SLT Tactic TTX850 User manual

TTX850

TM

Tactic’s TTX850 computer transmitter uses

the advanced 2.4GHz spread spectrum SLT

“Secure Link Technology” protocol for solid,

interference-free control of R/C models. A

large backlit LCD, wired and wireless trainer

systems, 30 model memories, plus advanced

programming options are just a few of the

benefits which can be used for models of all

sizes. Tactic 2.4GHz transmitters are compat-

ible only with Tactic brand receivers and

those utilizing the SLT protocol.

2.4GHz 8-CHANNEL

COMPUTER RADIO

INSTRUCTION MANUAL

For safe operation and

best results, it’s strongly

recommended to read

this manual in its entirety before

use! Also read and understand the

instructions included with the model.

Damage resulting from misuse or

modification will void your warranty.

™

2

TABLE OF CONTENTS

SLT TECHNOLOGY, Tx-R, AND

COMPATIBLE RECEIVERS . . . . . . . . . . . . . 3

RECEIVER INSTALLATION . . . . . . . . . . . . . . . . 3

TTX850 POWER SYSTEM . . . . . . . . . . . . . . . . . 4

Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Charge Jack and Charging

Rechargeable Batteries . . . . . . . . . . . . . 4

Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FLIGHT CONTROLS. . . . . . . . . . . . . . . . . . . . . . 4

Gimbal Sticks. . . . . . . . . . . . . . . . . . . . . . . . . 5

Stick Tension and Throttle Ratchet . . . . . . . . 5

Case Separation and Assembly . . . . . . . . . . 5

Digital Stick Trims . . . . . . . . . . . . . . . . . . . . . 6

Toggle Switches. . . . . . . . . . . . . . . . . . . . . . . 6

LCD, PROGRAMMING CONTROLS,

MENU NAVIGATION . . . . . . . . . . . . . . . . . . 7

MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SYSTEM SETUP . . . . . . . . . . . . . . . . . . . . . . . . . 7

User Name. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Stick Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Speaker Volume. . . . . . . . . . . . . . . . . . . . . . . 8

Battery Alarm . . . . . . . . . . . . . . . . . . . . . . . . . 8

Vibration Power . . . . . . . . . . . . . . . . . . . . . . . 8

Back Light . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MODEL SETUP MENU – AIRPLANES. . . . . . . . 8

Model Select . . . . . . . . . . . . . . . . . . . . . . . . . 8

Model Management . . . . . . . . . . . . . . . . . . . . 9

Wing Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Channel Assignments . . . . . . . . . . . . . . . . . .11

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Trainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Trim Step Setting . . . . . . . . . . . . . . . . . . . . . 12

SETTINGS MENU – AIRPLANES . . . . . . . . . . 12

Servo Set . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dual-Rates, Exponential . . . . . . . . . . . . . . . 13

CH 5-CH 8 Set. . . . . . . . . . . . . . . . . . . . . . . 13

Throttle Curve . . . . . . . . . . . . . . . . . . . . . . . 14

Throttle Cut . . . . . . . . . . . . . . . . . . . . . . . . . 15

Advanced Gyro Gain . . . . . . . . . . . . . . . . . . 15

Aileron Mixer . . . . . . . . . . . . . . . . . . . . . . . . 16

Rudder Mixer . . . . . . . . . . . . . . . . . . . . . . . . 16

Aileron Differential . . . . . . . . . . . . . . . . . . . . 16

Flap Mixer . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air Brake Set . . . . . . . . . . . . . . . . . . . . . . . . 17

Programmable Mixer . . . . . . . . . . . . . . . . . . 17

RF Output . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Camera Gimbal . . . . . . . . . . . . . . . . . . . . . . 18

Digital Switch Assignments . . . . . . . . . . . . . 18

MODEL SETUP MENU – HELICOPTERS . . . . 19

Swashplate Type . . . . . . . . . . . . . . . . . . . . . 19

SETTINGS MENU – HELICOPTERS . . . . . . . . 19

Throttle Curve . . . . . . . . . . . . . . . . . . . . . . . 19

Throttle Hold . . . . . . . . . . . . . . . . . . . . . . . . 20

Pitch Curve . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pitch Curve Hold . . . . . . . . . . . . . . . . . . . . . 20

Swashplate Ring . . . . . . . . . . . . . . . . . . . . . 20

Throttle Mixer . . . . . . . . . . . . . . . . . . . . . . . . 20

Swashplate Mixer. . . . . . . . . . . . . . . . . . . . . 21

Cyclic Mixer . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rudder Mixer . . . . . . . . . . . . . . . . . . . . . . . . 21

MODEL SETUP – MULTI-ROTORS . . . . . . . . . 21

SETTINGS MENU – MULTI-ROTORS . . . . . . . 21

LINK THE Rx TO THE Tx . . . . . . . . . . . . . . . . . 21

FAILSAFE FUNCTION . . . . . . . . . . . . . . . . . . . 21

WIRELESS TRAINER . . . . . . . . . . . . . . . . . . . . 22

WIRED TRAINER . . . . . . . . . . . . . . . . . . . . . . . 24

RANGE TEST . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FIRMWARE UPDATES . . . . . . . . . . . . . . . . . . . 24

WARNING INDICATIONS . . . . . . . . . . . . . . . . . 25

SYSTEM CHECK AND OPERATION . . . . . . . . 25

FLYING THE AIRCRAFT. . . . . . . . . . . . . . . . . . 26

IMPORTANT WARNINGS

AND PRECAUTIONS . . . . . . . . . . . . . . . . . 26

TTX850 SPECIFICATIONS . . . . . . . . . . . . . . . . 27

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . 27

SAFETY GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . 28

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . 28

FCC STATEMENT . . . . . . . . . . . . . . . . . . . . . . . 29

INDUSTRY CANADA NOTICE . . . . . . . . . . . . . 29

CE COMPLIANCE INFORMATION

FOR THE EUROPEAN UNION . . . . . . . . . 30

1-YEAR LIMITED WARRANTY. . . . . . . . . . . . . 30

3

Neck

Strap

Eyelet

Power

Switch

LED Power

Indicator

LCD

Pushbuttons

Carrying

Handle

Toggle

Switches

Charge

Jack

Trim

Levers

Battery Connector Socket

Firmware

Upgrade

Jack

Firmware

Upgrade

Jack

Accessory

Port

Accessory

Port

Side

Lever

Side

Lever

SLT technology ensures that transmitters emit a strong, clear, frequency-hopping

2.4GHz signal, and that your compatible receiver accepts no signal except yours.

Linking Tactic brand receivers is as simple as pushing a button, which creates a

locked-in, interference free link. The TTX850 is also compatible with non-Tactic

brand receivers which use the *SLT protocol, for the ultimate in convenience and flexibility.

* Make sure optional receivers have the genuine SLT protocol before use with the TTX850.

The TTX850 is also compatible with all transmitter-ready aircraft bearing the

“Tx-R” logo. Such aircraft include receivers having the SLT protocol.

Always mount the optional receiver, servos, switch harness, battery, electronic speed control, etc. as explained

in the manual included with such equipment and/or the model. Keep the Rx and its antenna(s) as far away

from the engine/motor, servos, and ESC and other electronic items as possible. It may also be a good idea

to mount the Rx inside certain models using Velcro,

®and wrap it in foam rubber to prevent damage from

strong vibrations or crash damage (except in extremely warm environments). It’s best to have as few items

surrounding the receiver’s antenna tips as possible inside the model, to allow for the most obstruction-free

signal path to the transmitter. Exposing the receiver’s antenna tip outside the model is recommended if

possible. For receivers with two antennas, position the antennas at 90 degree angles with the tips resting

at least 5 inches apart. If possible, allow one antenna to point vertically above the receiver itself.

SLT TECHNOLOGY, Tx-R, AND COMPATIBLE RECEIVERS

™

TM

RECEIVER INSTALLATION

4

INPUT POWER

One assembled 4.8V 1000mAh nickel-metal hydride (NiMH) battery pack is included. Optional 1.2V NiCd

or 1.5V alkaline batteries can be used with an optional 4-cell flat battery holder with universal connector.

Do not mix cell types, or old and new cells, etc.

Battery voltage is shown on the LCD’s home screen for easy monitoring. A “LOW BATTERY” warning will

show when battery power drops to the voltage value shown in the BATTERY ALARM screen as described

on page 8.

WARNING! Never operate an R/C model with weak Tx batteries! Reduced operational

range and/or possible loss of control of the aircraft could result. Replace weak alkaline

batteries, or re-charge NiCd or NiMH batteries, before attempting a flight!

A “Tx Battery” timer in the TIMER menu described on page 18 can track the total amount of time the

transmitter has been operational.

See the ACCESSORIES section on page 28 for optional batteries and chargers available at local hobby

retailers.

CHARGE JACK AND CHARGING RECHARGEABLE BATTERIES

The charge jack should only be used for rechargeable batteries. Do not try to

recharge alkaline batteries. Charge adapters for Futaba

®

brand transmitters are

compatible, with the center pin being positive polarity. The Tx power switch must

be in the OFF position to recharge batteries. For depleted batteries, connect

the included TC100 charger to the Tx charge jack and allow to charge for 10 to

12 hours. Charge is being delivered to the battery when the charger’s LED is red. The battery is fully charged

when this LED is green, and the charger should be disconnected. Do not allow charger to remain connected

indefinitely. Do not charge batteries at greater than 1 amp. Cycling of the Tx batteries can be accomplished

through this jack. Misuse, improper charging, or over-charging of rechargeable cells can result in damage

to the cells that could include cell rupture, explosion, or fire!!

WARNING! Do not accidentally short circuit the terminals inside the charge jack, as

this can cause permanent damage to the radio’s charge circuitry and battery and void

the warranty.

POWER LED

The blue LED illuminates when the power switch is turned on and ample voltage is supplied by the battery.

This LED will flash if battery voltage drops to the voltage set in the BATTERY ALARM setting described

on page 8.

All channels are fully proportional, depending if controlled by a switch or mixed to another proportional

channel. Channels 5-8 can be controlled by a non-proportional switch or proportional side lever. However,

if a proportional channel (1-4) is mixed to channel 5-8 these channels can provide proportional control.

Aircraft control is accomplished through various devices by the pilot (sticks, switches, etc.), and other control

inputs can be manipulated electronically by the Tx to alter the control signals before they are delivered to the

TTX850 POWER SYSTEM

TTX850 Charge Jack

FLIGHT CONTROLS

5

receiver (mixes, exponential, etc.). Some electronic functions can be turned on/off by the pilot during flight

such as a timer. Other functions can only be altered while the model is on the ground, such as changing

travel limits or reversing for a particular channel.

For multi-rotors, sideways movement of the aileron control (right stick for radios set on mode 2) controls

right / left movement. Up/down movement of the elevator control (right stick for mode 2) controls forward/

backwards movement. Pushing the stick towards the Tx handle moves the nose of the model forward; pulling

the stick down away from the handle moves the nose of the model backwards. Up/down movement of the

throttle control (left stick for mode 2) increases motor speed (RPM) and controls the up / down movement.

Pushing the stick up (towards the Tx handle) moves the model up vertically. Pulling the stick down (away

from the handle) moves the model downward. Sideways movement of the rudder control (left stick for mode

2) controls clockwise/counter-clockwise rotation of the model.

GIMBAL STICKS

Ball-bearing construction allows both sticks to provide the ultimate in smooth, precise control. Stick length

can be adjusted for optimum feel and control. Each stick consists of a base and a tip. To adjust, hold the base

tightly, then loosen the tip by turning it counter-clockwise. Adjust the stick tip to the desired length. Tighten

the stick by holding the tip in place and turning the base counter-clockwise until it’s tight against the tip.

STICK TENSION AND THROTTLE RATCHET

Each control stick can be adjusted for softer or stiffer movement tension. A ratchet is also included for the

throttle stick which can be adjusted for feel depending on personal preference. Adjustment of either feature

requires removal of the rear of the Tx case as explained in the CASE SEPARATION AND ASSEMBLY

section below.

CASE SEPARATION AND ASSEMBLY

WARNING! Failure to follow these instructions for separating and re-assembling the Tx

case can result in permanent damage to the transmitter and void the warranty. Contact

Hobby Services if you do not feel comfortable that you can safely and accurately perform

these steps.

ALWAYS disconnect and remove the batteries from the battery compartment FIRST. Failure to

do so can result in permanent damage to the Tx.

Remove the six screws from the back of the Tx case. Carefully pull the case rear away from the case

front and note exactly how all wires are routed inside the case.

After adjustments are made as described in other sections of this manual, close the case by first carefully

tucking all cables back inside as when the case was opened. Align the case rear back onto the case front,

making sure that no wires are pinched between the case parts. Press the case halves together. Insert

the screws back into their positions and carefully tighten them until snug - making sure not to cross the

threads or over-tighten the screws. Re-connect the battery holder’s connector to the socket inside the

Tx. Insert the battery into the compartment, and carefully tuck the wires inside the cavity so they do not

become pinched when the door is closed. Close the battery door.

6

STICK TENSION: Silver screws on the

back of each gimbal are used to adjust the

stick tension. Turn the screw clockwise to

make stick tension more firm. Turn the

screw counter-clockwise to make stick

tension more light.

THROTTLE RATCHET: A silver ratchet

bar is mounted across the throttle gimbal.

For smooth throttle feel for helicopter use,

you may wish to remove this bar. Remove

both screws which hold the ratchet bar then

remove the bar.

DIGITAL STICK TRIMS

The trim controls for the four main

channels are digital. Holding the trim

lever will cause the servo output to move

repeatedly. Trim positions are visible

on the LCD’s home screen, and stored

into that respective memory. Changing

the model memory will also cause trim

settings to change accordingly.

For aircraft with glow engines, the precise

position of the trim lever is helpful when determining the engine’s preferred idle point. When the throttle

stick is above 50% full throttle it will not be possible to trim the throttle servo – even though the indicator

on the LCD will move.

The amount of servo movement for each increment of a digital trim can be adjusted as desired, as explained

in the TRIM STEP SETTING section on page 12.

TOGGLE SWITCHES

Each switch can be assigned to control one of a variety of functions as desired and described throughout

this manual. The identification of each switch by letter is marked on the Tx. The factory default switch

assignments are as follows:

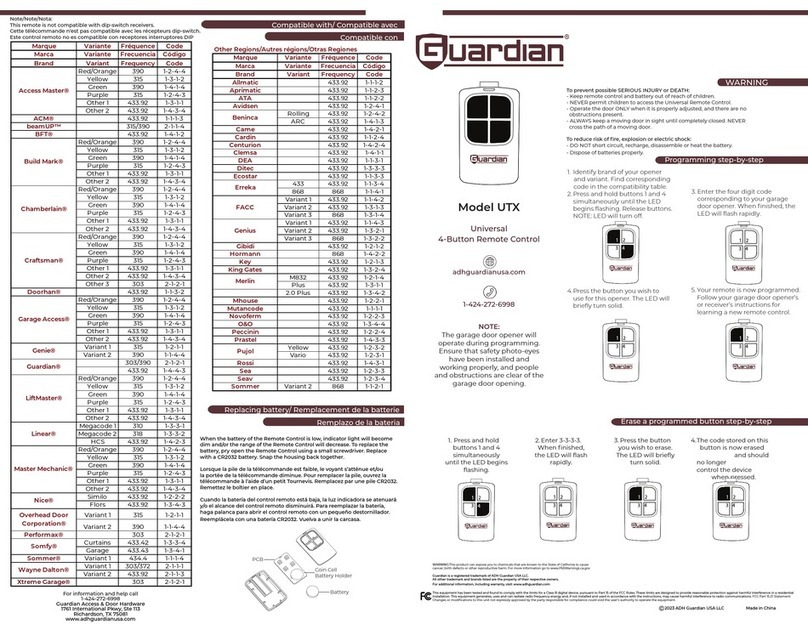

A

B

C

D

E

F

G

H

I

J

Switch

3-position

3-position

3-position

3-position

3-position

2-position mom.

3-position

2-position

Sweep Lever

Sweep Lever

Type

Elevator D/R

Flaps

(no setting)

Aileron D/R

Rudder D/R

Trainer

(no setting)

(no setting)

(no setting)

(no setting)

Airplane

Default Functions

Timer Control

Gyro Gain

(no setting)

Ail/Ele/Rud D/R

Normal/Idle-up

Throttle Cut

(no setting)

Throttle Hold

(no setting)

(no setting)

Helicopter

Timer Control

Gyro Gain

(no setting)

Ail/Ele/Rud D/R

(no setting)

(no setting)

(no setting)

Throttle Hold

(no setting)

(no setting)

Multi-Rotor

Right stick,

up/down

tension

adjustment

Right stick,

sideways

tension

adjustment

Left stick,

up/down

tension

ratchet

Left stick,

sideways

tension

adjustment

7

LCD contrast and backlight intensity are adjustable for optimum viewing. Six pushbuttons navigate

the menus and settings. Single button pushes will result in a single incremental adjustment on-screen.

Holding a button for a short time will result in slow scrolling of adjustments; continued holding will result

in fast adjustments.

LEFT SIDE BUTTONS

Press any time to see the servo position screen. Indicators for certain channels will change

depending on model type, wing type, etc. Moving any Tx control will graphically be shown

on this screen. When setting / adjusting mixes to determine if the mix is as desired, set the mix and then

view this screen. Move all controls to determine if the mix moves each respective channel as needed.

Quickly resets certain values and settings back to factory defaults. Press to backspace in

the model and user name screens.

Jumps back to the previous screen, and removes certain pop-up messages from the screen.

RIGHT SIDE BUTTONS

Adjustment of values on-screen.

Moves the cursor up, and increases highlighted values/settings.

Moves the cursor down, and decreases highlighted values/settings.

To select or de-select a setting, or enter a screen. Press briefly to access the SETTINGS

menu. Press and hold to access the MODEL SETUP menu.

The TTX850 has three types of menus.

The SYSTEM SETUP menu allows for setting basic operational functions for the radio itself.

Selecting and managing the model memories, configuring the radio for the structure of the airplane, helicopter,

or multi-rotor is done in the MODEL SETUP menu. Most functions apply for all model types. Select functions

are available for certain model types only.

Setting various radio functions to control the model is done in the SETTINGS menu. Some settings apply

for all model types, while certain functions are available for certain model types only.

Fundamental settings for the transmitter itself are located in this menu. With the power switch in the OFF

position, press and hold ENTER, turn the power switch ON and wait for the SYSTEM SETUP screen to

show. Move the cursor and press ENTER to select any setting. Press and to change settings. Press

ENTER to confirm the setting.

HOME SCREENLCD, PROGRAMMING CONTROLS, MENU NAVIGATION

MENUS

SYSTEM SETUP

8

USER NAME

Enter your name to identify the radio. The cursor will be under the first character. Press ENTER to highlight

this character. Press and to find the desired character, then ENTER to confirm. The cursor will

automatically move to the next cursor. Repeat as necessary for up to 11 characters. Pressing CLEAR will

move the cursor back one space and erase the character in that space. Press ESC when finished.

STICK MODE

The TTX850 is factory set to Mode 2 configuration,

but can be changed to Mode 1, 3, or 4 as explained

below. To change modes in the programming, move

the cursor to the STICK MODE line, highlight and

press ENTER, then press or to find the

desired mode. Press ENTER to confirm.

In addition to programming changes, stick mode changes require relocation of gimbal stick parts to achieve

the proper control. Go to www.tacticrc.com and click on the TTX850 link to find directions for how to change

gimbal settings.

CONTRAST

Adjust the LCD’s contrast level for optimum viewing.

SPEAKER VOLUME

Adjust the loudness of the radio’s beeper as desired. This volume setting affects all tones that are emitted

from the radio including trim adjustments, alarms, programming changes, etc. Speaker volume for all alarms

is not adjustable.

BATTERY ALARM

An alarm will sound and the display will show a warning when the Tx battery’s voltage drops to the level

shown in this setting. Do NOT set this value too low, as the radio could lose power very rapidly as the

battery nears full discharge and cause a loss of control of the model. Land the model immediately once

this alarm has sounded!

VIBRATION POWER

Turn the vibration feedback ON or OFF.

BACK LIGHT

Adjust the intensity of the LCD’s red backlight.

Once all functions in this menu are set, press ESC to return to the home screen.

From the home screen, press and hold ENTER for 2 seconds to find the MODEL SETUP menu for setting

of fundamental operating parameters as explained here.

MODEL SELECT

Memories are available to store parameters for up to 30 different models. With this selection highlighted

press ENTER. Press or to move the cursor up/down the screen to find the desired memory to make

active, and press ENTER twice to confirm the selection and automatically return to the home screen. Or

press ESC to return to the home screen.

1

2

3

4

Mode

aileron/rudder

throttle/rudder

aileron/elevator

throttle/aileron

Left Stick

throttle/elevator

aileron/elevator

throttle/rudder

elevator/rudder

Right Stick

MODEL SETUP MENU – AIRPLANES

9

Changing the model memory is not possible if the Tx battery voltage is too low. See the INPUT POWER

section on page 4. It’s a good idea to keep a record of all settings in each memory as a backup in case

parameters in a particular memory are accidentally changed, etc.

MODEL MANAGEMENT

Shows basic information regarding the model setup

in the “Model” memory number at top-left. Move the

cursor up or down to select / change the function to

adjust, and press ENTER to adjust the function.

Name: With the cursor on this line press ENTER.

The method for setting the model name is the same

as for entering the USER NAME as described on

page 7. The maximum number of characters is eleven. Press ESC when finished.

Model Type: Press to place the cursor on this line, and ENTER to highlight the selection. Press

or to select the model type as airplane, helicopter, or quadcopter. Press ENTER to confirm.

Model Copy: To copy all parameters from one model memory to another, place the cursor at this

line and press ENTER. The “COPY FROM” page will show. Highlight the memory to copy FROM and

press ENTER. Now the “COPY TO” page will show.

Place the cursor over the memory number to copy TO, and press ENTER. The “COPY CONFIRM”

screen will show. To abandon the copy function as shown on-screen, highlight “NO” and press ENTER

to return to the “COPY TO” screen. Press ESC to return to the “MODEL MANAGEMENT” screen.

Otherwise, press to highlight “YES” and press ENTER. All settings that previously existed in the

receiving memory will be permanently erased. The display will return to the COPY TO screen. Return

to the “MODEL SELECT” screen to confirm the copy function was successful by looking at the memory

that was copied “to”.

Model Reset: Use this function to clear all parameters of any single memory except model type back

to factory defaults. Enter this screen, move the cursor over the memory to reset and press ENTER.

Select “NO” to cancel or “YES” to proceed with the reset, and press ENTER. The display will then

return to the “MODEL RESET” screen.

Wireless Transfer: To transfer all parameters

of one memory in this transmitter to another Tactic

TTX850 transmitter, move the cursor to this line and

press ENTER. Press or to select “Send” or

“Receive”. Press ENTER, then or to select

the model number to send or receive data. Press

ENTER to perform the function, or ESC to cancel.

WING TYPE

This is for setting the type of tail and wing configuration for the model. Depending on the mixes used and

setup of the aircraft, it might be necessary to change the aileron, elevator, or rudder reversing settings to

achieve the proper throw directions for the model.

For best results, selecting certain tail or wing types might require some servos to be connected

to different outputs on the receiver (not the normal channel slots). The TTX850 will automatically

map all controls accordingly. See the servo connection charts in this section for details.

TAIL SETTINGS

“Normal” is the factory default setting for the “TAIL” type. Move the cursor over “Normal”, press ENTER

then or to select from V-Tail, Delta (elevon), and 2 Elevator options. Press ENTER to confirm the

selection. The charts below can aid in determining the preferred tail and flap setting for the model.

Model :OO Name : Sensei SS1

Model Type : Airplane

Model Copy

Model Reset

Wireless Transfer

Model Management

Send OO Sensei SS1

Receive OO Sensei SS1

Transferring .

Wireless Transfer

10

Normal: One servo each is used for aileron(s), elevator(s), and rudder.

V-tail: Elevator and rudder channels are mixed. Two servos are used in the tail – one for each control

surface, with connections as shown in the graphic below. V-tail mixing controls the airplane’s “pitch”

and “yaw” axis at the same time. If the elevator and rudder functions appear reversed at the control

surfaces, it may be necessary to swap the channel 2 and channel 4 servo plug positions in the Rx. The

travel limits for each servo can be adjusted independently.

Delta wing (elevon): Elevator and aileron channels are mixed, useful for aircraft such as flying

wings and other models not having a tail. Elevon mixing controls the airplane’s “pitch” and “roll” axis at

the same time. One servo is used for each control surface. Travel limits for each servo can be adjusted

separately. If the elevator and aileron functions appear reversed at the control surfaces, it may be

necessary to swap the channel 1 and channel 2 servo plug positions at the Rx for the delta wing mix.

If the delta wing option is selected, and the “FLAP” option below is set to 2AI1FL, the elevator channel

will mix 100% to the aileron channel.

2-Elevators: Elevator channel 2 and another channel are mixed for aircraft which have two separate

servos moving separate elevator surfaces. Both elevators move independently, and are independently

adjustable for travel limits, etc. See the charts below for details.

FLAP SETTINGS

The “FLAP” setting allows for configuration of the ailerons and/or flaps of the airplane. Move the cursor over

“1AI” to select from the following options:

1AI : Use this “1 aileron”

setting for normal

wing types having

one aileron on each

wing connected with

a Y-harness or where

one servo controls the

movements of both

ailerons simultaneously.

1AI1FL : This “1 aileron

+ 1 flap” setting is for

wings having one

servo (or 2 servos

on a Y-harness) that

controls the ailerons on

both wings, and another

servo that controls the

flaps on both wings

(both servos moving

in the same direction).

Connect the aileron

servo to Rx channel 1,

and the flap servo to

channel 5 (not available for delta). See the CH5-CH8 Set section for switch assignments for flaps.

CH 2 Elevator

1AI & Normal

CH 3 Throttle

CH 4 Rudder

CH 5 Aux 1

CH 6 Aux 2

CH 7 Aux 3

CH 8 Aux 4

CH 1 Aileron

CH 2 V- tail 1

1AI & V-tail

CH 3 Throttle

CH 4 V- tail 2

CH 5 Aux 1

CH 6 Aux 2

CH 7 Aux 3

CH 8 Aux 4

CH 1 Aileron

CH 2 Elevator 1

1AI & 2 Elev

CH 3 Throttle

CH 4 Elevator 2

CH 5 Aux 1

CH 6 Rudder

CH 7 Aux 2

CH 8 Aux 3

CH 1 Aileron

CH 2 Elevator

1AI1FL & Normal

CH 3 Throttle

CH 4 Rudder

CH 5 Flap

CH 6 Aux 1

CH 7 Aux 2

CH 8 Aux 3

CH 1 Aileron

CH 2 V- tail 1

1AI1FL & V-tail

CH 3 Throttle

CH 4 V- tail 2

CH 5 Flap

CH 6 Aux 1

CH 7 Aux 2

CH 8 Aux 3

CH 1 Aileron

CH 2 Elevator 1

1AI1FL & 2 Elev

CH 3 Throttle

CH 4 Elevator 2

CH 5 Flap

CH 6 Rudder

CH 7 Aux 1

CH 8 Aux 2

CH 1 Aileron

11

CH 2 Elevator

2AI & Normal

CH 3 Throttle

CH 4 Aileron 2

CH 5 Aux 1

CH 6 Rudder

CH 7 Aux 2

CH 8 Aux 3

CH 1 Aileron 1

CH 2 V- tail 1

2AI & V-tail

CH 3 Aileron 2

CH 4 V- tail 2

CH 5 Throttle

CH 6 Aux 1

CH 7 Aux 2

CH 8 Aux 3

CH 1 Aileron 1

CH 2 Ailevator 2

2AI & Delta

CH 3 Throttle

CH 4 Rudder

CH 5 Aux 1

CH 6 Aux 2

CH 7 Aux 3

CH 8 Aux 4

CH 1 Ailevator 1

CH 2 Elevator 1

2AI & 2 Elev

CH 3 Aileron 2

CH 4 Elevator 2

CH 5 Throttle

CH 6 Rudder

CH 7 Aux 1

CH 8 Aux 2

CH 1 Aileron 1

2AI: This “2 ailerons” setting is for airplanes having one aileron servo for each wing. Connect one aileron

servo to Rx channel 1, and the other to another channel as listed in the tables above. This setting allows

each aileron servo to function independently of the other.

2AI1FL: This “2

ailerons + 1 flap” setting

is for airplanes having

two separate aileron

servos, requiring one

servo to control each

aileron, and also one

servo (or 2 servos on

a Y-harness) that will

control flaps for both

wings simultaneously

(not available for

2-elevator tail settings).

CHANNEL ASSIGNMENTS

This function allows transmitter channels to be re-

assigned to different outputs before being sent to the

receiver. This can be useful for models having unusual

configurations.

Some small electric flight models use only elevator,

throttle, and rudder channels (not aileron). Here, it’s

often preferred that the rudder be controlled with the

opposite stick (right stick for Mode 2 configurations).

Such channel re-assignment can be done in this screen.

Determine which Tx channel input on the left should control which output channel at the receiver as shown

on the right. Move the cursor to the desired output on the left. Press ENTER then or to adjust the

output channel as desired. Press ENTER when finished.

CH 2 Elevator

2AI1FL & Normal

CH 3 Throttle

CH 4 Aileron 2

CH 5 Flap

CH 6 Rudder

CH 7 Aux 1

CH 8 Aux 2

CH 1 Aileron 1

CH 2 V- tail 1

2AI1FL & V-tail

CH 3 Aileron 2

CH 4 V- tail 2

CH 5 Throttle

CH 6 Flap

CH 7 Aux 1

CH 8 Aux 2

CH 1 Aileron 1

CH 2 Ailevator 2

2AI1FL & Delta

CH 3 Throttle

CH 4 Rudder

CH 5 Flap

CH 6 Aux 1

CH 7 Aux 2

CH 8 Aux 3

CH 1 Ailevator 1

Channel Assignments

Channel1 Output1

Channel2 Output2

Channel3 Output3

Channel4 Output4

Channel5 Output5

Channel6 Output6

Channel7 Output7

Channel8 Output8

12

WARNINGS

Warnings can be set to alert you of undesireable switch or throttle positions when the radio power switch

is first turned on. For example, if the throttle is at full when the radio is turned on you would see and hear

an alarm. The alarms shown can be set to “ACT” (active) or “INH” (inhibit).

Thro Pos: The throttle position warning sounds when the throttle stick is over 25%. Clear the alarm

by moving the stick down. Note: if in heli mode and you have an idle-up programmed, this alarm will

also sound to indicate that you have an idle-up switch active.

Thro Cut: The warning will sound when the throttle cut function is set and this switch is turned on.

Turn off the switch to clear the alarm.

Thro Hold: The warning will sound when this switch is on. Turn off the switch to clear the alarm.

TRAINER

The process of linking transmitters for wireless training purposes is explained on page 22. When in training

mode with the TTX850 being used by the teacher, this radio can allow the teacher to transfer control of all

or only certain channels to the student if desired.

Enter this screen. Press or to select a channel to set. Press ENTER to toggle the setting. Repeat

with other channels as desired. Setting a channel to SLAVE means the student will have control of that

channel when the teacher pulls the trainer switch on the master radio. Those channels which are set to

MASTER will be controlled by the teacher at all times.

The teacher can select which switch will control the training function at the CTRL line at bottom. The control

positions for the trainer switch can also be selected as described on page 13 (for the Control function).

Press ESC to confirm settings and return to the MODEL SETUP menu.

TRIM STEP SETTING

The number of degrees a servo will rotate with each increment of digital trim deflection can be adjusted

from very small up to large steps. Enter this screen, select the channel trim to adjust ranging from “1” for

the smallest steps to “8” for the largest steps.

This menu is for setting servo control functions for airplane use. Press ENTER briefly to access this menu.

SERVO SET

Enter this function to adjust any channel’s reversing, travel limits, or sub-trim settings. Press or to

select the desired function to adjust and press ENTER.

Reverse: Sets the rotational direction for a channel’s output relative to the movement of the control stick.

Move the cursor to the channel to adjust. Set to “NOR” normal or “REV” reverse. Adjust all reversing

settings before making any other settings or adjustments in the programming.

Travel limits: Sets the maximum travel limits for each channel. Limits can be set for each side of

center. If two channels are mixed, adjusting the travel limits of each individual channel may be necessary

to adjust the travel limits for the entire mix. Move the cursor to the channel to adjust. Deflect the control

stick for that channel to one side and notice the cursor on-screen will move accordingly. Set the percent

for that direction of travel as needed. Move the stick to the opposite direction and repeat. Repeat for

all channels as needed.

SETTINGS MENU – AIRPLANES

13

Sub-trim: Finely adjusts a channel’s center position. Be aware that extreme adjustments of sub-trim

could possibly result in servo binding if the servo’s output arm moves too far in the model. This is

available for all channels.

DUAL-RATES, EXPONENTIAL

For setting dual-rates and/or exponential travel for the

aileron, elevator, and rudder channels. Dual-rates allows

a channel’s maximum travel limits to be switched between

two limits. Exponential changes the rate at which a servo

rotates per degree of control stick deflection. The rate of

servo movement is non-linear in relation to the movement

of the stick. The higher the exponential percentage, the

more the servo will rotate as the stick is moved away

from center position.

To select the desired channel to adjust, press ENTER, then or . Press ENTER when finished.

To assign a different switch to change the dual-rate / exponential setting, move the cursor to the CTRL line

and press ENTER. Select the switch that will control this function as explained on page 12. Press ESC

when finished.

Different dual rate and exponential settings can be set for each position of the switch. Highlight the dual-

rate percentage and move the assigned switch to the position that will allow for the furthest servo travel.

Adjust this percentage to the widest travel distance as needed for this channel. Note that the slope of the

diagonal line in the graph changes as the percent is adjusted. Deflect the control switch to the opposite

position, and adjust the percentage to the lowest travel distance needed. The diagonal line on-screen will

now show the slope for the low dual-rate setting. A high rate can allow for better control of the model while

on the ground, at low altitudes, or while performing certain maneuvers. A low rate can allow for optimum

control of the aircraft in mid-flight.

To set an exponential value, move the cursor to the EXPO line and repeat the steps explained above to

set a different value for each position of the control switch. This function reduces the sensitivity around the

stick’s center position, and can be handy for optimum control of the model - especially around center-stick

position, and when performing stunts or aerobatic maneuvers.

Moving the control stick for the channel shown on-screen will change the position of the vertical line in the

graph. The point where the vertical line intersects the diagonal line is shown at the bottom-left on the screen.

The “x” (horizontal) coordinate is on the left, and “y” (vertical) coordinate is on the right.

Repeat the above steps for each the aileron, elevator, and rudder channels as desired.

CH5-CH8 SET

Enter this screen to set the functions of channels 5 through 8. At the INPUT line select the desired

channel to adjust. Then, follow the steps below.

Name: A name for the function of this channel can be set as desired. The method for setting this

name is the same as for setting the USER NAME as described on page 8.

Control: Choose which switch will control the selected channel. Switches are identified by letters

A through H, as printed on the transmitter next to each switch.

On screen the switches will be identified as “SA” for switch A, “SH” for switch H, and so on. Deflect the

switch which will ultimately control this function.

CHANNEL: AILE

DUAL RATE:

100% 100%

EXPONENTIAL:

-65% -65%

CTRL: SD(O)

+O% -> +O%

Dual Rate, Exponential

14

The display will show a graphic representing the switch, and the different control positions of the switch

as shown here (0, 1, and 2 if applicable). The default position for “0” will always be in the up direction.

The control positions of the switch can be assigned to fit personal preference. To use the default settings,

simply press ESC to confirm. To change the control locations of the switch to be high “H”, medium “M”,

or low “L” position, press or to move the cursor to the position to be changed. Press ENTER to

highlight the function at this position. Then press or to change the control function. Repeat as

necessary for all switch positions. Press ESC when finished.

To remove the switch that has been set in the Control function, press ENTER to highlight the switch

selection and press CLEAR.

Other functions in this radio allow for assigning a switch to a specific function. Refer back to this section

as needed.

Offset: Move the cursor to this function. Press ENTER, then or to find the percent to offset

the center position of the channel shown on this screen.

Speed: When a control input for channels 5 through 8 is deflected, the speed at which the device

connected to that channel moves can be custom set. This can be useful for some accessory type

items for certain models. Move the cursor to this function. Press ENTER, then or to find the

desired speed (100% = life speed).

While the output channel is being operated normally, any movement of the input channel will be mixed

to - and also affect the movement of - the output channel.

THROTTLE CURVE

The throttle’s output is normally linear in relation to

movement of the throttle stick. A non-linear relation

between the two - or curve - can allow for optimum

power control in certain models or for specific types of

flying styles.

Make sure the model’s full throttle position can be

achieved when the throttle stick is at maximum deflection.

The throttle trim must be able to minimize throttle control completely when the throttle is at minimum.

Enter this function. Up to twelve points can be placed on the throttle curve, as designated next to “Point”

on the graph. Points L (low) and H (high) are each limited to a fixed range on the curve. Points 1, 2, 3, and

4, etc. can be set if desired with respect to the position of the throttle stick.

As the throttle stick is advanced note the point where the vertical line (throttle position) intersects the diagonal

line (curve). The coordinates of this point are shown at the bottom. The “x” (horizontal) coordinate is on the

left, and the “y” (vertical) coordinate on the right.

To set points on the curve, start at the minimum throttle position which will be noted as point “L”. A point for

“L” is not marked on the graph, but is the left-most end of the curve line. The vertical position of this point

can be adjusted by moving the cursor to the RATE percentage, press ENTER then or as desired.

Press ENTER when finished.

To set point 1 on the graph, advance the throttle stick until *shows next to “Point”. Find the desired throttle

stick position and press ENTER. A +symbol will be placed on the curve to mark this point.

Pressing or will adjust the vertical position of curve at this exact point. Adjust as desired.

POINT

RATE

CTRL

EXPO

+2%

L

25%

-----

ACT

+25%

:

:

:

:

->

Throttle Curve

15

Repeat these steps to set additional points on the graph as desired. A point for “H” is not marked on the graph,

but is the right-most end of the curve line. The vertical position of this point can be adjusted by moving the

cursor to the RATE percentage, pressing ENTER, then or buttons. Press ENTER when finished.

To clear any point on the graph, place the cursor on the RATE percent, move the throttle stick until the

graph’s vertical line intersects the point, press ENTER and then CLEAR.

A switch can be assigned to toggle between the linear curve (for starting the engine, etc.) and the user-

defined curve (for forward flight, stunts, etc.). Select the switch on the CTRL line.

The exponential control of the user-defined throttle curve (but not the linear curve) can be active or inhibited.

This will soften or make the transition of the throttle curve more smooth. Move the cursor next to the EXPO

line and toggle between “ACT” and “INH”. Press ENTER when finished.

THROTTLE CUT

Allows the throttle channel’s output to be quickly moved to a user-defined position by flipping a switch. This

is to reduce engine / motor power for safety reasons. Default setting is -100% (idle).

Select a switch to control the throttle cut function on the CTRL line. Press ESC.

The throttle cut function will only work when the throttle stick position is below the trig point. To set this point,

move the cursor next to TRIG but do not press ENTER. Move the throttle stick to the desired position that

will trigger the throttle channel to move to the cutoff position. The graph will move accordingly as will the

percent shown on the THRO line at bottom. Press ENTER. The arrow on the left will now move and mark

this selected trigger position.

Move the cursor to the CUT percentage, press ENTER and adjust this cutoff value by pressing or

to the desired position for the throttle channel’s output to move to when the throttle cut function is activated.

This position will be marked by the arrow on the right. Press ENTER to confirm this mark.

When the throttle cut switch is in the ON position and the throttle stick is positioned above the trigger mark,

reducing the throttle stick to the trigger mark will automatically drop the throttle channel to the throttle cutoff

mark. The throttle channel will remain in this position. To regain full control of the throttle channel, move

the control switch to the OFF position.

ADVANCED GYRO GAIN

This screen is for setting gain sensitivities if using a

stabilization gyro in the aircraft. Up to three sensitivity

adjustments can be set for a gyro’s X, Y, and Z axes

(if applicable).

For each respective axis, move the cursor to the rate

percentage at top and press ENTER. Adjust this value

to the desired gain sensitivity for this axis. Then move the cursor to the output channel “OUT.CH” selection

at bottom to set which channel that this sensitivity will control. A control switch can also be selected by

moving the cursor to the “CTRL” line at bottom and selecting a switch as explained earlier in the manual.

Once all gyro gain sensitivities are set press ESC to exit this screen.

NOTE: The method for setting the various following mixer screens is the same for each mixer. Refer to the

instructions for the DIFFERENTIAL mixer screen for adjustment of all other mixer screens. Any difference in

any one mixer screen will be noted accordingly. Normal wing mixing is the factory default setting. Depending

on the mixes used and setup of the aircraft, it might be necessary to change the setting of the aileron,

elevator, or rudder reversing settings to achieve the proper throw directions for the model.

Gyro X Axis

OUT.CH: -

CTRL:-----

NORM:+0%

Gyro Y Axis

OUT.CH: -

CTRL:-----

NORM :+0%

G y r o Z A x i s

OUT.CH: 5

CTRL:SB (1)

SP.0:+100%

SP.1:+75%

SP.2:+25%

Advanced Gyro Gain

16

AILERON MIXER

The aileron channel can be mixed to the rudder channel, which can be useful with certain wing/airplane types.

To make this AILE RUDD mix active at all times do NOT assign a switch at the CTRL line. Adjust the

mixture percentage and press ENTER. On/off control of this mix can be assigned to a switch. Set the mix

rates as desired for each switch position. Press ESC when finished.

RUDDER MIXER

Mixing the rudder channel to the aileron and/or elevator channels can be very useful for trimming an airplane

to be neutral when using the rudder. Select the rudder channel to mix to the aileron or elevator channels

as needed. This mix can be active at all times by not selecting a switch on the CTRL line. Or, for on/off

control of this mix, select a control switch at the bottom of the screen.

AILERON DIFFERENTIAL

Only available when 2AI and 2AI1FL wing types are selected, to help offset unwanted yaw which can occur

when ailerons are moved. One servo must be connected to each aileron for this mix. Instead of equal linear

movement between both ailerons, a differential percentage can be assigned so that the deflection of one

aileron is at a lower or higher rate than the opposite aileron. Certain applications may require a reduction

in the aileron differential rate when an airbrake is applied. This feature is useful for glider and/or sailplane

applications which use other settings to achieve “butterfly” or “crow” functionality.

Enter the DIFFERENTIAL function. There are two ways to control the mix. One is to make the mix be active

at all times. Another is to control the mix with an otherwise unused switch.

Normal: To make AILE DIFFERENTIAL active at all times do NOT assign a switch at the CTRL line.

Press ENTER to highlight the differential rate percent and press or to find the desired value.

Press ENTER when finished.

Switch Control: To control the mix with a switch, move the cursor to the CTRL line and press

ENTER. Deflect the switch that will control the mix. The screen will show the functional assignments

for each position of the switch as described previously. Press ESC to confirm the switch selection.

The display will now show the different switch positions (SP.0, SP.1, SP.2). A different rate can be set

for each switch position.

Deflect the switch to one position, and note the cursor on-screen will move automatically to the rate for that

position. Adjust that rate as desired. Deflect the switch to the remaining positions and repeat. To remove

a switch which might have been assigned previously, highlight the switch selection in the CTRL line and

press CLEAR.

Press ESC once all mixing values are set to return to the FUNCTION menu screen.

FLAP MIXER

This function allows flaps to be set, adjusted, and mixed to the ailerons and/or elevator channels. Mixes

such as flaperons, air brake, and spoilers can be achieved in the FLAP MIXER. These settings or mixes

can be assigned and activated by a two or three position switch. Not available for 1AI or 2AI wing types.

Different setup options are available depending on the selected wing type, where the flaps can be mixed

to the aileron or elevator.

1AI1FL : Highlight the FLAP -> ELEV mix percent and adjust as desired. Press ENTER when finished.

Assigning a switch can allow on/off control of the mix. Set a mix percentage for each position of the

switch (SP.0, SP.1, SP.2).

17

2AI1FL: If this wing type was set, the flap channel can be mixed with the aileron, elevator, or back to

the flap. Set the mix percent for each channel to be mixed, for all switch positions that control the mix.

Do NOT assign a switch at the CTRL line to make the mix active at all times. Press ENTER when done.

AIR BRAKE SET

This function will allow you to define the air brake position and activate it with a switch. It’s available only

when 1AI1FL or 2AI1FL wing types are chosen.

When the 1AI1FL wing type is selected the brake can be mixed to elevator and/or flaps. Adjust each mix

percentage as needed. Select a switch to turn the mix on/off.

When the 2AI1FL wing type is selected the brake can be mixed with the elevator, aileron, or flaps. Adjust

each mix as needed. Select a switch to turn the mix on/off.

PROGRAMMABLE MIXER

Up to six programmable mixes can be set, with one

channel being mixed to any one or more channels.

Control characteristics from the input channel will be

passed to the output channel(s), such as travel limits,

exponential, etc. The output channel will still be able

to function independently as if it were not mixed with

another channel, but once an adjustment is made to the

input channel a resulting change will be seen on the

output channel as well. The mix level can be adjusted by

percent. A switch can be assigned to turn this mix on/off.

Enter the mixer screen. Move the cursor to select which mix to set and press ENTER.

The top line will show the mix number, with the cursor over the input channel, and the output channel to the

right. Press ENTER and or to highlight and set the input channel.

The rate of the input channel to mix with the output channel can be adjusted for each the right and left side

of the input channel’s center position. With the cursor next to RATE L, set the desired mix percentage.

Repeat for RATE R. Note the curve on the display’s graph will adjust according to the percentages entered.

The amount of the input channel to be mixed can be offset by setting a percentage next to “OFFSET”.

Assign a switch to control the mix in the CTRL line as explained earlier. Repeat the above procedures for

each of the four mixes that are to be configured.

RF OUTPUT

The Rf output signal can be turned on or off. If changing any programming parameters in the radio, it’s

recommended to turn the Rf off so not to unnecessarily clutter the flying space with radio signals. Leave

the Rf output signal ON anytime the model is being controlled.

Enter this screen to perform a range check on the radio system, as fully explained on page 24.

TIMERS

Two timers are shown on the home screen, which can be configured in this screen. The timer at the top of the

homescreen is T1, and the bottom is T2. The timers can be set to count up or down, and can be controlled

by a user assigned switch. The timers can also be controlled by the throttle stick if desired.

ENTER this screen and press or to move the cursor to the timer feature to adjust for each timer

as desired. Once in the proper place, press ENTER to highlight the value. Press or to adjust the

time as needed.

MIX1:

MIX2:

MIX3:

MIX4:

MIX5:

MIX6:

CH5

---

---

---

---

---

CH5

---

---

---

---

---

ACT

INH

INH

INH

INH

INH

SFOFF

-----

-----

-----

-----

-----

->

->

->

->

->

->

Programmable Mixer

18

To count UP as a stopwatch, leave the timer set to 00:00. To configure the timer to count DOWN, set a

time other than 00:00 with a maximum possible start time of 99:59. When used as a countdown timer, a

set of tones will sound at 00:10 and every second thereafter to warn that the timer is nearing the end. After

reaching 00:00, the timer will automatically begin counting up to help track how much longer the model

was operational after the timer ended.

A switch can be selected on the right side of the screen to turn each timer on / off. Place the box on-screen

over this setting and deflect the switch that will control the timer. In operation, the timer will be stopped

when the switch is in one position. Moving the switch to the opposite position will cause the timer to count.

To reset the timer, move the switch to the stop position and press the CLEAR button.

The timer can also be started and stopped by the throttle stick. Move the throttle stick to the minimum

throttle position. Place the box on-screen over this setting and press ENTER. When “Choose the control

switch” displays, move the throttle stick up from minimum throttle.

The “START/STOP” screen should show. Moving the stick up or down will show changes to the “THROTTLE”

position value. The “START/STOP” value shows the trip point where starting and stopping the timer will

occur. Move the stick to the position of the timer’s trip point and press ENTER. The position value for

START/STOP should now match that for THROTTLE.

Press ESC to return the timer setting screen. The throttle stick’s START/STOP position for the timer should

show below the timer settings.

For example, if a throttle stick START/STOP value of +45% is selected, anytime the throttle stick is below

this value the timer will be stopped. Anytime the throttle stick is above this value the timer will count. To

reset the counter, move the throttle stick below this value and press the CLEAR button.

The “Tx Battery” timer at the bottom of the TIMER setting screen accumulates the total amount of time

the radio has been operational. This time can only be reset by moving the cursor over “Tx Battery” and

pressing the CLEAR button.

To reset either timer, while in the homescreen, press and hold CLEAR, then press to reset T1 or press

to reset T2.

CAMERA GIMBAL

The TTX850 includes the ability to control a camera which might be attached to a model, housed in an

optional camera gimbal which can provide pan and/or tilt movements.

For PAN CH, highlight and select the auxiliary channel to control sideways (pan) movements of the camera

gimbal. Directly underneath for CTRL, select which switch to control this function. Then set the RATE or

maximum travel distance this function can move when the switch is activated. Repeat these procedures

for up/down TILT movement of the camera gimbal.

For the “SMOOTH” function, “OFF” causes the servos to move at a linear rate compared to the movement

of the control lever for quick pan/tilt the camera. “ON” causes the servos to move at an automatic and

slowed rate which is non-linear to the movement of the control lever, for very gradual camera movements.

DIGITAL SWITCH ASSIGNMENTS

Functions in this screen can support the use of miscellaneous accessories in the model, and can range from

video, still camera, LEDs, etc. More than one accessory could be controlled simultaneously, and manipulated

by the pilot through just one channel on the TTX850. This function requires special SLT receivers (see

those instruction manuals for details).

19

This menu is for setting control functions for use with helicopters. See the MODEL SETUP MENU –

AIRPLANES section for functional descriptions of most menus. A swashplate type selection function is

included for helicopters. With the model type set to helicopters, press ENTER for 2 seconds to access

this menu from the home screen.

All channels for helicopters are assigned as shown in the chart on page 6.

SWASHPLATE TYPE

Enter this screen to select the type of swash plate in the helicopter. Setting this properly allows for proper

mixing of all controls for the main rotor. Three options are available, with some offering cyclic and collective

pitch mixes (CCPM) for optimum simplicity and performance. It may be necessary to reverse the direction

of a control when using a CCPM mix to achieve the proper functionality.

1 Servo (90º): Tilting of the swash plate is accomplished with one

servo for control of the elevator axis and one servo for the aileron

axis. Another servo directly controls collective pitch. Selecting this

swash type means that no swash plate mixers are required or used.

This is typically used for flybarless systems.

3 Servos (120º): For CCPM with three servos connected to the

symmetrical swash plate at 120º angles from each other. One pitch

servo, one elevation servo, and one aileron servo are connected

to the swash plate. See the chart to the right for proper connection

of all servos to the receiver.

3 Servos (140º): For CCPM with three servos connected to the

swash plate. The connections are similar to the 3 Servos (140º)

setting but with slightly different geometry (two servos are connected

at 135º angles forward from the rear of the swash plate). See the chart above for servo connections.

Functions for helicopters are available to support models with various fixed mixes, programmable mix

options, swash types. Press ENTER briefly to access this menu.

Setting of many functions is the same as described for airplanes in the previous sections. However, if using

a helicopter which has CCPM mixing, read the SWASHPLATE TYPE section above before adjusting the

reversing and travel limits settings.

THROTTLE CURVE

The throttle’s output is normally linear in relation to movement of the throttle stick. A non-linear relation

between the movement of the throttle stick and the throttle in the model can allow for optimum control of

power to the model (which is also linked to the control of the pitch of the main rotor blades). These non-

linear control curves can be customized for the particular model.

The idle-up function is used to optimize the throttle position for all flight envelopes including aerobatic flight.

By default the TTX850 assigns switch E as the idle-up control switch. This switch incorporates one “normal”

and two “up” functions within the three positions of the switch.

MODEL SETUP MENU – HELICOPTERS

CH 2 Elevator

3 servos 120° & 140°

CH 3 Pitch

CH 4 Rudder

CH 5 Gyro

CH 6 Throttle

CH 7 Aux 1

CH 8 Aux 2

CH 1 Aileron

SETTINGS MENU – HELICOPTERS

20

Position 1 = normal: Used for startup, take-off, landing, and typical flight profiles.

Position 2 = idle-up 1: Used for aerobatic flight

Position 3 = idle-up 2: Typically used as a secondary setup for aerobatic flight.

Make sure all mechanical linkages are connected exactly as specified in the helicopter’s instruction manual.

Make sure the model’s full throttle position can be achieved when the throttle stick is at maximum deflection.

The throttle trim must be able to minimize throttle control completely when the throttle limiter is at idle position.

Follow all other instructions for THROTTLE CURVE as explained on page 14.

THROTTLE HOLD

Throttle hold allows full use of collective pitch while setting the throttle at a user pre-determined position.

This function is often used for autorotation. The pilot can then release the hold and regain full control of

the throttle as needed.

With the cursor over “Position”, set a percent of full throttle that the throttle channel will deflect to automatically

when the control switch is moved to the ON position.

The CTRL line is for setting the ability to turn this function ON/OFF with a switch. Selecting “INH” inhibits

this function from operating. With the cursor next to CTRL, deflect the switch that will control throttle hold.

In one position the control will be ON. Moving the switch to the opposition will turn the control OFF.

To enable the PITCH CURVE HOLD function described below, select “ACT” on the “PITCH CRV” line.

Otherwise leave at “INH”.

PITCH CURVE

The method for setting the blade collective pitch curve is the same as for the throttle curve as explained

above, by moving the throttle stick and using the same controls within the pitch curve screen. This works

in conjunction with the throttle curve for optimum vertical movement of the helicopter. Separate curves can

be set for normal, idle-up 1, and idle-up 2.

PITCH CURVE HOLD

The setting method is the same as for throttle and pitch curve.

SWASHPLATE RING

Depending on how certain mixes are set and mechanical linkages are connected to the swash plate, it’s

possible that the mechanical connections can accidentally be damaged or dislodged if they are forced to

try and move past their own limitations. By adjusting the maximum amount of travel the aileron and elevator

channels can move the controls away from center, this SWASHPLATE RING function can help prevent

damage from occuring to controls inside the model. At the default 150% setting the controls are not limited,

and effectively turns this function off.

Once inside this screen, press ENTER to highlight the “Rate” value. Press or to find the desired

maximum rate. The circle graphic represents the maximum movement rate. Moving the aileron and/or elevator

stick to their limits will cause the actual position of the these controls to show at the bottom of the screen.

THROTTLE MIXER

This mix is used for non-heading hold gyros or when a heading hold gyro is in normal mode. The helicopter’s

throttle channel can be mixed to the tail (rudder) channel. This mix can remain active at all times, or be

controlled by selecting a switch on the CTRL line. Move the cursor to select the rate to adjust, press ENTER

and then or to adjust the value. To reset any mix value or clear a switch selection, move the cursor

to the value, press ENTER, and then press CLEAR.

Table of contents

Other SLT Remote Control manuals