MTx TABLE OF CONTENTS

SKF Condition Monitoring Centre – Steyr 1 - 6 - 1

TABLE OF CONTENTS

1. VERSION OF MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1. ABOUT THIS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.1. Typographic instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

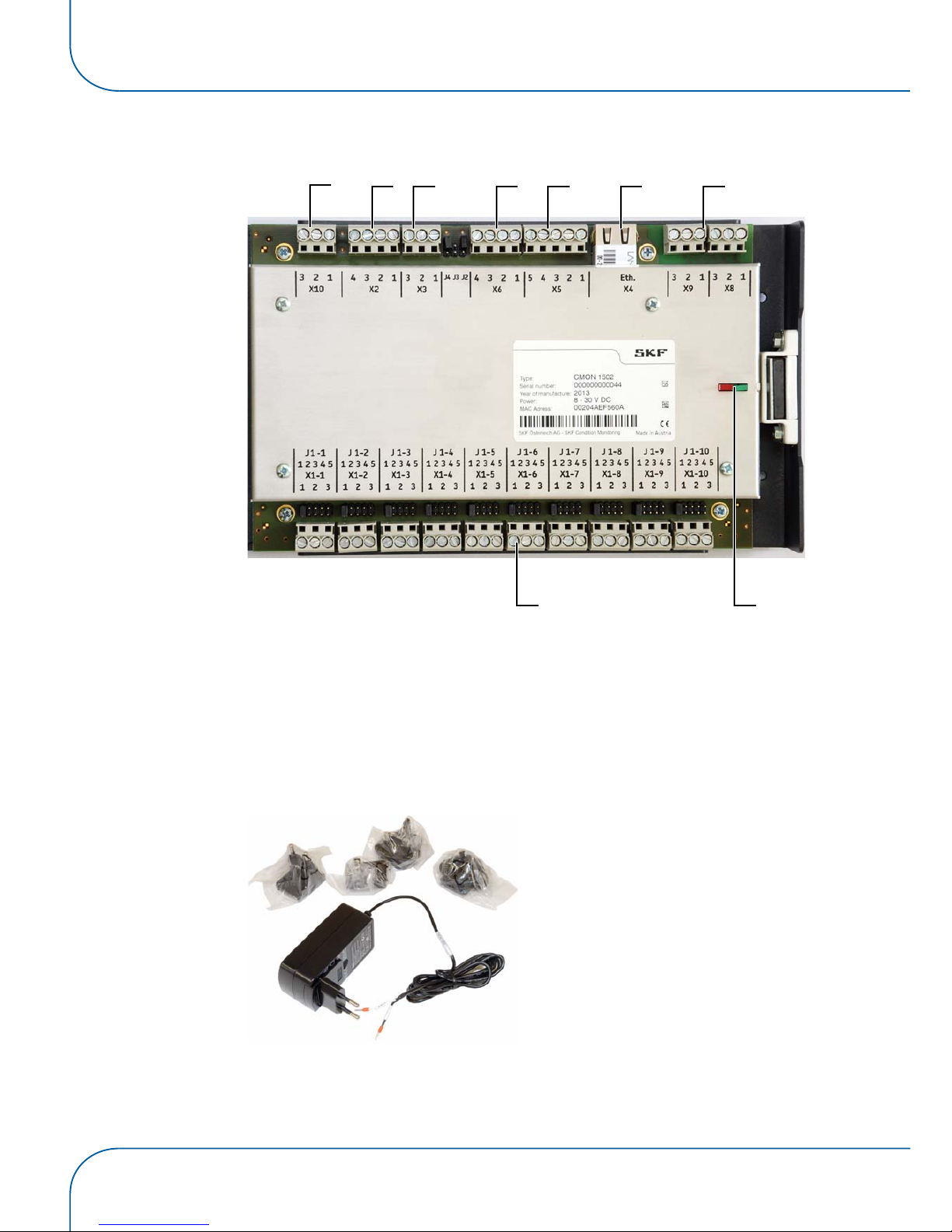

3. HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1. GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2. DETAILED INFORMATION ABOUT INPUTS. . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1. Acceleration sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2. Rotation sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.3. Switching sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.4. Voltage sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.5. Current sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.6. Temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3. SWITCHING OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4. CONNECTION PLAN AND JUMPER SETTINGS . . . . . . . . . . . . . . . . . . . . . . 23

3.4.1. Supply voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.2. Speed sensor sine/cosine 1 Vpp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.3. Speed sensor 5 Vpp or 24 Vpp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.4. Standard industrial sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.5. Triax accelerometer [CMSS-ONL-1500E-2] . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.6. Ethernet Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.7. Switching output 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.8. Switching output 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.9. Universal sensor input connector (n here can be 1 to 10) . . . . . . . . . . . . . 25

4. SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1. MTx SERVER SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.1. Server intallation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.2. Server configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.3. Server monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2. MTx CLIENT SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2.1. Client installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2.2. Uninstall software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2.3. Choosing the network interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2.4. Start screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.4.1. Connect to device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2.5. MTx device panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.5.1. File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.5.2. Device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2.5.2.1. Basic configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2.5.2.2. Input configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2.5.2.3. Matrix configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.5.2.4. Switching output configuration . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.5.2.5. User Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46