CLEANING GUIDE

TROUBLESHOOTING GUIDE

Problem Cause How to Fix

Beer doesn’t flow The keg is not connected correctly Check that the keg coupler is connected properly

Tap is closed Adjust the flow using the handle on the side of the tap

Beer isn’t cold enough Cooling not on or high enough Turn the cooling dial to max

Bad air circulation Check that the plate of the condenser isn’t blocked,

if so clean with soft brush or vacuum cleaner

The machine has overheated Place the machine in a colder environment with good air flow around

the condenser grill

Keg is too warm (>22oC) Place the keg in a colder environment and out of sunlight

Excessive beer foaming Cooling not on or high enough Turn the cooling dial to max

Beer flow is too high Slow the beer flow by turning the tap lever upwards

Lines are dirty Clean regularly with an approved agent

We advise line cleaning the unit after every use if you do not intend to re-use it again for a while.

If you are using the unit every day then you should run a line clean at least every 10 days.

How to line clean:

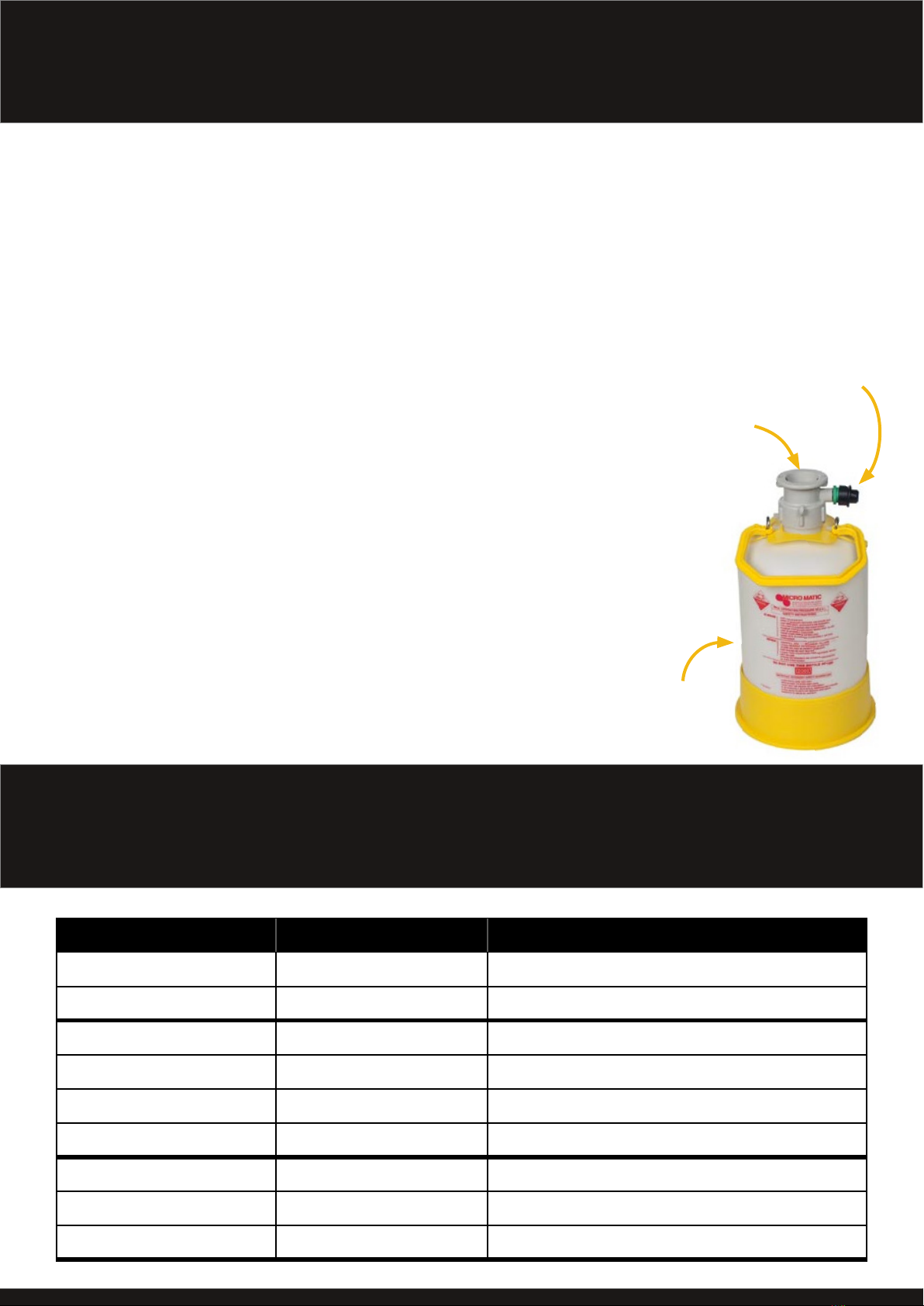

RINSE

1. Fill the 5L cleaning bottle with water.

2. Attach the keg coupler to the top of the cleaning bottle.

3. Ensure the unit is turned ON and the cooling OFF.

4. Pull all the water through the unit.

5. De-pressurise the bottle by pulling the tab on the side.

CLEAN

6. Now add 50ml of the supplied line cleaner to a full cleaning bottle of water.

7. Start to pull the diluted cleaning solution through the unit and stop when the

solution starts to come out of the tap. Leave for approx. 10 mins.

8. Then pull some more solution through the unit and leave for a further 10 mins.

9. Then pull all the solution through the unit remembering to de-pressurise once finished.

Note - For a deeper clean you may repeat for extra multiples of 10 mins however……

DO NOT LEAVE CLEANING SOLUTION IN THE UNIT FOR LONGER THAN 45 MINS IN TOTAL!

Note - If using a dierent line cleaner than supplied please check the label for dilution levels and cleaning times.

RINSE

10. Rinse the cleaning bottle out with plenty of water.

11. Fill the cleaning bottle with water and pull all the water through the unit again,

remembering to de-pressurise once finished.

NEVER GO FROM CLEANING SOLUTION STRAIGHT TO PRODUCT!

Keg Coupler here

5L Cleaning Bottle

De-pressurise here