Skinner Innovations HST Series User manual

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

HST Series

Operation Manual

www.skinnerinnovations.com email: [email protected]

Rev 11-24-2017

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 1

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Contents

1. Table of Contents

2. Model number configuration guide

3. Specifications

4. Safety warnings

5. Assembly

6. Operation

7. Remote Temperature Output

8. Troubleshooting

9. Service

10. Product Warranty

11. Appendix A - Technical Note: Rate Compensated Heat Detector Testing

12-13. Appendix B – Operation Supplement: Rate Control option / rate compensation verification

14. Appendix C- Operation Supplement: Testing Fenwal® 17343 series detectors

15. HST Output Cable

16-17. HST Output Extension Cable

18-19. HST Power Supply

20-21. HST Power Extension Cable

Attention:

This manual should be read by all who will be using or maintaining this product. Information herein is

subject to change without notice. Testing procedures, tolerances, and pass/fail criteria are the

responsibility of the end user. Information in this manual is for informational purposes only.

This product is not field repairable due to the meticulous alignment and calibration of the device.

Do not attempt to repair or modify. Doing so will impair the devices performance and void the Skinner

Innovations LLC Product Warranty

This product is protected under patent numbers GB2468393 / U.S. Pat. No. 8,454,228

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 2

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Mode l number configuration guide

HST- #- ### -#

Sensor size:Set points (degrees Fahrenheit): Options:

A= 5/8”*** (Fenwal® /DAF) ALO=140, 160, 190, 210, 225 C=rate controlled* **

B=17/32” (Thermotech) MEL*=160, 190, 210, 225, 275

C= 16mm (Olsen / Tyco) MEH*=190, 210, 225. 275, 325

D=20mm* ALM=225, 275, 325, 360, Cool down

E=18mm* AME=275, 325, 360, 450, Cool down

P=23mm*(Pastor) AMH*=325, 360, 450, 500, Cool down

AHI=450, 500, 600, 725, Cool down

BLO=135, 194 (2 temperature for Thermotech detectors)

*contact for availability

**temperature rate control "Rate Compensation Verification"(see Appendix A&B for details)

***models shown are for Fenwal® DETECT-A-FIRE® model 27127, 28021, 27120, and 28020

contact Skinner Innovations to confirm correct HST model to use with other sensors

Example model number: HST-A-ALO

HST tester- For use on 5/8” sensors, calibrated set points: 140,160,190,210, & 225°F, no options

For other temperatures, sizes, custom options, or custom temperature set points, consult

Skinner Innovations: email: info@skinnerinnovations.com

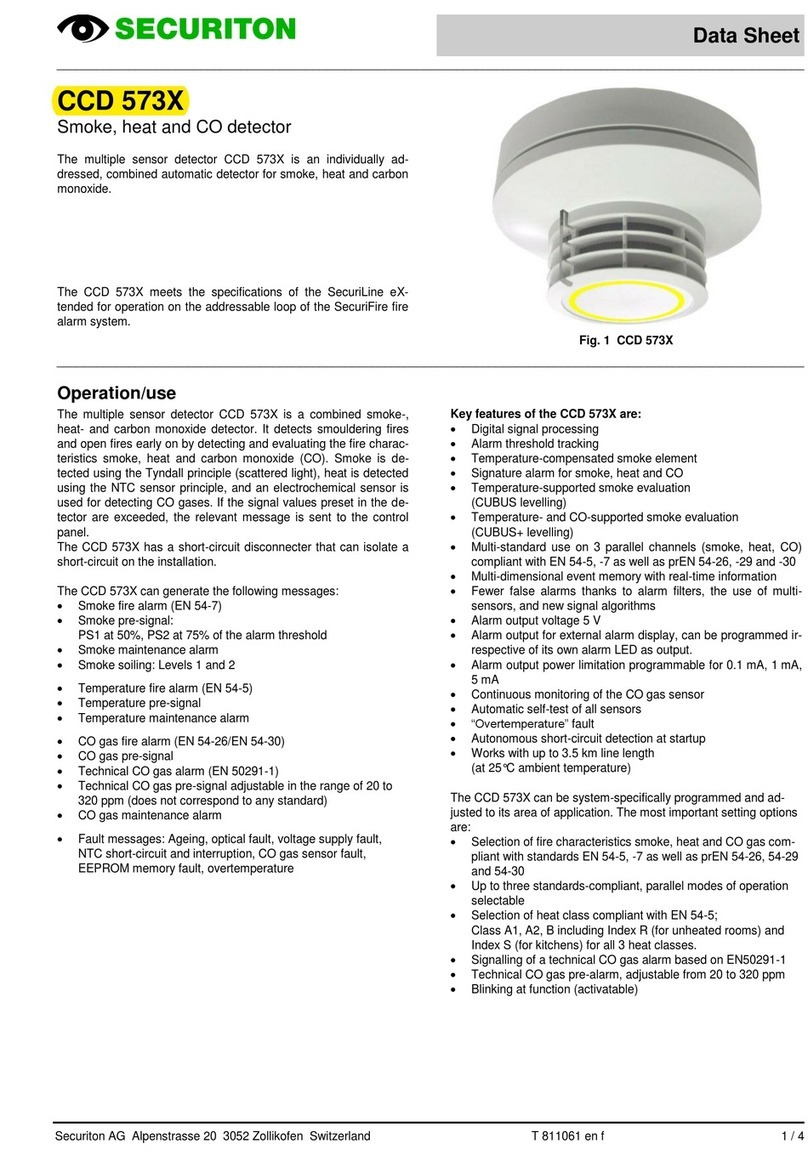

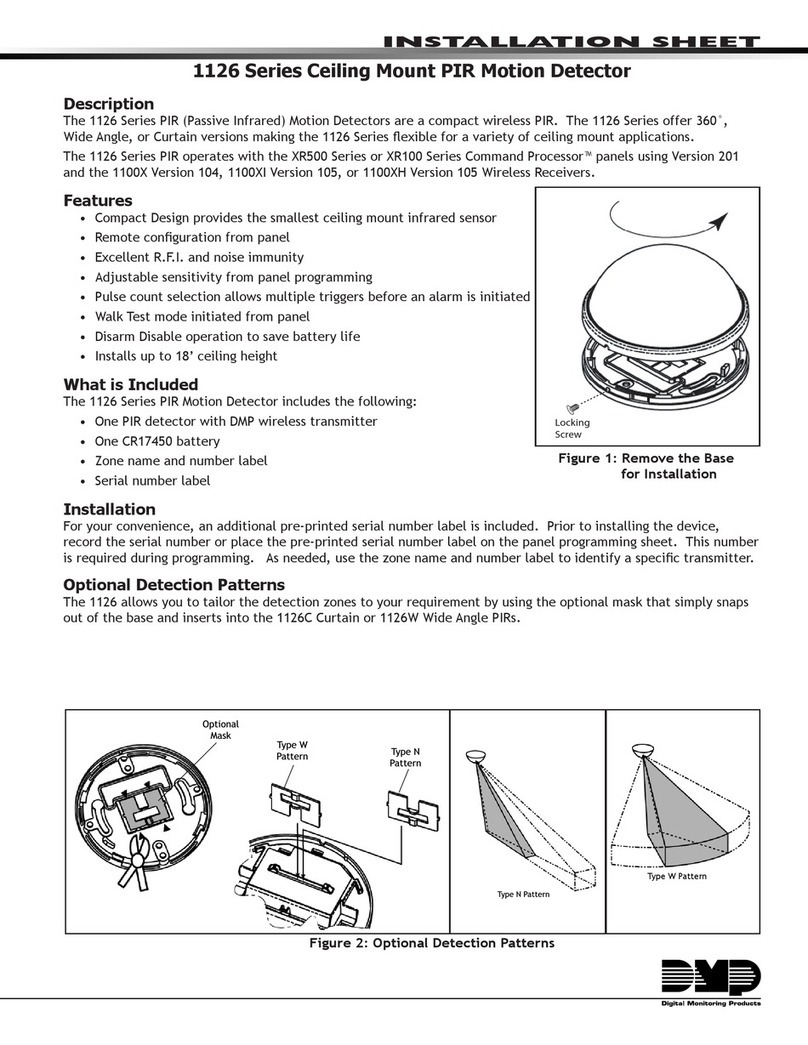

HST tester- shown with compatible poles and large carry bag (part number: HST-BAG-LRG)

Consult Skinner Innovations about where to obtain compatible poles

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 3

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Specifications

HST test head:

•Aluminum housing

•1 to 5 temperature set points- factory set

•Large easy to see LED indicator light

•Heavy duty power switch

•Solid state temperature control unit

•Auto off timer feature (default setting=5 minutes from time set-point is reached)

•Remote temperature output- connection to directly read temperature with digital voltmeter

•CE Conformity

Battery:

•18vdc or 24vdc Li-Ion battery pack

•Capacity: 3000mAh

•CE Conformity

•Protective circuit installed within the battery pack protects product from:

- Over current

- Over-charging cut-off

- Over-discharge cut-off

- Short circuit and wrong polarity

•Charger: Only use charger supplied with the HST battery pack

•Battery Storage: for optimum performance, store battery at 60% charge, do not place a

discharged battery into storage, as the cell voltage may further drop below acceptable voltage

level and pack safety circuit will not allow re-charging

Battery charger:

•Intelligent charger designed for Li-Ion battery pack.

•UL CE Conformity

•Worldwide input- AC power from 100V-240V -50/60Hz.

•Charging time for battery pack is about 1.5 Hrs.

•Built in circuit to cut off power automatically when battery is fully charged.

•Red LED indicates battery charging and Green LED indicates battery fully charged

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 4

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Safety Warnings

Do not use the HST test tool in any area where flammable gas is present.

The HST test tool is a heat producing device; keep away from skin, body parts, and flammable materials.

Do not leave unit unattended. Always wear safety glasses, appropriate gloves, and other personal

protective equipment when using the tool.

The HST utilizes Li-Ion batteries; refer to the battery and charger section of this manual before charging

or use. Do not make any changes to the charger, charger accessories or connectors, as this might cause

electrical short, fire or over-heating during charging.

Use special caution when working with Li-Ion cells, they are sensitive to charging

characteristics and should not be mishandled.

oNever leave a charging battery unattended

oDo not set battery or charger on wood, carpet, or any other flammable surface

oUse only charger supplied, do not alter charger or battery

oLi-Ion cells are sensitive to charging characteristics and can be dangerous if

mishandled

oRead and understand all instructions before use

When using pole-mounted tools overhead, ensure that poles are locked and secure. Consult Skinner

Innovations about where to obtain compatible poles.

Barricade areas around and below test areas so that persons not involved with testing will not enter the

work area where overhead testing is taking place.

Always inspect poles, batteries, battery case, and HST test head for damage prior to each use. If any

damage is noted during this check, remove from service immediately, and have the unit serviced.

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 5

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

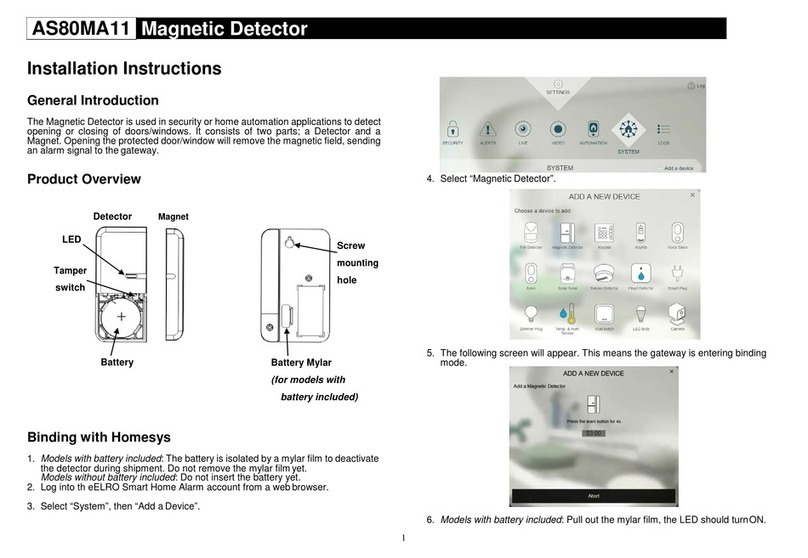

Assembly

1. Thread the rubber straps though the loops on back side of cloth battery holder, leaving a loop in the

middle of each strap.

Battery holster- showing proper installation of rubber straps Holster with strap-loops around pole

2. Insert battery into the battery holder and secure the side release buckles.

3. Place holder over HST compatible pole with rubber straps looped around the pole

Holster with rubber strap fastened HST Series heat detector tester- installed on an HST compatible pole

4. Snug down rubber straps and ensure that straps are secure

5. Insert test head onto pole. Ensure that buttons are secure.

6. Plug cord into battery and twist lock ring to fasten connector in place

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 6

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Operation (For operation with Rate Control option, see Appendix B)

1. Ensure bypasses are in place, including disabling of any fire suppression systems.

2. Ensure that HST is correct temperature range for detectors to be tested. If using multi-

temperature HST, ensure that correct temperature setting is selected.

3. Turn on HST by pressing the power button. The indicator light will turn on steady until temp

setting is reached.

4. Place tool over the sensor to be tested

5. Wait for sensor to trip. When the indicator light begins to cycle off and on, the tool has

reached its calibrated set point. (If light does not cycle and stays off for more than 30 seconds,

battery may require recharging) After a preset timeout period, indicator light will flash at a fast

rate and heating unit will turn off. To reset unit, press power button off and on again.

6. After HST has reached its set point temperature, the temperature will hold steady for 5

minutes.

7.Next the heat will turn off for 1 minute (detector should auto-reset during this off-time)

before heat is again turned on allowing user to verify the set point trip of the heat detector.

(For testing with Rate Control option, see Appendix B)

8. Heat is turned off for 1 minute then on again for 3 more cycles.

9. Repeat process for each device to be tested.

Note: If the HST is not cooled down between tests, the sensor to be tested will be heated at a

much faster rate. This faster rate of heating could cause the rate compensated fire detector to trip at a

temperature lower than the stated set point on the sensor. See Appendix A for more information.

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 7

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Remote Temperature Output see appendix A

1. Connect HST to digital voltmeter using special connection cable

Requires 1.5 meter cable part number HST-A5-CBL (sold separately). For longer distance use

with 8.3 meter extension cable part number HST-EXT-CBL.

2. Read temperature directly from voltmeter.

Example: 0.325vdc = 325 degrees F

Notes on Remote Temp Output (also see appendix A):

1. If sensor trips lower than the manufacturer’s set point:

a.) Remember that some detectors are Rate Compensated. The actual trip point will vary

depending ambient temperature and the rate of temperature rise.

2. If sensor does not trip:

a.) Check sensor shell for damage. Small dings, dents, and overheating can shift the set point.

b.) Let sensor cool down, then place fully heated tester onto sensor

c.) If using multi-temperature tester, try turning up to next temp setting.

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 8

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Troubleshooting

Problem

Possible cause

Remedy

Indicator light does not

turn on

If indicator light stays off for over

60 seconds, power may be off or

battery may require recharging

1. Push power button

2. Recharge battery

Indicator light on, unit

heating, but sensor is not

tripping

1. Sensor set point is higher than

the set point of the HST

2. Detector is damaged

3.HST tester model incorrect for

detector

Sensor/detector may be damaged

Visually check sensor for damage, including

signs of overheating.

1. Use tool with proper set point

2. Place fully heated tool onto ambient

temperature sensor. If sensor trips, its set

point may have shifted (a common result of

overheating or other damage)

3. Confirm HST model is matches detector

4. Try using the tester on a known working

sensor

Indicator light flashing at

2-blink rate Heater fault

1. Charge battery

2. Return for service

Indicator light flashing at

3-blink rate

Internal sensor has detected a

failure Return for service

Indicator light flashing at

4-blink rate

Over temperature alarm the

tester is above the selected set

point temp

(This will occur when changing

from a high temp setting to a

lower temp setting)

1. Allow unit to cool down to set point

temperature

2. Reset by pressing power button off and then

restarting

Indicator light flashing on

and off quickly Internal safety timer has timed out

Reset by pressing power button off and then

restarting

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 9

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Service

For technical assistance or repair contact Skinner Innovations

Email:service@skinnerinnovations.com

Website: www.skinnerinnovations.com

Physical address

Skinner Innovations LLC

708 North Douglas Street

Lake City, Iowa 51449

Mailing address

Skinner Innovations LLC

PO BOX 97

Lake City, Iowa 51449

Phone: (801) 766- 4782

Along with a detailed description of the problem, please include:

1. The manufacturer, model number, and set point of the heat sensors you are testing.

2. The model and serial number of the HST

Periodic Service and maintenance:

1. Inspect the tool as described in this manual before each use.

2. Return tool to Skinner Innovations LLC for repair or calibration.

Call for return authorization prior to sending in any unit for service or repair.

3. Do not attempt to disassemble the tool. There are no user serviceable parts. Special care is

required for disassembly.

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 10

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Product Warranty

To the original purchaser, for one year from date of purchase, Skinner Innovations

LLC will warranty repair or replace any damaged components that are determined

to be the result of manufacturer defect. Any unit that has been opened up,

disassembled, or otherwise worked on by anyone other than Skinner Innovations

LLC, will not be covered under this warranty. Normal wear and tear is not

covered. Scratches and other cosmetic issues are not covered. Batteries, cloth

battery holder, and rubber straps are not covered other than for manufacturer

defect.

This warranty statement is not intended to limit or take away any persons legal rights.

Contact Skinner Innovations LLC customer service before returning any unit for warranty repair.

He at dete cto r tes ter for Rate Co mp ens ated he at de tec to r

He at de tec to r te s ter for Rate An tic i pa ti o n de tec t or

He at de tec to r te ste r f or p rob e s tyl e hea t det ector

Heat detector tes ter forT hermald etecto r

He at de tec to r te s ter for fire d e tec to r

He at de tec to r te s ter for Fe nw a l he at de tecto r

Heat detectortester for Detect-A-Fire hea t detect or

Heat detector tes ter forFenwal T hermos witch

Fenwal 15000 01-015050-000

Fenwal 16000 01-016050-000

Fenwal 16000 01-016051-001

Fenwal 17000 01-017000-000

Fenwal 17000 01-017021-000

Fenwal 17000 01-017002-000

Fenwal 17000 01-017023-000

Fenwal 17100 01-017100-000

Fenwal 17100 01-017121-000

Fenwal 17100 01-017102-000

Fenwal 17100 01-017123-000

Fenwal 17200 01-017200-000

Fenwal 17200 01-017221-000

Fenwal 17200 01-017202-000

Fenwal 17200 01-017223-000

Fenwal 17300 01-017300-000

Fenwal 17300 01-017321-000

Fenwal 17300 01-017302-000

Fenwal 17300 01-017323-000

Fenwal 17800 01-017800-000

Fenwal 17800 01-017821-000

Fenwal 17800 01-017802-000

Fenwal 17800 01-017823-000

Fenwal 18000 01-018000-000

Fenwal 18000 01-018021-000

Fenwal 18000 01-018002-000

Fenwal 18000 01-018023-000

Fenwal 18000 01-180020-029

Fenwal 18000 01-018002-021

Fenwal 18000 01-018023-007

Fenwal 27000 27020-0

Fenwal 27000 27020-1

Fenwal 27000 27021-0

Fenwal 27000 27021-1

Fenwal 27100 12-X27120-000

Fenwal 27100 12-X27120-022

Fenwal 27100 12-X27121-000

Fenwal 27100 12-X27121-020

Fenwal 28000 12-X28020-003

Fenwal 28000 12-X28021-000

Fenwal 28000 12-X28021-005

Fenwal 08-80 08-80

Fenwal 08-80 08-80

Fenwal 08-81 08-81

Fenwal 08-82 08-82

Fenwal 67000 67000-0

Fenwal 67100 67100-0

Fenwal 67100 67100-1

Fenwal 67100 67121-0

Fenwal 67300 67300-0

Fenwal 67300 67321-0

Fenwal 17343-113 600F

Fenwal 17343-113 950F

Fenwal 17343-78 500F

Fenwal 17343-78 725F

Fenwal 17343-78 900F

Fenwal 17343-78 950F

Fenwal 17343-124 140F

Fenwal 17343-124 325F

Fenwal 17343-124 425F

Fenwal 17343-124 600F

Fenwal 17343-124 725F

Fenwal TSK, TSO

Fenwal 18423-0

Fenwal 17322-3

Fenwal 17343-108

Fenwal 17343-85

Fenwal 67121-31

Fenwal 17343-116-

Fenwal 17343-16

Fenwal 17343-3

Fenwal 17347-6

Fenwal 17303-6

Fenwal 370000 370000-000

Fenwal 371000 371000-000

Fenwal 17500 17502-0

Fenwal 17500 17503-0

Fenwal 20000 23-0201

Fenwal 20000 23-0203

Fenwal 20000 23-0208

Fenwal 20000 23-0210

Fenwal 20000 23-0211

Fenwal 20000 23-0227

Fenwal 20000 23-0228

Fenwal 34-011201-000

Fenwal 34-011204-001

Fenwal 34-011100-002

Fenwal 34-011208-000

Fenwal 47002-0-X XX

Fenwal 47023-0-X XX

He at de tec to r tes ter for U la ne t h eat d e tec to r

UL AN E T FM132

UL AN E T FM156

UL AN E T FM165

UL AN E T FM171

UL AN E T FM247

UL AN E T FM344

UL AN E T DM401

UL AN E T SE

UL AN E T 440

UL AN E T 374

He at dete cto r tes ter for Kli xo n he at de tec to r

Klixon 21542

Klixon 21543

Klixon 21545

Klixon 21546

Klixon 21547

Klixon 21548

Klixon 21549

Klixon 21550

Klixon 21557

Klixon 21561

Klixon 21562

Klixon 28303

Klixon 28509

Klixon 28514

Klixon C9192

Heat detector tester for T herm otech hea t detect or

He at d ete c to r te s ter for mod el 3 02 h e a t d e tec to r

Thermotech 302

Thermotech 302-EPM

Thermotech 302-AW

Thermotech 302-ET

Thermotech 302-H

Heat detecto r tester for H oneywell hea t detec tor

Honeywell 3000

He at de tec to r te s ter for T5 4 B he at de tec to r

Olsen T54B

Tyco T54B

He at de tec to r te s ter for T5 4 heat de te c to r

Olsen T54

Tyco T54

He at de tec to r te s ter for T he rma c T 10 0 0 he a t d e tec to r

The rma c T1000

He at de tec to r te s ter for T h erm os ti c k he at de tec tor

The rmo s tic k M-S

The rmo s tic k N S1-P2

The rmo s tic k N S1P-FS

The rmo s tick N S4 BRS

The rmo s tic k S 1P

The rmo s tic k S 4BRS

The rmo s tic k S 100

Heat detector tester for Og gioni hea t det ector

He at de tec to r te ste r f or T MP 2 he a t de tec tor

Oggioni TMP2

He at de tec to r te s ter for Si e m ens hea t de te c to r

Siemens DT-135CL

Siemens DT-200CL

Siemens DT-135CS

Siemens DT-200CS

Siemens DT-135WP

Siemens DT-200WP

He at de tec to r te ste r f or L ICO hea t de tec tor

He at d etec to r te s ter for H DL h ea t de tec tor

LICO HDL -2

LICO HDL -3-EX

LICO HDL -5-EX

LICO HDL 1

LICO HDL 4

LICO HDL 3

LICO HDL 5

He at de tec to r tester for Fi rebuy hea t detect or

Firebuys 1000

He at de tec to r te ste r f or N OV A-50000 h eat de tec tor

He at de tec to r te s ter for T3 0 0 he a t de tecto r

NO VA-5000 T300 300-140

NO VA-5000 T300 300-190

NO VA-5000 T300 300-225

NO VA-5000 T300 300-325

NO VA-5000 T300 300-144

He at de tec to r te s ter for Vul c an C al -s ta t

He at de tec to r te s ter for Vul c an T he r ma l S w i tc h

He at de tec to r te s ter for Vul c an T he r mo s ta t

He at de tec to r te s ter for Vul c an H ea t De te c to r

VulcanCal-sta t 1A1D5

VulcanCal-sta t 1A12D5

VulcanCal-sta t 1C1D5

VulcanCal-sta t 1C2D5

VulcanCal-sta t 1D1D5

VulcanCal-sta t 1D2D5

VulcanCal-sta t 1E1D5

VulcanCal-sta t 1E2D5

VulcanCal-sta t 1A1C9

VulcanCal-sta t 1A2C9

VulcanCal-sta t 1C1C9

VulcanCal-sta t 1C2C9

VulcanCal-sta t 1D1C9

VulcanCal-sta t 1D2C9

VulcanCal-sta t 1E1C9

Vulcan Cal-s tat 1E2C9

VulcanCal-sta t 1A1B9

VulcanCal-sta t 1A2B9

VulcanCal-sta t 1C1B9

VulcanCal-sta t 1C2B9

VulcanCal-sta t 1D1B9

VulcanCal-sta t 1D2B9

VulcanCal-sta t 1E1B9

VulcanCal-sta t 1E2B9

VulcanCal-sta t X1C2B2

GE 328A8092P001

He at de tec to r te s ter for Vulcanic Electro-MechanicalThe rmostat

He at de tec to r te s ter for Vul c an ic The rmal Swi tch

Heat detector tester for Vulca nic H eat Det ector

He at de tec to r te s ter for Vul c an ic The rm o s tat

Vulcanic 8311 8310-00 0

Vulcanic 8321 8320-00 0

Vulcanic 8331 8330-00 0

Vulcanic 83418340-00 0

Vulcanic 8351 8350-00

Vulcanic 8361 8360-00

Vulcanic 8411 8410-00

Vulcanic 8421 8420-00

Vulcanic 8451 8450-00

Vulcanic 8461 8460-00

Vulcanic 8453 8452-00

Vulcanic 8563 8462-00

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 11

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Appendix-A Technical Note: Rate Compensated Heat Detector Testing

Interpretation of test results

The purpose of this note is to explain detector set point, rate compensation, and how this should affect the

interpretation of test results observed on remote temperature readout of the HST heat detector tester. The HST

remote temperature output is taken directly from the heating unit. Detector trip points will often be observed to

be lower than the manufacturer rated set point. This is due to the unique way rate compensation works to self-

adjust the set point based on how quickly the temperature is rising from the starting temperature.

Set Point verses trip point- “virtual set point”

The unique feature of Rate Compensated heat detectors: "virtual” set point.

The detector has two main parts which expand or contract with temperature changes.

First is the outer expansion tube or shell.

Second is a pair of expansion "struts" or metal strips. This interior part also contains the electrical contacts.

These two parts work together to cause the detector to behave in 2 different ways:

1st- A slow rate of temp rise-Heat is allowed to penetrate into the struts, both parts expand together and detector

trips close to the rated set point.

2nd- A high rate of temp rise-The shell rapidly expands before heat can penetrate to struts and the detector trips

at a temperature that would appear to be lower than the rated set point.

Manufacturer Calibration (UL testing) vs. Compliance Testing

New heat detectors are calibrated (tested to UL521 standard) to a rated +/- set point.

This is done by raising the temperature in very slow, controlled manner (varying rates depending on the

temperature of the detector).

For example: the temperature could be raised at 50 degrees per minute until 150 degrees is reached. Then

continue at 1 degree per minute until the detector trips at 225°. Ambient temperature also needs to be accounted

for by heating to a pre-determined starting temperature for a set period of time. The detector should then trip

within the +/- range of manufacturers set point specification. This type of testing is not required for normal

detector compliance testing.

Compliance testing is done after installation of the detector in the intended area of use and is required by the

authority having jurisdiction. There is no requirement to test for a specific temperature. However, the test should

not damage the detector.

The HST can be custom programmed to raise temperature at a slower rate to trip detector closer to the rated set

point. (see Rate Control option Appendix B) However, the HST’s intended application is to compliance test

detectors in a non destructive manner, identify shifts in set point, and help ensure that the detector continues to

operate as it was originally calibrated by the manufacturer. Per the UL standard, there is no way to field re-

calibrate a heat/fire detector.

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 12

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Appendix-B Operation supplement:

Testing rate compensated heat detectors - HST Rate Control option/ Rate Compensation Verification

Sequence of Operation

Turn on HST by pressing the power button. Place tester firmly over detector. Then follow test stages 1-4 below.

Test

Stage HST LED condition

Power on/

sequence of

operation

Observed condition Interpretation of

test results*

Example results

140°F (+7/-8°)

Fenwal DAF detector

Stage 1

(used

on rate

control

models)

LED steady on until 60-

80% temp

When LED goes off,

then flashes 1 time

every 15 seconds, 180

second hold timer is

active

Temperature

rises to 60-80%

of set point

Then begin 180

second stage 1

hold timer

Detector should trip

for 1st time while

temperature is rising.

If using remote temp

display, note the trip

temperature.

Failure to trip may

indicate detector set

point has shifted

high

1st detector trip at

124°F

Hold temperature

128°F

1st stage hold time:

LED turns off then

flashes 1 time every 15

seconds

Temperature

holds at 60-80%

of set point for

180 seconds

Detector should auto-

reset within 1-2

minutes.

Observe that detector

has reset.

Failure to auto-reset

may indicate

detector set point

has shifted high

Auto-reset approx 30

seconds after 1st

stage timer begins

Stage 2

(not

used on

all

models)

LED steady on

When LED goes off,

then flashes 2 times

every 15 seconds, 180

second hold timer is

active

Temperature

rises to 85-95%

of set point

Begin 180

second stage 2

hold timer

Detector should trip

for 2nd time while

temperature is rising.

If using remote temp

display, note the trip

temperature.

Failure to trip may

indicate detector set

point has shifted

high

2nd detector trip at

130°F

Hold temperature

136°F

During 2nd stage hold,

LED turns off then

flashes 2 times every

15 seconds

Temperature

holds at 85-95%

of set point for

180 seconds

Detector should auto-

reset within 1-2

minutes.

Observe that detector

has reset.

Failure to auto-reset

may indicate

detector set point

has shifted high

Auto-reset approx 30

seconds after 2nd

stage timer begins

Stage 3

LED steady on until

temperature is a few

degrees below the

rated set point, then

LED begins slow flash

Temperature

rises to

detectors rated

set point

Detector should trip

for 3rd time while

temperature is rising.

If using remote temp

display, note the trip

temperature.

Failure to trip may

indicate detector set

point has shifted

high.

Auto reset after

tester has stabilized

may indicate that

detector has shifted

low

3rd detector trip at

140°F

Stage 4

LED steady on until

temperature is a few

degrees below the

rated set point, then

LED begins slow flash

Temperature

holds for 5

minutes then

heat turns off for

approx 60-90

seconds

Detector should auto-

reset during off-time.

Then, temperature

begins to climb to set

point again.

Detector should trip

at the actual set

point at this time

4th Detector trip at

141°F

5th Detector trip at

139°F

6th Detector trip at

142°F

Stage 4 repeats 3 more times with 5 second hold time between cycles, then temperature holds steady at set point

Use the average of the last four trips to determine the actual trip point*

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 13

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Appendix-B Operation supplement:

Testing rate compensated heat detectors - HST Rate Control option/ Rate Compensation Verification (cont.)

* Notes on testing rate compensated heat detectors using HST Series Heat Detector tester with rate control/rate

compensation verification:

•The LED indicator light flashes to indicate test progress. If the HST is producing quick flashes, this may

indicate a fault. Count the number of flashes and consult this manual or contact Skinner Innovations.

•Results will vary somewhat depending on ambient conditions.

•Do not expect trip points to be exactly as in the example or exactly at the manufacturers rated set point.

•Completely cool the tester before starting on next rate compensation detector test.

•After noting trip points for all detectors, it is recommended to use manufacturers +/- tolerances and good

judgment to determine Pass/Fail criteria for your particular environment. Detectors should be within

similar +/- tolerances. A device which falls outside of this parameter may require replacement or further

evaluation. Results will vary somewhat depending on ambient temperature, battery charge, etc. The HST

can accurately determine if detector set point has shifted low or high. However these limitations should be

considered when interpreting test results.

Detector calibration requires specialized laboratory-type equipment and is performed on new detectors at

the manufacturers factory. The HST will help to detect major shifts in set point but is not intended to be

used to calibrate heat detectors. To meet listing requirements, detector manufactures do not usually

provide a way to field adjust heat detector set point.

The material presented in this document is for informational purposes only. Follow the manufacturer's

specific testing instructions. Detectors may require additional tests, especially if open flame or other

uncontrolled source of heat has been used in the past for testing purposes. See Fenwal® Operation,

Maintenance, and Installation manual for complete testing instructions.

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 14

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Appendix-COperation Supplement: Model HST-A-17343 models

Testing Fenwal® Fire/Overheat Detector part number 17343 using the HST Series heat detector tester.

The following HST models are available for testing Fenwal® 17343 detectors:

Model HST-A-17343-124-1 for 140 degree F detector

Model HST-A-17343-124-2 for 325 and 425 degree F detectors

Model HST-A-17343-124-3 for 600 and 725 degree F detectors

Model HST-A-17343-113-950 for 950 degree F detectors

There are several sub-models of 17343 detectors contact Skinner Innovations to verify HST tester matches detector.

Operation:

1. Select the desired temperature setting on the HST tester. The HST temperature setting refers to the detectors rated trip point, the

actual temperature that the HST produce will be slightly higher to account for the manufacturers +/- specification.

For additional operation instructions see the "Operation" section of the HST Series Operations Manual

2. Turn on power to the HST and place tester over the detector. The indicator light will turn on while temperature is rising. Indicator

light will blink slowly when the HST is close to the detector set point. This may take several minutes. As the temperature nears the

set point the rate of rise will be slower, if detector has not already tripped, continue to wait until temperature stops climbing.

3. When detector trips, note the temperature readout on the voltmeter

For more information refer to HST Operations Manual section on "Remote Temperature Output"

If temperature has completely stabilized and the detector still has not tripped, turn the HST to the next higher temperature setting

until it does trip, then return the HST set point to the correct temperature setting and proceed to step 4.

4. Cycle power to HST off for 5 seconds, then turn power back on.

The HST will begin to cool briefly when power is cycled, during this time the detector should cool enough to reset.

After HST re-boots temperature will start to climb, continue to watch temperature readout and note when detector trips.

5. Repeat step 4, two additional times until you have recorded a total of 4 separate trips

6. Take the average of only the last three trips points only and record this as the actual trip point

7. Three minutes after the HST has reached the maximum temperature, the heating unit will turn off and the indicator light will blink

rapidly. Continue to watch the temperature readout and remove tester when the temperature drops to within 100 degrees of the

ambient temperature.

8. Repeat steps 1 thru 7 for remaining detectors

Interpretation of test results:

After noting trip points for all the detectors, it is recommended to use manufacturers +/- tolerances and good judgment to determine Pass/Fail

criteria for your particular environment. Detectors should be within similar +/- tolerances. A device which falls outside of this parameter may

require replacement or further evaluation. Results will vary somewhat depending on ambient temperature, battery charge, etc.

Detector calibration requires specialized laboratory-type equipment and is performed on new detectors at the manufacturers factory. The HST

will help to detect major shifts in set point but is not intended to be used to calibrate heat detectors. To meet listing requirements, detector

manufactures do not usually provide a way to field adjust heat detector set point.

The material presented in this document is for informational purposes only. Follow the manufacturer's specific testing instructions. Detectors

may require additional tests, especially if open flame or other uncontrolled source of heat has been used in the past for testing purposes. See

Fenwal® Operation, Maintenance and Installation manual for complete testing instructions.

Example test 1 Trip temp Manufacturer Detector Set Point Manufacturers tolerance

Fenwal® 725 +/-25

Trip 1 724°

Trip 2 729°

Trip 3 719°

Trip 4 718°

Result 722°

Example test 2

Trip 1 755° No initial trip using the 725 setting, changed temp setting to next higher setting, until trip, then return to 725

Trip 2 729°

Trip 3 719°

Trip 4 718°

Result 722° Average of Trip 2, Trip 3, and Trip 4

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 15

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

Remote Temperature Output Connection Cable

Specifications

Part Number: HSTA5CBL

FEATURES:

•This double banana plug cable is designed to be used with all standard .166” (4mm)

diameter banana jacks. It can be used with most digital multimeters that have the

common and volt-ohm jacks at the standard spacing. These jacks are usually spaced at

.75” (19mm) Apart

•Use with 23' (7m) HST extension cable p/n HST-EXT-CBL for combined reach of about

27.5' (8.3m)

MATERIALS:

•The double banana plug is insert molded with black polypropylene

•The cable is RG58C/U - 0.195” diameter – 50 ohms impedance

•The HST double pin cable connector is UL recognized black Nylon

ELECTRICAL / MECHANICAL:

•Durability – minimum 300 cycles without mechanical or electrical failure

•Voltage – Maximum 24vdc @ 2 amps

ENVIRONMENTAL:

•Temperature--55°C to +55°C (-67°F to +131°F)

•Corrosion 300 Hr salt spray contacts

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 16

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

HST Output Extension Cable

Specifications

Part Number: HSTEXTCBL

FEATURES:

•The heavy duty coiled extension cable is designed to be connected with standard HST

remote temperature output and the standard connection cable HST-A5-CBL. The

combined length of these cables is approx. 27.5' (8.3m)

•Allows for monitoring of temperature at heights and greater troubleshooting

capabilities

•Retracted Length: approx. 64" (1.6m)

•Working length: approx. 23' (7m)

•Rubber strap at male connector end fastens to inspection pole to prevent cable from

pulling on connectors and prevents cable from falling should it become disconnected

while in use. Do not use if rubber strap is not in place and properly fastened.

MATERIALS:

•The cable is 2 conductor, 0.18” diameter – coil O.D. is 5/8"

•The HST double pin cable connectors on each end are UL recognized black Nylon

ELECTRICAL / MECHANICAL:

•Durability – minimum 300 cycles without mechanical or electrical failure

•Voltage – Maximum 24vdc @ 1.0 amps

•Weight: 8.5oz

ENVIRONMENTAL:

•Temperature--55°C to +55°C (-67°F to +131°F)

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 17

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

HST Output Extension Cable

Important directions on safe usage

Part Number: HSTEXTCBL

When using with extension poles, the cable must be fastened to the inspection pole using the

rubber strap provided. The purpose of this is to provide strain relief on the connectors and to

prevent the cable from falling on the user should the connection to the HST become

disconnected. Make sure that cable does not touch hot surface, moving equipment, or any

other dangerous surface.

See following picture for clarification on proper attachment.

Picture 1: Fasten the axial cable lead to the pole using the rubber strap provided. Note that the actual

cable has longer axial lead than pictured to provide for swivel movement of test head

DO NOT USE CABLE WITHOUT SECURING CABLE TO POLE USING RUBBER STRAP

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 18

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

HST Power Supply

Specifications

Part Numbers: HSTPWR148, HSTPWR185, HSTPWR259

FEATURES:

•Universal AC input

•3 pole AC inlet connector IEC320-C14

•Output:

15VDC (14 volt HST models)

20VDC (18 volt HST models)

24VDC (24 volt HST models)

•Allows for providing power to HST heat detector tester at distances of up to 20 feet

away when used with 20' extension cable p/n HSTEXT148, HSTEXT185, or HSTEXT259

•Fanless design, cooling by free air convection

MATERIALS:

•Housing- hard ABS plastic

•Output cable connector- 250 volt, IP40 connector, bayonet locking, PA and PBT plastic

ELECTRICAL / MECHANICAL:

•Durability – minimum 300 cycles without mechanical or electrical failure

•Voltage- 90-264VAC

•Frequency range- 47-63Hz

•AC current- 3A/115VAC 1.5A/230VAC

•Model, Voltage, Connector configurations:

Model HSTPWR148, use with 14 volt HST, 15vdc output, 2pin connector

Model HSTPWR185, use with 18 volt HST, 20vdc output, 4pin connector

Model HSTPWR259, use with 24 volt HST, 24vdc output, 3pin connector

•Weight: 1.5kg

ENVIRONMENTAL:

•Temperature--30°C to +60°C

•Humidity- 20%-90% RH non-condensing

Skinner Innovations LLC 708 N. Douglas St. Lake City, IA 51449 (801) 766 4782 www.skinnerinnovations.com

Page | 19

HST Series Heat Detector Tester

For Rate Compensated Fire Detectors

and Thermal Switches

HST Power Supply

Important directions on safe usage

Part Numbers: HSTPWR148, HSTPWR185, HSTPWR259

When using power supply with extension cable part numbers HSTEXT148, HSTEXT185, or

HSTEXT259, the extension cable must be fastened to the inspection pole using the rubber

strap provided. The purpose of this is to provide strain relief on the connectors and to

prevent the cable from falling on the user should the connection to the HST become

disconnected. Make sure that cable does not touch hot surface, moving equipment, or any

other dangerous surface.

See following picture for clarification.

Picture 1: Fasten the axial cable lead to the pole using the rubber strap provided.

DO NOT USE CABLE WITHOUT SECURING CABLE TO POLE USING RUBBER STRAP

This manual suits for next models

5

Table of contents

Popular Security Sensor manuals by other brands

Lufft

Lufft SHM 31 user manual

Pyronix

Pyronix PCX 46 APP ASSEMBLY AND PROGRAMMING MANUAL

IFM Electronic

IFM Electronic Efector500 PF2058 operating instructions

SKYLOTEC

SKYLOTEC Skytac Instructions for use

DMP Electronics

DMP Electronics 1126 Series Installation sheet

ELRO

ELRO AS80MA11 installation instructions