DOL 192 Egg Counter

1 Product description ....................................................................................................................................... 4

2 Product survey ............................................................................................................................................... 5

2.1 Accessories................................................................................................................................ 6

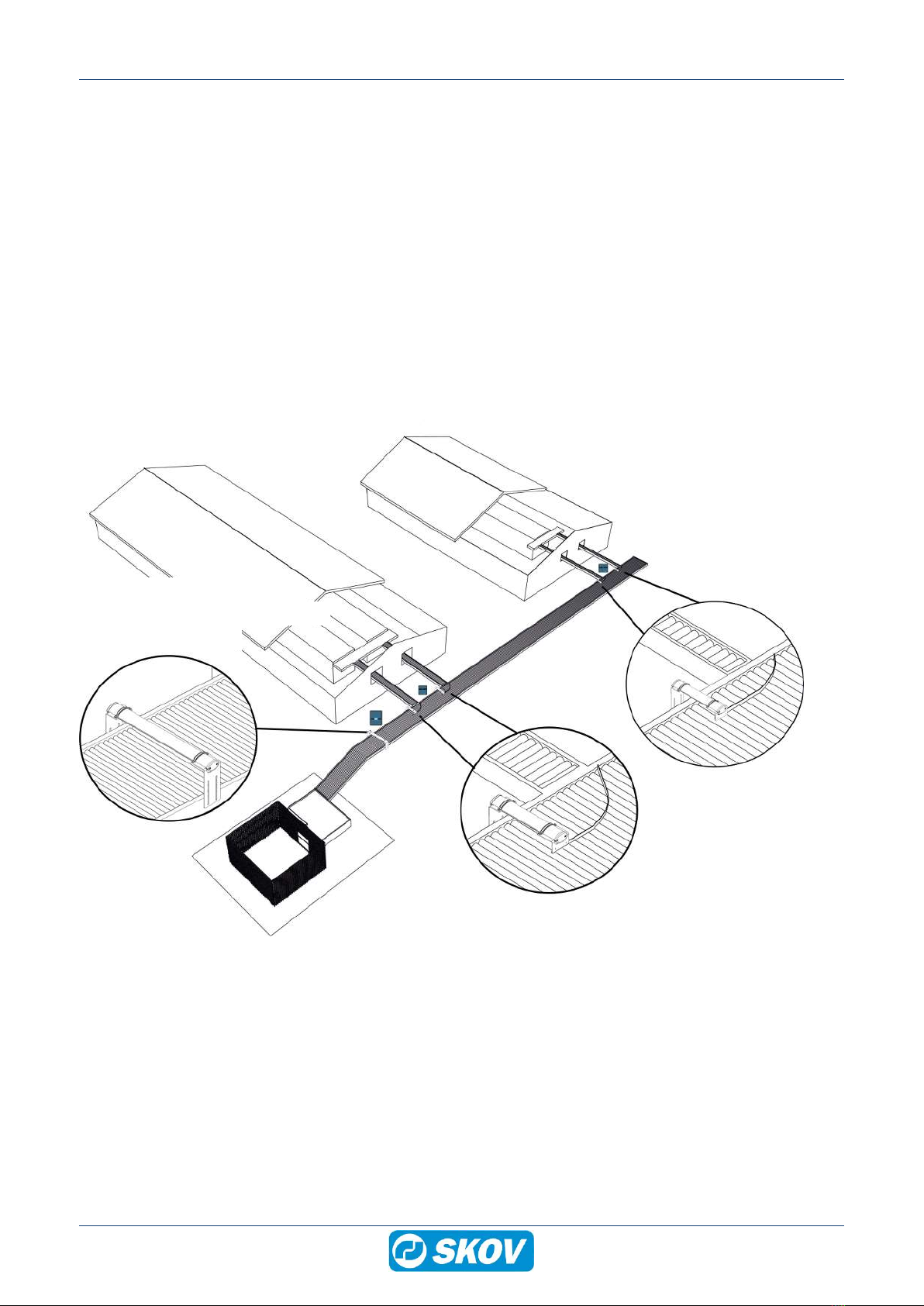

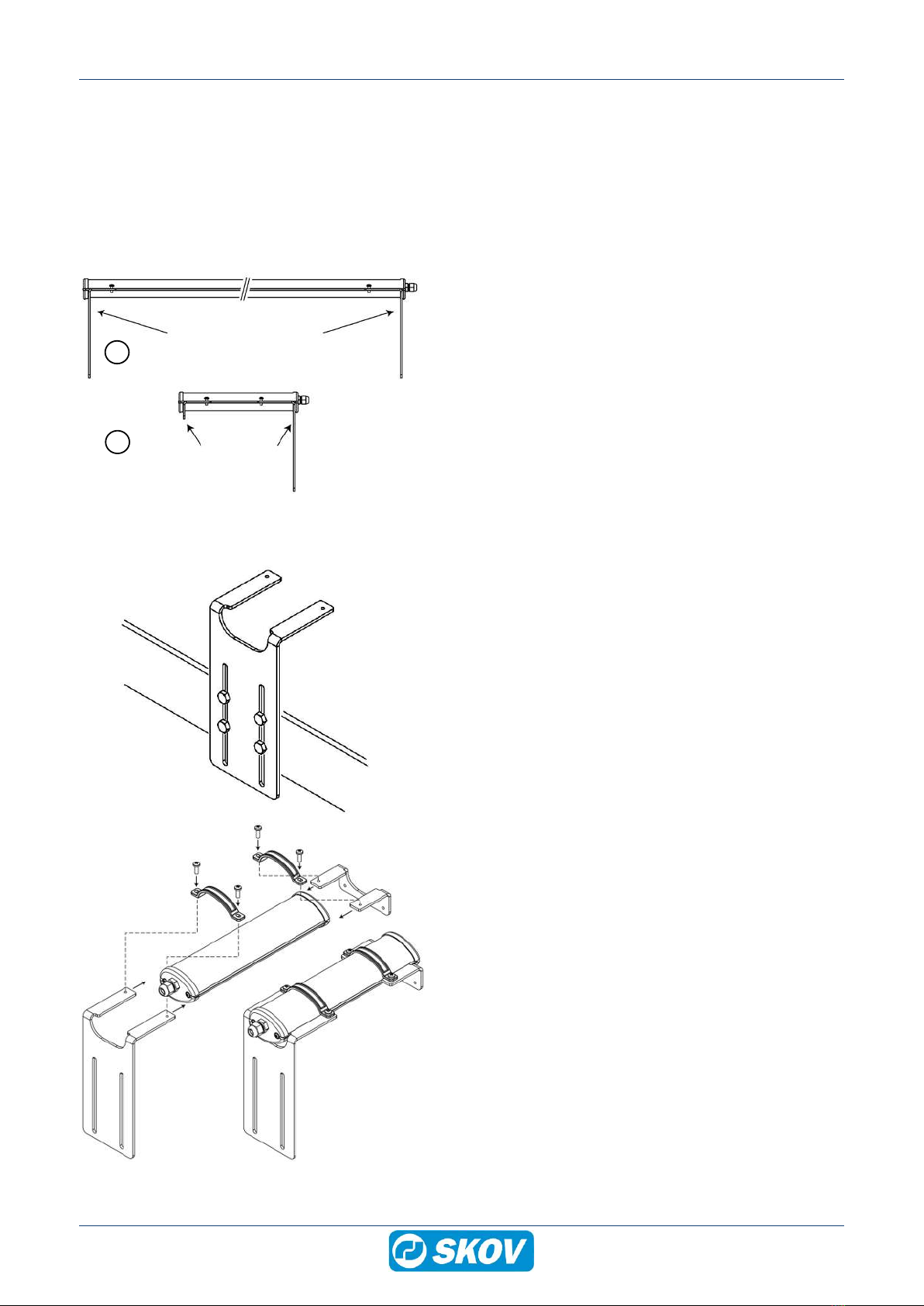

3 Mounting guide............................................................................................................................................... 8

3.1 Recommended tools.................................................................................................................. 8

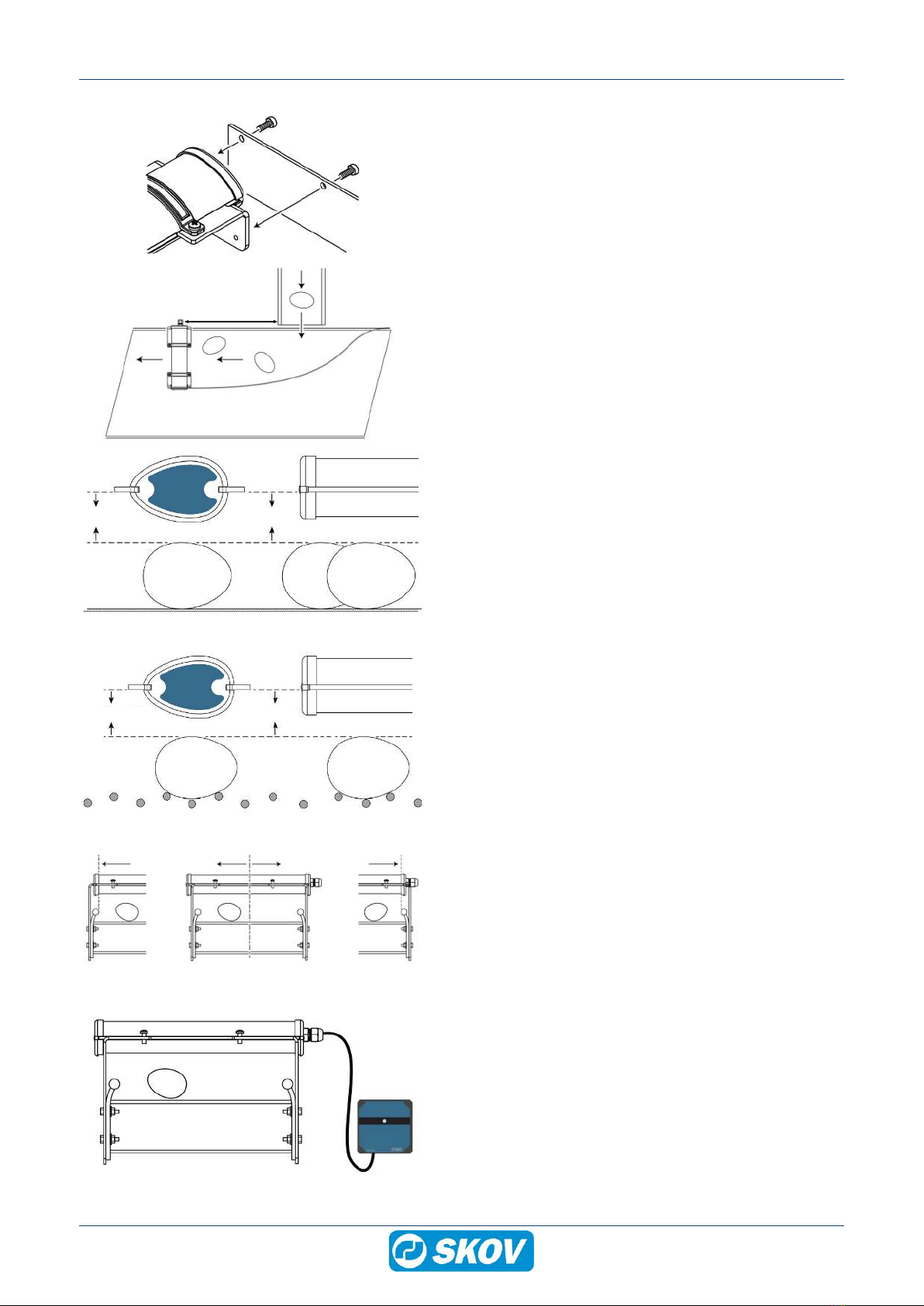

3.2 Mounting the egg counter......................................................................................................... 9

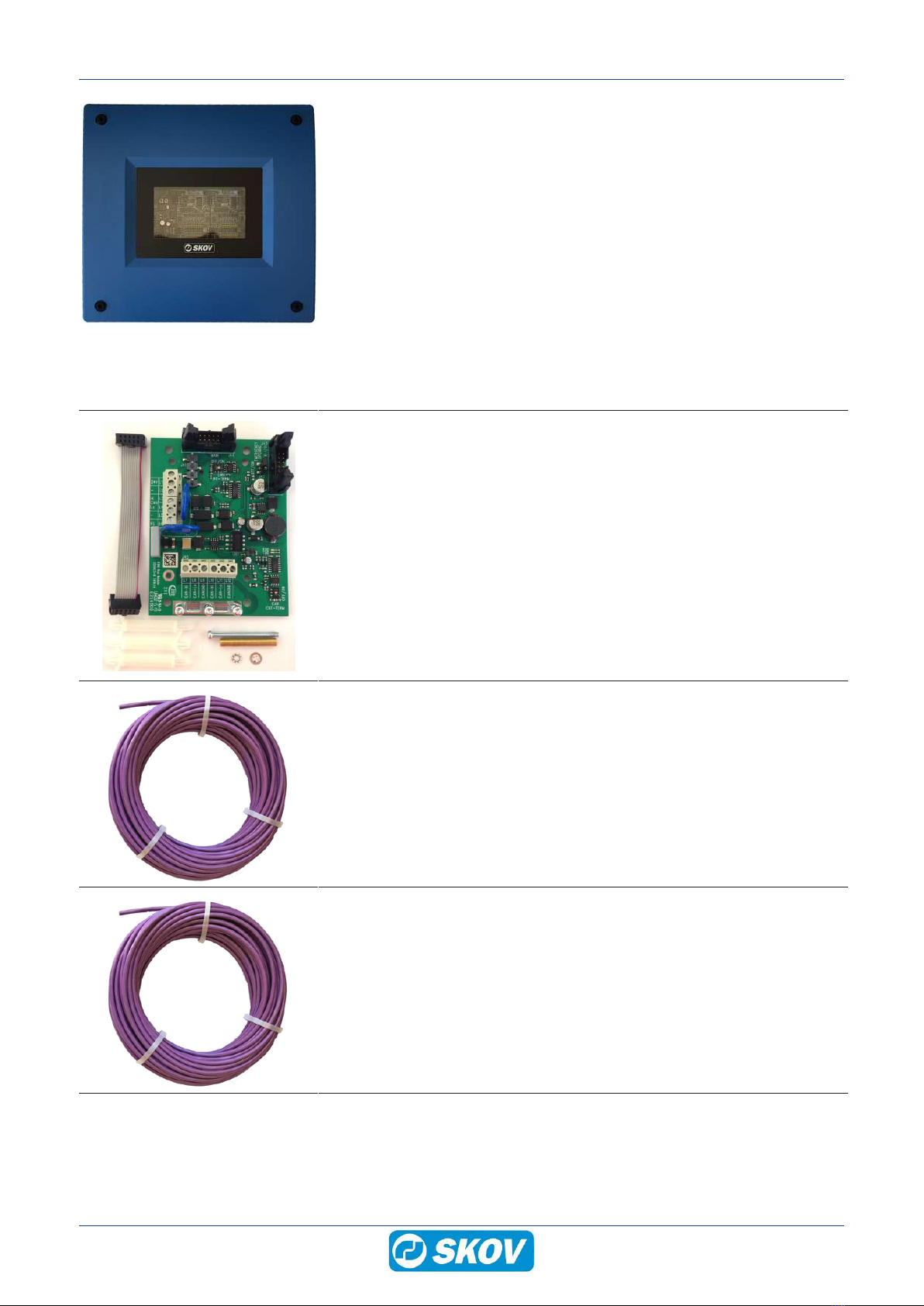

4 Installation guide.......................................................................................................................................... 11

4.1 Connecting the egg counter to the DOL 192 box ................................................................. 11

4.1.1 Cable diagram egg counter........................................................................................................ 11

4.1.2 DOL 192 box 24 V ..................................................................................................................... 12

4.1.3 DOL 192 box w/display 230V..................................................................................................... 13

4.2 Connecting pulse and standby functions ............................................................................. 14

4.3 DIP switch settings .................................................................................................................. 14

4.4 Choice of egg counter in controller ....................................................................................... 15

4.5 Clock setting DOL 192 box w/display .................................................................................... 16

5 General information about circuit diagrams.............................................................................................. 17

5.1 Color code ................................................................................................................................ 17

5.2 Letter code................................................................................................................................ 17

6 Cable plans and circuit diagrams ............................................................................................................... 18

6.1 Cable plan DOL 192 box 24V 1 egg counter.......................................................................... 18

6.2 Circuit diagram DOL 192 box 24 V 1 egg counter................................................................. 18

6.3 Cable plan DOL 192 box 24 V 2 egg counters....................................................................... 19

6.4 Circuit diagram DOL 192 box 24 V 2 egg counters............................................................... 19

6.5 Cable plan Dol 192 box w/display 230 V ................................................................................ 20

6.6 Circuit diagram DOL 192 box w/display 230 V ...................................................................... 20

7 User Guide .................................................................................................................................................... 21

7.1 Operating DOL 192 box w/display.......................................................................................... 21

8 Maintenance instructions ............................................................................................................................ 22

8.1 Cleaning.................................................................................................................................... 22

8.2 Recycling/Disposal .................................................................................................................. 22

9 Trouble shooting instructions .................................................................................................................... 23

9.1 Error messages LED on DOL 192 box ................................................................................... 23

9.2 Error messages DOL 192 box w/display................................................................................ 23

9.3 Unexpected counting results.................................................................................................. 23

10 Technical data .............................................................................................................................................. 24

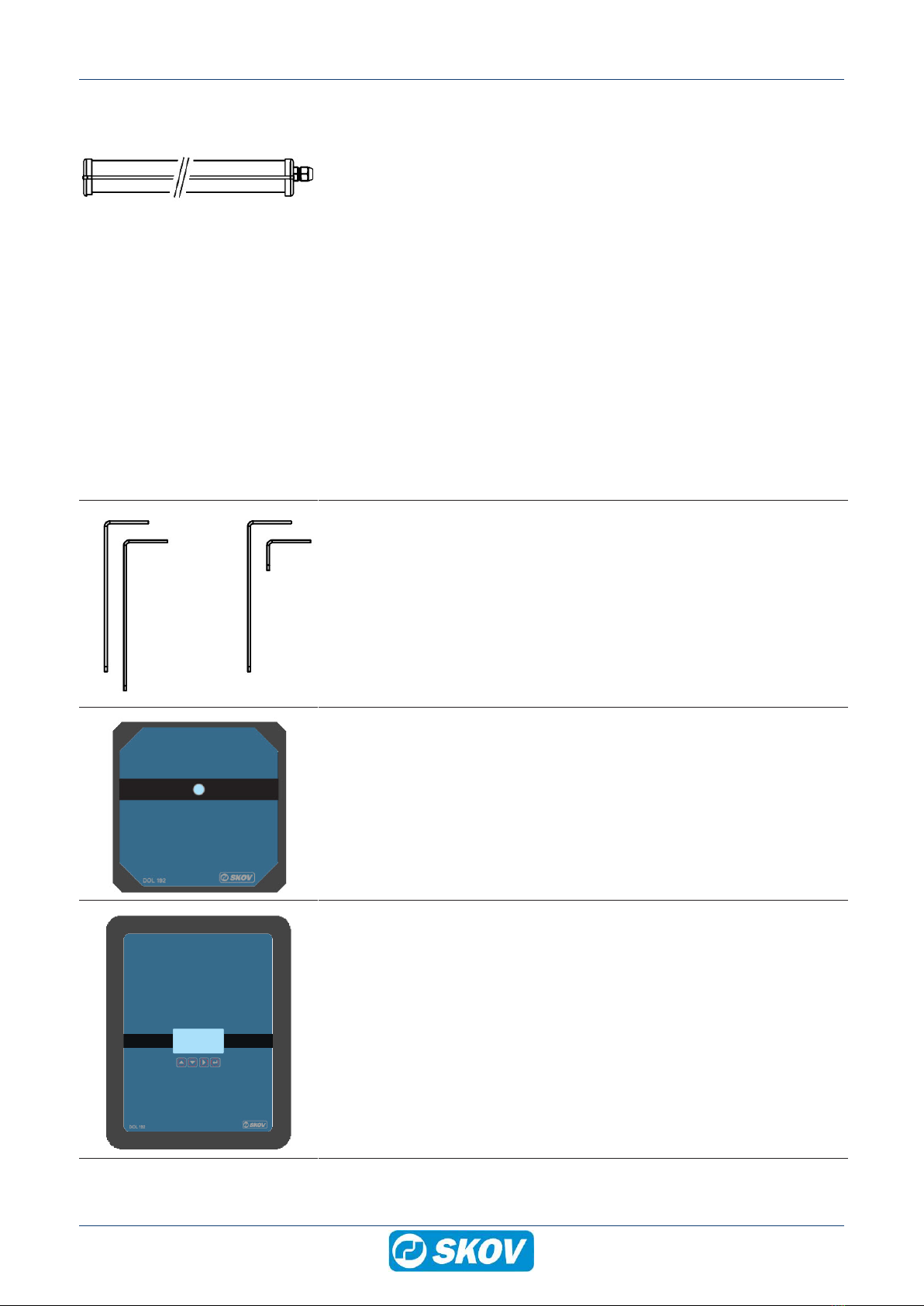

10.1 DOL 192 egg counter............................................................................................................... 24

10.2 DOL 192 box ............................................................................................................................. 25

10.3 Maximum number of devices connected to power supply .................................................. 25

10.4 Dimensioned sketch ................................................................................................................ 26

10.4.1 DOL 192 egg counter................................................................................................................. 26

10.4.2 DOL 192 box w/display 230 V f/1 egg counter........................................................................... 26

10.4.3 DOL 192 box 24 V f/2 egg counters........................................................................................... 27

Technical User Guide