SKETCHNBUILD SNB-PX24 User manual

SNB-PX24 25” PLANER

MANUAL

SNB-PX24 PLANER MANUAL

2

6/2016

CONTENTS

1. TECHNOLOGY PARAMETER AND SPECIFICATION INDEX...………………….….3

2. OPERATION AND SAFETY…………………….……………………..……………………….…4

3. ELECTRICAL CONFIGURATION……………………………………….……………………….5

4. OILING SYSTEM.…………………………………………………………………….………….…...5

5. OPERATION…………………………………………………………….…………………….………..7

6. ADJUSTMENT ……………………………………………….……………………………..………...7

7. TESTING …………………………………………………………………………………………………10

8. ACCESSORY & PARTS LIST………………………………………………………………….……10

CAUTION: Read these instructions carefully before turning on the machine.

SNB-PX24 PLANER MANUAL

3

6/2016

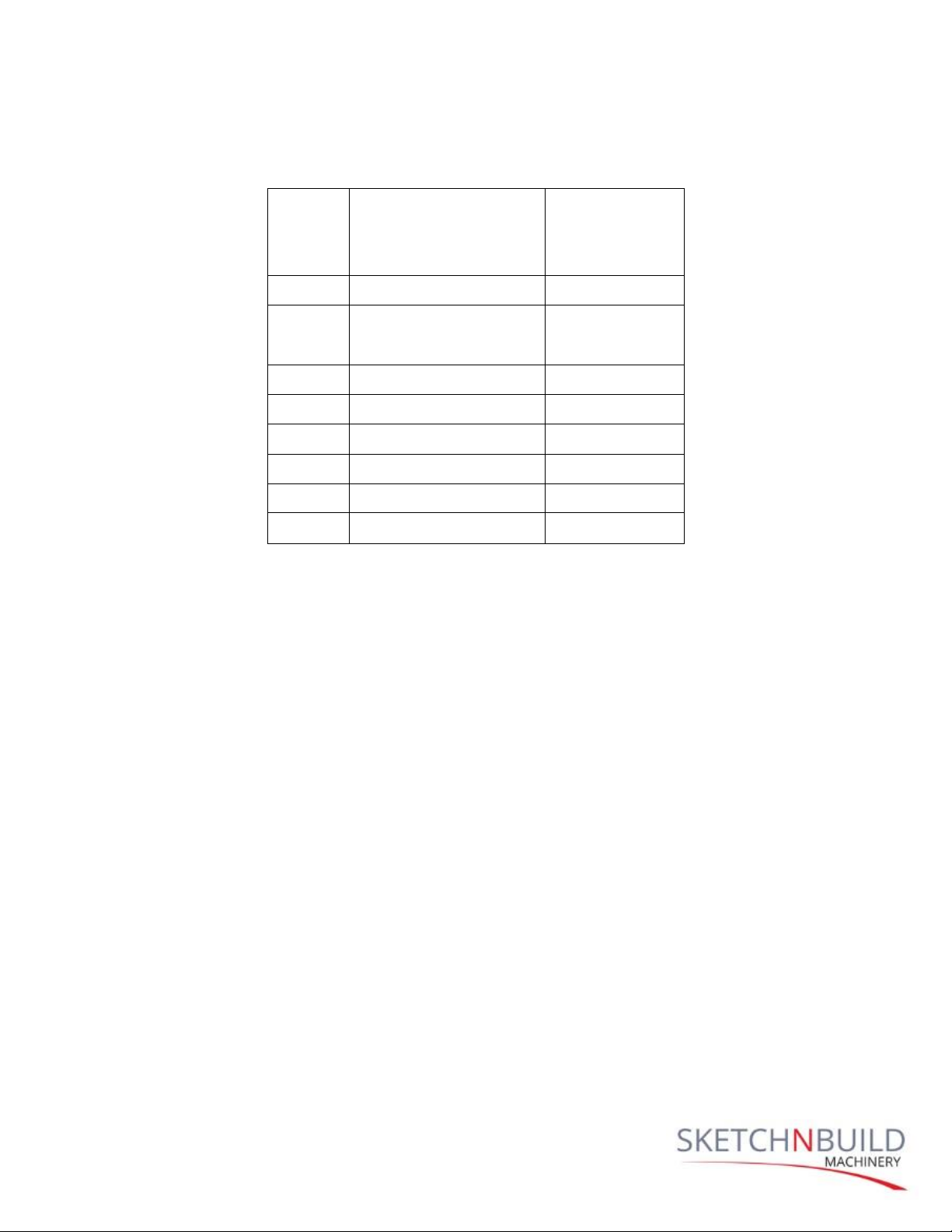

1. PARAMETER AND SPECIFICATION INDEX

No.

Parameter

SNB-PX24

Specification

1

Max working width

24”/600mm

2

Max working

thickness

8”/200mm

3

Min working length

8”/200mm

4

Max cutting depth

0.2”/5mm

5

Cutter head speed

5000r/min

6

Feeding speed

6.5-9m/min

7

Spindle motor

5HP/7.5kw

8

Equipment weight

1168lbs/530kg

NOTE: The above design and specifications might differ on each machine model.

Please refer to the actual machine.

SNB-PX24 PLANER MANUAL

4

6/2016

2. OPERATION AND SAFETY

1. Keep doors closed and all the tools and adjustment wrenches away from the work

table before operation.

2. Be sure all parts are securely tightened and oil relevant parts before operation.

3. TURN DOWN the triangle belt of motor by hand to ensure the shaft of blade, gear

work well and without collision.

4. STOP the planer immediately once there is abnormal sound and do not start it

without finding out the reason.

5. SAFETY OF OPERATOR AND EQUIPMENT, keep the planer power-off when doing any

adjustments, maintenance and cleaning.

6. KEEP PLANER IN A DRY COOL WORKING ENVIRONMENT and do not operate under

direct sunlight or outside in wet rainy conditions.

7. CHANGE THE BLADE when it is worn or after using for a period of time. And make

sure to change all blades at the same time to keep the same weight for each blade,

otherwise, high speed imbalance will shorten the accuracy and planer’s operating

time.

8. KEEP CHILDREN, VISITORS and PETS AWAY. All non-operating personnel should keep

a safe distance from working equipment to avoid any accident or injury.

9. 9、KEEP WORK AREA AND PLANER CLEAN AFTER USE. Switch off the power after use

every day.

10. CHANGE OR REPAIR BROKEN PARTS. DO NOT OPERATE MACHINE WITH FAULTY

PARTS, to avoid machine malfunction and injury to user.

11. KEEP THE MAX CUTTING WORKING AREA DEPTH less than 0.2” (5 mm). 0.2” (5 mm)

for less than 8” (200mm) of lumber width, O.O78” (2 mm) for more than 16” (400

mm) of lumber width) to prevent part damage or overheating.

12. SWITCH OFF PLANER for inspection to prevent damage to the motor or relevant

parts such as the blades or bolts from over loading under the following situations:

A.The shaft of blade slows down or cannot move because of cutting over depth or

there is an obstruction on the workpiece from a nail or screw.

B. There is abnormal sound.

RESTART PLANER once problem is resolved.

SNB-PX24 PLANER MANUAL

5

6/2016

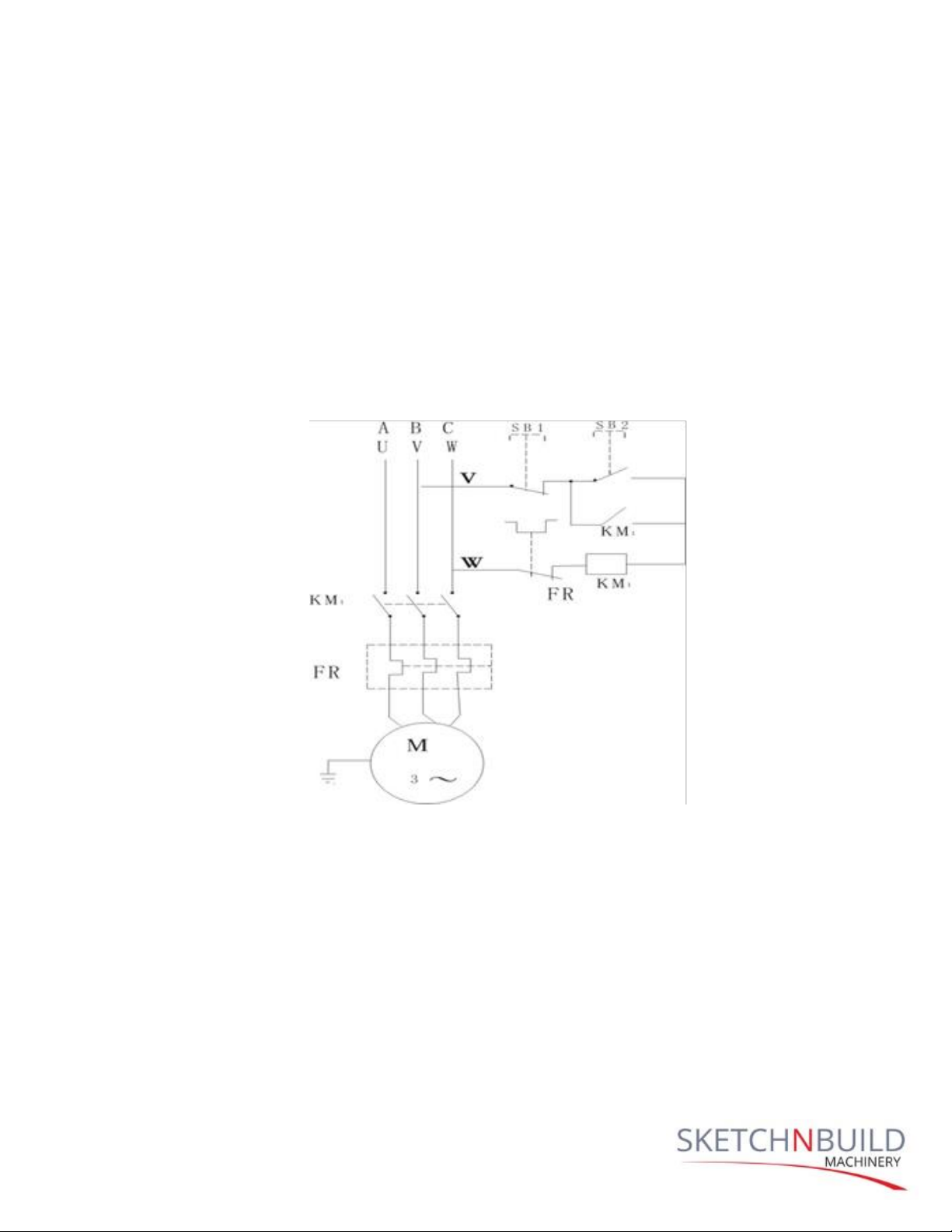

3. ELECTRICAL CONFIGURATION

The motor is controlled by a magneto-electricity starter. This provides the advantages

of a simplified connection, easy operation and over load prevention. In the graphic

below, electric principle A, connecter will be looped when the start button is pulled, and

then the loop will be locked as the power gets through the connecter to make the

motor run. The relay FR will work and make KMI lose press when the motor is under

over loading and KMI will switch off.

NOTE: The wiring for this planer is four-core cable. Please make sure the earth

installation is safe before setting.

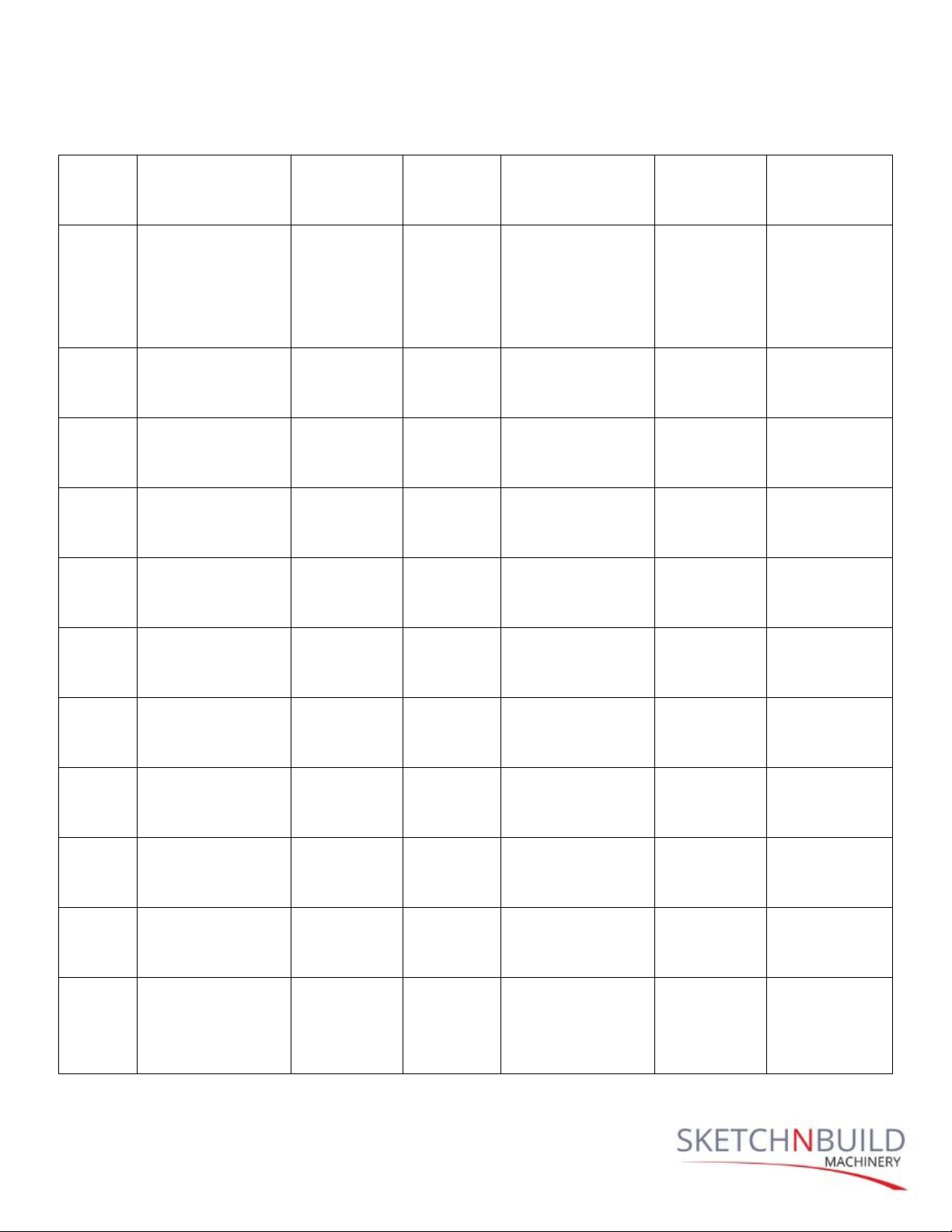

4. OILING SYSTEM

The planer should be oiled by hand regularly to extend the working life, maintain a smooth

operation, as well as improve the working efficiency., Oiling should be done on relevant

parts with minimal oil to avoid oil run over which wastes oil and damages other parts. Refer

to oiling instructions below:

SNB-PX24 PLANER MANUAL

6

6/2016

Oiling Instructions

No

Area

Oiling Part

Drops of

Oil

Oiling

instruction

Type of Oil

Oiling Time

1

Motor

Bearing

2

Take the front

cover apart and

remove the

cover of motor

CAS#3

Every 6

months

2

Lever on work

table

Worm gear

2

Take apart and

oil

CAS#3

Every 6

months

3

Lever on work

table

screw

2

Direct

Engine oil

Per week

4

Lever on work

table

Chain&

chain wheel

2

Direct

Engine oil

Per shift

5

Lever on work

table

Lever path

4

Direct

Engine oil

Per shift

6

Hand wheel

fastening

Oil cup

1

Direct

Engine oil

Per shift

7

Holding roller

work table

Bearing

4

Direct

Cas#3

Every 6

months

8

Shaft of planning

blade

Bearing

2

Direct

Cas#3

Per month

9

Delivery roller

Bearing

2

Take the end

cover apart

Cas#3

Every 6

months

10

Press roller

Bearing

2

Take the end

cover apart

Cas#3

Every 6

months

11

Drive system of

delivery and

press roller

Skew gear

5

Direct

Cas#3

Per shift

SNB-PX24 PLANER MANUAL

7

6/2016

12

Drive system of

delivery and

press roller

bearing

5

Take the end

cover apart

Cas#3

Every 6

months

13

Gear box

gear

2

Take the end

cover apart

Cas#3

Every 6

months

14

Gera box

Bearing

4

Take the end

cover apart

Cas#3

Every 6

months

15

Gear box

Chain&

chain wheel

2

Direct

Engine oil

2 times per

shift

5. OPERATION

The motor is shared by the blade shaft, delivery and press roller. These mechanisms work

together once the Start button is pressed. Otherwise, the planer will stop when the Stop

button is pulled. The lever on work table works when the hand wheel is turned manually.

Release the fastener at the back of hand wheel when turning it to position the work table

then lock the fastener to keep the wheel position and make the work piece the same width.

Both rollers to the left and right sides of the breaker installed on top of planer use the same

setting as cutting the work piece a second time.

6. ADJUSTMENT

1. Up and down adjustment.

Before adjusting the position of work table, first release the fastener at the back of

hand wheel, and then turn the hand wheel left to adjust the work table. Fasten the

fastener to maintain position and to make the work piece the same width. When

adjusting, should check the index on work table position the scale on the gauge base.

This shows the thickness of the finished work piece in relation to the thickness of work

piece. Finally fasten the fastener after performing a cutting test and inspecting the

work piece. The thickness of most work pieces will be the same after performing the

above steps.

2. Sharpening and changing of planer blade should be done on worn blades which is

or after using for a period of time.

Use the steps below to change the blades:

SNB-PX24 PLANER MANUAL

8

6/2016

1) Lift the breaker, and use the wrenches to loosen the bolt on the pressing strip, take out

the blade for sharpening or changing

2) Setting and adjustment of planer blade:

a) Make sure both ends of blade machine are even and fixed, and then adjust four

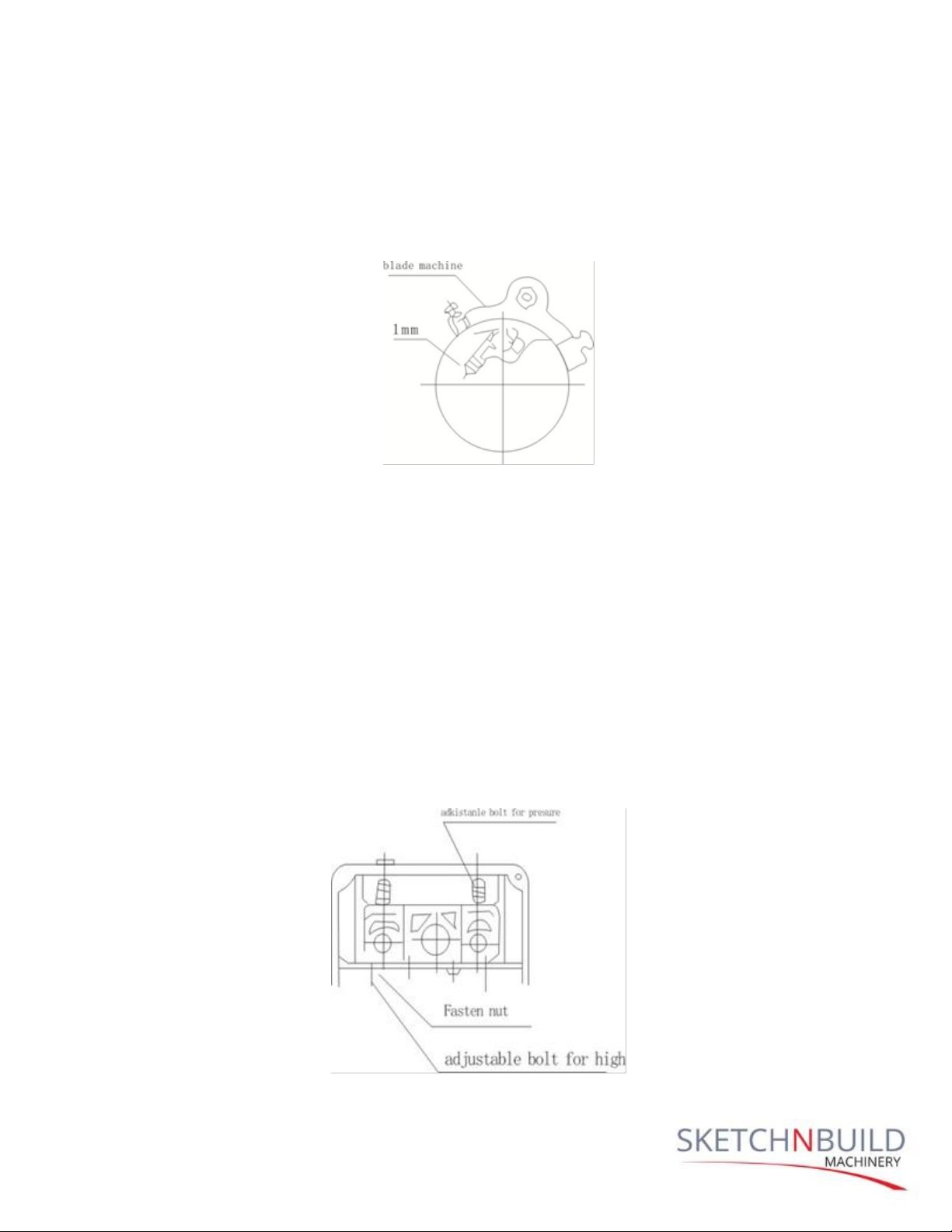

adjustable bolts to keep them in the same position (1mm more or less).(Graph B)

Graph B

b) Put two springs into the 2 hold ¢at the bottom of blade groove.

c) Insert the planer blade and pressing strip to the blade groove. The elasticity of the

two springs will make the blade and blade edge spring to the arc surface of the

blade machine. Tighten the fastening bolt of pressing strip.

d) Set one blade at a time, whilst keep all blades in the same position. Finally inspect

the fastening of all bolts of pressing strip to avoid the blades from getting loose and

causing damage.

3) Adjustment for bearing pressure of press roller

The pressure of spring on top of bearing of the pressing roller is adjusted at the factory.

The user can adjust by turning the left or right wheel to tighten or loosen. The left-hand

threaded nut tightens the spring, whereas the right-hand threaded nut loosens the

spring (Graph C)

Graph C

SNB-PX24 PLANER MANUAL

9

6/2016

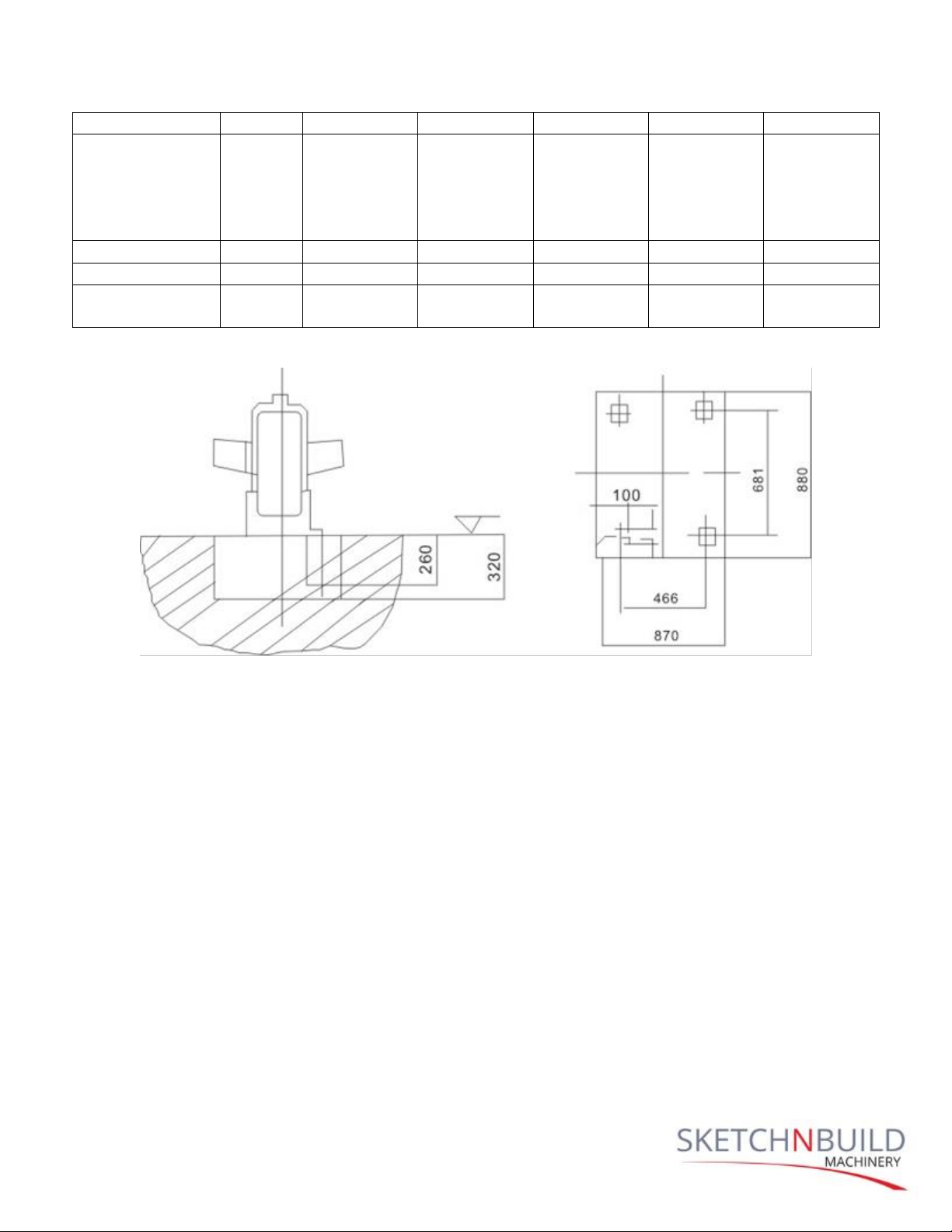

4) Up and down adjustment for delivery roller and press roller.

The positions of the bearing of the delivery roller and press roller have been factory

adjusted. If bearings to the right or left become uneven, the user can loosen the four

fastening nuts under the bearing so that outer diameter of the delivery roller and press

roller are positioned over the blade shaft by about 1mm. Tighten the four fastening

nuts after adjustment (Graph D).

Graph D

5) Up and down adjustment of the holding roller on work table:

a) The Up and Down adjustment for the holding roller on work table has been factory

adjusted. The user can loosen the four fastening nuts under the work table for

readjustment. Revolve those four adjustable nuts to position the outer diameter of

the holding roller over the table by about 0.01~0.2mm. Tighten the four fastening

nuts after adjustment (Graph D-above).

b) Maintaining a parallel line between work table and blade shaft:

The work table and blade shaft adjusted to be parallel to each other. The user can

loosen the two fastening bolts at the pedestal for readjustment. Revolve the

pedestal screw left or right to move the table up or down, then tighten the fastening

bolts after adjustment.

6) Up and down adjustment (for blade shaft) of breaker and press roller:

The up and down adjustment for blade shaft by breaker and press roller have been factory

adjusted. The user can adjust the position of two adjustable bolts to the left and right sides

of the breaker for readjustment.

Additionally, adjust the position of the two adjustable bolts positioned to the left and right

side of the press roller then continue to follow instructions below:

SNB-PX24 PLANER MANUAL

10

6/2016

Loosen the fastening bolts, and revolve the transfer bolt to align to the bottom of the

breaker and back press machine just above the cutting circle of blade shaft (about 0.5mm,

then tighten the fastening bolts after adjustment.

7. TESTING

1. Adjust all parts and fasten all fixtures, paying special attention attention bolts on the

pressing strip to ensure blades are properly secured and prevent personal injury or

damage to machine.

2. Ensure everything is running smoothly, and no abnormal sounds and or collision

before start the planer. Inspect the turning direction of trigonal belt from the side of

motor to see whether the blade shaft is turning left with the delivery roller and press

roller turning right. If not switch of the planer and change the electrical connection of

the motor.

3. Remove all tools, gauges and wrenches from the work table to avoid them from

rolling into the machine to avoid personal injury and damage to the machine.

4. Stop the planer for inspection when there is an abnormal sound and collision. Check

all parts to ensure that they are securely fastened. Do not restart the planer before

resolving the problem to prevent damage.

8. ACCESSORY & PARTS LIST

Accessory List

Name

Specification

Quantity

Equipment

Planer

1

Triangle belt

900

1

Dust hood

1

Manual

1

SNB-PX24 PLANER MANUAL

11

6/2016

Parts List

Part

Code #

Dimension

Name

Precision

grade

Quantity

Remark

Blade shaft

360

30x70x19

Single redial

ball bearing

E

2

Delivery &Press

Roller

204

20x47x14

Single radial

ball bearing

4

Holding roller on

work table

61004

20x40x12

Single radial

ball bearing

with

dustproof

cover

4

Lift wheel box on

working table

8200

10x26x11

Single thrust

bearing

2

Principal Axis

Gear

80106

30x55x13

Single radial

ball bearing

with

dustproof

cover

1

Gear box

105

25x47x12

Single radial

ball bearing

with

dustproof

cover

4

Copper gear

8004

20x42x12

Single radial

ball bearing

with

dustproof

cover

2

Triangle belt

70105

25x47x12

Single radial

ball bearing

with

dustproof

2

SNB-PX24 PLANER MANUAL

12

6/2016

cover

Tension wheel

80201

12x32x10

Single radial

ball bearing

with

dustproof

cover

2

Motor box

1803

Triangle belt

3

Gear box

1397

Triangle belt

1

Gear box

1041

Triangle belt

1

990(preparati

on)

Table of contents