ADJUSTING CUTTERHEAD

DRIVE BELTTENSION

1. Loosen bottom nut on RB-47

threaded rod (#80 on parts break-

down drawing).

2. To tighten belt, tighten nut on rod

that is above RB-187 adjustment

bracket. This should lower the mo-

tor adjustment bracket. (fig. 8)

3. When drive belt is of desired ten-

sion, tighten bottom nut on rod

against the adjustment bracket.

RB-85 BED HEIGHT ADJUSTMENT

1. Place RB-84crank handle on RB-79

crank screw. (fig. 9)

2. Turning handle clockwise raises

bed. Counter-clockwise lowers

bed.

3. Bed moves 1/16" with each com-

plete turn. Maximum depth of cut

for this machine is 3/32" (1 1/2

turns).

CLEANING RB-51-Z FEED ROLLERS

During extended periods of time and

during moist wood operation, resin

may accumulate on the feed rollers.

To remove this build-up, wipe the

rollers with a rag moistened with

kerosene.

KNIFE SHARPENING

1. For major sharpening, the beveled

edge of the knife should be ground

to a 30 or 45 degree angle over the

entire length of the knife to remove

all nicks and notches.

2. For minor sharpenings between

major sharpenings, use ahone on

the flat side of the knife cutting

edge over the entire length of the

knife.

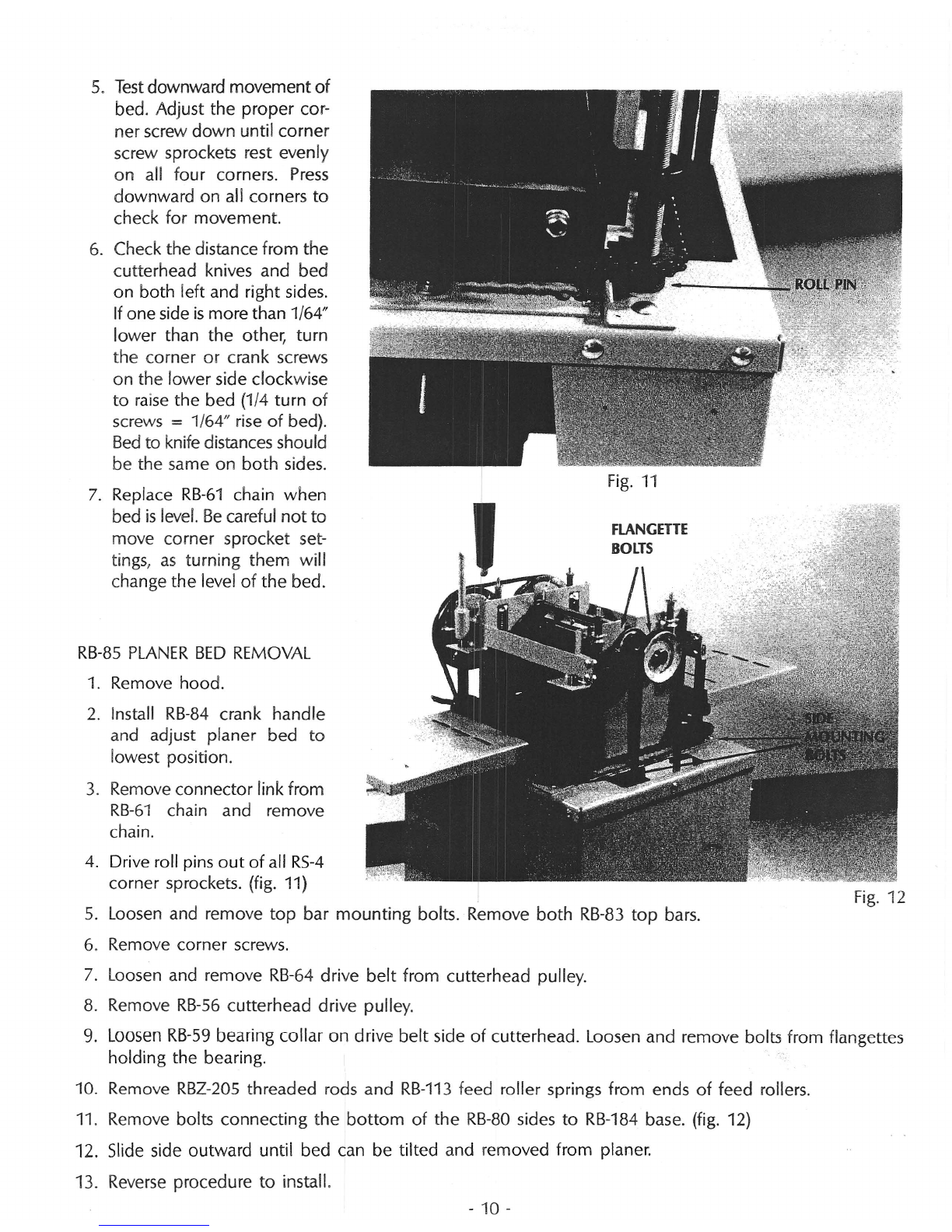

RB-85 PLANER BED LEVELING

1. Place the RB-84 crank handle on

RB-79 crank screw.

2.

Turn crank until the top of the cor-

ner screw ear on the bed is five

inches from the top of the base.

3. Remove the RB-61chain connector

link and remove chain from sprock-

ets. (fig. 10)

4. Adjust the corner screws until all

ears are the same distance from the

top of the base.

THREADED

ROD Fig. 8

Fig. 9

MASTER

LINK

Fig. 10

- q -