SLS LAB BASICS SLS2600 User manual

SLS Lab Basics

Mini Vacuum Pumps

United Kingdom:

International:

Northern Ireland:

Republic of Ireland:

Code: SLS2600/2602 |User Manual

1. About this document.....................................................................................................................3

2. Use ................................................................................................................................................4

3. Safety ............................................................................................................................................5

4. Technical Data ............................................................................................................................. 7

5. Design and Function ..................................................................................................................10

6. Installation and connection.........................................................................................................11

7. Operation.....................................................................................................................................12

8. Servicing......................................................................................................................................14

9.Troubleshooting............................................................................................................................17

10. Spare parts and accessories.....................................................................................................19

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

Contents

3

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

1 .About this document

1.1. Using the Operating Instructions

The Operating Instructions are part of the pump.

►Carefully study the Operating Instructions before using a pump.

► Always keep the Operating Instructions handy in the work area.

►Pass on the Operating Instructions to the next owner.

1.2. Symbols and Markings

Warning

A danger warning is located here.

Possible consequences of a failure to observe the warning are specified here.

The signal word, e.g. Warning, indicates the danger level.

►Measures for avoiding the danger and its consequences

are specified here.

WARNING

Warning

Signal word Meaning Consequences if not observed

DANGER Warns of immediate danger Death or serious injuries and/or serious

damage are the consequence.

WARNING Warns of immediate danger Death or serious injuries and/or serious

damage are possible.

CAUTION Warns of a possibly dangerous situation Minor injuries or damage are possible.

Table. 1

Other information and symbols

►An activity to be carried out (a step) is specified here.

1. The first step of an activity to be carried out is specified here.

Additional, consecutively numbered steps follow.

iThis symbol refers to important information.

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

4

2 .Use

2.1. Proper use

The pumps are exclusively intended for transferring gases and

vapours.

Owner’s responsibility

Only install and operate the pumps under the operating parameters

and conditions described in chapter 4, Technical data.

Make sure that the installation location is dry and the pump is

protected against rain, splash, hose and drip water.

Before using a medium, check whether the medium can be

transferred danger-free in the specific application case.

Before using a medium, check the compatibility of the materials of

the pump head, diaphragm and valves with the medium.

Only transfer gases which remain stable under the pressures and

temperatures occurring in the pump.

Laboratory equipment or additional components connected to a

pump have to be suitable for use with the pneumatic capabilities of

the pump.

2.2. Improper use

The pumps may not be operated in an explosive atmosphere.

The pumps are not suitable for transferring dusts.

The pumps are not suitable for transferring liquids.

The pumps must not be used to create vacuum and overpressure

simultaneously.

An overpressure must not be applied to the suction side of the pump.

Operating parameters

and conditions

Requirements for

transferred medium

Accessories

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

3 .Safety

iNote the safety precautions in chapters 6. Installation and connection,

and 7. Operation.

The pumps are built according to the generally recognized rules of

technology and in accordance with the occupational safety and

accident prevention regulations. Nevertheless, dangers can result

during their use which lead to injuries to the user or others, or to

damage to the pump or other property.

Only use the pumps when they are in a good technical and proper

working order, in accordance with their intended use, observing the

safety advice within the operating instructions, at all times.

Make sure that only trained and instructed personnel or specially

trained personnel work on the pumps. This especially applies to

assembly, connection and servicing work.

Make sure that the personnel has read and understood the operating

instructions, and in particular the “Safety” chapter.

Observe the accident prevention and safety regulations when

performing any work on the pump and during operation.

Do not expose any part of your body to the vacuum.

Open housing parts with notice sticker (see fig. 1) only after

separating mains plug from power source.

When transferring dangerous media, observe the safety regulations

when handling these media.

Be aware that the pumps are not designed to be explosion-proof.

Make sure the temperature of the medium is always sufficiently

below the ignition temperature of the medium, to avoid ignition or

explosion. This also applies for unusual operational situations.

Note that the temperature of the medium increases when the pump

compresses the medium.

Hence, make sure the temperature of the medium is sufficiently

below the ignition temperature of the medium, even when it is

compressed to the maximum permissible operating pressure of the

pump. The maximum permissible operating pressure of the pump

is stated in the technical specifications (see chapter 4).

If necessary, consider any external sources of energy, such as

radiation, that may add heat to the medium.

In case of doubt, consult the SLS customer service.

Store all replacement parts in a protected manner and dispose of them

properly in accordance with the applicable environmental protection

regulations. Observe the respective national and international regulations.

This especially applies to parts contaminated with toxic substances

.

5

Personnel

Working in a safety

conscious manner

Handling dangerous

media

Handling flammable

media

Environmental

protection

Fig. 1: Notice sticker

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

6

The pumps conform to the Directive 2011/65/EU (RoHS2).

The pumps conform to the safety regulations of the Directive

2014/30/EU concerning Electromagnetic Compatibility and the

Directive 2006/42/EC concerning Machinery.

The following harmonized standards have been used:

• DIN EN 61010-1

• DIN EN 61000-3-2/3

• DIN EN 55014-1/2

• DIN EN 50581

• DIN EN 1012-2

• DIN EN ISO 12100

The pumps correspond to IEC 664:

• the overvoltage category II

• the pollution degree 2

Standards

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

7

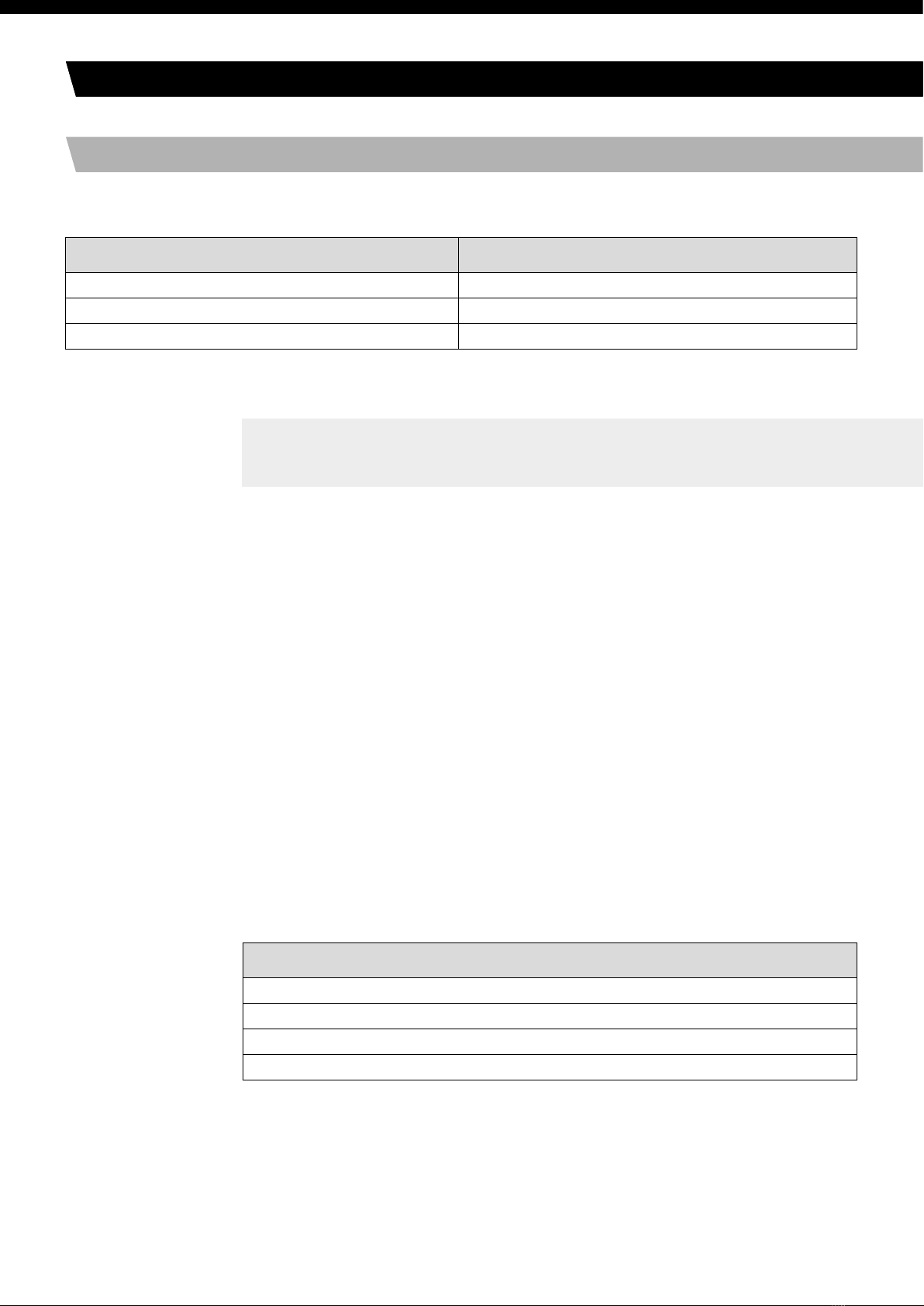

4 .Technical Data

Component Pump material

Pump head PPS

Diaphragm EPDM

Valve plates/sealings FPM

iAll pumps are secured against overheating with thermal switches and are equipped with a

mains fuse.

Pump materials

SLS2600

SLS2602

Component Pump material

Pump head PPS

Diaphragm PTFE-coated

Valve plates/sealings FFPM

Table. 2

Table. 3

iRefer to the type plate for the pump’s electrical configuration.

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

Pneumatic performance

Max. permissible operating pressure [bar g] 2.4

Ultimate vacuum [mbar abs.] 100

Delivery rate at atm. pressure [l/min]* 6.0

Pneumatic connections

Hose connection [mm] ID 4

Ambient and media temperature

Permissible ambient temperature + 5 °C to + 40 °C

Permissible media temperature + 5 °C to + 40 °C

Other parameters

Weight [kg] 1.9

Dimensions: L x H x W [mm] 164 x 141 x 90

Maximum permissible ambient relative humidity 80% for temperatures up to 31 °C, decreasing

linearly to 50 % at 40 °C

Max. altitude of site [m above sea level] 2000

SLS2600

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Max. operating current [A] 1.8 1.1 0.65

Power consumption pump [W] 60 55 60

Maximum permitted mains voltage fluctuations +/- 10 % +/- 10 % +/- 10 %

Fuse pump** (2x) T [A] 3.15 3.15 1.0

Protection class motor IP20

Table. 4 *Liters in standard state (1,013 mbar)

** For spare part-No. see chapter 10

8

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

Pneumatic performance

Max. permissible operating pressure [bar g] 2.5

Ultimate vacuum [mbar abs.] 160

Delivery rate at atm. pressure [l/min]* 5.5

Pneumatic connections

Hose connection [mm] ID 4

Ambient and media temperature

Permissible ambient temperature + 5 °C to + 40 °C

Permissible media temperature + 5 °C to + 40 °C

Other parameters

Weight [kg] 1.9

Dimensions: L x H x W [mm] 164 x 141 x 90

Maximum permissible ambient relative humidity 80% for temperatures up to 31 °C, decreasing

linearly to 50 % at 40 °C

Max. altitude of site [m above sea level] 2000

SLS2602

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Max. operating current [A] 1.8 1.1 0.65

Power consumption pump [W] 60 55 60

Maximum permitted mains voltage fluctuations +/- 10 % +/- 10 % +/- 10 %

Fuse pump** (2x) T [A] 3.15 3.15 1.0

Protection class motor IP20

Table. 5 *Liters in standard state (1,013 mbar)

** For spare part-No. see chapter 10

9

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

5 .Design and Function

SLS2600/2602

1 Outlet (pressure side)

2 Inlet (suction side)

3 Pump head

4 Power switch

Aufbau und Funktion Mini-Laborpumpen N 86.18, N 811.18

12 Original-Original-Betriebsanleitung,deutsch, KNF121435-121437 04/18

5. Aufbau und Funktion

Aufbau N 86 K_.18

1Auslass (Druckseite)

2

Einlass (Saugseite)

3

Pumpenkopf

4

Netzschalter

Abb. 2

Aufbau N 811 K_.18

1Auslass (Druckseite)

2

Einlass (Saugseite)

3

Pumpenkopf

4

Netzschalter

Abb. 3

1 Outlet valve

2 Inlet valve

3 Transfer chamber

4 Diaphragm

5 Eccentric

6 Connecting rod

7 Pump drive

Mini-Laborpumpen N 86.18, N 811.18 Aufbau und Funktion

Original-Original-Betriebsanleitung, deutsch, KNF121435-121437 04/18 13

Funktion Membranpumpe

1Auslassventil

2

Einlassventil

3

Förderraum

4

Membrane

5

Exzenter

6

Pleuel

7

Pumpenantrieb

Abb. 4: Pumpenkopf

Membranpumpen fördern, komprimieren (je nach Ausführung) und

evakuieren Gase und Dämpfe.

Die elastische Membrane (4) wird durch den Exzenter (5) und den

Pleuel (6) auf und ab bewegt. Im Abwärtshub saugt sie das zu

fördernde Gas über das Einlassventil (2) an. Im Aufwärtshub

drückt die Membrane das Medium über das Auslassventil (1) aus

dem Pumpenkopf heraus. Der Förderraum (3) ist vom Pumpenan-

trieb (7) durch die Membrane hermetisch getrennt.

DE

EN

FR

ES

IT

Diaphragm pumps transfer, compress (depending on pump version) and evacuate gases and vapours.

The elastic diaphragm (4) is moved up and down by the eccentric (5) and the connecting rod (6).

In the downward stroke it aspirates the gas to be transferred via the inlet valve (2). In the upward

stroke, the diaphragm presses the medium out of the pump head via the outlet valve (1). The

transfer chamber (3) is hermetically separated from the pump drive (7) by the diaphragm.

Fig. 2

Fig. 3 Pump Head

10

Function Diaphragm Pump

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

6 .Installation and connection

Only install and operate the pumps under the operating parameters and

conditions described in chapter 4, Technical data.

Observe the safety precautions (see chapter 3).

6.1. Installation

►Before installation, store the pump at the installation location to

bring it up to room temperature.

►See chapter 4, Technical data, for the dimensions of pump.

►Install the pump so that the motor fan can intake sufficient

cooling air.

►Make sure that the installation location is dry and the pump is

protected against rain, splash, hose and drip water.

► Choose a safe location (flat surface) for the pump.

►Protect the pump from dust.

►Protect the pump from vibration and jolt.

6.2. Connection

►Only connect components to the pump which are designed for the

pneumatic data of the pump (see chapter 4).

►If the pump is used as a vacuum pump, safely discharge the pump

exhaust at the pump’s pneumatic outlet.

iA marking on the pump head shows the direction of flow.

1. Remove the protective plugs from the pneumatic connectors of the pump.

2. Mount accessory parts filter or silencer (if present).

iIf the pump is used as a vacuum pump, mount a silencer at the

pressure side if necessary. If the pump is used as compressor, mount

a filter at the suction side if necessary.

Before mounting the filter or silencer, unscrew the corresponding

hose connector from the threads in the pump head.

3. Connect the suction line and pressure line.

4. Lay the suction and pressure line at a downward angle to prevent

condensate from running into the pump.

5. Insert the power cable’s plug into a properly installed shockproof socket.

11

Dimensions

Cooling air supply

Installation location

Connected components

Pump exhaust

Connection

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

Operational requirements

Pump All hoses attached properly

Fan openings not blocked

Specifications of the power supply correspond with

the data on the pump’s type plate.

The pump outlet is not closed or constricted.

7 .Operation

7.1. Installation

Before switching on the pump, observe the following points:

7.2. Starting

►Only operate the pump under the operating parameters and conditions

described in chapter 4, Technical data.

►Make sure the pump is used properly (see chapter 2.1).

►Make sure the pump is not used improperly (see chapter 2.2).

►Observe the safety precautions (see chapter 3).

Table. 6

WARNING

Hazard of the pump head bursting due to excessive

pressure increase

►Do not exceed max. permissible operating pressure

(see chapter 4).

►Monitor pressure during operation.

►If the pressure exceeds the maximum permissible

operating pressure, immediately shut down pump and

eliminate fault (see chapter 9. Troubleshooting).

►

Only throttle or regulate the air or gas quantity in the suction

line to prevent the maximum permissible operating pressure

from being exceeded.

►If the air or gas quantity in the pressure line is throttled or

regulated, make sure that the maximum permissible

operating pressure of the pump is not exceeded.

i

Excessive pressure (with all of the related hazards) can be prevented by placing

a bypass line with a pressure-relief valve between the pressure and suction side

of the pump. For further information, contact your SLS technical adviser.

► With the pump at a standstill, open pressure and suction lines to normal

atmospheric pressure.

12

Pump standstill

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

WARNING

Automatic starting can cause personal injury and

pump damage

When the operation of the pump is interrupted by the

thermal switch, the pump will restart automatically

after cooling down.

►After triggering of the thermal protection or in the event of

power failure, remove the pump’s mains plug from the

socket so that the pump cannot start uncontrollably.

►Attempt work on the pump only if the pump is separated

from mains power.

7.3. Switching pump on and off

Switching pump on

iThe pump may not start up against pressure or vacuum during

switch-on. This also applies in operation following a brief power failure.

If a pump starts against pressure or vacuum, it may block. This

activates the thermal switch, and the pump switches off.

►Make sure that no vacuum or pressure is present in the lines

during switch-on.

►Switch on pump with mains switch (see fig. 2).

Switching off the pump/removing from operation

►When transferring aggressive media, flush the pump prior to switch-off

to increase the service life of the diaphragm (see chapter 8.2.1).

►Switch off pump with mains switch (see fig. 2).

►Open pressure and suction lines to normal atmospheric pressure.

►Disconnect the power source.

13

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

8 . Servicing

Component Servicing interval

Pump Regular inspection for external damage or leaks

Filter (Accessory) Replace if it is dirty

Diaphragm and valve plates/sealings (valve plates) Replace at the latest, when pump output decreases

8.1. Servicing Schedule

Table. 7

8.2. Cleaning

iWhen cleaning, make sure that no liquids enter the inside of

the housing.

8.2.1. Flushing Pump

►Before switching off the pump, flush it with air (if neccesary for safety

reasons: with an inert gas) for about five minutes under

atmospheric conditions (ambient pressure).

8.2.2. Cleaning Pump

►As far as possible, clean the parts with a dry cloth.

►Only use solvents for cleaning if the head materials cannot be

attacked (check the resistance of the material!).

►If compressed air is available, blow out the components.

8.3. Changing Diaphragm and Valves

►Pump is switched off and mains plug is removed from the socket

►Pump is clean and free of hazardous materials

►Tubes removed from pump’s pneumatic inlet and outlet

►Always replace diaphragm and valve plates together to maintain

the pump performance.

Conditions

Spare part/tool

Information on

procedure

Spare part/tool

Service Set (according to chapter 10)

Philips-head screwdriver No. 1

Small screwdriver, blade width 0.5 mm

Pencil

Table. 8

14

WARNING

Health hazard due to dangerous substances in the pump!

Depending on the substance transferred, caustic burns or

poisoning are possible.

►Wear protective clothing if necessary, e.g. protective gloves.

► Flush pump before replacing the diaphragm and

valve plates (see chapter 8.2.1).

Removing pump head

1. Mark the position of head plate (Fig. 4 (3), cover (5) and

cover plate (6) by a drawing line with a pencil. This helps

to avoid incorrect assembly later.

2. Undo the 4 screws (4) in the head plate (3) and lift the

head plate together with cover (5) off the pump housing.

3. Mark the position of intermediate plate (fig. 5 (2) and housing (1)

relative to each other by a drawing line with a pencil.

4. Lift intermediate plate (2) off the housing (1).

Change diaphragm

1. Using a small screwdriver, between the housing (1) and

the outer edge of the diaphragm (9), carefully lever the edge of

the diaphragm lightly upwards

2. Grip the diaphragm (9) on opposite sides, unscrew it

about two turns (anti-clockwise).

3. Hold the pump with one hand, so that the head is pointing

downwards. Turn the diaphragm (9) anti-clockwise to unscrew it.

4. Take the diaphragm support (10) and diaphragm spacer(s)

(11) off the threaded portion of the diaphragm (9) and retain them.

5. Check that all parts are free from dirt and clean them if

necessary (see chapter 6. Cleaning).

6. Put the diaphragm support (10) and diaphragm spacer(s)(11),

in that order, on the threaded portion of the new diaphragm (9).

7. Screw the new diaphragm (9) complete with diaphragm

support (10) and diaphragm spacer(s) (11) into the connecting

rod (clockwise) and tighten it by hand.

Instandhaltung Mini-Laborpumpen N 86.18, N 811.18

18 Original-Original-Betriebsanleitung,deutsch, KNF121435-121437 04/18

WARNUNG

Gesundheitsgefährdung durch gefährliche

Sto

ffe in der Pumpe

Je nach gefördertem Stoff sind Verätzungen oder

Vergi

ftungen möglich.

Bei Bedarf Schutzausrüstung tragen, z. B.

Schutzhandschuhe.

Pumpe vor dem Wechsel von Membrane und

Ventilplatten spülen (siehe Kapitel 8.2.1).

Pumpenkopf abmontieren

1. Kopfdeckel (Abb. 5/3), Abdeckung (5) und Gehäusede-

ckel (6) mit einem durchgehenden Bleistiftstrich markie-

ren. Damit lässt sich ausschließen, dass die Teile beim

späteren Zusammenbau falsch montiert werden.

2. Die vier Kopfdeckelschrauben (4) lösen und den Kopf-

deckel (3) zusammen mit der Abdeckung (5) vom Pum-

pengehäuse abnehmen.

3. Zwischenplatte (Abb. 6/2) und Gehäuse (1)durch einen

durchgehenden Bleistiftstrich markieren.

4. Zwischenplatte (2)von Gehäuse (1)abnehmen.

Membrane wechseln

1. Mit einem kleinen Schraubendreher vorsichtig zwischen

Gehäuse (1) und dem äußeren Rand der Membrane (9)

einfahren; Membranenrand leicht hochhebeln.

2. Die Membrane (9) an den gegenüberliegenden Seiten-

rändern anheben, fassen und gegen den Uhrzeigersinn

etwa zwei Umdrehungen herausdrehen.

3. Pumpe derart in eine Hand nehmen, dass Pumpenkopf

nach unten zeigt. Membrane (9) gegen den Uhrzeiger-

sinn vollständig herausdrehen.

4. Stützkelch (10) und Passscheibe(n) (11) vom Gewinde-

bolzen der Membrane (9) abnehmen und aufbewahren.

5. Alle Teile auf Verunreinigung kontrollieren und gegebe-

nenfalls reinigen (siehe hierzu Kapitel 6. Reinigung).

6. Stützkelch (10) und Passscheibe(n) (11) auf den Gewin-

debolzen der neuen Membrane (9) schieben.

7. Die neue Membrane (9) mit Stützkelch (10) und Pass-

scheibe(n) (11) auf den Pleuel schrauben (im Uhrzeiger-

sinn) und handfest anziehen.

Abb. 5: Pumpenkopf

abmontieren

Abb. 6: Pumpenkopf

Instandhaltung Mini-Laborpumpen N 86.18, N 811.18

18 Original-Original-Betriebsanleitung,deutsch, KNF121435-121437 04/18

WARNUNG

Gesundheitsgefährdung durch gefährliche

Sto

ffe in der Pumpe

Je nach gefördertem Stoff sind Verätzungen oder

Vergi

ftungen möglich.

Bei Bedarf Schutzausrüstung tragen, z. B.

Schutzhandschuhe.

Pumpe vor dem Wechsel von Membrane und

Ventilplatten spülen (siehe Kapitel 8.2.1).

Pumpenkopf abmontieren

1. Kopfdeckel (Abb. 5/3), Abdeckung (5) und Gehäusede-

ckel (6) mit einem durchgehenden Bleistiftstrich markie-

ren. Damit lässt sich ausschließen, dass die Teile beim

späteren Zusammenbau falsch montiert werden.

2. Die vier Kopfdeckelschrauben (4) lösen und den Kopf-

deckel (3) zusammen mit der Abdeckung (5) vom Pum-

pengehäuse abnehmen.

3. Zwischenplatte (Abb. 6/2) und Gehäuse (1)durch einen

durchgehenden Bleistiftstrich markieren.

4. Zwischenplatte (2)von Gehäuse (1)abnehmen.

Membrane wechseln

1. Mit einem kleinen Schraubendreher vorsichtig zwischen

Gehäuse (1) und dem äußeren Rand der Membrane (9)

einfahren; Membranenrand leicht hochhebeln.

2. Die Membrane (9) an den gegenüberliegenden Seiten-

rändern anheben, fassen und gegen den Uhrzeigersinn

etwa zwei Umdrehungen herausdrehen.

3. Pumpe derart in eine Hand nehmen, dass Pumpenkopf

nach unten zeigt. Membrane (9) gegen den Uhrzeiger-

sinn vollständig herausdrehen.

4. Stützkelch (10) und Passscheibe(n) (11) vom Gewinde-

bolzen der Membrane (9) abnehmen und aufbewahren.

5. Alle Teile auf Verunreinigung kontrollieren und gegebe-

nenfalls reinigen (siehe hierzu Kapitel 6. Reinigung).

6. Stützkelch (10) und Passscheibe(n) (11) auf den Gewin-

debolzen der neuen Membrane (9) schieben.

7. Die neue Membrane (9) mit Stützkelch (10) und Pass-

scheibe(n) (11) auf den Pleuel schrauben (im Uhrzeiger-

sinn) und handfest anziehen.

Abb. 5: Pumpenkopf

abmontieren

Abb. 6: Pumpenkopf

Fig. 4 Removing pump head

Fig. 5 Pump Head

15

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

Changing the valve plates/sealings

1. Remove the valve plates/sealings (fig. 4 (7) from the intermediate

plate (2).

2. Check that the valve seats, the head plate (3) and intermediate

plate (2) are clean. If scratches or distortion are evident on these

parts they should be replaced.

3. Lay the new valve plates/sealings (7) in the recesses in the

intermediate plate (2). The valve plates/sealings for suction and

pressure sides are identical, as are upper and lower sides of the valve

plates/sealings.

4. Check that the valve plates/sealings (7) are not deformed by

moving them gently sideways in their recesses.

5. Dispose of the old diaphragm and valve plates/sealings properly.

Refitting pump head

1. Place the intermediate plate (2), with valve plates/sealings (7) on the

housing, in the position indicated by the drawing line.

2. Place the head plate (3) with cover (fig. 4 (5) on the housing (fig. 5 (1),

in the position indicated by the drawing line.

3. Check that the head plate (3) is centred by moving it gently sideways.

4. Tighten the screws (4), evenly and diagonally, first gently, then firmly.

Final steps

1. Reconnect suction and pressure line to the pump.

2. Reconnect the pump to the electricity supply.

If you have any question about servicing call your SLS technical

adviser (see last page for contact telephone number).

16

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

WARNING

Extreme danger from electrical shock!

►Disconnect the pump power supply before working

on the pump.

►Make sure the pump is de-energized and secure.

►Check the pump (see Tab. 9 to 12).

Pump produces no flow

Cause Fault remedy

No voltage in the power source ►Check room fuse and switch on if necessary.

Thermal switch has operated following to over-heating.

►Disconnect pump from mains.

►Allow pump to cool.

►Trace cause of over-heating and eliminate it.

Connections or lines blocked. ►Check connections and lines.

►Remove blockage.

External valve is closed or filter is clogged. ►Check external valves and filters.

Condensate has collected in pump head. ►Detach the condensate source from the pump.

►Flush pump (see chapter 8.2.1).

Diaphragm or valve plates/sealings (valve plates)

are worn.

► Replace diaphragm and valve plates/sealings

(valve plates) (see chapter 8.3).

9 .Troubleshooting

Flow rate, pressure or vacuum too low

The pump does not achieve the output specified in the Technical data or the data sheet.

Cause Fault remedy

Condensate has collected in pump head. ►Detach the condensate source from the pump.

►Flush pump (see chapter 8.2.1).

There is gauge pressure on pressure side and at

the same time vacuum or a pressure above

atmospheric pressure on suction side.

►Change the pressure conditions.

Pneumatic lines or connection parts have an

insufficient cross section.

►Disconnect pump from system to determine

output values.

►Eliminate throttling (e.g. valve) if necessary.

►Use lines or connection parts with larger cross

section if necessary.

Leaks occur on connections, lines

or pump head.

►Check that tubes sit correctly on hose nozzles.

►Replace leaky tubes.

►Eliminate leaks.

Table. 9

17

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

Flow rate, pressure or vacuum too low

The pump does not achieve the output specified in the Technical data or the data sheet.

Cause Fault remedy

Connections or lines completely or

partially jammed.

►Check connections and lines.

►Remove the jamming parts and particles.

Head parts are soiled. ►Change the pressure conditions.

Diaphragm or valve plates/sealings (valve plates)

are worn.

►Replace diaphragm and valve plates/sealings,

(valve plates) (see chapter 8.3).

After diaphragm and valve plates/sealings (valve

plates) have been replaced.

►Check that the spacers have been replaced onto

the diaphragm screw thread.

►Check head connection and hose connections

for leaks.

►Possibly carefully tighten the outer screws of

the top plate crosswise.

Table. 10

18

Pump is switched on, but does not run, the on/off-switch on the pump is not lit

Cause Fault remedy

Pump is not connected with the power source. ►Connect pump to mains power.

No voltage in the power source. ►Check room fuse and switch on if necessary.

Fuse in the pump is defective. ►Remove pump’s mains plug from the socket.

►Loosen marked lid on underside of the pump.

►Select and replace suitable fuse (see chapter 4).

Table. 11

Pump is switched on, but does not run, the on/off-switch on the pump is lit

Cause Fault remedy

The thermal switch has opened due to overheating

►Remove pump´s mains plug from the socket.

►Allow pump to cool.

►Trace cause of over-heating and eliminate it.

Table. 12

SLS Lab Basics Mini Vacuum Pumps SLS2600/2602

10 . Spare parts and accessories

10.1. Spare parts

A Service Set contains all spare parts needed for one complete service.

►For pump range SLS2600/2602:

1 diaphragm, 2 valve plates/sealings.

Service Set for pump type: Order-No.:

SLS2600 043241

SLS2602 043242

Table. 13

Fuses

Each pump contains two fuses.

Pump range Order-No. fuse (1 piece)

SLS2600/2602 – 230V 025250

SLS2600/2602 – 115V 020085

SLS2600/2602 – 100V 020085

Table. 14

10.1. Accessories

Description Order-No.:

Silencer 000345

Filter 000346

Hose connector PVDF 025671

Table. 15

19

United Kingdom:

International:

Northern Ireland:

Republic of Ireland:

SLS Lab Basics

Mini Vacuum Pumps

Our Knowledge + Your Equipment = Service Tailored to You

Clarity in Servicing

Our service options:

Fault Find & Fix

With service prices starting at just £17.95,

the Fault Find & Fix Service will collect your

benchtop laboratory equipment, diagnose the

faults and repair them

Service Contracts

For business critical equipment where

continual operation is a priority, we offer

annual preventative maintenance contracts

Pipette Servicing

As an independent channel partner to a vast

range of liquid handling solutions, we offer

pipette servicing solutions for an extensive

range of brands

On-Site Repairs

For an agreed fee, the SLS Service Centre

will dispatch an engineer to your site to

evaluate your equipment and diagnose

potential repairs.

To book your service or for further information

please contact us…

Email:

servicecentr[email protected]

Telephone:

0115 977 5075

Website:

www.scientificlabs.co.uk/servicecentre

SERVICE

CENTRE

Website: www.scientificlabs.co.uk/servicecentre

Clarity in Servicing

Our service options:

Plan ahead for fewer disruptions and greater productivity.

Keep your lab running smoothly with the SLS Service Centre.

To book your service or for further information

please contact us…

Email:

Telephone:

0115 977 5075

Repair

Calibration

Spare Parts

Training

Validation

Maintenance

Qualification

Installation

Project Design

& Management

Project Design & Management

Installation

Qualification

Repair

Maintenance

Calibration

Validation

Spare Parts

Training

SERVICE

CENTRE

Scientific Laboratory Supplies Ltd

Wilford Industrial Estate

Ruddington Lane

Wilford

Nottingham

NG11 7EP

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Agilent Technologies

Agilent Technologies VS PD03 installation instructions

Ulvac

Ulvac MBS-053 instruction manual

Metabo

Metabo HWA 5500 M Original operating instructions

pumpa

pumpa BLUE LINE 3SKM 100 Translation of the original instruction manual

Simplex

Simplex PAM Series Operating & maintenance instructions

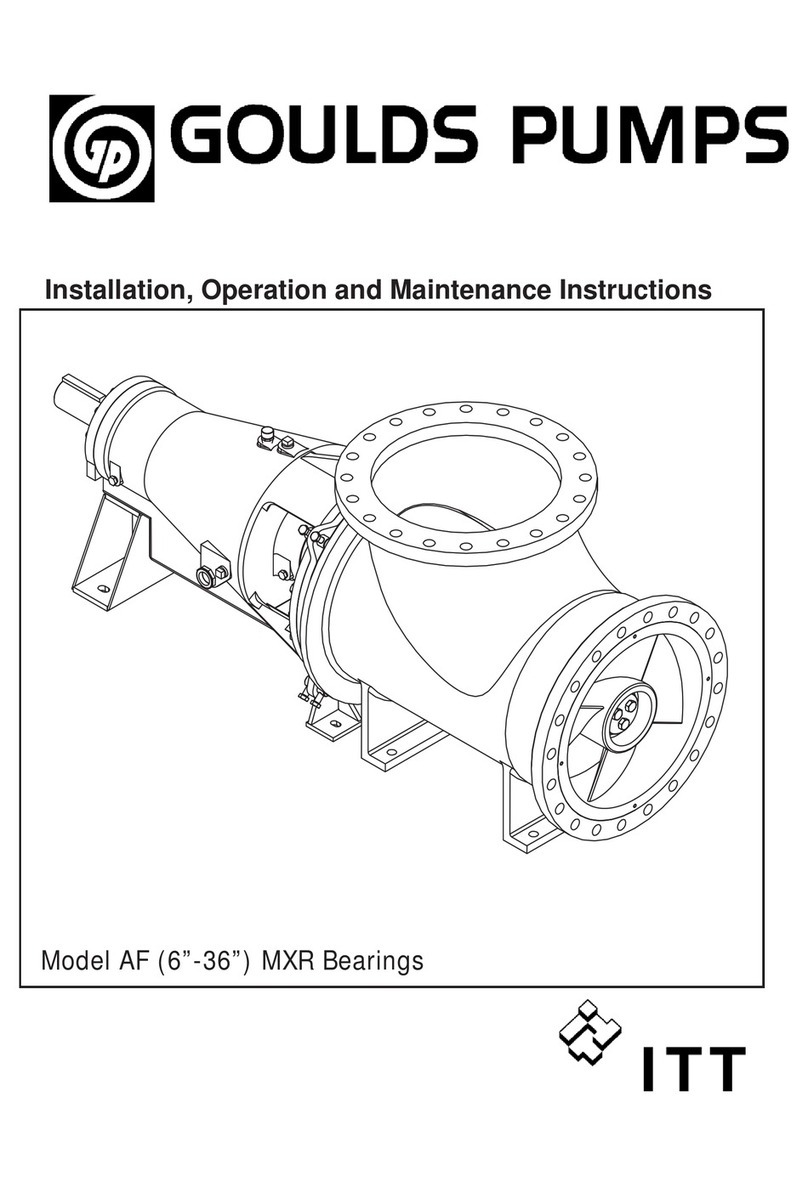

ITT

ITT Goulds Pumps AF Installation, operation and maintenance instructions