Slingshot S64 Operation instructions

11

SLINGSHOT

PROFESSIONAL

COFFEE GRINDER

ORIGINAL INSTRUCTION USER HANDBOOK

Models S64 S75 C68

INSTRUCTIONS FOR USE

Page 3

INDEX

Page 5

Page 6

Page 8

Page 7

Page 9

Page 11

Page 12

Page 18

Page 10

Precautions and Safety Features

Application and use of the Grinder

Initial Setup

Adjusting the Fork-Portalter

Function Selector

• Auto Mode

• On Demand

• Burrs Life

Ready to Start

Using the Grinder

Dispensing the Coee in the Portalter

Safety Devices

Cleaning and Maintenance

Trouble Shooting

Adjusting the Grind

Adjustable Grinding Scale

Adjusting the Dosage

Grinding Time Delay

General Description

SLINGSHOT TECHNOLOGY CORPORATION LTD

All right reserved. It is prohibited to reproduce, adapt or translate this document without prior written authorisation.

33

The packing materials (carton, cellophane, staples, polystyrene, etc..) can cut, wound or create hazards

if used improperly or handled carelessly. Store such materials out of reach of children and irresponsible

persons.

This symbol on the appliance or package means that the appliance must not be considered as normal

household refuse but that it must instead be delivered to an appropriate collection centre for the recycling

of electric and electronic appliances.

Read this manual from cover to cover before using the appliance as it contains important instructions

for the safety, operation and maintenance of the appliance. Look after this manual and keep it in a safe

place.

DISPOSAL OF THE UNIT

At the end of its service life, this product cannot be disposed of in normal domestic waste. The symbol on

the product and in the operating instructions point out to this fact. The materials are recyclable according

to your marking. With the reuse, recycling or other forms of recycling of old equipment, you make an

important contribution to the protection of our environment. Please ask your municipal administration for

the disposal point.

The manufacturer reserves the right to make changes to the product and to the manual.

The company cannot be held liable for any damage to people or property resulting from failure to respect

the instructions concerning safety, installation and maintenance contained in this manual.

Before connecting the machine, check that voltage and frequency values of the supply mains correspond

to the ratings indicated on the label featuring the grinder’s technical data.

IT IS COMPULSORY TO EARTH THE APPLIANCE.

Avoid use of multiple-plug adapters and extension cords or makeshift connections.

The Coee Grinder must be installed only by authorised, qualied personnel.

THE COFFEE BEANS HOPPER MUST BE PLACED ON THE APPLIANCE AND PROPERLY FIXED

WITH THE APPROPRIATE SCREW.

If the thermal breaker to protect the motor is triggered, do not attempt any other manoeuvre. Unplug the

machine from the power mains and make sure that any problems have been solved before switching the

machine on again.

It is essential to check the state of the supply cable and plug periodically.

IN THE EVENT THE SUPPLY CABLE OR PLUG ARE DAMAGED, CALL IN SKILLED TECHNICAL

PERSONNEL TO REPLACE THEM, THIS TO PREVENT ANY RISK.

ELECTRICAL INSTALLATION RULE (S64, S75, C68)

Prior to installation, make sure there is a circuit breaker installed with a distance between the contacts

that allows for complete disconnection when there is a category III overload and that provides protection

against current leakage equal or less than to 30 mA. The circuit breaker must be installed on the power

supply in compliance with installation rules.

If the power supply is not working properly, the machine can cause transitory voltage drops.

The electrical safety of this machine is only ensured when it is correctly connected to an ecient earthing

system in compliance with the electrical safety laws in force. This fundamental safety requirement must

be veried. If in doubt, request that a qualied electrician inspect the system. The manufacturer cannot be

held responsible for any damage caused by the lack of an earthing system on the electrical supply.

It is unadvisable to use adaptors, multiple plugs, and/or extension cords. If their use is indispensable, only

use simple or multiple adaptor plugs and extension cords that are in compliance with safety laws. Make

sure these devices do not exceed the voltage capacity marked on the simple adaptor and on extension

cords, and the maximum voltage marked on the multiple adaptor.

PRECAUTIONS AND SAFETY FEATURES

33

44

This coee grinder has been designed only for grinding roasted coee beans.

Any other use is understood to be improper, and therefore hazardous.

OPERATING RANGE OF THE MOTOR

10s ON for 2 times / 60s OFF point out an allowed duty cycle of 10 seconds switched on for 2 times and

60 seconds switched o.

The manufacturer cannot be held responsible for any damage as a result of improper or incorrect use.

THIS COFFEE GRINDER HAS BEEN DESIGNED ONLY FOR PROFESSIONAL USE BY TRAINED

PERSONNEL AND NOT FOR HOUSEHOLD USE.

The user must be an adult. Do not allow children or incapable persons to use this coee grinder.

Children should be supervised to ensure that they do not play with the appliance.

The instructions concerning persons (including children) with reduced physical, sensory or mental

capabilities or lack of experience and knowledge and children playing with the appliance are not

applicable.

The grinder is intended to be used for commercial applications, for example in kitchens of restaurants,

canteens, hospitals and in commercial enterprises such as bakeries, but not for continuous mass

production of ground coee.

This appliance is to be connected with exible connections for equipotential bonding and connection to

services such as electricity supply, water supply, gas supply and steam supply such that the appliance

can be moved in the direction required for cleaning a distance not less than the dimension of the

appliance in the direction of movement plus 500 mm without the exible connections becoming taut or

being subject to strain.

WARNING:

Installation, dismantling, and adjustments must only be performed by qualied and authorised

technicians.

Carefully read the warnings and rules in this manual because they provide important information

regarding safe installation, use and maintenance of the machine.

Keep this booklet handy for easy reference.

After removing the machine from its packing materials, make sure that the machine and its safety devices

are intact.

If the power supply cord is damaged, it can only be replaced by qualied and authorised technicians.

(S64, S75, C68)

Packing materials (plastic bags, polystyrene foam, staples, etc.) must be keptout of the reach of children

because they are potentially hazardous.

Before plugging in the machine, make sure that the information on the nameplate (voltage, etc.) matches

that of the electrical and water systems.

Completely unwind the power supply cable.

The coee grinder should sit on a at, stable surface at least 20 mm from walls and from the counter.

Room temperature must range between 10 C and 32 C (50 F and 90 F).

Do not install in rooms (kitchens) that are cleaned with jets of water.

Do not clean the machine with jets of water.

Do not obstruct openings or ventilation and heat vents.

Do not install the machine outdoors.

APPLICATION AND USE OF THE GRINDER

55

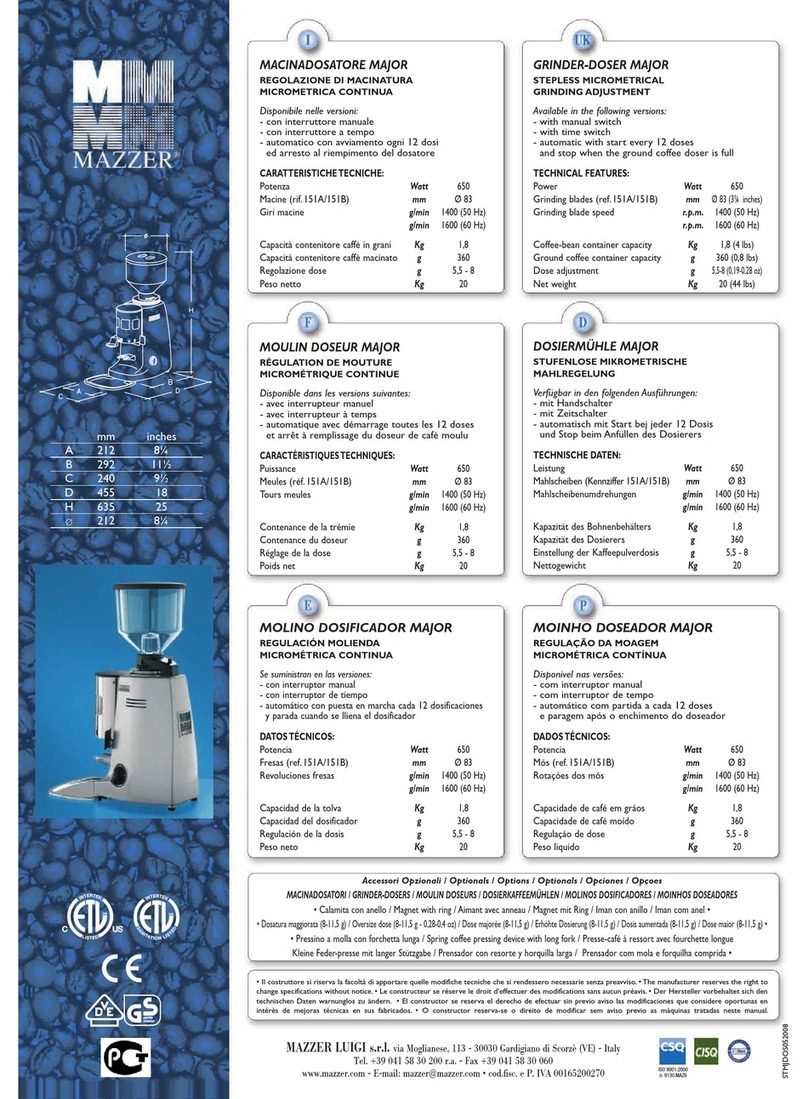

MODEL S64 S75 C68

Volts (V) 220-240V 220-240V 220-240V

Frequency (Hz) 50-60Hz 50-60Hz 50-60Hz

Power (W) 380-460W 450-570W 450-570W

Revolution per min. (rpm) 1215-1458 750-900 450-540

Burrs type/size Flat 64mm Flat 75mm Conical 68mm

Noise level (dba) 85 87 87

Weight (kg) 19.5kg 23.5kg 23.5kg

Fig. A

Fig. C

Fig. B

1

2

3

4

5

6

7

8

910

11

19

13

12

14

15

16

18

20

17

Width - 212mm

Depth - 440mm

Height - 632mm

AUTO

MODE

ON

DEMAND

BURRS

LIFE

General Description

1. Display Window - Hopper Lid

2. Coee Bean Hopper

3. Adjustable Scale

4. Side Panels

5. Digital Display

6. LED Light

7. Single Dosage Adjustment

8. Double Dosage Adjustment

9. Main Power Switch

10. Function Selector

11. Fork Portalter

12. Doser Locking Screw

13. Sliding Gate

14. Grinding Adjustment

15. Position Counter

16. Push Button

17. Open/Close Coee Bean Hopper

18. Coee Hopper Screw Holder

19. Extractor Fan

20. Adjustment Scale Knob

66

INSTRUCTIONS FOR USE

INITIAL SETUP

ADJUSTING THE FORK PORTAFILTER

The Slingshot features a unique volumetric self-dosing chamber which is always on standby to provide

the professional barista with their next shot of espresso. To be able to perform at its optimum an initial

setup is required.

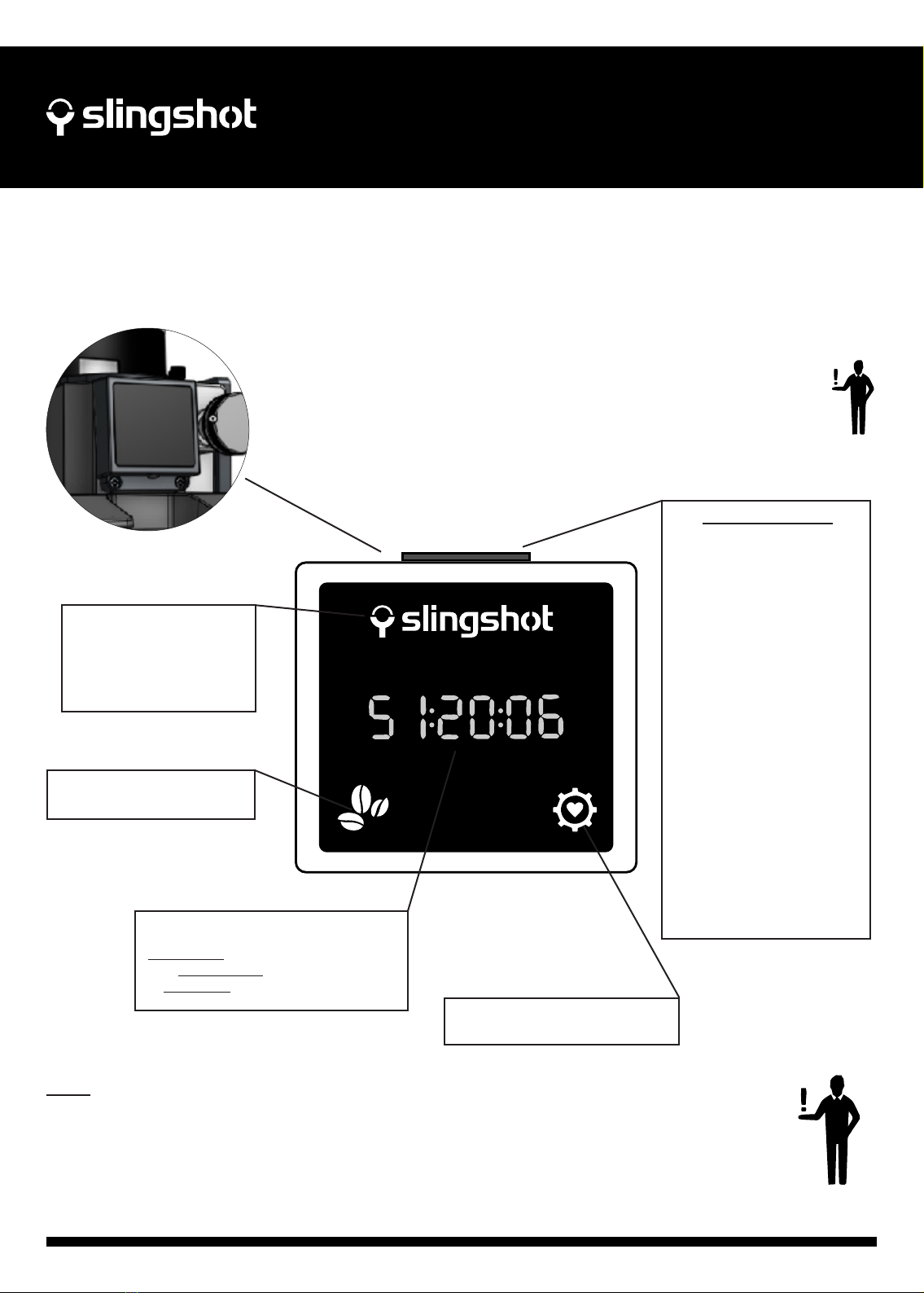

Before you start using the grinder, you will need to adjust the height of the Fork-portalter. Slingshot can

accommodate any type and brand of portalter thanks to its patented spring-loaded support system.The

height of the portalter can vary from 36 to 48 mm, 54mm or 57-58 mm basket diameter.

(A) Using the appropriate tool, untighten the screw that holds the Fork

(B) Insert the Portalter

(C) Lift up the Fork (11) until the top of the portalter is attached to the sliding gate

(D) Re-tighten screw making sure that the top of the portalter stays ush against the sliding gate

NOTE: To be able to deliver the correct coee dose, the portalter top edge must always be in contact with

the stainless steel sliding gate. Once set in position, push the portalter towards the grinder until it stops

then pull the portalter back out making sure that it moves smoothly.

Fig. D Fig. E

Note: To test if Portalter has been set up correctly, push down on the center of the portalter when locked in. If done

correctly, there should be no movement.

Push up until top of

Portalter is attached

to the sliding gate then

re tighten the screw

Untighten the single

screw that hold the

Fork - this will allow

you to adjust up or

down.

77

INSTRUCTIONS FOR USE

USING THE GRINDER

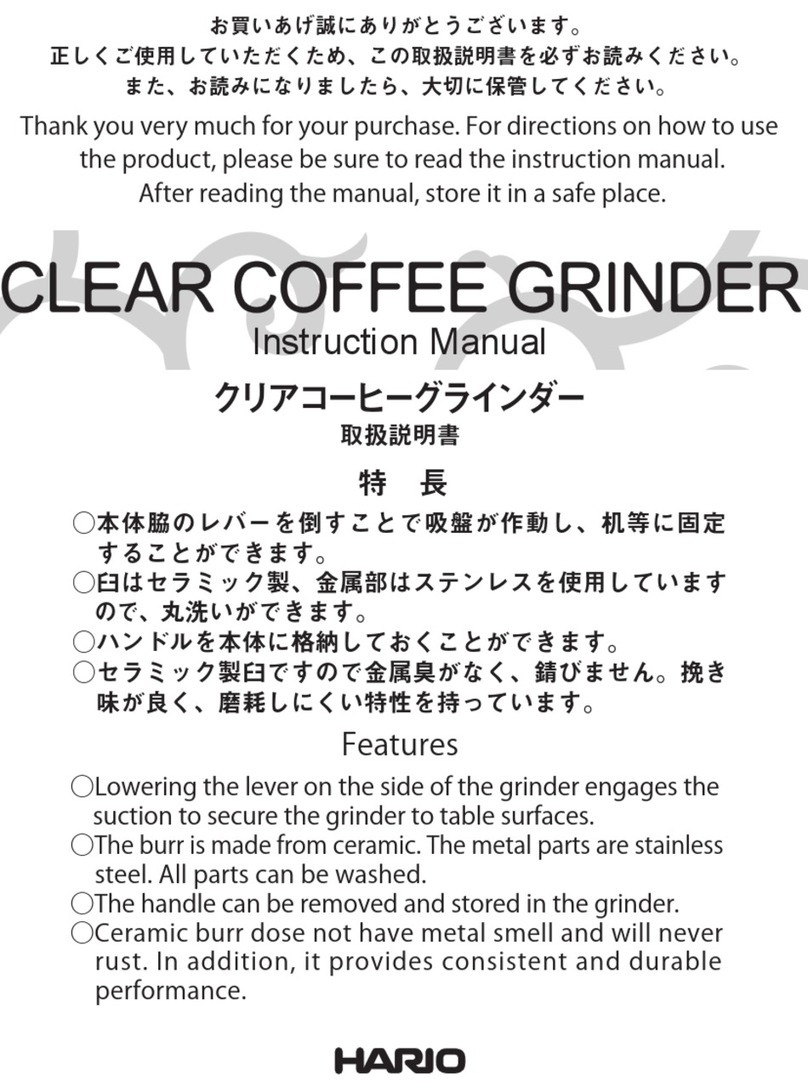

Before you start using the grinder, It is important to understand the information displayed:

Fig. F shows all the available information displayed, and the functionality of the press button.

NOTE: THE COFFEE BEAN ICON WILL ONLY LIGHT UP WHEN COFFEE BEAN HOPPER IS EMPTY.

THE BURRS LIFE ICON WILL ONLY LIGHT UP WHEN THE BURRS NEED REPLACING.

To reset the Coee Beans icon: Fill up coee beans hopper with fresh coee beans then press the top

button.

Only an authorised technician can reset the Burrs Life icon after replacing the old burrs with new ones.

REAL TIME COFFEE MATURATION

In AUTO MODE the display will show the time since last grinding coee in

between the burrs (tail of the coee) and if you press the top button once

the display will show the total resting time of the ground coee in the coee

chamber (head of the coee).

This information will help the Barista to determine when the coee is at its best.

Fig. F

Slingshot GREEN

Ready to dispense coee

Slingshot RED

Wait until grinding is

complete

Beans Icon RED

Coee beans hopper empty

Button Functions

AUTO MODE

Press to swap between:

1. Time since last grinding

2. Time spent of ground

coee inside the coee

chamber

3. Time needed for last

grinding

ON DEMAND

Press to Start/Stop grinding

BURRS LIFE

Press to swap between:

1. Time left in the burrs

2. Total number of doses

delivered on current set

of burrs.

3. Total number of doses

delivered over the

Grinder’s life.

Digital Timer

Auto Mode: Time since last grinding

On Demand: Grinding time

Burrs Life: Time left in the burrs

Burrs Icon RED FLASHING

Call technician to replace burrs

88

INSTRUCTIONS FOR USE

FUNCTION SELECTOR

READY TO START

1) Fill the Hopper with fresh coee beans (max. capacity is approx. 1.2kg).

3) Position the Function Selector to ON DEMAND

4) Turn the ON/OFF switch ON. Switch will light up indicating Grinder is ready for use.

2) Open the Hopper Slide.

Slingshot features a Function Selector (Fig.C) that allows the user to set the grinder in three dierent

modes: AUTO MODE, ON DEMAND and BURRS LIFE.

AUTO MODE

The grinder will always grind for the next shot. Use this

function during the busy service.

ON DEMAND

The grinder will grind only when you press the Push Button.

Use this function during slow service or for calibration

purposes.

BURRS LIFE

When the Function Selector (Fig. C) is set on BURRS LIFE

the coee grinder wont operate and the digital display will

show the number of grinding hours left before changing the

burrs. When the display reaches 3 hours of grinding left,

the burrs life icon in the screen (Fig. F) will start ashing.

This will warn the user to call the technician to change the

burrs.

NOTE: To familiarise yourself with the grinder and to adjust (calibrate) both the coee grind size

(coarser or ner) and dosage, we advise to select the ON DEMAND function.

When ON DEMAND mode, each time you press the button, the grinder will grind until the coee ground

chamber is full (approximately 30g of ground coee).

Fig. C

AUTO

MODE

ON

DEMAND

BURRS

LIFE

99

INSTRUCTIONS FOR USE

DISPENSING THE COFFEE IN THE PORTAFILTER

Slingshot’s unique self-dosing coee chamber delivers the desired coee dosage directly into the portalter:

1

2

3

NOTE: The portalter will

stop once it has reached

the dosage rods

NOTE: You must not wait

with the portalter inserted

all the way. Pull it back as

soon as it has completed

its travel.

Insert the portalter straight between the fork,

then start to push towards the grinder.

Push the portalter gently until it stops.

Pull back the portalter. The dosage has

been delivered.

1010

INSTRUCTIONS FOR USE

ADJUSTING THE GRIND

ADJUSTABLE GRINDING SCALE

GRINDING TIME DELAY

To adjust grinding neness, it is necessary to use the knob (Fig. G1), turning it clockwise for ner grinding

or anti-clockwise for a coarser grind.

Each complete turn of the digital position counter will increase/decrease by 10.

Please consider that the coee ground chamber may hold up to 35 grams of coee grounds, after

changing the coee grinding size it is necessary to dispense a minimum of 3 double doses before the new

grinding setting can be used.

Once the Barista has adjusted the Slingshot to the perfect espresso shot, the main grinding scale (Fig. A3)

is reset to the Absolute Zero.This adjustable point of reference facilitates coee grinding calibration

throughout the day.

To be able to reset the grinding scale unlock the adjustment scale knob (Fig. B18) and reset the scale

to the “0”.

When in AUTO MODE the grinder will start grinding for a new coee dose as soon as you have inserted the

portalter. It is possible to program a time delay for retarding the start of the grinding. This will improve dosage

consistency, especially for the beginner.

When in AUTO MODE press and hold the top button until the display shows a single digit number (time delay in

seconds). Press the button to increase the time delay (from 0 seconds to a max of 5 seconds). Once you have

set the desired time delay, wait until display goes back to the normal AUTO MODE.

0085

NOTE: To be able to recognise the single portalter, the single spout needs to be positioned in the

left at a 90 degree angle in relation to the portalter handle.

In the case where the single portalter’s spout is positioned on the right, unscrew ROD B completely and

screw into location C(Fig. G)

B

1

A

C

Fig. G

ADJUSTING THE DOSAGE

To adjust the coee dosage delivered into the portalter:

Turn the metal rods located under the doser CLOCKWISE (for more coee)

or ANTI-CLOCKWISE (for less coee)

To adjust for a double portalter use ROD A

To adjust for a single portalter use ROD B.

NOTE: The quantity of coee dosed is directly related to the SIZE of

your portalter basket.

Ensure that the basket size you are using is appropriate for your needs.

1111

SAFETY DEVICES

THERMAL OVERLOAD PROTECTION

The appliance’s motor is protected against overheating resulting from overload by a thermal overload

protection which, when tripped, cuts o the power supply to the motor.

Should the protection trip as a result of anomalous operation, such as the grinding blades jamming, the

appliance must be turned o using the on-o switch, UNPLUGGED FROM THE MAINS, AND SKILLED

TECHNICAL PERSONNEL CONTACTED. NEVER PERFORM ANY WORK ON THE APPLIANCE

WHILE IT IS ATTACHED TO THE MAINS, TO AVOID THE RISK THAT MOTOR TURNS ON SUDDENLY.

If the appliance overheats as a result of the motor stopping, allow the appliance to cool down before

performing any repair work.

MOTORSAFETY MICROSWITCH

There is a system that protects against accidental contact with the rotating parts of the grinder consisting of

a micro-switch. Situated under the body of the grinder, the micro-switch will cut electricity to the motor if the

coee hopper is not properly positioned in place.

The push button that controls this device is operated by the back screw (Fig. B16) that holds the coee

hopper. If the hopper is removed or not properly in place, the micro-switch prevents the grinder from

working.

WARNINGS REGARDING SAFETY

This electrical appliance must be used in conformity with the rules in force governing safe operation.

When operating the appliance, beware of the moving mechanical parts’ in the area of the grinding blades and of

the ground coee outlet.

Before removing the hopper from the grinding system, disconnect the power supply.

Avoid removing foreign bodies from the grinding system or hopper without rst unplugging the appliance from

the mains.

The user is not authorised to remove screws or any parts screwed onto the coee grinder.

In the event the appliance is not working properly or is faulty, contact skilled technical personnel, and do not

attempt to make repairs yourself.

Before performing any work on the appliance, including cleaning and/or maintenance, disconnect it from

the power supply by unplugging. Turning o the grinder using its master switch does not assure the same

conditions of safety.

The operator must be aware of the sharpness of the blades-burrs and care is needed when handling cutting

blades-burrs during cleaning.

Take care, as the grinding blades may continue rotating for a short while even after the appliance is switched o.

When the appliance is not in use, the appliance’s power supply must be disconnected using its main switch.

Do not let liquids of any kind come into contact with the internal or external parts of the appliance.

Never put ground coee in the hopper. Intended only for coee beans.

The manufacturer cannot be held responsible for bodily injury or damage to property if these regulations are not

complied with.

1212

CLEANING AND MAINTENANCE

CLEANING THE GRINDER

COFFEE HOPPER

MIXING CHAMBER

GRINDING SYSTEM

DISCONNECT THE APPLIANCE’S POWER SUPPLY BY UNPLUGGING IT BEFORE CLEANING.

THE APPLIANCE MUST BE CLEANED PERIODICALLY BY SKILLED TECHNICAL PERSONNEL ONLY.

Wash the coee hopper once it has been removed from the appliance, using neutral soap and water, rinse

abundantly with lukewarm water and dry thoroughly.

It is advisable to clean the hopper periodically. Once the hopper has been cleaned it must be put back on

the appliance properly, xing it with the relevant screws.

Having discharged the ground coee, clean the coee ground mixing chamber with a clean brush,

expelling the material removed by pushing the sliding gate.

When a more thorough cleaning is required, the operation must be performed only by skilled authorised

technical personnel.

After removing the coee hopper:

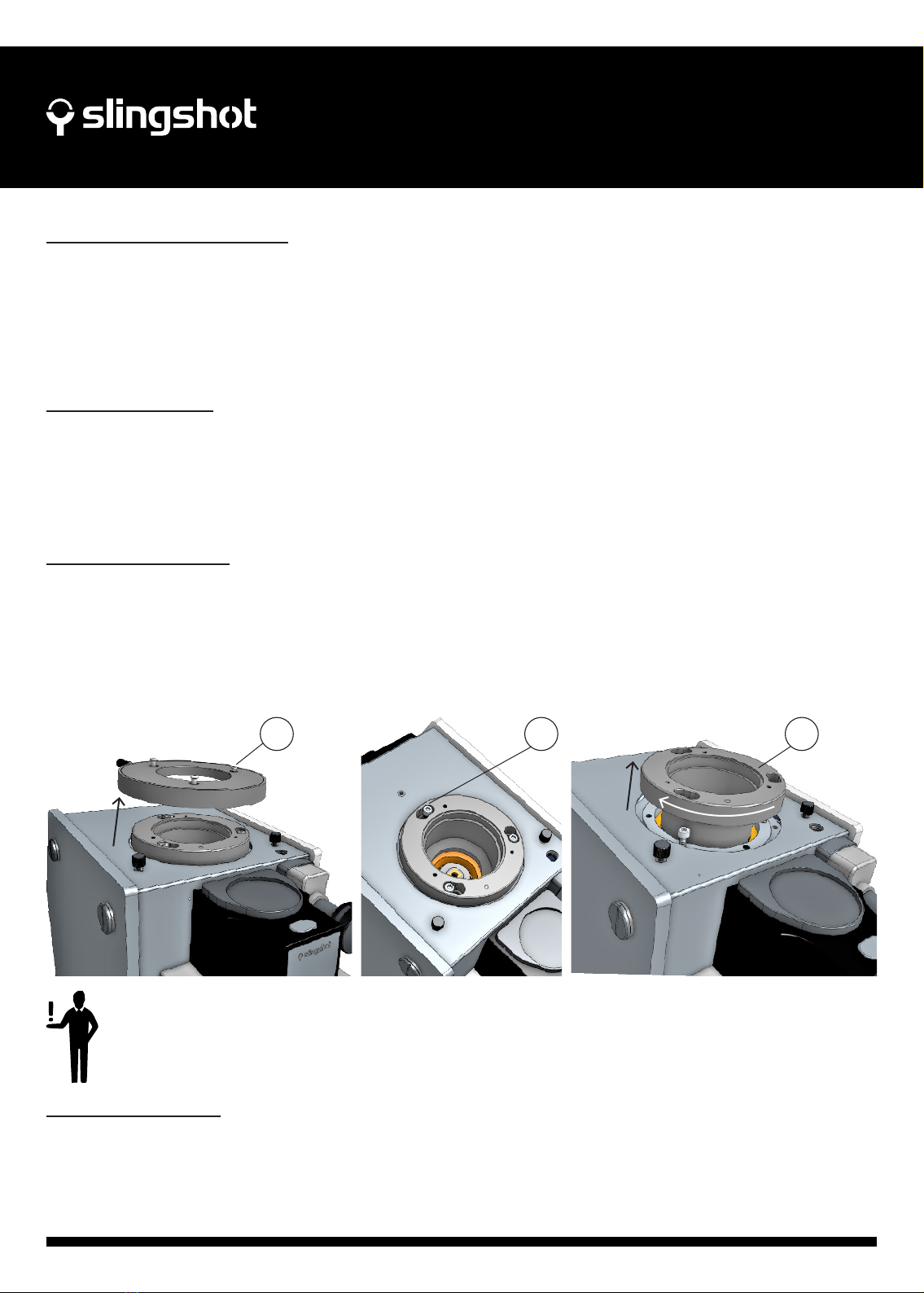

Step 1: Unscrew the 3 screws (Fig. H1) that hold the adjustable grinding scale, lift and remove.

Step 2: Slightly loosen the screws that hold the top burr (Fig. H2)

Step 3: Twist and lift the top burr holder (Fig. H3) to remove.

Use perfectly clean, disinfected cloths or brushes for cleaning.

Do not use abrasive products as these are liable to take the sheen o shiny parts.

1 2 3

Having removed the upper grinding burr holder, clean the grinding burrs and the entire grinding chamber thoroughly using a clean

brush and cloth.

When nished the cleaning, reassemble following the steps from 3 to 1.

Fig. H

1313

CLEANING AND MAINTENANCE

DISASSEMBLING THE DOSAGE MECHANISM

Before starting, ensure that the following has been done:

• Ensure that the grinder has been completely turned o. Disconnect from the appliance’s power supply.

• Empty the hopper and ensure that all coee has been removed from the mixing chamber.

• Carefully place the grinder on it’s back

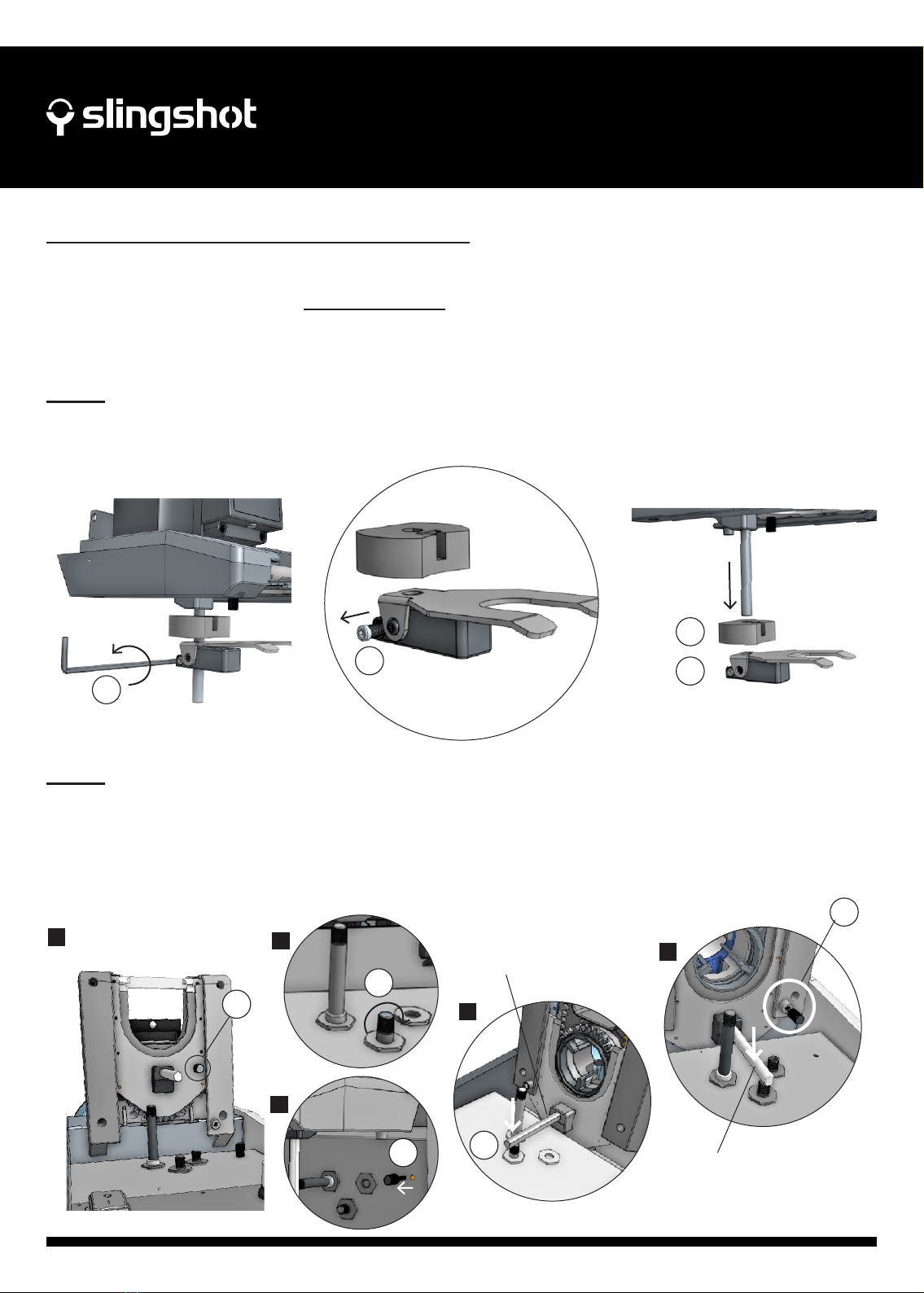

Step 1

• Using the appropriate tool, slightly loosen the single screw (A) clamping the back of the Fork Portalter.

• Once loosened, slide o the Fork Portalter (B) and Rubber Adaptor (C) from the Portalter Rod.

A

A

B

C

Step 2

1. Using your ngers, remove completely the screw on the Sliding Gate (D) and store safely.

2. Rotate the Double Dosage Adjustment Rod (E) CLOCKWISE until you’ve reached its maximum.

3. Using your ngers, remove completely the Doser Locking Screw (G).

4. Using your hand, push the Portalter Rod (F) all the way in.

5. Using your other hand insert and tighten Doser Locking Screw (G) into screwhole as shown. This will lock the

plate in place.

D

G

G

E

F

Ensure that the rod (F) is

pushed all the way in to allow

the screw (G) to be tightened

to its maximum.

Ensure that you are still applying

pressure on the rod (F) whilst

tightening the screw (G).

12

3

4

5

1414

CLEANING AND MAINTENANCE

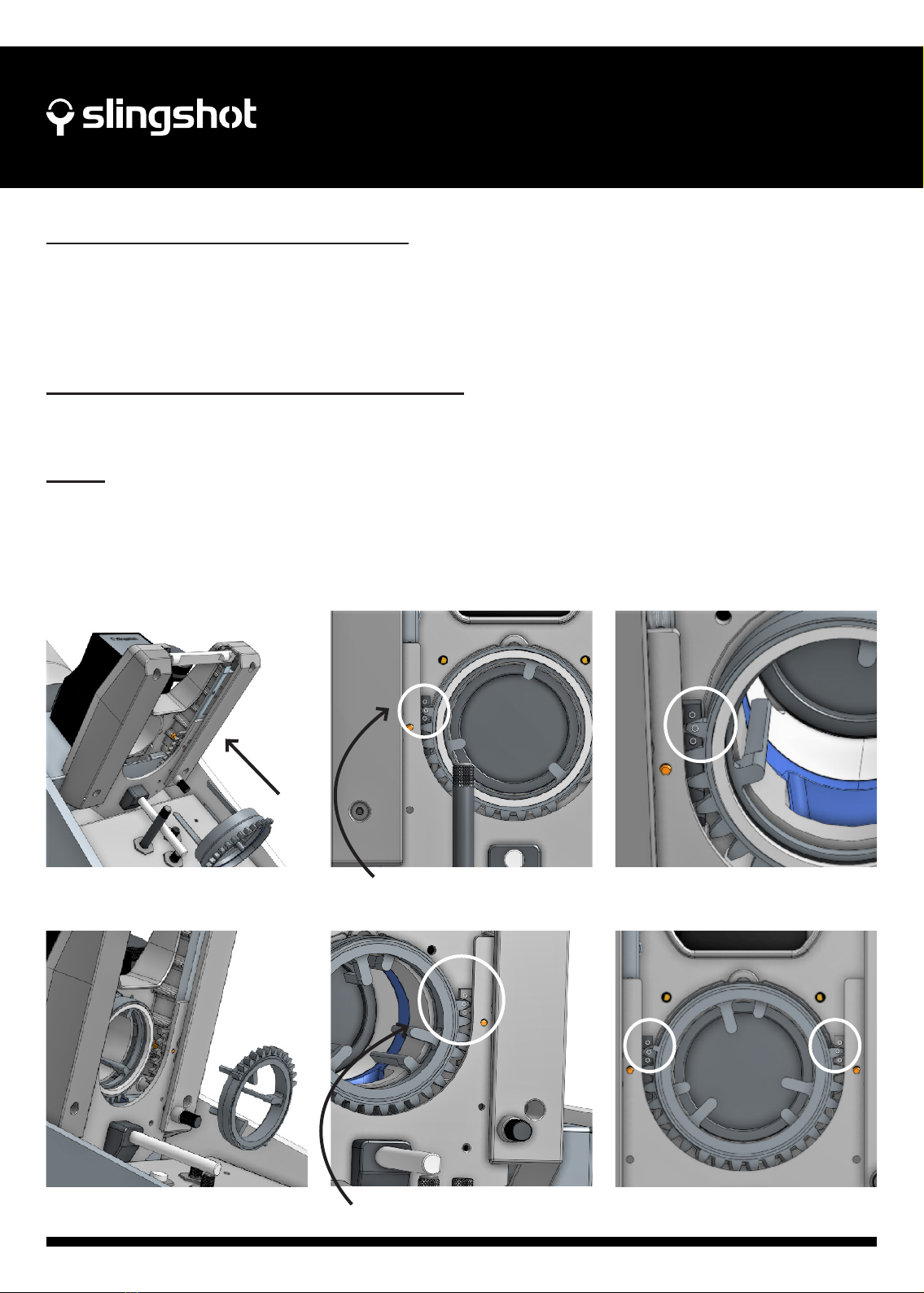

Step 3

Step 4

• Using your ngers, carefully slide out the Sliding Plate (H).

• Carefully remove the two scrapers for cleaning.

Bottom Scraper

marked with a

WHITE dot

Top Scraper

marked with a

GREEN dot

H

1515

REASSEMBLING THE DOSAGE MECHANISM

Once the two scrapers have been cleaned it is now time to reassemble the dosage mechanism.

CLEANING AND MAINTENANCE

Step 1

• Ensure that the felt seals are inserted back into the Upper Scraper.

• Reinsert the Upper Scraper making sure to align the teeth of the scraper to the correct gear rack (see below)

• Reinsert the Lower Scraper making sure to align the teeth of the scraper to the correct gear rack (see below)

• Remove the felt seals and brush o any coee grounds

• Brush o any coee ground build up

• Using a mild soap and warm water, wash the scrapers to remove excess oils from coee ground build up.

• Ensure that the scrapers are completely dry before attempting to reassemble.

HOW TO CLEAN THE TWO SCRAPERS

Ensure that the WHITE dots are correctly aligned as shown in the diagram.

Ensure that the GREEN dots are correctly aligned as shown in the diagram.

1616

CLEANING AND MAINTENANCE

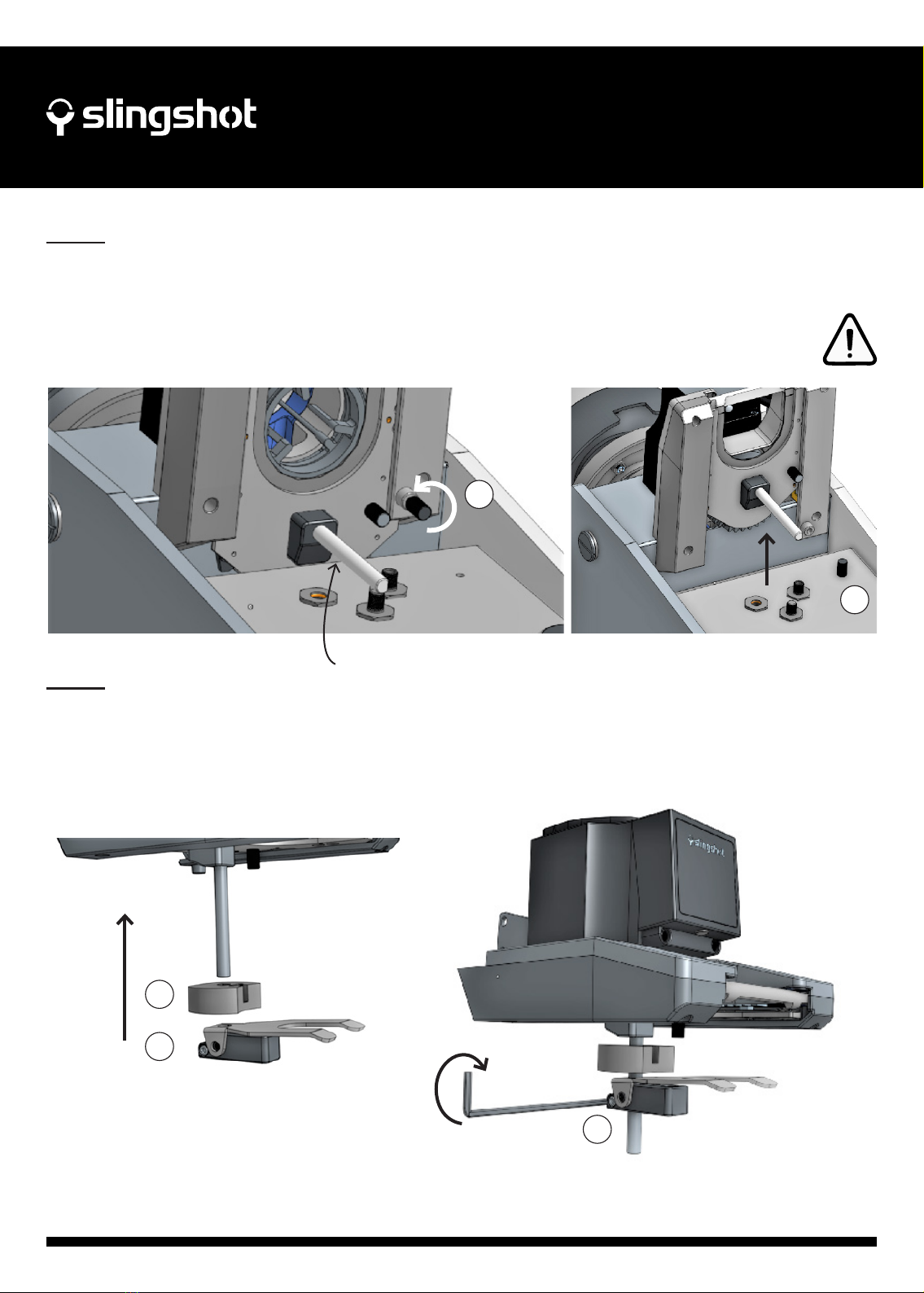

Step 2

Step 3

• Slide the Sliding Plate back into place, ensuring that it’s pushed all the way in.

• Using your ngers, screw back into place the screw (D) for the Sliding Gate.

D

1717

Step 4

• Using one hand, keep applying pressure on the rod and continue to push it towards the body of the Grinder

• Using your other hand, slightly loosen the screw (G) until you feel the rod trying to spring back.

• Slowly release pressure on the rod to allow the Sliding Gate to spring back into position.

• Return Doser Locking Screw (G) back to its orginal position on the body of grinder.

Note: Sliding Plate is spring loaded. Be sure to exercise caution when performing this procedure.

Step 5

• Put back both the Adaptor (B) and Portalter Fork (C)

• Re-adjust the forks based on your Portalter and refasten the screw (A) to lock in position.

Continue to push down on the rod until you feel

the rod trying to spring back.

B

C

A

G

G

1818

TROUBLESHOOTING

Before requesting the technical assistance of the service centre, carry out the following checks:

NOTE: If it is not possible to solve the problem as suggested, or if problems other than those described

above occur, please contact an authorised technical service centre.

PROBLEM POSSIBLE CAUSE SOLUTION

Grinder does not start after

pressing START|STOP

button

• Grinder not plugged in properly.

• Bean hopper not attached correctly

• Grinder has overheated.

• Ensure plug is plugged into power outlet.

• Lock bean hopper into position ensuring that Safety Screw

is screwed in.

• Remove power plug from power outlet. Leave for 20 minutes

to cool down before using again.

Beans Icon ashing.

• No coee beans in hopper

• Hopper sliding gate is closed

• Grinder/bean hopper is blocked

• Fill hopper with fresh coee beans

• Ensure hopper gate is open

Digital Display not turning on

• Grinder not switched on

• Grinder not plugged in correctly

• Hopper Safety Switch screw not

screwed in all the way

• Check that machine is correctly plugged in

• Ensure that the Coee Hopper Screw is fastened all the way.

Not enough/too much coee

grind in portalter

• Dosage rods not correctly set up

• Portalter not set up correctly

• Incorrect portalter basket size

• Incorrect technique of dispensing

coee into portalter

• Refer to Adjusting the Dosage on page 10

• Ensure Portalter is adjusted correctly for use (refer to

Adjusting the Fork Portalter on page 6)

• Ensure portalter basket size is appropriate for your

espresso recipe

• Refer to Dispensing the coee in the Portalter on page 9

to ensure correct technique.

Inconsistent dosage

• Portalter not set up correctly

• Incorrect technique of dispensing

coee into portalter

• Ensure Portalter is adjusted correctly for use (refer to

Adjusting the Fork Portalter on page 6)

• Refer to Dispensing the coee in the Portalter on page 9

to ensure correct technique.

Dosage Mechanism isn’t

operating smoothly

• Portalter not set up correctly

• Coee grind build up

• Ensure that portalter is set up correctly (refer to Adjusting

the Fork Portalter on page 6)

• Clean dosage mechanism (refer to Disassembling of

Dosage Mechanism on page 13)

Adjustment of grind (coarser/

ner) not taking eect

• Dosing chamber still contains coee

with pre-adjusted setting

• Adjustment on Position Counter not

sucient enough

• Ensure that you have purged the grinder of any coee

that had been ground on the pre-existing setting (usually

takes around 3 grind cycles).

SLINGSHOT TECHNOLOGY CORPORATION LTD reserves the right to apply technical changes to the equipment

should they become necessary, without advance notice.

In case of loss or damage of this Original Instruction Manual, user can download a PDF copy of the original instruction

from www.slingshot.coee/manual

1919

EC Declaration of Conformity

The manufacturer:

Slingshot Technology Corporation Ltd

7/F Meyer Industrial Building , 2 Chong Yip Street, Kowloon , Hong Kong

declares that the product described is in conformity with the following European Directives: 2006/42/EC

and The EMC Directive:2014/30/EU

For verication of compliance with said directive, the following harmonized standards have been applied:

2006/42/EC Annex I

EN ISO 12100:2010

EN60204-1:2006+A1:2009/AC:2010

Product Name: Slingshot Coee Grinder

Product Model: S64, S75, C68

Trade Mark: SLINGSHOT

AUTHORISED PERSON TO

COMPILE THE TECHNICAL FILE

Mr. Luca Giorgella

2/19 Rudloc Rd, Morley WA 6062

+61 1300 066 992

We guarantee that we will provide the authorised representative information before we export the

machine to E.U.Responsible for making this declaration is the manufacturer.

Luca Giorgella

Director R&D

ASIA

Slingshot Technology Corporation Ltd

7/F Meyer Industrial Building

2 Chong Yip Street, Kowloon. HK

+852 23438211

USA & CANADA

+1-201-745-6765

EUROPE

Slingshot Europe

Via Industriale, 1

24040 Chignolo D’isola BG, Italy

+39 035 494 9555

AUSTRALIA & NZ

Slingshot Technology Pty Ltd

2/19 Rudloc Rd

Morley WA 6062

+61 1300 066 992

Other manuals for S64

1

This manual suits for next models

2

Table of contents

Other Slingshot Coffee Grinder manuals