19

5 611 52 019

-

SE20 & SE25 & SE30 & SE40

Electrical Specifi cations

EN MC_0044

*Valid for DC motors

Model Size Voltage

Nominal

current

draw

Min. battery

CCA Rec. fuse

<7m total + & - 7-14m total + & - 15-21m total + & - 22-28m total + & - 28-35m total + & - 36-45m total + & -

Min. Rec. Min. Rec. Min. Rec. Min. Rec. Min. Rec. Min. Rec.

*20/110S 12 V 150 A

DIN: 200

SAE: 380

EN: 330

ANL 150

mm2 25 35 35 50 50 70 70 95 95 95 2 x 95 2 x 120

AWG 1 1 1 1/0 1/0 2/0 2/0 3/0 3/0 3/0 2 x 3/0 2 x 4/0

*25/110S 12 V 200 A

DIN: 200

SAE: 380

EN: 330

ANL 150

mm2 25 35 50 50 70 70 95 95 120 120 2 x 70 2 x 70

AWG 1 1 1/0 1/0 2/0 2/0 3/0 3/0 4/0 4/0 2 x 2/0 2 x 2/0

*30/125S 12 V 245 A

DIN: 200

SAE: 380

EN: 330

ANL 150

mm2 35 50 50 70 70 95 95 120 120 2 x 70 2 x 70 2 x 95

AWG 1 1/0 1/0 2/0 2/0 3/0 3/0 4/0 4/0 2 x 2/0 2 x 2/0 2 x 3/0

*40/125S 12 V 315 A

DIN: 300

SAE: 570

EN: 520

ANL 250

mm2 35 50 70 95 95 120 120 2 x 70 2 x 95 2 x 95 2 x 120 2x 120

AWG 1 1/0 2/0 3/0 3/0 4/0 4/0 2 x 2/0 2 x 3/0 2 x 3/0 2 x 4/0 2 x 4/0

*50/140S

12 V 370 A

DIN: 350

SAE: 665

EN: 600

ANL 325

mm2 50 50 70 95 120 2 x 70 2 x 70 2 x 95 2 x 95 2 x 120 2 x 120 2 x 120

AWG 1/0 1/0 2/0 3/0 4/0 2 x 2/0 2 x 2/0 2 x 3/0 2 x 3/0 2 x 4/0 2 x 4/0 2 x 4/0

24 V 170 A

DIN: 175

SAE :332

EN: 280

ANL 150

mm2 25 25 25 35 35 50 35 50 50 70 70 70

AWG 1 1 1 1 1 1/0 1 1/0 1/0 2/0 2/0 2/0

*60/185S

12 V 370 A

DIN: 350

SAE: 665

EN: 600

ANL 325

mm2 50 50 70 95 120 2 x 70 2 x 70 2 x 95 2 x 95 2 x 120 2 x 120 2 x 120

AWG 1/0 1/0 2/0 3/0 4/0 2 x 2/0 2 x 2/0 2 x 3/0 2 x 3/0 2 x 4/0 2 x 4/0 2 x 4/0

24 V 170 A

DIN: 175

SAE: 332

EN: 280

ANL 150

mm2 25 25 25 35 35 50 35 50 50 70 70 70

AWG 1 1 1 1 1 1/0 1 1/0 1/0 2/0 2/0 2/0

*80/185T

12 V 530 A

DIN: 550

SAE: 1045

EN: 940

ANL 400

mm2 70 70 120 2 x 70 2 x 95 2 x 95 2 x 120 2x 120 2 x 120

340* NA NA

AWG 2/0 2/0 4/0 2 x 2/0 2 x 3/0 2 x 3/0 2 x 4/0 2 x 4/0 2 x 4/0

24 V 280 A

DIN: 300

SAE:570

EN: 520

ANL 250

mm2 35 35 35 50 50 70 70 95 95 120 120 2 x 95

AWG 1 1 1 1/0 1/0 2/0 2/0 3/0 3/0 4/0 4/0 2 x 3/0

*100/185T

12 V 740 A

DIN: 750

SAE: 1425

EN: 1320

ANL 500

mm2 95 95 2 x 70 2 x 95 2 x 120

280* 280* 320* NA NA NA NA

AWG 3/0 3/0 2 x 2/0 2 x 3/0 2 x 4/0

24 V 340 A

DIN: 400

SAE: 760

EN: 680

ANL 325

mm2 50 50 50 70 70 95 95 120 120 2 x 95 2 x 95 2 x 120

AWG 1/0 1/0 1/0 2/0 2/0 3/0 3/0 4/0 4/0 2 x 3/0 2 x 3/0 2 x 4/0

*120/215T 24V 420 A

DIN: 450

SAE: 855

EN: 760

ANL 325

mm2 70 70 70 70 70 95 95 120 120 2 x 70 2 x 70 2 x 95

AWG 2/0 2/0 2/0 2/0 2/0 3/0 3/0 4/0 4/0 2 x 2/0 2 x 2/0 2 x 3/0

*130/250T

12V 800 A

DIN: 750

SAE: 760

EN: 680

ANL 500

mm2 95 95 2 x 70 2 x 95 2 x 120

- 330* 375* - - - -

AWG 3/0 3/0 2 x 2/0 2 x 3/0 2 x 4/0

24V

340 A DIN: 400

SAE: 760

EN: 680

ANL 325

mm2 35 50 50 70 70 95 95 95 120

-

2 x 95

-

(350 A) AWG 1 1/0 1/0 2/0 2/0 3/0 3/0 3/0 4/0 2 x 3/0

*150/215T 24V 610 A

DIN: 560

SAE: 1064

EN: 940

ANL 500

mm2 70 70 95 95 120 120 2 x 95

-

2 x 95

-

2 x 120

-

AWG 2/0 2/0 3/0 3/0 4/0 4/0 2 x 3/0 2 x 3/0 2 x 4/0

*170/250 24V 550 A

DIN: 560

SAE: 1064

EN: 940

ANL 400

mm2 70 70 70 95 95 120 120 2 x 95 2 x 95

-

2 x 120

-

AWG 2/0 2/0 2/0 3/0 3/0 4/0 4/0 2 x 3/0 2 x 3/0 2 x 4/0

*210/250 24V 500 A

DIN: 560

SAE: 1330

EN: 940

ANL 400-

500

mm2 70 70 70 95 95 120 120 2 x 70 2 x 70 2 x 95 2 x 95

-

AWG 2/0 2/0 2/0 3/0 3/0 4/0 4/0 2 x 2/0 2 x 2/0 2 x 3/0 2 x 3/0

*250/300 24V 610-670 A

DIN: 700

SAE: 1330

EN: 1170

ANL 500

mm2 70

-

95 120 120 2 x 95 2 x 95 (350CCA) 2 x 95 (400CCA) 2 x 120 (400CCA)

AWG 2/0 3/0 4/0 4/0 2 x 3/0 2 x 3/0 (665CCA) 2 x 3/0 (760CCA) 2 x 4/0 (760CCA)

*300/300

24*2 400-450A

(48V)

DIN: 400

SAE: 760

EN: 680

ANL 325

mm2 50

-

50 70 70 95 95 120 120 120 140

-

48V AWG 1/0 1/0 2/0 2/0 3/0 3/0 4/0 4/0 4/0 4/0

MG_0019

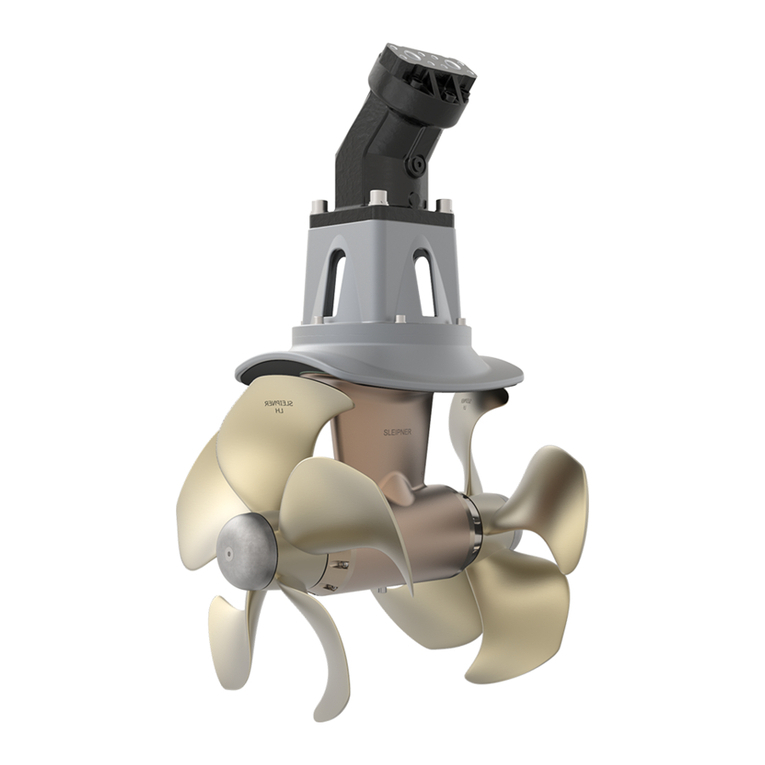

Thuster

Motor

Battery

12V or

24V

Fuse

Main

switch

Nut

Tighten to

18Nm (13.28lb/ft)

Nut

Tighten to

18Nm (13.28lb/ft)

washers

Lugs

++

--

IMPORTANT

Do NOT use washers between lugs

and terminals, this can cause

overheating. Washers must be placed in

the outer position before tightening nut.

MC_0143

Thruster Electrical Installation

EN

IMPORTANT

Check the following with the main switch set to off :

After all electrical connections have been completed check with an ohm meter that there is no electrical connection between

1. electro-motor fl ange and the positive terminal on the motor

2. electro-motor fl ange and the battery negative terminal on the motor

If unsure contact skilled personnel.

1. Explanation of electrical table. see next page

- All power cable lengths are the total of + and - (to and from).

- Battery size is stated as minimum cold crank capacity, not Ah.

- Use slow fuse rated to hold stated Amp-Draw for min. 5 minutes.

* Cable size and main battery size when an extra bow battery with minimum the CCA mentioned as A is installed.

2. Use appropriate sized cables and batteries with a high cranking capacity to feed the thruster. The actual voltage at the motor while running the

thruster decides the motors output RPM and thrust. You can use larger cables for better results.

- Advised minimum cables and batteries sizes. See next page.

3. Install the main switch in the main positive lead that can take the load without noticeable voltage drop and that can be turned off independently

when not on board or in emergencies. Ensure it is easily accessible and update instructions that this should be turned off like the boat’s other main

switches.

*It is advised to install a fuse in the positive lead for protection against short-circuiting. Ensure a slow type and appropriately sized to take the

amperage draw for at least 5 minutes.

- A circuit breaker can be used instead of the fuse and main power switch If the functionality is the same.

(NB: For Ignition Protected installations remember to use ignition protected fuses and switches if fi tted in areas that require this

feature.)

5. Cables must have adequate electrical and mechanical isolation against contact with anything but the lead terminal on the battery and tted with

cable ends.

6. Fasten cables to the required torque. see next page

!Please refer to the graphic for special considerations relating to your model !