SlatPro SLAG HOG 67123 SH3G User manual

User Manual

67123 SH3G

Slag Removal Tool for use on laser cutting machines with

minimum 1.75” between slats

Slatpro LLC

4757 Mustang Circle

Mounds View, MN USA

Phone: +1 763-452-4550

Fax: +1 763-452-4560

www.slatpro.com

1. Safety

1.1 General Safety Instructions

ΔWARNING! Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

1.2 Slaghog Specific Safety Warnings and Instructions

A. Unplug tool from power before performing maintenance on Slaghog

B. Use protective equipment. Always wear safety glasses when working with the machine.

Protective clothing is recommended such as dust mask, gloves, steel toed non-slip footwear

and hearing protection.

C. Do not expose tool to wet conditions or operate in damp environment

D. Power cord to be kept clear from working range of machine. Always lead cord away from

machine. Do not apply tension to power cord.

E. Switch tool off immediately if it stalls. Lift cutters out of slats before restarting.

2. Supporting Information

2.1 Conditions of use

The tool is only to be use for removing the slag from slats on laser cutting machines where the slats

create a horizontal plane and the vertical slat sides are cleaned. The slats may be steel, stainless

steel or copper. Not to be used in wet areas or outside.

WARNING

2.2 Mains Connection

Connect only to single-phase AC voltage as indicated on the rating sticker. Plug-in receptacle to

have ground contact with current capacity exceeding the tools rating.

Only plug in when tool switches are off.

2.3 Maintenance

The ventilation slots must be kept clear or over-heating may result.

If the supply cord is damaged it must only be replaced by qualified personnel. Only use SlatPro

replacement parts when performing repairs or maintenance.

2.4 Technical Information

TechnicalData

SlagHogSlagRemovalTool

Productioncode 67123‐120V 67123‐230V

Voltage 120Va.c. 230Va.c.

Current 10amps 6amps

Frequency 50/60hz

Weight 47lb 21.4kg

NoiseInformation

MeasuredvaluesdeterminedaccordingtoEN60745.Typically,theA

weightednoiselevelsofthetoolare:

Soundpressurelevel(UncertaintyK=3db(A)) 90db(A)

Soundpowerlevel(UncertaintyK=3db(A)) 101db(A)

WearearProtectors!

Vibrationinformation

Vibrationtotalvalues(triaxialvectorsum)determinedaccordingto

EN60745

Connectonlytoasingle‐phaseACcurrentsupplyandonlytomains

voltagespecifiedontheratingplate

Vibrationemissionvalueah,d 4.3m/s2

UncertaintyK= 1,5m/s2

Warning

The Vibration emission level given in this information sheet has been measured in accordance with a

standardized test given in EN 60745 and may be used to compare one tool with another. It may be used for a

preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However, if the tool is used for

different applications, with different accessories or poorly maintained, the vibration emission may differ. This may

significantly increase the exposure level over the working period.

An estimation of level of exposure to vibration should also take into account the times when the tool is switched

off or when it is running but not actually doing the job. This may significantly reduce the exposure level over the

total working period.

Identify additional safety measures to protect the operator from the effects of vibrations such as: maintain the tool

and the accessories, keep the hands warm, organization of work patterns.

2.5 Symbols

Caution! Warning! Danger!

Always disconnect the plug from the socket before carrying out

any instructions

Please read the instructions carefully before starting the

machine.

Tool uses protective earth and must be plugged into grounded

outlet

3. Description

The tool is moved along the slats on the bed of a laser machine to remove slag that accumulates while

cutting. Rotary cutting tools ride on each side of the slat to lift and remove the slag. It may be used on

steel, copper or hybrid steel/copper slats. When not in use it may be rolled along the floor and stored in

the upright position.

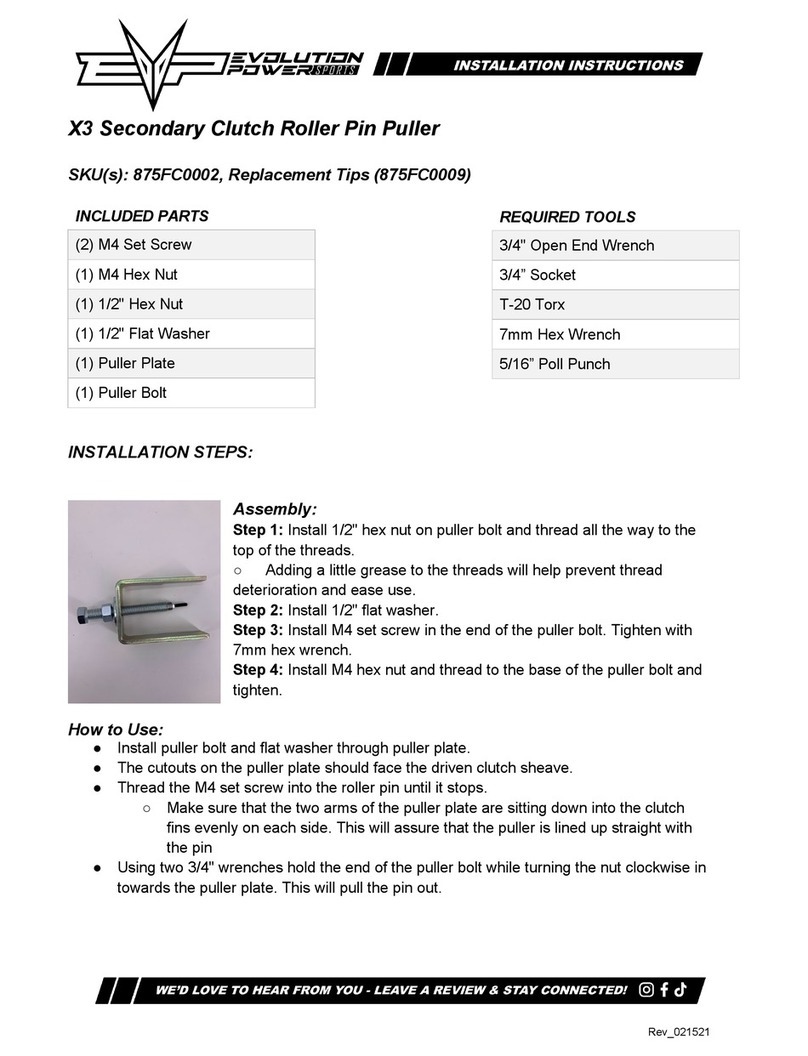

4. Initial Assembly

The Slag Hog ships in two pieces; power unit and the handle assembly. All fasteners are metric.

Remove the nuts and button head socket screw from the 1.36” diameter stub on the power

unit.

Slide the handle on the stub with the power out cord of the handle on the same side as the

plug in on the power unit.

Plug the power cord from handle tube into the power unit

WARNING

Do not plug into power outlet before verifying the switches on the handle and power unit are

off; both rocker switches to 0.

5. Operation

The tool must be plugged into a receptacle with a grounded outlet

Before plugging into power verify that the two switches are turned off

Wear work gloves and safety glasses when operating

Lift onto the cutting machine bed with care

WARNING Use extreme care near the cutters. Do not touch them unless the tool is unplugged.

The tool has two on/off switches

Figure 1

Figure 2

Rocker switch on handle end, in off position,

acts as circuit breaker reset in case of over-

current

Rocker Switch on motor enclosure in off

position.

Both switches must be in ON or “l” position to run. Turning either switch OFF (“0” position) stops motor

operation.

The upper left picture shows the on/off switch that acts as the circuit breaker when the unit is overworked.

If the slats are not straight it is possible for the cutters to grab onto two slats and stall the motor which will

trip the breaker. If this occurs wait a minute, reset the breaker switch, and resume operation. When slats

have excess slag build up it may cause the circuit breaker to overload. If this happens the operator will

need to reduce force used for cleaning slats. If this occurs, reset the breaker, and resume operation.

To begin use, place the tool on the slat bed of the laser machine, center the cutters over a slat, and turn

on both switches. Cutter rotation will pull the tool down on the slats. The slats can be cleaned by moving

the tool in either direction along the slat.

Figure 3

With switches off, plug tool into a power outlet with appropriate current capacity to accept value given on

machine label or as shown above in the Technical Data table.

Figure 4

Cutters shown centered on slat

To see the unit in operation, go to Youtube and search for Slaghog. The best video is:

https://www.youtube.com/watch?v=PDvEFRREdgg

The cutter geometry is ideal for most slat/pallet bed configurations. If the fit of the cutters on the slats

does not seem correct contact the factory to find out options that are available.

When storing in upright position the unit is unstable and care must be taken to ensure that it does not fall

over, which may lead to damage of handle end components. Damage due to dropping, improper

handling, or falling over is not covered by warranty.

6. Maintenance

WARNING Disconnect power by unplugging from outlet before performing any work on the

tool

6.1 Cutters

The cutters will wear over time and require replacement.

Tools required for replacement

6mm L hex wrench

6mm male hex socket wrench

Adjustable open wrench

Replacement Cutters

66106 – 14ga Slats

66031 – 11-12ga Slats

66105 – 10ga Slats

66095 – 7ga Slats

66096 – .250” Slats

67067 – .11/12ga Deep Slats

Parts required are RH & LH Cutter Set with cap screws. The most common cutters are 66031 SET

for 11/12ga slats. Most replacement cutters come with two M8 x 22 cap screws, two washers, and

Blue Loctite 242. 67067 Cutter is longer and uses a M8 x 70 cap screw.

Place the tool on its back with the cutters up.

Place the wrenches as shown and remove the right cutter cap screw with counterclockwise rotation.

Remove the right cutter. The cutter may be tight on the shaft and will require light tapping with a

hammer to remove.

Figure 5

Place adjustable wrench on flats of right shaft and remove left cutter with counterclockwise rotation.

Figure 6

Slide the new right hand and the left-hand cutters so that the flats between the shaft are facing the

base plate as shown. The cutters rotate so that the slag chips are pulled up toward the base plate.

The cutters must be installed as shown.

Figure 7

Apply Loctite 242 to the cap screw threads. With washers in place, thread then tighten cap screws into

shaft ends using the male hex socket wrench and L hex wrench approach.

Cutter Wear

Even though cutters are made from hardened tool steel they do wear and will need to be replaced.

When slag removal gets worse it may be time to replace cutters. The best way to determine if they are

worn is to measure the distance between cutter tips. The below picture shows the proper gap for new

11-gauge cutters.

Figure 8 Measuring Cutter Gap

Slat Max

gauge Thick(inch) Gap

14 0.074 0.124

12 0.104 0.154

11 0.119 0.169

10 0.135 0.185

7 0.179 0.229

Table 1 Max Gap for Cutter Replacement

When the gap has increased by .050 it is time to replace cutters.

Other Wear

If the measured gap is less than the slat thickness, the Cutter Support Plates may have worn from

hammering action after repeated use. This condition will overwork the motor and cause short brush life

and may damage the motor. Call SlatPro for further advice on this problem.

Flat side of cutters towards base

p

late

6.2 Motor Brushes

If the tool has less torque while in use, it is likely that the brushes need replacement.

Parts Required: Qty 1 of 67179SET Brush Kit for SH3

There are access holes to brushes in top and bottom of Motor Enclosure

Unthread and remove Brush Caps from motor

Remove old brushes and install new and thread caps back in place

6.3 Other maintenance

All other repairs require qualified personnel to perform. In this case, the factory or distributor should

be contacted for further instructions.

SlaghogTroubleshootingGuide

Problem ProbableCause Solution

Ifmeasuredgapissmallerthanslatthickness,sendunitinfora

rebuild/repair.Thiscouldmeanthatcuttersupportplatesare

wornortherehasbeenabearingfailure.

Ifthegapistoobig,replacethecutters.

Cuttersareinstalled

incorectly.Seefigure7

Checktoseeifthecuttersmayhavebeeninstalledbackwards.

Installthecutterscorrectly.

Theswitchinthehandleend

boxhasfailed.

Replacetheswitch.Seepartslistforpropperpartnumber.

Theswitchinthemotor

enclosurehasfailed.

Ifyoureplacetheswitchinthehandleendboxandtheunitisstill

notstarting,replacetheswitchontopofmotorenclosure.

Issuewithwiring.

Refertorepairmanual,verifyallwiresareproperlyconnected.

Checktoseeifbrusheshaveworn.Ifworn,replacebrushes.

Ifbrushesarenotworn,replacethemotor.

Checktoseeifbrusheshaveworn.Ifworn,replacebrushes.

Ifbrushesarenotworn,replacethemotor.

Burningsmell

andsparks

comingfrom

insidemotor

enclosure

Motorhasmalfunctioned. Replacethemotor.

Grinding

soundwhile

running,or

cuttersnot

rotating

Brokengearsingearhousing Checkandreplacegearsandmotor.

Motorhasmalfunctionedor

brushesareworn.

Sparksare

comingfrom

insidemotor

l

Themachineis

notstarting.

Motorhasmalfunctioned

Cuttergapistoolargeortoo

small.SeeFigure8andMax

gaptable.

Themachineis

notcleaning

well.

SLAGHOG laser slat cleaner

SLAGHOG WARRANTY

www.slatpro.com

Subject to the exclusions described below, all Slaghog products (“Products”) as manufactured by Slatpro

LLC are warranted to be free from defects in materials and workmanship under normal use and service

for 12 months after the ship date to the purchaser. Unless otherwise set forth in a quotation or agreed to

by Slatpro in writing, Product warranty only applies to the first using purchaser. Warranty is not

transferable beyond the first using purchaser and is limited to new Products sold by Slatpro or through

authorized representatives and channel partners.

EXCLUSIVE REMEDY. In the event that Slatpro determines that a Product contains a defect in materials

or workmanship, then Slatpro, in its sole discretion, will (a) repair the Product, (b) replace the Product with

new or rebuilt (c) refund the purchase price of the Product. THIS LIMITED WARRANTY IS EXCLUSIVE

AND IS IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. THE REMEDY OF REPAIR, REPLACEMENT OR REFUND IS BUYER’S

SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. IN NO EVENT SHALL SLATPRO'S

LIABILITY UNDER THIS WARRANTY EXCEED THE PURCHASE PRICE OF THE PRODUCT GIVING

RISE TO THE WARRANTY CLAIM. All Products which are repaired or replaced shall be warranted only

for the unexpired portion of the original warranty period.

EXCLUSIONS. This warranty does not cover (a) any failures which are not attributable to defects in

materials or workmanship, including without limitation, failures caused by accidents, inadequate

maintenance, misuse, unauthorized modifications or repairs, improper storage, and normal wear and tear,

(b) any consumable parts or accessories, such as cutter blades, are designed to wear over time or through

use of the product, (c) Excessive use which is contributed from overuse, recommended use is for 1

cleaner to service 1-3 machines under normal use conditions. Recommended cleaning interval of

once per weekif production levels equal 2 shifts.

WARRANTY RETURNS. No Products shall be returned without prior authorization from Slatpro. Buyer

shall prepay all shipping charges for the return of Products to Slatpro designated service location.

LIMITATION OF LIABILITY. IN NO EVENT SHALL SLATPRO BE LIABLE FOR ANY INCIDENTAL

DAMAGES, CONSEQUENTIAL DAMAGES, SPECIAL DAMAGES, INDIRECT DAMAGES, LOSS OF

PROFITS, LOSS OF REVENUES, OR LOSS OF USE, EVEN IF INFORMED OF THE POSSIBILITY

OF SUCH DAMAGES. SLAPRO'S LIABILITY FOR DAMAGES ARISING OUT OF OR RELATED

TO ANY ORDER IS LIMITED TO THE ORDER PRICE FOR THE SPECIFIC PRODUCT THAT

GIVES RISE TO THE CLAIM. TO THE EXTENT PERMITTED BY APPLICABLE LAW, THESE

LIMITATIONS AND EXCLUSIONS SHALL APPLY REGARDLESS OF WHETHER LIABILITY

ARISES FROM BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING BUT NOT LIMITED TO

NEGLIGENCE), BY OPERATION OR LAW, OR OTHERWISE.

Effective Date: October 15, 2020

Mailing Address: 4757 Mustang Circle · Mounds View, MN 55112 USA Phone: 763-452-4550 www.slatpro.com

Slag Hog Assembly

P/N: 67123-120VG or -230VG ModelSH3G

Item Qty Part No. Description sheet 1 of 2

The following items are for the drive portion of the assembly

1167121 Input Shaft

2 2 66034 Cutter Shaft

3 2 66135 Idler Shaft

4 1 67077 Driven Idler Shaft

5 2 66083 Thrust Spacer

6 4 66041 Gear Support Plate

7 2 66040 Cutter Support Plate

8 15 66115 Needle Bearing .62 ID

9 4 67007 Needle Bearing .62 ID Closed End

10 1 67167 Ball Bearing .62IDx1.38ODx.344W

11 1 67168 Seal .62IDx1.12ODx,12W

12 2 NI Clamp Collar 9520T8

13 4 67058 Input Shaft Spacer

14 8 66081 Idler Shaft Washer

15 4 66054 Pivot Washer

16 4 66048 Spur Gear 14T

17 2 66049 Spur Gear 16T

18 1 66058 Gear Box

19 1 66042 Pivot End Plate Cutter Side

20 1 67119 Gear Housing

21 1 66044-RH Top Gear Support RH

22 1 66044-LH Top Gear Support LH

23 2 66025 Spring Guide Male

24 2 66051 Spring Guide Female

25 2 66126 Die Spring

26 6 67204 Thrust Washer .625ID x 1"OD x .125 Thk

27 7 NI Machine Key 98870A140

28 2 NI Dowel Pin, Pull-out 97175A390

29 1 66039 Chip Deflector

30 2 66053 Spacer, Cutter

31 1 67155 Gear 93T

32 1 67156 Gear Shaft 20T

33 1 67157 Gear 82T

34 1 67159 Filler Gear Housing

35 267166 Bearing 10 IDx26 ODx8mm W

36 1 67120 Motor Mount Plate

37 1NIOring -047 9452K312

Slag Hog Assembly

P/N: 67123-120VG or -230VG ModelSH3G

Item Qty Part No. Description sheet 2 of 2

The following items are for the housing portion of the assembly

40 1 67114 Side Plate Set

41 1 67164 Base Plate

42 1 67118 Motor -120VG or -230VG

43 REF 67179 Carbon Brush Set for Motor (Not Shown)

44 167184 Grease Seal Adapter

45 167206 Grease Seal

46 1NI Oring -024 9452K78

47 1 67112 Motor Enclosure

48 1 67116 Top Cover

49 1 67115 Wire Access Cover

50 2 66117 Wheel

51 1 NI Clamp Collar 6157K14

52 1 NI Shaft .5 dia x 10.38 1255T17

53 1 66116 Handle

54 1 67063 On/Off Switch 15A

55 1 67065 Receptacle

56 1 NI Ground Wire 2196k42

The following items are for the fasteners

70 2 NI Flat Hd Phillips Mach Scr M3x8 92010A118

71 8 NI Socket Head Cap Screw M4x14 91290A150

73 21 NI Vib Resist Hex Hd Flange M5x12 92820A215

74 9 NI Hex Hd Flange M5x20 98093A320

75 4 NI Socket Head Cap Screw M5x14 91290A230

76 1 NI Button Hd SCS M6x12 91239A318

78 2 NI Socket Head Cap Screw M6x25 90128A265

79 4 NI Button-Head SCS M8x16 91306A677

80 14 NI Socket Head Cap Screw M8x25 90128A275

81 7 NI Nylock Flanged Nut M6x1 99908A101

82 2 NI Nylock Nut M10x1.5 90576A118

83 2 NI Button Hd SCS M10x55 SST 92095A426

85 1 67171 Foam Packaging SH3

See67173forhandletubeoptions

NImeansnon‐inventoryitem

Table of contents

Other SlatPro Tools manuals