SKIDRIL G23 Application guide

SPECIFICATIONS

UNIT SERIAL NUMBER

_________________________

SKIDRIL

P.O. BOX 8041

GREENSBORO, NC 27419

TEL: 800-843-3745

MODEL G23

DIMENSIONS 32”X18”X13

WEIGHT 50 LB.

ENGINE

TYPE SINGLE CYLINDER,

AIR COOLED, 2 CYCLE

DISPLACEMENT 40.2 CC

OUTPUT 1.4PS/6000 RPM

CARBURATION DIAPHRAGM,

W/PRIMER AND

CHOKE

AIR CLEANER WASHABLE, SEMI-WET

STARTER RECOIL

IGNITION ELECTRONIC,

SPARK PLUG NGK BPM4A

FUEL TANK SIZE 0.28 US GALLON

FUEL MIX RATIO 20-25:1

FUEL MIX OIL TYPE 2 CYCLE

FUEL TYPE REGULAR NO LEAD

IMPACT RATE 1200 BPM

IMPACT FORCE 60-70 FT-LB.

IMPACT SECTION

LUBRICATION OIL BATH

LUBRICANT TYPE SAE 10W-30

LUBRICANT VOL 5 0Z

LUBRICANT USE 1.3 OZ /8 HOURS

12

1-800-843-3745

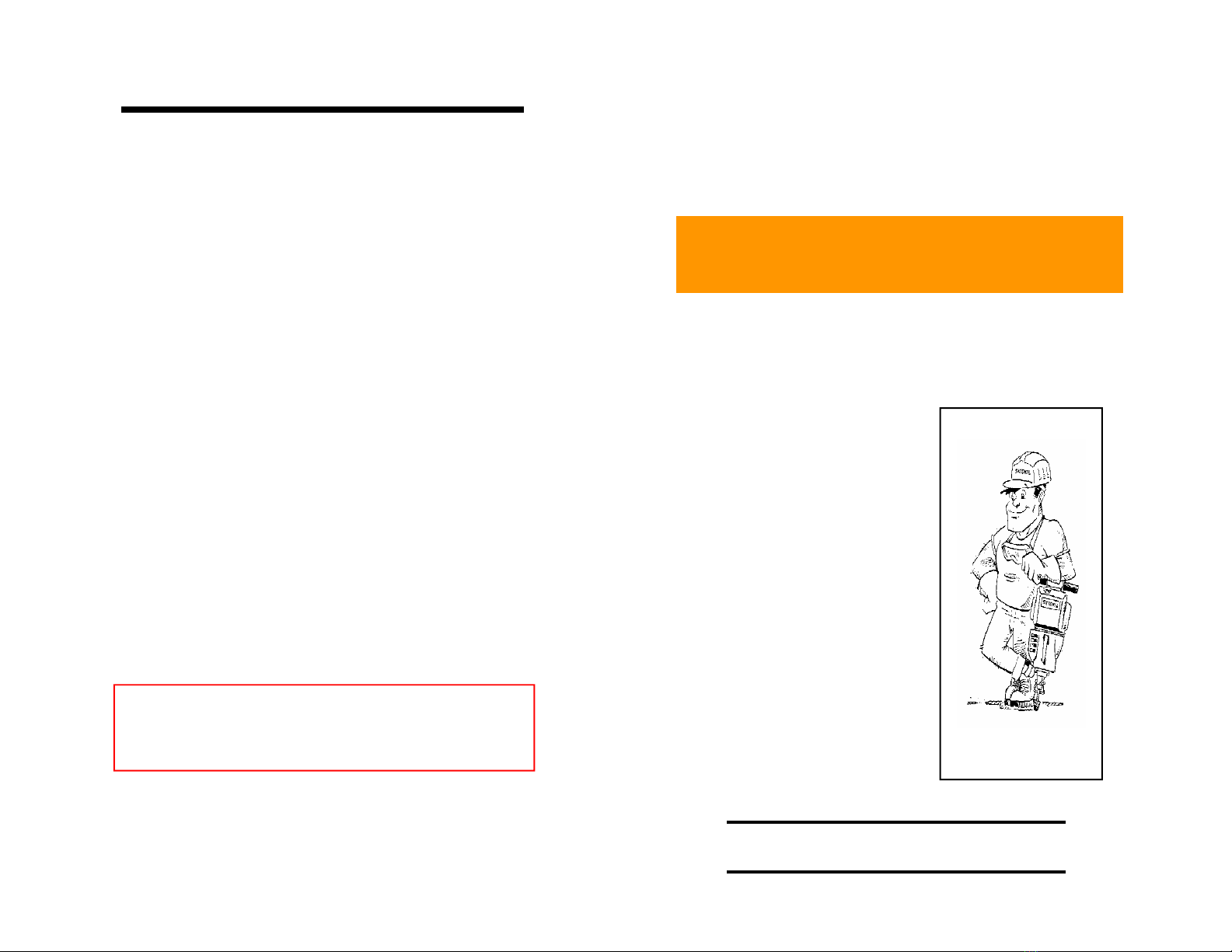

OPERATION & PARTS

MANUAL

SKIDRIL

ENGINE BREAKER G23

ANY PERSON

OPERATING THIS

MACHINE SHOULD

READ AND

UNDERSTAND THIS

MANUAL FIRST!

FOLLOW ALL SAFETY

INSTRUCTIONS

Page

4

5

7

9

10

12

Contents

CONTROL IDENTIFICATION

OPERATION

MAINTENANCE

EXPLODED VIEW

PARTS LIST

SPECIFICATIONS

3

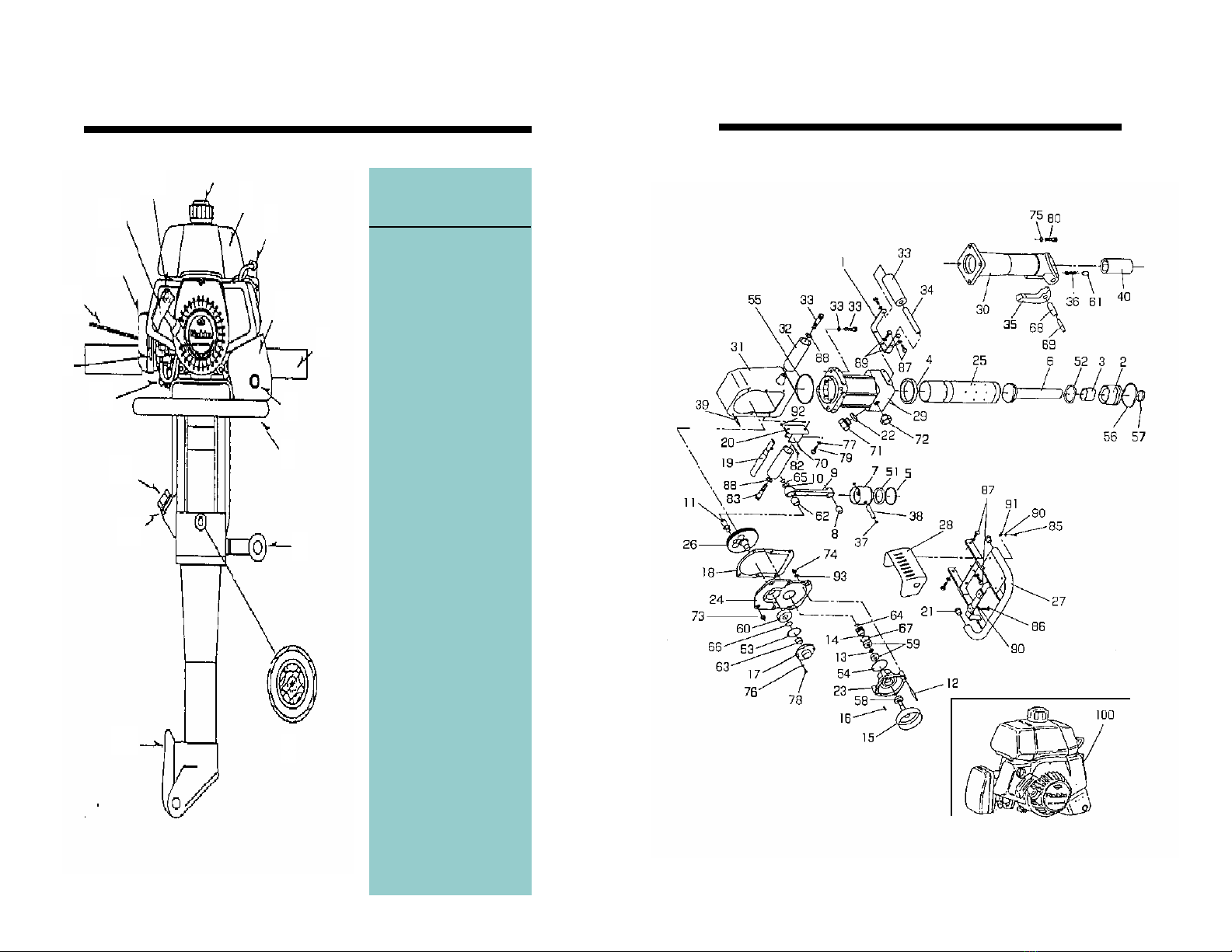

1 MA02E001A1 STAY 1

2 E002A3 GUIDE 1

3 E003A0 BUSHING 1

4 E004A1 LINER 1

5 E005A1 PISTON RING 1

6 E006A2 HAMMER PISTON 1

7 E007A0 PISTON 1

8 E008A1 BUSHING 1

9 E009A1 CON-ROD 1

10 E010A0 SPACER 1

11 E011A1 PIN 1

12 E012A1 BOLT 4

13 E013A0 COLLAR 1

14 E014A0 PINION 1

15 E015A1 CLUTCH SHAFT 1

16 E016A1 KEY 1

17 E017A1 BEARING COVER 1

18 E018A0 PACKING 1

19 E019A1 LEVER 1

20 E020A0 HANDLE SUPPORT 1

21 E021A1 LID 2

22 E025A0 PACKING 1

23 D051A0 CLUTCH COVER 1

24 D052A1 CRANK BRACKET 1

25 D053A2 CYLINDER COVER 1

26 D054A1 CRANK SHAFT 1

27 D055A2 GUARD PIPE 1

28 D058A1 MUFFLER COVER 1

29 C071A2 CYLINDER COVER 1

30 C072B0 FRONT END 1

31 C073A0 CRANK CASE 1

32 MIKTE119A1 HANDLE GRIP 2

33 1120-414 HANDLE GRIP 1

34 1120-422 GRIP SHAFT 1

35 1110-402-01 LATCH 1

36 1110-410-01 LOCK SRPING 1

37 1014-112 PISTON PIN RING 2

38 1044-818A COMP. PISTON PIN 1

39 1044-6190 BOLT M8X17 6

40 MB03E108A1 COLLET (1-1/4X6) 1

51 0G-50 O-RING 2

52 0G-55 O-RING 1

53 0S-44 O-RING 1

54 0S-50 O-RING 1

55 0S-90 O-RING 1

56 0G-75 O-RING 1

57 CL0050C0 DUST SEAL 1

58 AP0687F0 TVC OIL SEAL 1

Part List

No. Part No. Name QTY

10

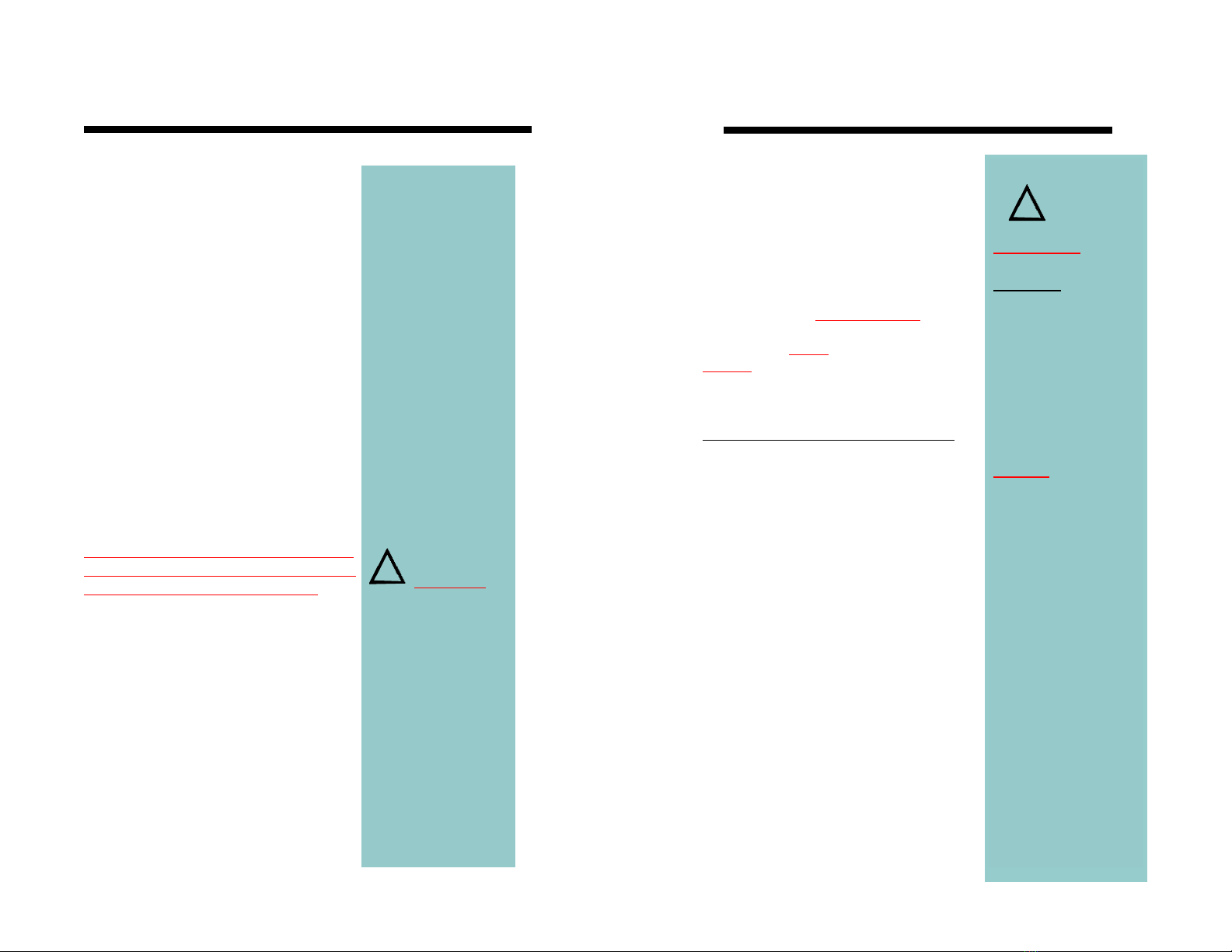

Maintenance cont.

M1: Impact Oil Sight

M2: Spark Plug Gap

M3: Carb Filter

To Check Oil Level: Be sure Machine is in

the vertical position and the oil level is

somewhere between the two horizontal lines

To Check Plug Gap: First remove and clean

carbon or dirt using a wire brush. Using a

feeler gauge check and adjust the plug gap

to .024-.028”.

To Check or Clean Air Filter: First unlock

cleaner cover and twist cover off as shown.

Wash filter in appropriate cleaner, then wring

dry. Put a few drops of motor oil on it and

squeeze to distribute. Re-install.

Lock Cover

Filter

Gap

Notice:

*Do: Always fill/

check the oil level

with the machine in

the upright position.

Notice:

*Do not: Over fill

the machine with

lubricant

Notice:

*Be sure to apply

sufficient torque to

the spark plug, to

eliminate unwanted

loosening.

Notice:

*Never operate the

machine with a

missing or damaged

filter.

8

PREPARATION FOR USE

1. IMPACT LUBRICANT:

- Remove fill cap (item 12, p4).

- keep breaker in vertical upright

position while filling.

- use 10w30 4 cycle oil

- fill to the lip and install fill cap.

2. FUELING:

-Mix 20-25 to 1 regular no-lead

gasoline with 2 cycle engine oil.

-Fuel tank will hold approx. 1 quart.

3. OPERATION:

Before operation perform daily

inspection per maintenance section of

this manual.

a. Fill fuel tank (item 1, p4).

b. Attach a tool for the required job

(chisel, drive head etc.) by first opening

the tool latch (item 10, p4), by pushing

down with your foot.

c. Insert tool and close tool latch by

pushing upwards.

Operation

NOTICE:

* Do not use 2 cycle

or non 10W30 type

oils.

WARNING:

*Do not: Fuel a hot

machine!

*Do not: Smoke

While Fueling!

*Do not: Operate

the machine without

protective/safety

clothing and

equipment!

*Do not: Use the

machine without first

contacting the

Utilities for a

‘Locate’!

*Do not: Use the

machine without

reading and

understanding the

safety section of this

manual!

!

5

D. Start the engine by:

1. Close the choke lever item14, p4) by

pushing it upwards.

2. Push the primer button (item 13,

p4) 3-5 times.

3. Pull the starter grip while holding the

throttle (item 15, p4) in the down

position.

4. Quickly release the throttle lever

when the engine starts.

5. Gradually open the choke lever, by

pushing downwards as the engine

warms up.

E. Stopping the engine:

-Press the stop button (item 18, p4) to

kill the engine.

-If the kill switch malfunctions, you can

stop the engine by pressing the throttle

lever down and closing the choke.

F. Operation:

1. By pressing the throttle lever the

machine speed and impact force is

increased.

2. You need not apply excessive

pressure on the machine during

operation.

Operation continued

Warning:

*Discontinue use of

the machine until

repairs can be

made!

!

WARNING:

*Do not: Operate

a machine with

missing, damaged or

loose parts.

Notice:

*Failure to follow

this schedule may

result in damage to

the machine, and

could void the

warranty.

*Service beyond

what is indicated

here should not be

performed by

untrained persons,

and could void the

warranty.

1. DAILY INSPECTION:

A. Look for loose or missing

nuts, bolts or screws.

B. Check the starter rope for wear and

replace if required.

C. Inspect the tool blade and shank for

cracks and discard if required.

D. Check the impact section lubricant level

(item 9, p4)., see sketch m1 , p8 .

E. Check the air cleaner and clean if

required, see sketch

m2, p8.

2. PERIODIC MAINTENANCE:

Item time (hrs)

Cleaning exterior daily

Clean/adjust plug 50

Replace impact oil 150

Inspect/replace clutch 300

Replace O-ring/seal 300

Clean exhaust port 300

Clean Carburetor 300

3. Extended storage:

A. Remove fuel from tank and burn excess

in engine.

B. Place a few drops of 2 cycle oil in engine

through spark plug opening.

C. Clean and keep dry.

!

Maintenance

67

Item

1. Fuel cap

2. Fuel tank

3. Spark plug

4. Muffler cover

5. Handle

6. Exhaust outlet

7. Guard handle

8. Side handle

9. Impact oil window

10. Tool latch

11. Impact oil inlet

12. Impact oil cap

13. Primer pump

14. Choke lever

15. Throttle lever

16. Air cleaner

17. Starter grip

18. Stop switch

Controls

1

11

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

4

Exploded View

9

SAFETY FIRST

READ, UNDERSTAND AND FOLLOW

SAFETY GUIDELINES AND SAFE WORK

PRACTICES.

Special

notice

goes here

TAKE NOTE OF WARNINGS IN THIS MANUAL

AS THEY IDENTIFY INSTRUCTIONS INTENDED

TO PREVENT INJURY TO YOU OR OTHERS.

NOTICES:, ARE INTENDED TO PREVENT

DAMAGE TO THE MACHINE OR PROPERTY.

WARNING:

DO NOT: USE EQUIPMENT IN

APPLICATIONS FOR WHICH IT IS NOT INTENDED.

DO NOT: USE IMPROPERLY TRAINED OR

UNQUALIFIED PERSONNEL TO OPERATE

THIS EQUIPMENT.

DO NOT: LEAVE MACHINE RUNNING

UNATTENDED OR WHEN NOT IN USE.

DO NOT: REFUEL A HOT OR RUNNING ENGINE.

DO NOT: SPILL FUEL WHEN FUELING THE

ENGINE.

DO NOT: SMOKE WHILE FUELING OR

OPERATING THE MACHINE.

DO NOT: REFUEL NEAR AN OPEN FLAME OR

SPARK.

DO NOT: OPERATE THE MACHINE WITHOUT

PROPER SAFETY PROTECTION SUCH AS

PROTECTIVE EYEWEAR, SAFETY BOOTS,

EAR PROTECTION, HARD HAT, GLOVES ETC.

DO NOT: OPERATE THE MACHINE INDOORS OR IN AN

AREA WHERE EXHAUST GASESMAY COLLECT., OR

WHERE VENTILATION IS NOT ADEQUATE.

DO NOT: OPERATE THE MACHINE WITHOUT SOLID

FOOTING OR WITH THE MACHINE ELEVATED ABOVE

YOUR HEAD.

DO NOT: STORE THE MACHINE IN A PLACE OR POSITION

THAT IT MAY FALL , DROP OR SLIDE FROM WHEN NOT IN USE.

!

NOTICE:

!

2

59 6001 BEARING (C-TYPE) 2

60 6204 BEARING (C-TYPE) 1

61 QC-12X18 ROLLER 1

62 TA 1520Z NEEDLE BEARING 1

63 TLA1512Z NEEDLE BEARING 1

64 CS-12 SNAP RING 1

65 CS-15 SNAP RING 1

66 CS-20 SNAP RING 1

67 CH-28 SNAP RING 1

68 PR16X50 SPRING PIN 1

69 PR10X50 SPRING PIN 1

70 PR 4X28 SPRING PIN 1

71 NK-2OIL CAP 1

72 FG-10 OIL WINDOW 1

73 NFL-8 LOCK NUT W/FLANGE 6

74 NFL-6 LOCK NUT W/FLANGE 4

75 WF2L-10 SPRING WASHER 8

76 WF2L-5 SPRING WASHER 4

77 WF2L-8 SPRING WASHER 2

78 SBH-5X12 HEX SOCKET BOLT 4

79 SBH-8X20 HEX SOCKET BOLT 2

80 BH-10X30 HEX SOCKET BOLT 4

81 BH-10X35 HEX SOCKET BOLT 4

82 BH- 5X35 HEX SOCKET BOLT 1

83 BH-12X50 HEX SOCKET BOLT 1

84 BH-12X55 HEX SOCKET BOLT 1

85 B-6X12 HEX BOLT 4

86 B-6X25 HEX BOLT 2

87 B-8X20 HEX BOLT 8

88 WS-12 PRING WASHER 2

89 WS-8 SPRING WASHER 8

90 WS-6 SPRING WASHER 6

91 WP-6 PLAIN WASHER 6

92 NN-5 NYLON NUT 1

93 W6S1 SEAL WASHER 4

100 EC04 ENGINE 1

Parts List Continued

No. Part No. Name QTY

NOTE: WHEN ORDERING PARTS

PLEASE INCLUDE SERIAL NUMBER

FOUND ON PAGE 12 OF THIS

MANUAL.

11

Table of contents