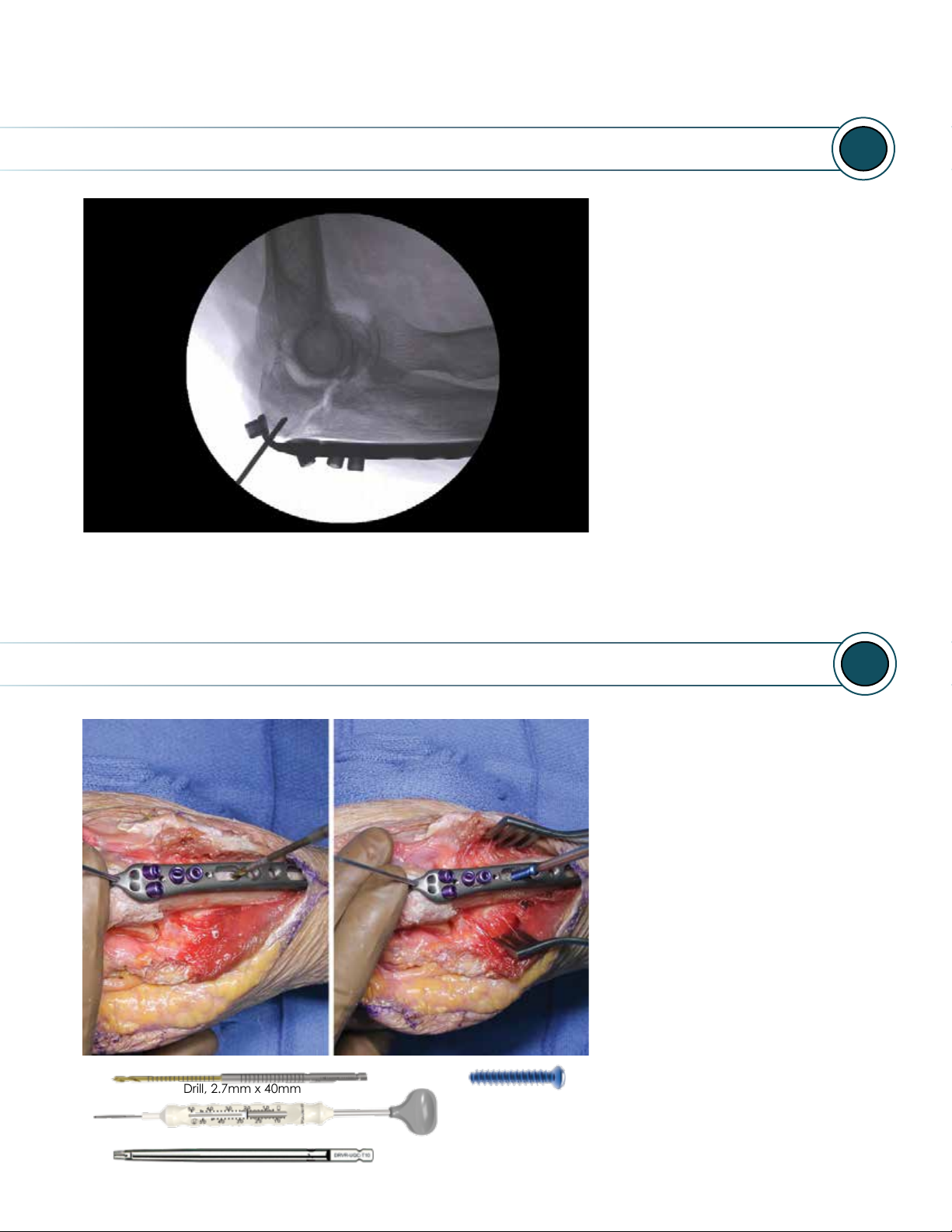

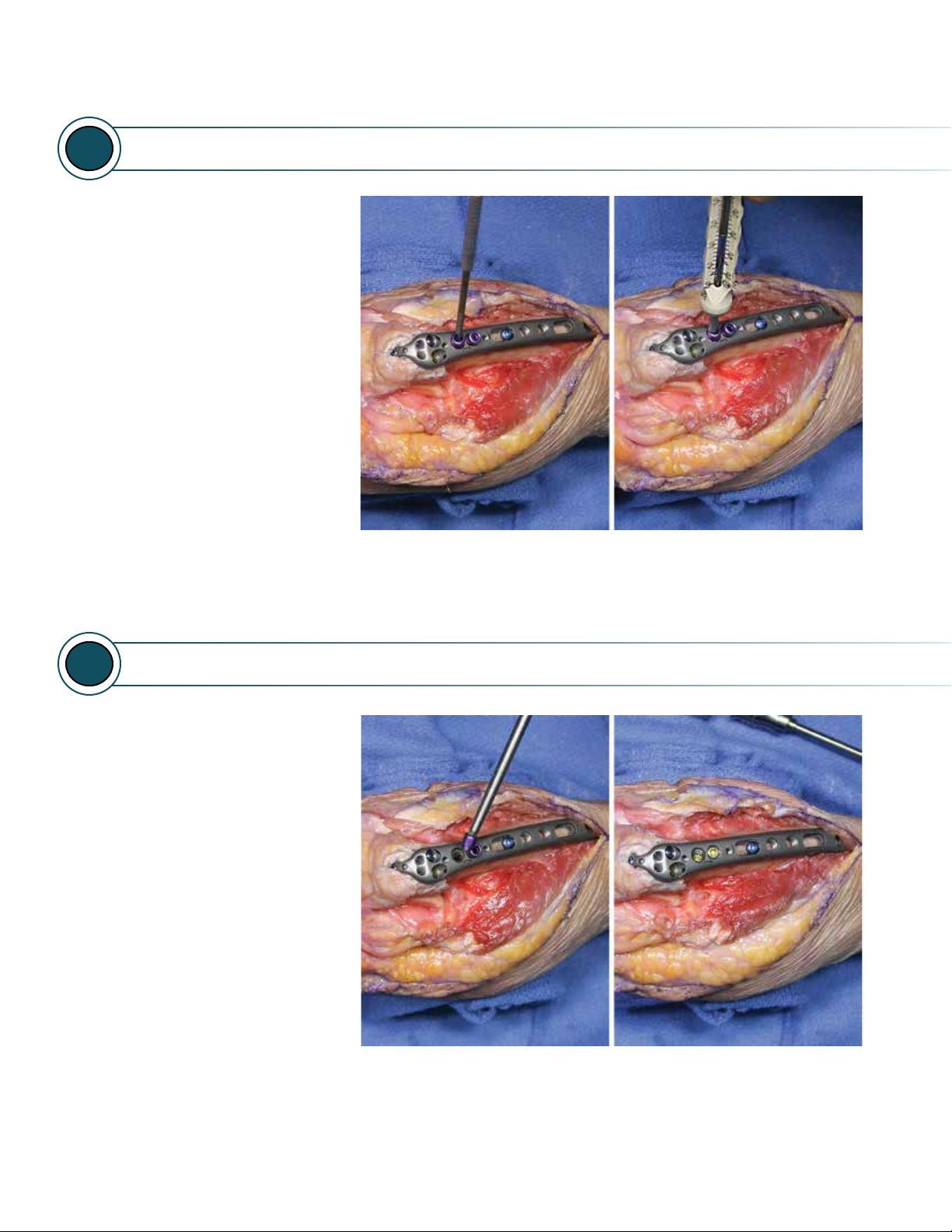

PLATE SELECTION

PROVISIONAL PLATE FIXATION

Select the appropriate

length of plate that provides

at least six cortices of xation

distal to the fracture line.

NOTE:

The shaft of the 151mm

length plate can be bent

using the Bending Irons. If

plate bending is necessary,

please refer to step 29 in this

surgical technique guide.

WARNING:

Bending may weaken or

break the plate. Be sure

to inspect the plate for

damage prior to use.

Apply the plate to the

proximal fragment conrming

that the plate is centered on

the unla shaft and that the HR

tab is ush to the olecranon.

Secure the plate to the

proximal fragment using a

2mm K-wire through the hole

at the base of the HR tab.

K-wire, 2.0mm

9

10

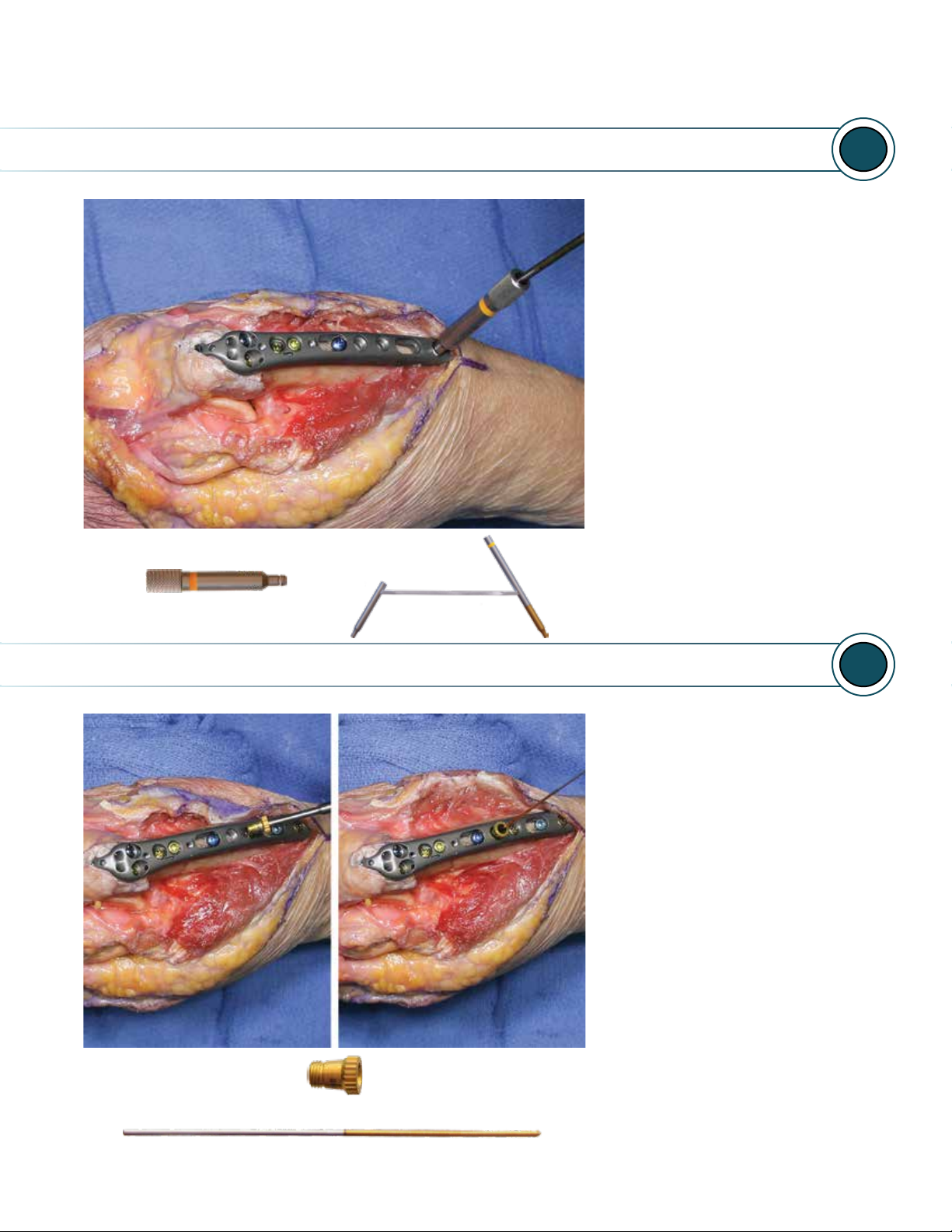

FRACTURE REDUCTION

Reduce the fracture by

levering the shaft of the

plate to the distal fragment.

Conrm fracture reduction

and plate alignment using

uoroscopy.

DISTAL FRAGMENT FIXATION

Using the 2.7mm x 40mm bit,

drill bicortical through the

distal end of an oblong hole

that is distal to the fracture

line. This will allow for dynamic

compression of the fracture.

Measure screw length using

the appropriate scale on the

50mm Depth Gauge, then

insert a 3.5mm compression

screw (PANL series) using the

T-10 Driver while applying

interfragmentary compression.

NOTE:

The depth gauge has a dual

scale to reect measurements

through the PDG’s (top scale)

or directly through the plate

(bottom scale).

Drill, 2.7mm x 40mm Compression

Screw

(3.5mm PANL)

Driver, T-10

Depth Gauge, 50mm

11

12

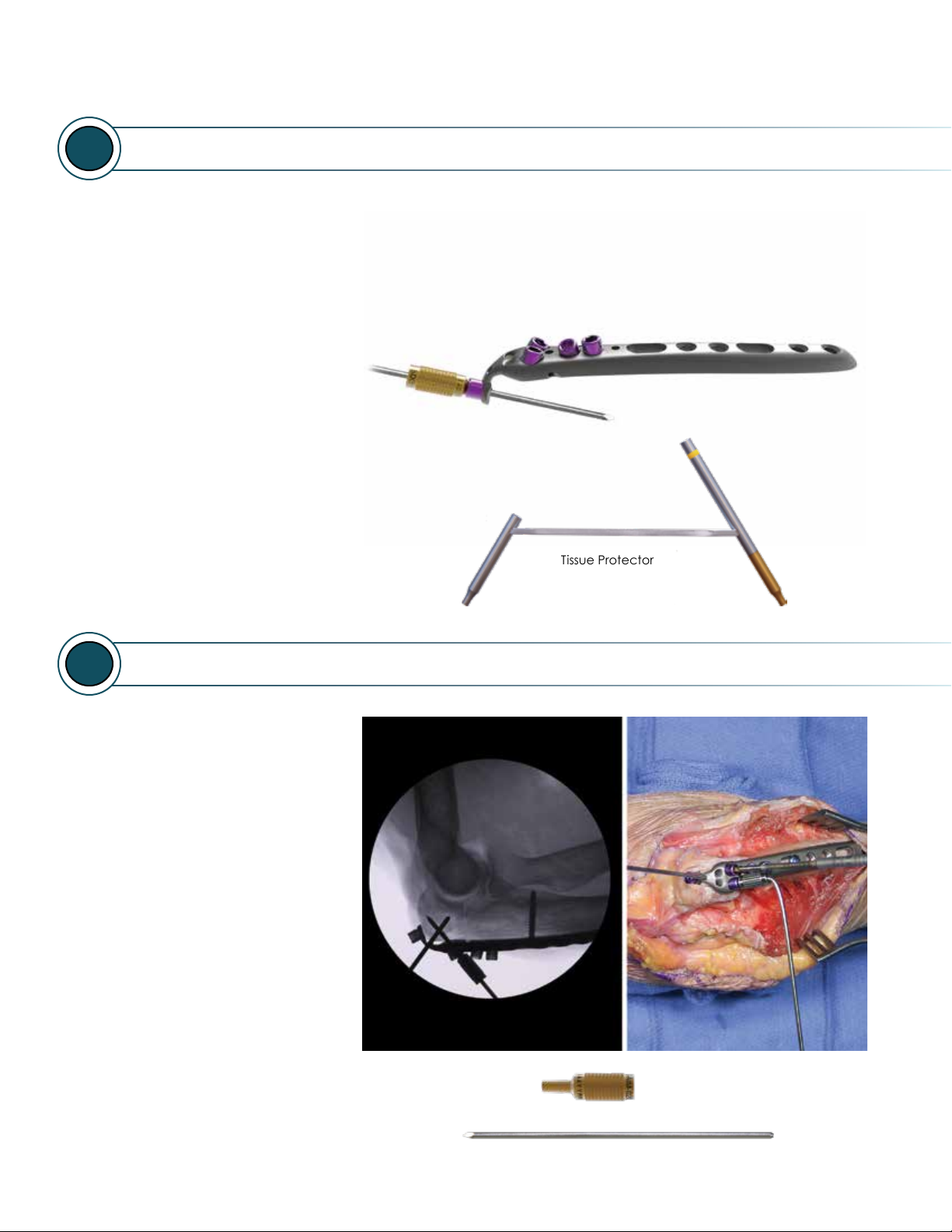

PROXIMAL FIXATION OPTIONS

The two proximal holes

containing PDG’s are for

xation to the olecranon (A).

The adjacent two distal holes

containing PDG’s are for

xation to the coronoid (B).

All of the PDG’s can accept

an A.I.M.ing Guide 2.0 (C) if

provisional K-wire xation is

necessary using 2.0mm K-wires.

If it is necessary to vary a screw

trajectory, remove the PDG

and drill free-hand. A tissue

protector is provided in the

system.

If a 3.0mm Cannulated

Polyaxial Locking Screw (PLS)

is needed, please refer to steps

22 through 25 in this surgical

technique guide.

PROVISIONAL K-WIRE FIXATION

A B

C

Tissue Protector

A.I.M.ing Guide, 2.0mm

K-wire, 2.0mm

If provisional plate xation is

needed, insert an A.I.M.ing

Guide 2.0 into the desired

PDG, then drive a 2.0mm

K-wire through the A.I.M.ing

Guide taking care to avoid

the articular surfaces of the

joint.

Using the 2.7mm bit, drill

through the PDG. If a K-wire

obstructs drilling, bend it out

of the way.

13

14

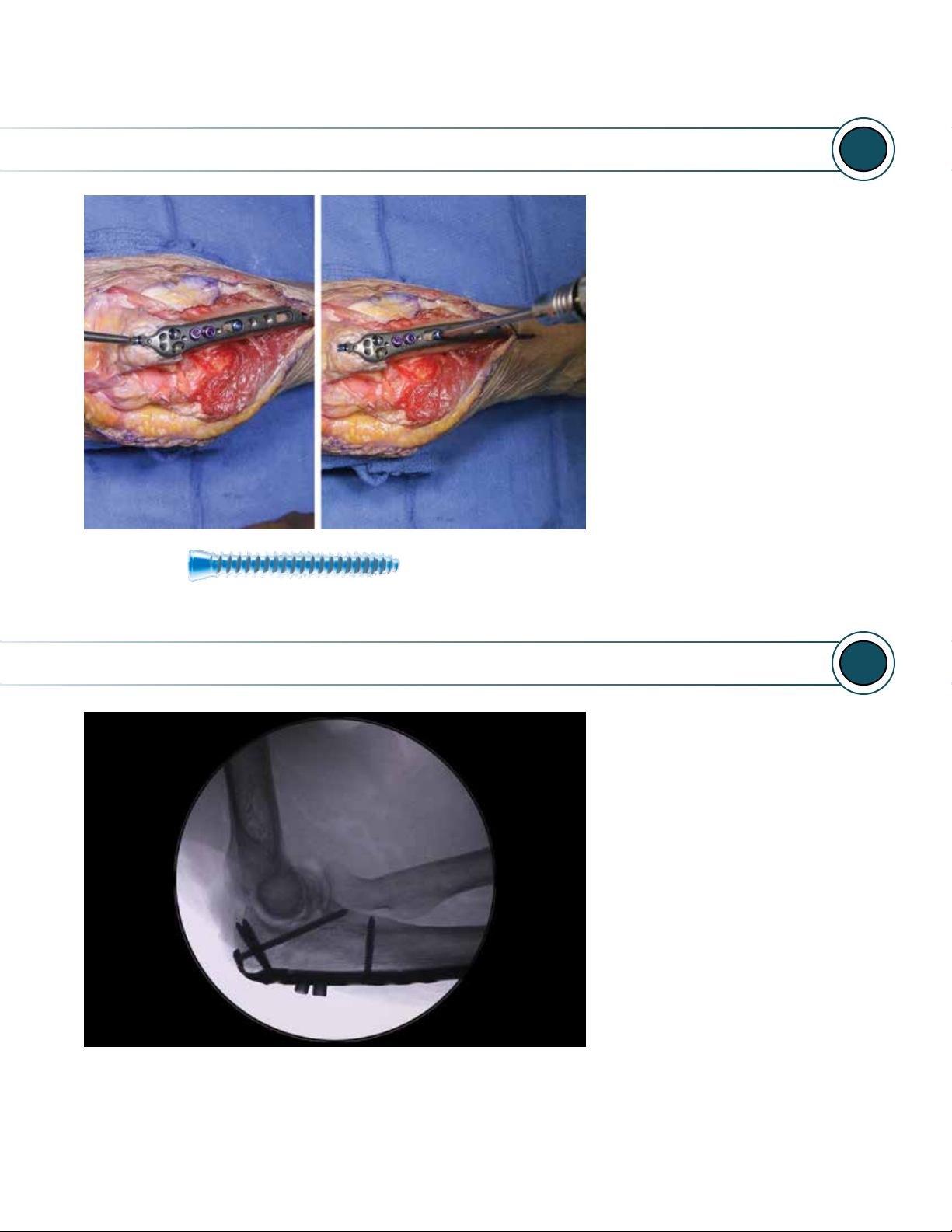

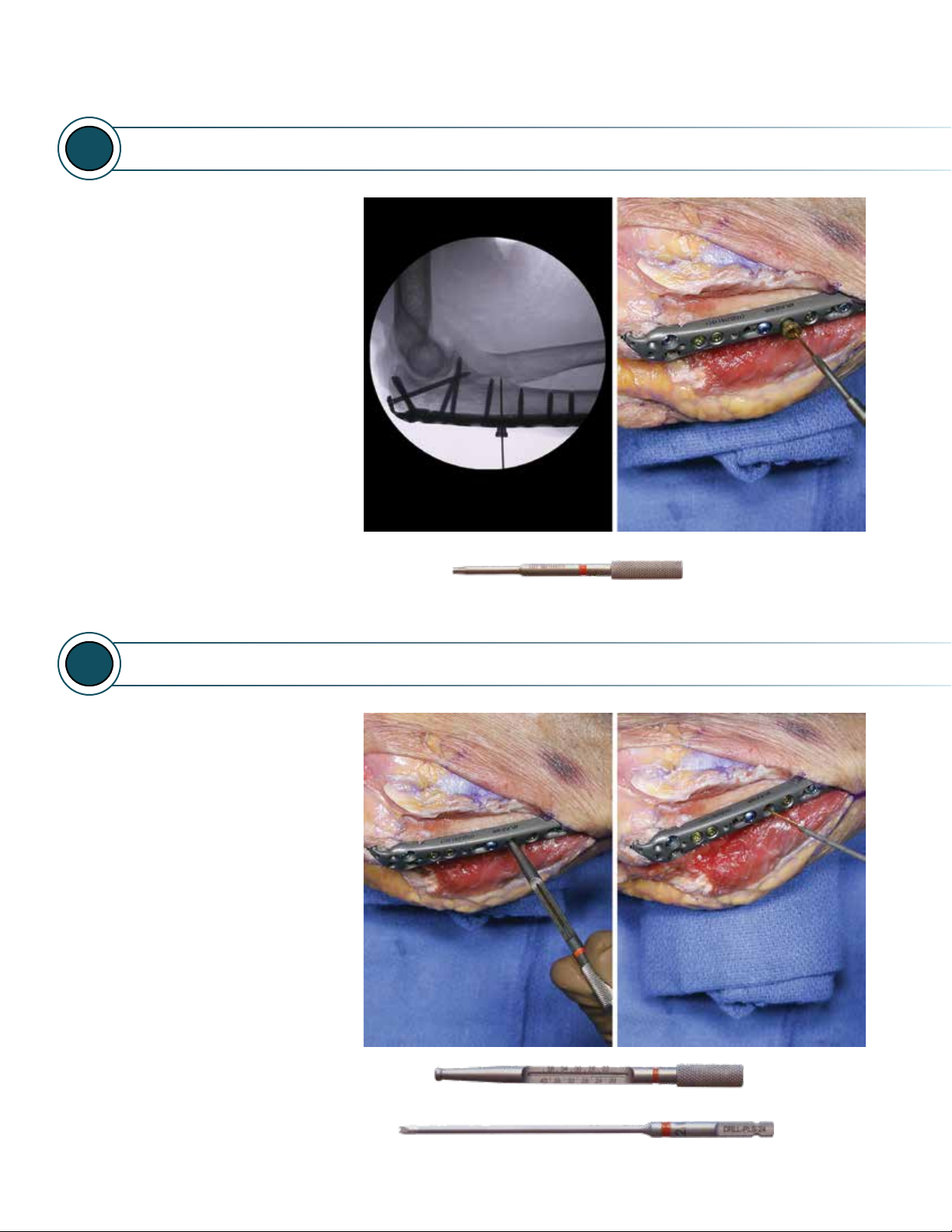

FLUOROSCOPIC CONFIRMATION

Repeat steps 12 and 13 for

the remaining olecranon

screw hole using a 3.5mm

Multi-Thread Locking Screw.

Conrm proper plate

positioning, fracture

reduction and screw lengths

using uoroscopic imaging.

OLECRANON FIXATION

Measure the screw length

using the appropriate scale

on the 50mm Depth Gauge.

Using the T-10 Driver, remove

the PDG and insert the

correct length 3.5mm Multi-

Thread Compression Screw

until the screw head contacts

the plate.

Remove the 2.0mm K-wire at

the base of the HR tab, then

fully seat the Compression

Screw until the plate is

reduced to the olecranon.

NOTE:

It is recommended to

subtract ~ 2mm from the

measured screw lengths to

avoid compromising the

articular surfaces and/or soft

tissue irritation.

Multi-Thread Compression Screw

Multi-Thread Locking Screw

15

16

PREPARING THE HOME RUN TAB

Conrm that the HR tab is ush

to the tip of the olecranon. If

necessary, you can bend the

tab as described in step 30 of

this surgical technique guide.

Using the 2.7mm x 80mm

bit, drill through the PDG,

then measure and record

the screw length using the

appropriate scale on the

80mm Depth Gauge.

NOTE:

If the HR tab was bent,

conrm that the new

trajectory will avoid contact

with the articular surfaces of

the joint.

WARNING:

Bending may weaken or

break the tab. Be sure to

inspect the tab for damage

prior to use.

OVERDRILLING THE HOME RUN TAB

Using the T-10 driver, remove

the PDG in the HR tab.

Drill up to the fracture

line using the 3.5mm bit.

Fluoroscopic imaging is

helpful during this step.

Drill, 3.5mm x 70mm

Drill, 2.7mm x 80mm

Depth Gauge, 80mm

17

18

FLUOROSCOPIC CONFIRMATION

Conrm proper plate positioning,

fracture reduction and screw

lengths using luoroscopic imaging.

LAGGING THE PROXIMAL FRAGMENT

Loosen the screw previously

placed in the oblong hole of the

shaft.

Insert the recorded length

3.5mm Multi-Threaded

Compression Screw through

the HR tab to further reduce

the fracture.

Retighten the screw in the

oblong hole of the shaft.

Multi-Thread Compression Screw

19

20

CORONOID PREPARATION

CORONOID FIXATION

Using the 2.7mm bit, drill

through a PDG.

Measure the screw length

using the appropriate scale

on the 50mm Depth Gauge.

NOTE:

If the HR Tab has been

repositioned, consider the

use of a Polyaxial Locking

Screw if impingement

occurs.

Using the T-10 Driver, remove

the PDG and insert the

correct length 3.5mm Multi-

Thread screw until fully

tightened.

Repeat steps 19 and 20 for

the remaining coronoid

screw hole.

21

22

CANNULATED 3.0 PLS SETUP (OPTIONAL)

If a Polyaxial Locking Screw

is needed in any of the

threaded holes, use the T-10

driver to remove the PDG if

present and insert the 1.1mm

PLS A.I.M.ing Guide.

Insert a 1.1mm guidewire

through the PLS A.I.M.ing

Guide in the desired

trajectory until the far cortex

is reached.

NOTE:

Fluoroscopy is helpful to

conrm the trajectory of the

guidewire.

DISTAL PLATE FIXATION

If xed angled xation

through any of the threaded

holes is desired, secure the

appropriate Thread-In Drill

Guide into the selected hole.

Using the 2.7mm bit, drill to

the proper depth. Read the

length directly from the drill or

by removing the Thread-In Drill

Guide and using the 50mm

Depth Gauge.

Insert and fully tighten the

desired screw using the T-10

Driver. Repeat this step for

the remaining distal threaded

holes.

For oblong holes, drill free-

hand, then measure and insert

a compression screw until fully

seated to the plate.

Thread-In Drill Guide

PLS A.I.M.ing Guide, 1.1mm x 100

K-wire, 1.1mm

Tissue Protector

23

24

FLUOROSCOPIC CONFIRMATION

CANNULATED 3.0 PLS PREPARATION

After conrming that the

guidewire is tacked to

the far cortex, use the

cannulated 3.0 PLS T-10

Driver to remove the PLS

A.I.M.ing Guide leaving the

guidewire in place.

Slide the cannulated Depth

Gauge over the guidewire

to measure the appropriate

length of screw.

Using the 2.4mm Cannulated

PLS bit, drill over the guidewire

to the proper depth.

3.0 PLS Driver (cannulated)

Depth Gauge, PLS 3.0

PLS Drill (cannulated) 2.4mm x 40mm

25

26

FLUOROSCOPIC CONFIRMATION

Using uoroscopic imaging,

conrm that proper reduction

has been maintained and

that all screws are of proper

length and fully engaged to

the plate.

Conrm that all PDG’s have

been removed.

CANNULATED 3.0 PLS FIXATION

Using the Cannulated 3.0

PLS T-10 Driver, thread the

screw down the guidewire

until the head of the screw

contacts the plate.

Remove the guidewire

and fully lock the screw to

the plate using the non-

cannulated T-10 driver.

PLS Screw, 3.0mm

T-10 Driver

27

28

SOFT TISSUE ATTACHMENT POINTS (OPTIONAL)

WOUND CLOSURE

All plates incorporate two

suture attachment points

proximal and distal to the

olecranon screw holes that

will accommodate a curved

needle.

The triceps attachment

points (A) are benecial

to augment plate xation

when the triceps insertion is

avulsed and osteoporotic

or comminuted olecranon

fractures are evident.

The fascia attachments

points (B) are benecial

for re-attaching the fascia

when necessary.

Conrm that the ulnar nerve

is free of any impingement.

Close deep to supercial in

your normal fashion. Apply

a standard long-arm post-op

dressing as necessary.

AB

1

3

29

30

HR TAB BENDING (OPTIONAL)

If it is necessary to modify the

HR tab, rmly hold the plate,

then grip the round node of the

HR tab using the Bending Pliers

and shape as intended.

A. Vertical Plane: Secure

the Bending Plier to bend

up to 300

B. Transverse Plane: Secure the

Bending Plier to bend up to 450

Conrm that the new trajectory

avoids contact with the

articular surfaces and other

screw trajectories using

uoroscopy.

NOTE:

Do not exceed the maximum

bend angles as described

above.

WARNING:

Bending may weaken or break

the plate. Be sure to inspect

the plate for damage prior to

use.

PLATE BENDING (OPTIONAL)

If it is necessary to modify the

shaft of the 151mm plate,

attach the Bending Irons to

bend the plate in any plane

up to 100.

A. Vertical Plane:

Use section 1 of the

Bending Irons.

B. Horizontial Plane:

Use section 2 of the

Bending Irons. This plate

manipulation can also

be performed in-situ.

C. Transverse Plane:

Use section 3 of the

Bending Irons.

NOTE:

Do not exceed the respective

maximum bend angles as

described above.

WARNING:

Bending may weaken or break

the plate. Be sure to inspect the

plate for damage prior to use.

2

1

3

A-1

B-2

C-3

Plate Catalog # Description

APL-PUP-3HL Proximal Ulna Plate, 73mm, Left

APL-PUP-3HR Proximal Ulna Plate, 73mm, Right

APL-PUP-6HL Proximal Ulna Plate, 108mm, Left

APL-PUP-6HR Proximal Ulna Plate, 108mm, Right

APL-PUP-9HL Proximal Ulna Plate, 151mm, Left

APL-PUP-9HR Proximal Ulna Plate, 151mm, Right

73mm

108mm

151mm

10mm

5.7mm

10mm

Proximal Ulna Plate Dimensions

Proximal Ulna Plates

APL-PUP-3HL Proximal Ulna Plate, 73mm, Left

APL-PUP-3HR Proximal Ulna Plate, 73mm, Right

APL-PUP-6HL Proximal Ulna Plate, 108mm, Left

APL-PUP-6HR Proximal Ulna Plate, 108mm, Right

APL-PUP-9HL Proximal Ulna Plate, 151mm, Left

APL-PUP-9HR Proximal Ulna Plate, 151mm, Right

Catalog # Description

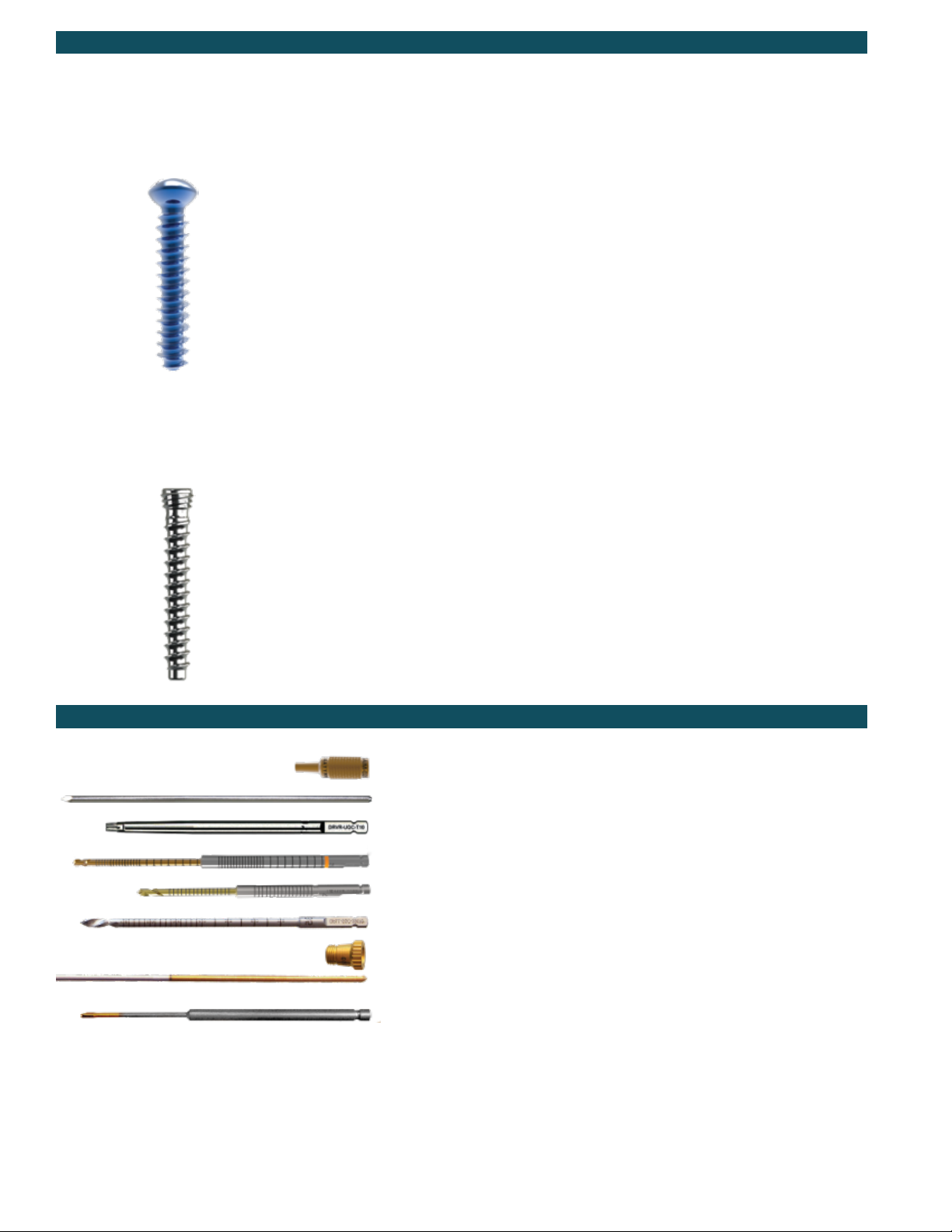

MTLS-35080-TS Screw, Multi-Thread Locking, 3.5mm x 8mm, Ti

MTLS-35100-TS Screw, Multi-Thread Locking, 3.5mm x 10mm, Ti

MTLS-35120-TS Screw, Multi-Thread Locking, 3.5mm x 12mm, Ti

MTLS-35140-TS Screw, Multi-Thread Locking, 3.5mm x 14mm, Ti

MTLS-35160-TS Screw, Multi-Thread Locking, 3.5mm x 16mm, Ti

MTLS-35180-TS Screw, Multi-Thread Locking, 3.5mm x 18mm, Ti

MTLS-35200-TS Screw, Multi-Thread Locking, 3.5mm x 20mm, Ti

MTLS-35220-TS Screw, Multi-Thread Locking, 3.5mm x 22mm, Ti

MTLS-35240-TS Screw, Multi-Thread Locking, 3.5mm x 24mm, Ti

MTLS-35260-TS Screw, Multi-Thread Locking, 3.5mm x 26mm, Ti

MTLS-35280-TS Screw, Multi-Thread Locking, 3.5mm x 28mm, Ti

MTLS-35300-TS Screw, Multi-Thread Locking, 3.5mm x 30mm, Ti

MTLS-35320-TS Screw, Multi-Thread Locking, 3.5mm x 32mm, Ti

MTLS-35340-TS Screw, Multi-Thread Locking, 3.5mm x 34mm, Ti

MTLS-35360-TS Screw, Multi-Thread Locking, 3.5mm x 36mm, Ti

MTLS-35380-TS Screw, Multi-Thread Locking, 3.5mm x 38mm, Ti

MTLS-35400-TS Screw, Multi-Thread Locking, 3.5mm x 40mm, Ti

MTLS-35450-TS Screw, Multi-Thread Locking, 3.5mm x 45mm, Ti

MTLS-35500-TS Screw, Multi-Thread Locking, 3.5mm x 50mm, Ti

MTLS-35550-TS Screw, Multi-Thread Locking, 3.5mm x 55mm, Ti

MTLS-35600-TS Screw, Multi-Thread Locking, 3.5mm x 60mm, Ti

MTLS-35700-TS Screw, Multi-Thread Locking, 3.5mm x 70mm, Ti

MTNL-35080-TS Screw, Multi-Thread Compression, 3.5mm x 8mm, Ti

MTNL-35100-TS Screw, Multi-Thread Compression, 3.5mm x 10mm, Ti

MTNL-35120-TS Screw, Multi-Thread Compression, 3.5mm x 12mm, Ti

MTNL-35140-TS Screw, Multi-Thread Compression, 3.5mm x 14mm, Ti

MTNL-35160-TS Screw, Multi-Thread Compression, 3.5mm x 16mm, Ti

MTNL-35180-TS Screw, Multi-Thread Compression, 3.5mm x 18mm, Ti

MTNL-35200-TS Screw, Multi-Thread Compression, 3.5mm x 20mm, Ti

MTNL-35220-TS Screw, Multi-Thread Compression, 3.5mm x 22mm, Ti

MTNL-35240-TS Screw, Multi-Thread Compression, 3.5mm x 24mm, Ti

MTNL-35260-TS Screw, Multi-Thread Compression, 3.5mm x 26mm, Ti

MTNL-35280-TS Screw, Multi-Thread Compression, 3.5mm x 28mm, Ti

MTNL-35300-TS Screw, Multi-Thread Compression, 3.5mm x 30mm, Ti

MTNL-35320-TS Screw, Multi-Thread Compression, 3.5mm x 32mm, Ti

MTNL-35340-TS Screw, Multi-Thread Compression, 3.5mm x 34mm, Ti

MTNL-35360-TS Screw, Multi-Thread Compression, 3.5mm x 36mm, Ti

MTNL-35380-TS Screw, Multi-Thread Compression, 3.5mm x 38mm, Ti

MTNL-35400-TS Screw, Multi-Thread Compression, 3.5mm x 40mm, Ti

MTNL-35450-TS Screw, Multi-Thread Compression, 3.5mm x 45mm, Ti

MTNL-35500-TS Screw, Multi-Thread Compression, 3.5mm x 50mm, Ti

MTNL-35550-TS Screw, Multi-Thread Compression, 3.5mm x 55mm, Ti

MTNL-35600-TS Screw, Multi-Thread Compression, 3.5mm x 60mm, Ti

MTNL-35700-TS Screw, Multi-Thread Compression, 3.5mm x 70mm, Ti

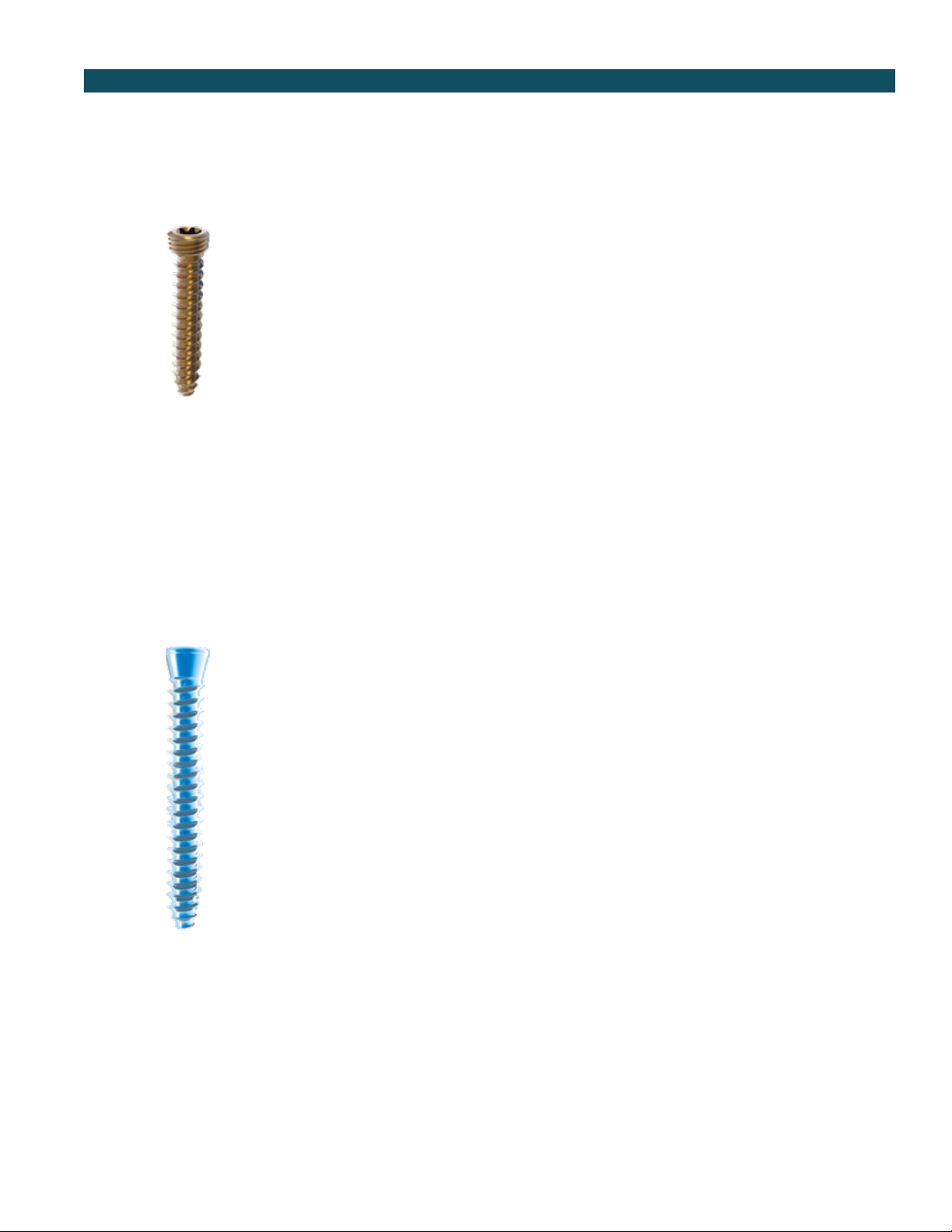

Screw Options

Screw Options

Catalog # Description

PANL-35080-TS Screw, Cortical Non Locking, 3.5mm x 8mm, Ti

PANL-35100-TS Screw, Cortical Non Locking, 3.5mm x 10mm, Ti

PANL-35120-TS Screw, Cortical Non Locking, 3.5mm x 12mm, Ti

PANL-35140-TS Screw, Cortical Non Locking, 3.5mm x 14mm, Ti

PANL-35160-TS Screw, Cortical Non Locking, 3.5mm x 16mm, Ti

PANL-35180-TS Screw, Cortical Non Locking, 3.5mm x 18mm, Ti

PANL-35200-TS Screw, Cortical Non Locking, 3.5mm x 20mm, Ti

PANL-35220-TS Screw, Cortical Non Locking, 3.5mm x 22mm, Ti

PANL-35240-TS Screw, Cortical Non Locking, 3.5mm x 24mm, Ti

PANL-35260-TS Screw, Cortical Non Locking, 3.5mm x 26mm, Ti

PANL-35280-TS Screw, Cortical Non Locking, 3.5mm x 28mm, Ti

PANL-35300-TS Screw, Cortical Non Locking, 3.5mm x 30mm, Ti

PANL-35320-TS Screw, Cortical Non Locking, 3.5mm x 32mm, Ti

PANL-35340-TS Screw, Cortical Non Locking, 3.5mm x 34mm, Ti

PANL-35360-TS Screw, Cortical Non Locking, 3.5mm x 36mm, Ti

PANL-35380-TS Screw, Cortical Non Locking, 3.5mm x 38mm, Ti

PANL-35400-TS Screw, Cortical Non Locking, 3.5mm x 40mm, Ti

PANL-35420-TS Screw, Cortical Non Locking, 3.5mm x 42mm, Ti

PANL-35440-TS Screw, Cortical Non Locking, 3.5mm x 44mm, Ti

PALS-30200-CC Screw, Polyaxial Locking, 3.0mm x 20mm Cannulated, CoCr

PALS-30220-CC Screw, Polyaxial Locking, 3.0mm x 22mm Cannulated, CoCr

PALS-30240-CC Screw, Polyaxial Locking, 3.0mm x 24mm Cannulated, CoCr

PALS-30260-CC Screw, Polyaxial Locking, 3.0mm x 26mm Cannulated, CoCr

PALS-30280-CC Screw, Polyaxial Locking, 3.0mm x 28mm Cannulated, CoCr

PALS-30300-CC Screw, Polyaxial Locking, 3.0mm x 30mm Cannulated, CoCr

PALS-30320-CC Screw, Polyaxial Locking, 3.0mm x 32mm Cannulated, CoCr

PALS-30340-CC Screw, Polyaxial Locking, 3.0mm x 34mm Cannulated, CoCr

PALS-30360-CC Screw, Polyaxial Locking, 3.0mm x 36mm Cannulated, CoCr

PALS-30380-CC Screw, Polyaxial Locking, 3.0mm x 38mm Cannulated, CoCr

PALS-30400-CC Screw, Polyaxial Locking, 3.0mm x 40mm Cannulated, CoCr

Single Use Instruments Catalog Number Dimensions

PDG-AIM-020 AIMing Guides, 2.0mm

KWIR-STD-20152 K-Wire, 2.0 mm x 152 mm

DRVR-UQC-T10 Driver, Universal Quick Connect, T10

DRLL-SSC-27080 Drill, 2.7mm x 80mm

DRLL-SSC-27040 Drill, 2.7mm x 40mm

DRLL-SSC-35070 Drill, 3.5mm x 70mm

PDG-AIM-011 PLS AIMing Guide, 1.1mm x 10°

KWIR-PLS-11152 K-Wire,1.1 mm x 152 mm

DRLL-PLS-24 Drill, Cannulated, PLS, 2.4mm x 40mm

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual