Foot valve body

Install o-ring () onto foot valve

body ().

Install ball (), spring () [small diam-

eter first], and washer () into foot

valve body.

Install pin () into foot valve.

. Make sure pin retains washer

properly and is flush with foot

valve body.

Clean and inspect

Clean all metal parts in cleaning solvent.

Solvent should be environmentally safe.

Inspect all parts for wear and/or damage.

. Replace as necessary.

Inspect air piston () for fatigue cracks.

. Replace as necessary.

Inspect rod () closely. Use a magnifying

glass to detect any score marks.

. Replace as necessary.

Closely inspect mating surfaces of all

check valve components for any imper-

fections. Ensure a smooth and clean

contact is obtained when assembled.

Example: place ball () into foot valve

body (). Fill foot valve body with sol-

vent. Make sure no leakage occurs.

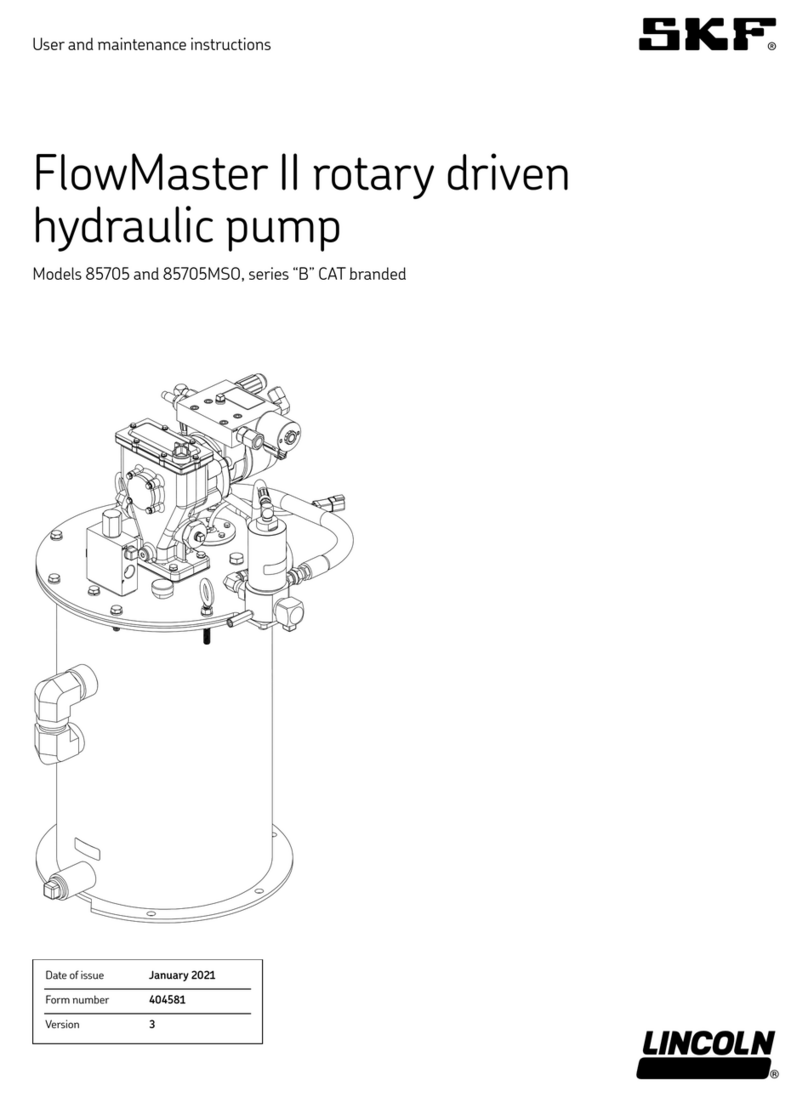

Assembly

NOTE

Prior to assembly, certain components

require lubrication (→Table , page ).

Refer to Fig. (page ) for a section

view of pump tube.

NOTE

Inspect chamber of rod for damage.

Chamber should be smooth and not

rough. If rough and not smooth, rod ()

must be replaced.

Failure to inspect may result in dam-

age to seals.

Table

Lubricated components

Item Description

Clean oil

O -ring, 3/8in ID × 1/2in OD

Quad -ring, -5/8in ID × in OD

O -ring, -3/4in ID × in OD

Seal, -5/8in ID × -7/8in OD

Seal, -5/8in ID × in OD

O -ring, -3/8in ID × -1/2in OD

Block-V packing

O -ring, -1/4in ID × -7/16 in OD

O -ring, -1/8in ID × -5/16 in OD

Coat bore of air motor assembly with PTFE grease. )

) Part number is a . ounce (21.8 g) tube of PTFE grease.

Install o-ring () onto upper groove of

body ().

Install and seat seal () [heel end first]

into bottom of body.

Install and seat bearing () [small diam-

eter first] into body.

Install and seat seal () [heel end first]

into body.

Install and seat washer () into body.

Install retaining ring () into body.

Install o-ring () into groove of body.

Rod

Install o-ring () into groove of rod and

plug assembly ().

Install block-v packing () [lips upward]

onto short end of piston ().

Install piston assembly onto rod and plug

assembly.

. Use care not to damage o-ring.

Install ball () into rod and plug

assembly.