DA 4200 Heating System

1 Product description ....................................................................................................................................... 5

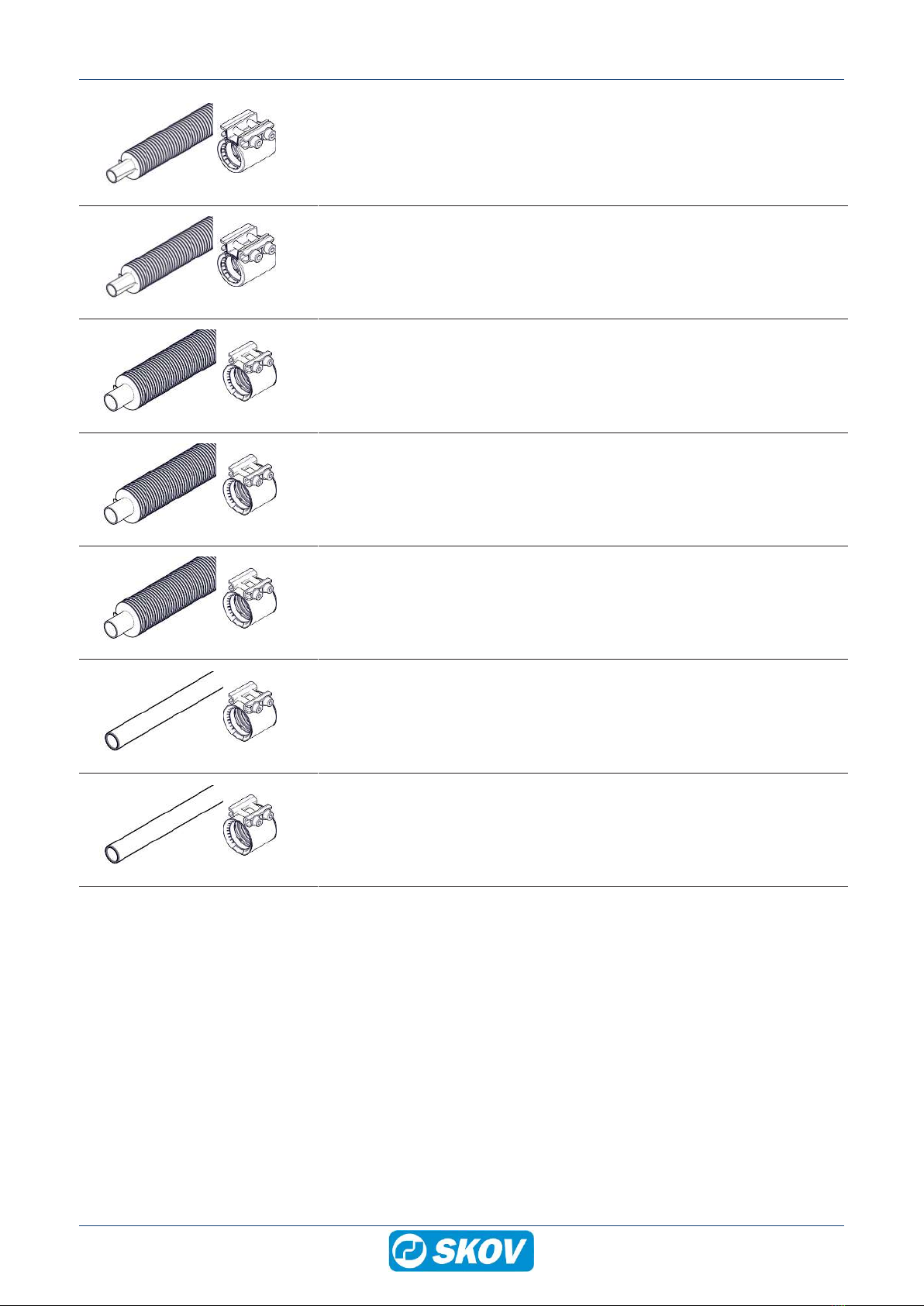

2 Product survey ............................................................................................................................................... 6

2.1 Regulation .................................................................................................................................. 6

2.1.1 Accessories.................................................................................................................................. 6

2.2 Pipe ............................................................................................................................................. 7

2.3 Mounting on wall and rafter ...................................................................................................... 9

2.4 Mounting on ceiling ................................................................................................................. 10

2.5 Mounting set............................................................................................................................. 11

2.6 Expansion, fittings etc............................................................................................................. 15

2.7 Additional ................................................................................................................................. 18

3 Mounting guide............................................................................................................................................. 19

3.1 Recommended tools................................................................................................................ 19

3.2 Mounting of sandwich screws................................................................................................ 20

3.3 Mounting of heating unit ......................................................................................................... 21

3.4 Finned tubes/smooth tubes .................................................................................................... 22

3.4.1 Placement .................................................................................................................................. 22

3.4.2 Support/Fixing............................................................................................................................ 23

3.4.2.1 Wall mounting on smooth-faced solid walls ............................................................................... 23

3.4.2.2 Wall mounting on sandwich panel ............................................................................................. 24

3.4.2.3 Wall mounting on walls with obstacles....................................................................................... 26

3.4.2.4 Mounting on ceiling .................................................................................................................... 27

3.4.3 Connecting pipes ....................................................................................................................... 28

3.4.4 Mounting pipe coupling on pipes ............................................................................................... 29

3.4.4.1 Expansion .................................................................................................................................. 31

3.4.4.2 Shortening of smooth pipes ....................................................................................................... 31

4 Installation guide.......................................................................................................................................... 32

4.1 Electrical connection............................................................................................................... 32

4.2 Settings in controller ............................................................................................................... 32

4.3 General information about circuit diagrams ......................................................................... 33

4.3.1 Power supply isolator................................................................................................................. 33

4.3.2 Letter code ................................................................................................................................. 33

4.4 Cable plans and circuit diagrams........................................................................................... 34

4.4.1 Cable plans ................................................................................................................................ 34

4.4.2 Circuit diagram........................................................................................................................... 34

4.5 Actuator .................................................................................................................................... 35

4.6 3-way control valve.................................................................................................................. 35

4.7 Setup of recirculation pump ................................................................................................... 36

4.7.1 Circulation pump UMP3 ............................................................................................................. 36

4.7.2 Circulation pump UMPXL........................................................................................................... 37

5 Maintenance instructions ............................................................................................................................ 38

5.1 Cleaning.................................................................................................................................... 38

5.1.1 Circulation pump, actuator and solenoid valve .......................................................................... 38

5.1.2 Finned tubes .............................................................................................................................. 38

5.2 Recycling/Disposal .................................................................................................................. 38

6 Trouble shooting instructions .................................................................................................................... 39

7 Service and maintenance of system .......................................................................................................... 40

8 Technical data .............................................................................................................................................. 42

8.1 Room heating unit ................................................................................................................... 42

Technical User Guide