DA 4200 Floor Heating System

6 Technical User Guide

439561 DA 4200 floor heating manifold kit 1+1

439562 DA 4200 floor heating manifold kit 2+2

439563 DA 4200 floor heating manifold kit 3+3

439564 DA 4200 floor heating manifold kit 4+4

439565 DA 4200 floor heating manifold kit 5+5

439566 DA 4200 floor heating manifold kit 6+6

439567 DA 4200 floor heating manifold kit 7+7

439568 DA 4200 floor heating manifold kit 8+8

439569 DA 4200 floor heating manifold kit 9+9

439570 DA 4200 floor heating manifold kit 10+10

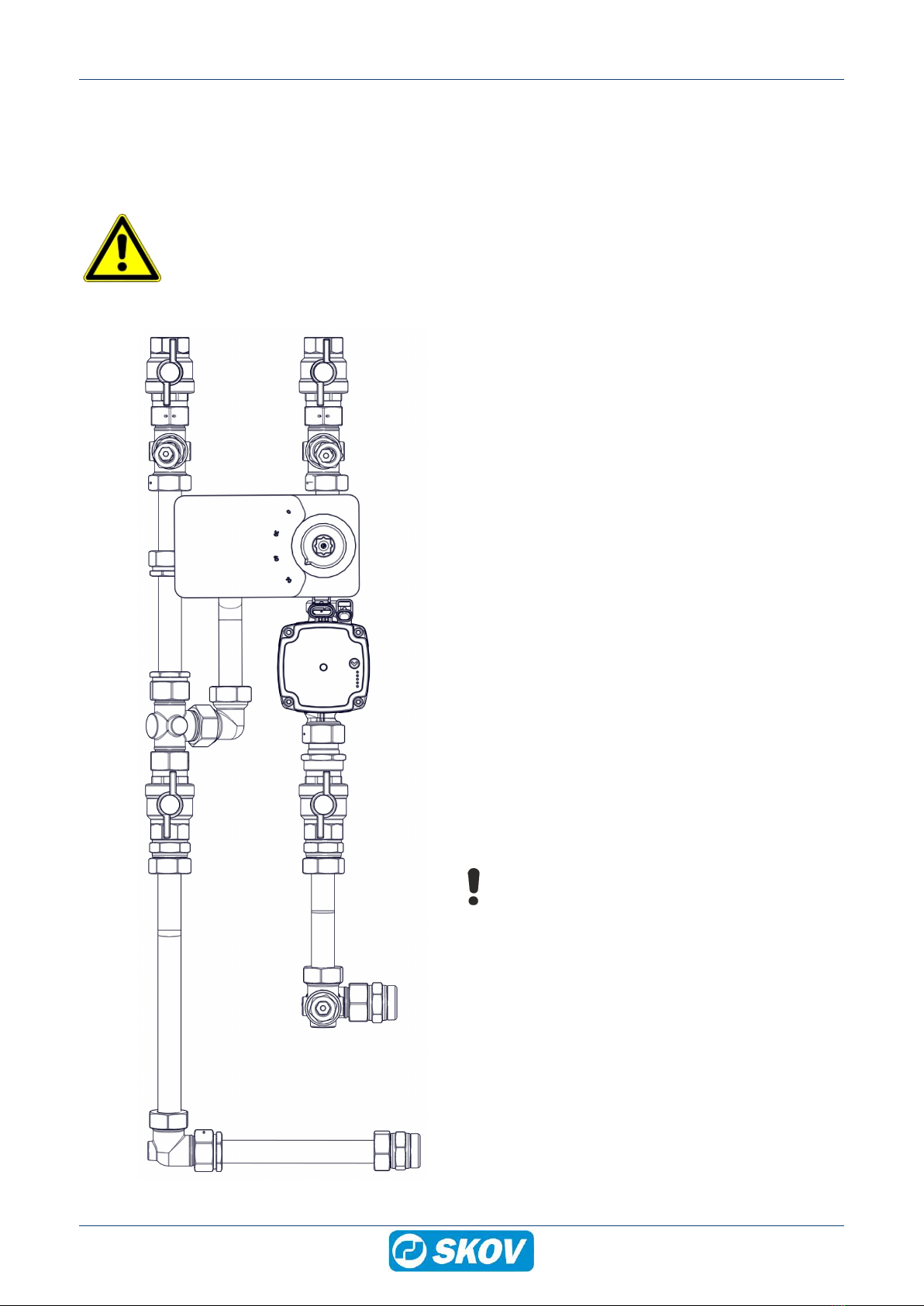

The manifold kit with bracket is used together with the floor heating unit

mentioned above.

The figures specify how many supply flows + return flows can be con-

nected. Each floor heating circuit is equipped with supply and return flow;

e.g.,4 floor heating circuits thus require a manifold kit 4+4.

Is supplied complete with connection set and automatic air vent.

2.2 Accessories

439304 DA 4200 SmartHeat kit DN 25

DA 4200 SmartHeat kit is an add-on that includes a flow sensor and a soft-

ware extension of the controller. SmartHeat kit is used together with DA

4200 room heating/floor heating units DN 25.

After updating and mounting of a flow sensor, the controller can measure

water flow and flow and return temperatures to a house/section. Based on

these recordings, the controller and FarmOnline can calculate and record

the instantaneous heat consumption in kilowatts (kW) and the number of

used kilowatt-hours (kWh) for the current house/section.

The controller generates an alarm if the water flow is too low and if the flow

temperature is too low.

The kit includes flow sensor and USB stick with SmartHeat software.

The SmartHeat software can only be installed on controllers with software

version 8.0 or later.

439305 DA 4200 SmartHeat kit DN 32

DA 4200 SmartHeat kit is an add-on that includes a flow sensor and a soft-

ware extension of the controller. SmartHeat kit is used together with DA

4200 room heating/floor heating units DN 32.

After updating and mounting of a flow sensor, the controller can measure

water flow and flow and return temperatures to a house/section. Based on

these recordings, the controller and FarmOnline can calculate and record

the instantaneous heat consumption in kilowatts (kW) and the number of

used kilowatt-hours (kWh) for the current house/section.

The controller generates an alarm if the water flow is too low and if the flow

temperature is too low.

The kit includes flow sensor and USB stick with SmartHeat software.

The SmartHeat software can only be installed on controllers with software

version 8.0 or later.