SMAC CBC-EIP User manual

CBC-EIP

USER MANUAL

Version 1.1

2

Disclaimer

The contents of this user manual are intended to be as accurate as possible, but may be subject to

change without prior notification. SMAC shall not be liable for any damages that may arise as a

consequence of the use of information presented in this user manual.

Document Version

Note

By

Date

1.0.3

STO and I/O connections updated

VM

10/16/2019

1.0.4

List of software troubleshooting is added

VM

12/04/2019

1.0.5

Motor quick stop section has been added

VM

01/02/2020

1.0.6

Implicit message data lengths are altered

VM

03/09/2020

1.1

Corrected the STO and implicit message tables,

modified the appendices to be more compact

RZ

5/4/2021

Copyright SMAC Moving Coil Actuators, 2021.

3

Content

1 Introduction ....................................................................................................................................4

2 Setup guide .....................................................................................................................................6

2.1 Hardware ................................................................................................................................6

2.1.1 Power/signal/communication connectors......................................................................6

2.1.2 STO..................................................................................................................................8

2.1.3 I/O and STO electrical schematics.................................................................................10

2.1.4 Deactivating the STO (OPTIONAL).................................................................................12

2.2 Software................................................................................................................................13

2.2.1 CBC-EIP basic configuration ..........................................................................................13

2.2.2 Modification of IP (Internet Protocol) settings.............................................................14

2.2.3 Connecting with a PLC...................................................................................................15

2.2.4 Explicit messaging .........................................................................................................15

2.2.5 Implicit (IO) messaging..................................................................................................15

3 Add-On Instructions (AOI) for STUDIO5000/RSLogix5000 PLC software......................................17

3.1 Position move .......................................................................................................................17

3.2 Softland.................................................................................................................................19

3.3 Homing..................................................................................................................................21

3.4 Velocity move........................................................................................................................22

3.5 Force Move ...........................................................................................................................24

3.6 Fault Status ...........................................................................................................................25

3.6.1 Performing a fault reset................................................................................................25

3.7 Motor halt.............................................................................................................................28

3.8 Motor On...............................................................................................................................30

3.9 Motor Off ..............................................................................................................................31

3.10 Motor Quick Stop..................................................................................................................32

A PLC Software Configuration..........................................................................................................33

A.1 Allen-Bradley PLCs ................................................................................................................33

A.2 Other PLCs.............................................................................................................................38

B Common Software Issues Troubleshooting..................................................................................39

4

1Introduction

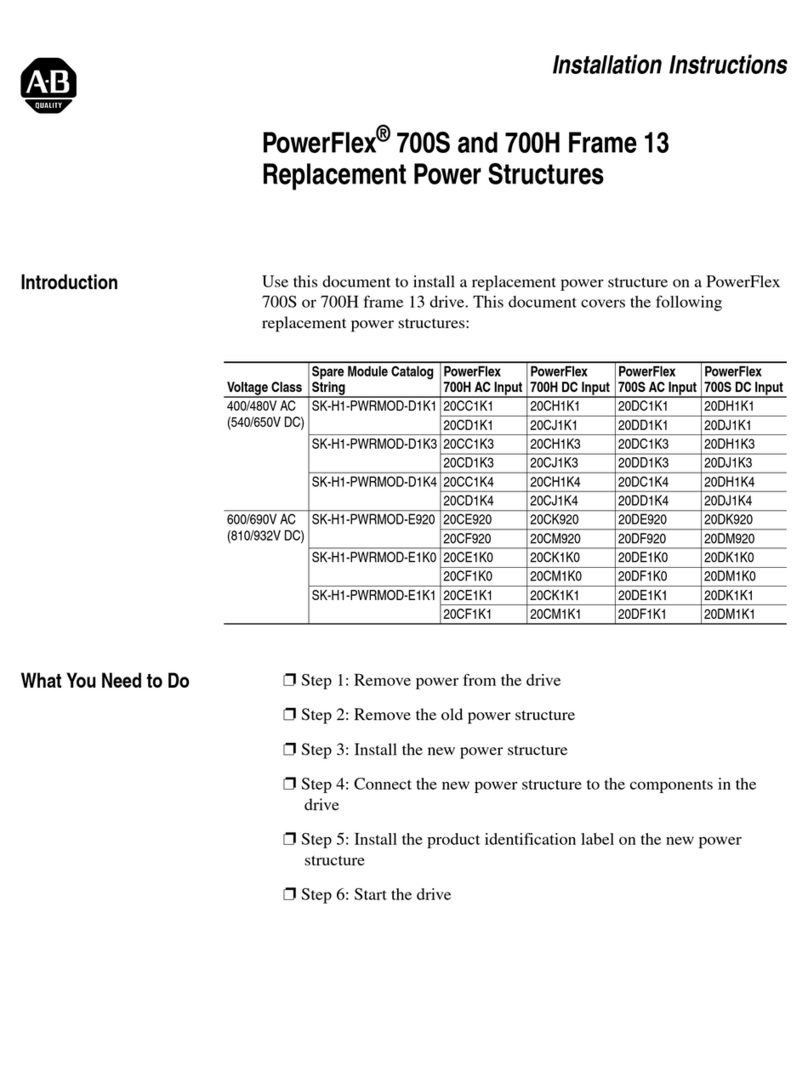

The CBC-EIP, shown in Figure 1.1, is an Ethernet/IP servo drive with specifications as presented in

Table 1.1. An example of Ethernet/IP network architecture involving CBC-EIPs can be seen in Figure

1.2.

Table 1.1. CBC-EIP specifications.

Description

Single axis servo motor controller/driver

Supported motor types

3-phase brushless rotary/linear, 1-phase rotary/linear

Control loop update rate

•Position loop: 1 kHz

•Current loop: 10 kHz

Power supply voltage

8 VDC –48 VDC

Power supply current

2 A –7 A

Continuous current

3 Arms

Peak current

6 Arms (for 1 s)

Power stage PWM frequency

20 kHz

Available feedback inputs

Differential digital encoder with index, analog input

Memory

1024 kB of program memory, 512 kB of EEPROM

memory

Digital inputs

4 x PLC level isolated digital inputs

Digital outputs

4 x SSR (solid-state relay) isolated digital outputs

Output supply

1 x 5V output supply for powering external circuitry

Analog input

1 x 0 –5V single ended analog input

Protections

•Driver overtemperature warning at 125 ⁰C

•Driver overtemperature at 150 ⁰C

•Overcurrent

•Reverse polarity protection

STO (Safe Torque Off)

SIL 3 compliant:

•2 x STO inputs, 5 V to 30 V isolated inputs

•1 x STO feedback output (optional)

•External diagnostics capability

•Abnormal operation detection

Communications

•RS232

•Ethernet/IP (2-port):

oODVA certified

oUp to 6 simultaneous Class 3 connections

(explicit messaging)

o1 simultaneous class Class 1 connection

(implicit messaging) of type exclusive owner

oRequested Packet Interval rate: 1 –3200 ms

oDevice Level Ring

5

Figure 1.1.CBC-EIP.

Figure 1.2. Typical Ethernet/IP network architecture with CBC-EIPs.

Ethernet/IP

master device, e.g. PLC

CBC-EIPs

Actuators

6

2Setup guide

2.1 Hardware

2.1.1 Power/signal/communication connectors

Figure 2.1 shows the connectors and status LED indication of the CBC-EIP. Further details

about these connectors are presented in Table 2.1.

Figure 2.1. Connectors and status LED indication on the CBC-EIP.

ETH 2

ETH 1

POWER

FAULT

RS232

I/O AND STO

POWER

ENCODER

GND

V+

U

V

W

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

Table 2.1.Details of connectors in Figure 2.1.

CONNECTOR

PIN DEFINITION

POWER (Terminal block header, 5 mm pitch)

1: Ground (DC power Return)

2: +24VDC/+48VDC supply

3: Actuator winding phase U

4: Actuator winding phase V

5: Actuator winding phase W

6: Ground

ENCODER (Standard D-SUB 15 pin, female)

1: A+

2: I+

3: B+

4: +5V

5: +5V

6: +5V

9: A-

10: I-

11: B-

12: Ground

13: Ground

I/O AND STO

(Manufacturer: Phoenix Contact, P/N:

1790357)

1: Digital input 1

2: Digital input 2

3: Digital input 3

4: Digital input 4

5: Digital input common

6: Analog input 1

7: Ground

8: +5VDC supply

9: Digital output 1

10: Digital output 2

11: Digital output 3

12: Digital output 4/STO Feedback (only

available by special request)

13: Digital output common

14: STO 1

15: STO 2

16: STO common

RS232 (RJ-25 Jack)

1: NC

2: NC

3: RS232 RX

4: RS232 TX

5: Ground

6: NC

ETH 1 & ETH 2 (Standard Ethernet jacks for

Ethernet/IP connection)

8

2.1.2 STO

The STO (Safe Torque Off) is a safety system that prevents motor from delivering torque in

an emergency event while the CBC-EIP remains connected to the power supply. When STO

is activated, the drive’s power stage is disabled regardless of what the CBC- EIP is doing and

the motor shaft will slow down until it stops under its own inertia and frictional forces.

The STO of CBC- EIP has been designed to be compliant with Safety Integrity Level 3 (SIL3)

according to IED 61800-5-2. To meet the requirements, the STO reliability has been

increased by means of the following characteristics:

•2x fully independent STO channels

•STO feedback output for external diagnostics. Note that by default this is not available

in the CBC- EIP, please ask SMAC to have this enabled when required.

•Detection of abnormal STO operation

Figure 2.2 depicts the schematic of the STO circuit in the CBC- EIP. The STO works with

negative logic: power stage is deactivated by default and in this state, a software fault (error

code 0xFF60) with will be generated if there is an attempt to activate the power stage. To

allow the activation of the power stage (by turning on the power stage transistors), STO

inputs 1 and 2 must be energized by supplying them with a DC voltage (see Figure. 2.7 for

the detailed electrical schematic). Alternatively, the STO inputs can be disabled by applying

jumper connections as described in section 2.1.4.

Figure 2.2. STO circuit schematic.

Figure 2.3 shows the behavior of STO_FB in relation to one of the STO inputs. The objective

of STO_FB is to provide external diagnostics of the STO circuit, to allow an increased system

reliability. A common practice in the diagnostics is to delay the stop of the power stage from

the deactivation of STO_FB and the STO inputs. This way, short pulses can be applied for

testing the STO circuit without stopping the system operation.

When only one of the STO input channels is energized, the STO operation is viewed as

abnormal. If only one channel is energized for more than the latching time (0.6 s < Tlatching <

2.6 s), a dangerous failure in the system is considered and the STO is activated in latching

STO1

STO2

STO_FB

Feedback

Logic

+12 V

DC/DC

+SUPPLY

PH. U

PH. V

PH. W

Power stage

9

mode. The generated software fault cannot be reset until a power supply reset is performed.

Figure 2.4 illustrates the abnormal STO operation.

Table 2.2 summarizes the STO modes that are previously described.

Figure 2.3. Timing diagram of CBC-ECT STO.

Figure 2.4. Illustration of the abnormal STO operation.

Table 2.2. Summary of STO modes.

Mode

Status

STO1

input

STO2

input

Power

stage

STO

FB

Drive function

Normal

operation

STO ACTIVE

0

0

Disabled

0

Drive cannot start or

provide power to motor

STO

INACTIVE

1

1

Enabled

1

Drive is enabled to run

under firmware control

Diagnostic

STO ACTIVE

PULSE (1 ms

< t < 23 ms)

x

0

Enabled

0

A short STO ACTIVE (“0”)

pulse does not stop the

motor operation.

However, it activates STO

FB. It can be used for

performing system

diagnosis.

STO ACTIVE

PULSE (1 ms

< t < 23 ms)

0

x

Enabled

0

Time

STOx

input

STO_FB

output

Power

stage state

0

800 ns

23 ms

Logic level

Time

STO1

input

STO2

input

Power

stage state

0

23 ms

0.6 s < Tlatching < 2.6 s

Logic level

10

Abnormal

operation

Abnormal

STO ACTIVE

0

1

Disabled

0

Drive cannot start or

provide power to the

motor. STO trip reported to

MCU. If this persists for

latching time the STO will

lock in FAULT state. To

reset this fault a power

cycle is needed (Toff > 3.2

s).

0.6 s < TLatching< 2.6 s

Abnormal

STO ACTIVE

1

0

Disabled

0

STO FAULT

x

x

Disabled

AND

(STO1,

STO2)

After exceeding latching

time of abnormal STO the

driver will stay latched in

this state until power

cycle (Toff > 3.2 s).

2.1.3 I/O and STO electrical schematics

For the purpose of interfacing I/Os and STOs between the CBC-EIP and external devices,

electrical schematics are given in Figures 2.5 –2.8.

Figure 2.5. Digital inputs electrical schematic.

+3.3 V

GPI_COM

GPI1

10KΩ

10KΩ

10KΩ

(5 –24 VDC)

(5 –24 VDC)

(5C –24 VDC)

(5–24 VDC)

To μC

10KΩ

GPI2

GPI4

GPI3

To μC

To μC

To μC

Internal to CBC

11

Figure 2.6. Digital outputs electrical schematic.

Figure 2.7. Analog input electrical schematic.

GPO1

GPO_COM

(200 mA, 60 VDC tolerant)

From μC

From μC

From μC

From μC

330Ω

330Ω

330Ω

330Ω

GPO2

GPO3

GPO4/STO_FB

(200 mA, 60 VDC tolerant)

(200 mA, 60 VDC tolerant)

(200 mA, 60 VDC tolerant)

(200 mA, 60 VDC tolerant)

Internal to CBC

(0 –5VDC)

AI

10.33 kΩ

20 kΩ

To μC ADC

(10-bit)

1 nF

Internal to CBC

12

Figure 2.8. STO electrical schematic.

2.1.4 Deactivating the STO (OPTIONAL)

In case the STO functionality is not required, the on-board +5VDC can be conveniently

applied to the STO inputs conveniently without needing an external voltage source. This can

be done by applying jumper connection on the I/O and STO connector as shown in Figure

2.9.

Figure 2.9. Disabling the STO on the I/O and STO connector.

STO1

STO2

STO_COM

(5VDC –30 VDC)

+5V

To STO circuit

To STO circuit

2.5 kΩ

2.5 kΩ

(5VDC –30 VDC)

Internal to CBC

14

15

16

7

8

➢Connect pins 8, 14, 15 together

➢Connect pins 7 , 16 together

13

2.2 Software

Remark: in order to work with the software part of CBC-EIP, the user is expected to have basic

familiarity with the Embedded Motion Control Library (https://www.smac-

mca.com/documents/PDFs/Embedded%20Motion%20Control%20Library.pdf) and the

CANopen protocol.

2.2.1 CBC-EIP basic configuration

Essentially, the CBC-EIP consists of an improved version of SMAC CBC controller and an

Ethernet/IP hardware and software interface. The improved version of the CBC controller

shares the basic functionalities of SMAC CBC/LCC controller and therefore, controller

configuration software such as LCC Control Centre, Motionlab and Composer can be used

(further details can be found here: https://www.smac-mca.com/lcc-single-axis-brushless-

controller-p-125.html?cPath=1_10 ).

The typical steps to perform a basic configuration of CBC-EIP are as follow:

1. Establish a physical connection between a PC (with LCC Control Centre software) and

the RS232 connector on the CBC-EIP (powered with 24/48VDC). Make sure that the STO

inputs are energized, see section 2.1.4 of this manual for an instruction on how this can

also be done easily by using the on-board +5V power supply.

2. Install the LCC Control Centre software (downloadable from the link above) and copy

the file “System Macro V2.mlm” (obtainable from a SMAC sales/tech representative,

ask for a specific version for the CBC-EIP) into the LCC Control Centre folder, which is

typically located in the directory path: C:\Program Files(x86)\SMAC\LCC Control

Centre . Overwrite the existing file of the same name.

3. Using the LCC Control Centre software, download the configuration file of the actuator

that is connected with the CBC-EIP. This file can be obtained from the link above or a

SMAC sales/tech representative.

4. Create an actuator initialization routine in macro 0:

a. For 1-phase actuators: Homing and a jump to macro 40

b. For 3-phase actuators: Phasing, homing and a jump to macro 40

Below is an illustration of the routine defined in macro 0. The command parameters

may be different from those indicated below.

If it is decided that the homing is to be done from the PLC through Ethernet/IP, then

the homing routine in macro 0 above could be removed.

5. Download macro 0 above into the CBC-EIP through the “Save all in controller” button.

6. If required, after executing macro 0 above, optimize the position control loop PID

parameters through the tuning feature in the LCC Control Centre software.

14

In step 2 above, the “System Macro V2.mlm” file contains the CBC-EIP default macros (see

Table 2.3) in addition to the standard LCC/CBC system macros. In conjunction with the

default implicit messaging mapping in Tables 2.5 and 2.6, the CBC-EIP default macros

facilitate the execution of various types of motions through Ethernet/IP.

To evaluate the contents of the macros in Table 2.3, Composer software (downloadable

from the same link as for the LCC Control Centre) can be used to open up the “System Macro

V2.mlm” file.

Table 2.3. Default macros in CBC-EIP.

Macro

Function

37

Motor halt

38

Motor on

40

Main program loop

41

Homing

43

Position move

44

Velocity move

45

Force move

46-48

Softland

2.2.2 Modification of IP (Internet Protocol) settings

By default, the IP address of the CBC-EIP is: 192.168.1.80

Table 2.4 presents the objects within CBC-EIP that can be modified.

Table 2.4. IP-settings-related objects of CBC-EIP

Index

Subindex

Name

Type

Default value

Description

0x2005

0x01

IP address

UINT32

0x5001A8C0

(192.168.1.80)

x.y.z.n → 0xNNZZYYXX

0x2005

0x02

Subnet mask

UINT32

0x00FFFFFF

(255.255.255.0)

x.y.z.n → 0xNNZZYYXX

0x2005

0x03

Gateway

UINT32

0

x.y.z.n → 0xNNZZYYXX

0x2005

0x04

Enable DHCP

UINT32

0 (disabled)

0x00 disabled, 0xFF enabled

0x2005

0x05

DNS 1

UINT32

0

x.y.z.n → 0xNNZZYYXX

0x2005

0x06

DNS 2

UINT32

0

x.y.z.n → 0xNNZZYYXX

The procedure to modify parameters in Table 2.4are as follow (assuming RS232

communication is used, see https://www.smac-mca.nl/Downloads/TechNote-SerialToPC-

LCC.pdf ):

1. Write the desired values to the objects

2. Save the parameters to non-volatile memory through the command:

0x00 W 0x11010 1702257011

3. Power cycle the CBC-EIP or perform a reset through Ethernet/IP explicit message

(service: 0x05, Class ID: 0x01, Instance: 1)

Another alternative to modify parameters in Table 3 is by through Anybus webserver of the

CBC-EIP (accessible through a web browser using the IP address 192.168.1.80), wherein a

table of parameter list can be found and changes can be performed.

15

2.2.3 Connecting with a PLC

See Appendix A for more information about this.

2.2.4 Explicit messaging

The CBC-EIP supports up to 6 simultaneous Class 3 connections. The explicit messaging

service provides access to standard Ethernet/IP objects such as Identity, TCP/IP Interface

and Ethernet Link, as well as all the objects belonging to the drive functionalities of CBC-EIP,

as can be found from object dictionary list in the embedded motion control library manual

(https://www.smac-

mca.com/documents/PDFs/Embedded%20Motion%20Control%20Library.pdf).

The supported explicit message CIP service codes are:

•0x0E: Get attribute single

•0x10: Set attribute single

Meanwhile, the mapping between CIP addressing and the CBC-EIP objects are:

•Class ID: 0x64

•Instance ID: CBC-EIP object Index from Embedded Motion Controller Library manual

•Attribute ID: CBC-EIP object Subindex from EMCL manual

Example: to obtain the value of object Max torque through Explicit messaging →service

code: 0x0E, Class: 0x64, Instance: 0x6072, Attribute: 0x00

2.2.5 Implicit (IO) messaging

The CBC-EIP supports a simultaneous class 1 connection type of exclusive owner, with the

specifications:

•Input data assembly (T→O, Target to Originator): Instance 100

oMax. number of mapped objects: 8

oMax. mapping length: 32 bytes

•Output data assembly (O→T, Originator to Target): Instance 150

oMax. number of mapped objects: 8

oMax. mapping length: 32 bytes

SMAC has defined a default mapping between the above IO data assemblies and CBC-EIP

objects to allow the execution of macros discussed in section 2.2.1 of this manual. The default

mapping is presented in Tables 2.5and 2.6, which have been tailored to work with Add-on

instructions in the programming environment of Allen-Bradley PLCs, as further described in

Section 3 of this manual. Please contact SMAC sales/tech representative if a different object

mapping is desired.

16

Table 2.5. Default mapping between CBC-EIP and input data assembly.

CBC-EIP object

Description

Input data byte location

(total: 26 bytes)

Status word

Actuator motion status

0 - 1

W4

Reserved-Macro status for AOI

2 - 5

Position actual value

Encoder actual position

6 - 9

Current actual value

Force/current value

10 - 11

Following error value

Position error value

12 - 15

Error code

Actuator fault code

16 - 17

W5

Register available to user

18 - 21

W6

Register available to user

22 - 25

Table 2.6. Default mapping between CBC-EIP and output data assembly.

CBC-EIP object

Description

Output data byte location

(total: 24 bytes)

W30

Macro-specific parameter

0 - 3

W31

Macro-specific parameter

4 - 7

W32

Macro-specific parameter

8 - 11

W33

Macro-specific parameter

12 - 15

W34

Macro-specific parameter

16 - 19

W35

Macro-specific parameter

20 - 23

17

3Add-On Instructions (AOI) for STUDIO5000/RSLogix5000 PLC

software

3.1 Position move

This AOI is used to perform a linear or rotary position move.

Position Move AOI: input and output parameters

Parameter

Unit

Description

INPUT

Busy bit

N/A

This bit is active when the AOI is being

executed, until Done bit is active.

Done bit

N/A

This bit is active when the target position has

been reached.

Actual_position

Counts

Actual position of the actuator/motor.

OUTPUT

Mode_SetPoint

N/A

1: Enables absolute position move

3: Enables relative position move

Target_Position

Counts

Final position to be reached by the actuator

Profile_Velocity

Counts/s

Max. velocity of the motion profiler

Profile_Acceleration

Counts/s2

Max. acceleration of the motion profiler

Profile_Deceleration

Counts/s2

Max. deceleration of the motion profiler

Max_Torque

‰ of motor

rated current

Max. permissible torque/force. Unless this

parameter is specified, the default value from

config. file is used.

Enable bit

N/A

Enables the AOI. Tis needs to be included in the

program after the AOI rung is energized.

18

Ladder logic example:

Mapping between position move AOI parameters and PLC IO data assemblies

Byte address

Description

Input: 2 –5

43: Position move in progress

53: Target position has been reached

Input: 6 - 9

Actual Position

Output: 0 - 3

Macro value of position move (Table 3)

Output: 4 - 5

Setpoint mode

Output: 6 - 7

Max. torque

Output: 8 - 11

Target position

Output: 12 - 15

Profile velocity

Output: 16 - 19

Profile acceleration

Output: 20 –23

Profile deceleration

19

3.2 Softland

This AOI is used to perform SMAC’s softland.

Softland Move AOI: input and output parameters

Parameter

Unit

Description

INPUIT

Done bit

N/A

This bit is active when the target position has

been reached.

Soft landed Position

Counts

Position of the actuator after softland action

Busy bit

N/A

This bit is active when the AOI is being

executed, until the Done bit is active

OUTPUT

Soft land direction

N/A

0-positive direction 1- negative direction

Soft land action

N/A

This bit is used to specify the action of the

actuator after softland operation

1: Apply force

2: Hold force

3: Hold position

4: Motor off

Soft land velocity

Counts/s

Max. velocity of the motion profiler

Soft land acceleration

Counts/s2

Max. acceleration of the motion profiler

Soft land sensitivity

Counts

This tag is used to set the sensitivity of softland.

Smaller value means higher sensitivity.

Max Torque

‰ of motor

rated current

Max. permissible torque/force. Unless this

parameter is specified, the default value from

config. file is used.

Enable bit

N/A

Enables the AOI. Tis needs to be included in the

program after the AOI rung is energized.

20

Ladder logic example:

Mapping between softland move AOI parameters and PLC IO data assemblies

Byte address

Description

Input: 2 - 5

46: Softland move in progress

56: Softland is complete

Input: 6 - 9

Softlanded Position

Output: 0 - 3

Macro value of softland move (Table 3)

Output: 4

Direction

Output: 5

Action after land

Output: 6 - 7

Max. torque/force

Output: 8 - 11

Profile velocity

Output: 12 - 15

Profile acceleration

Output: 16 - 17

Position error

Output: 18 - 19

Force

Other manuals for CBC-EIP

1

Table of contents

Other SMAC Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens Simatic S7-1500R Equipment manual

Hytronik

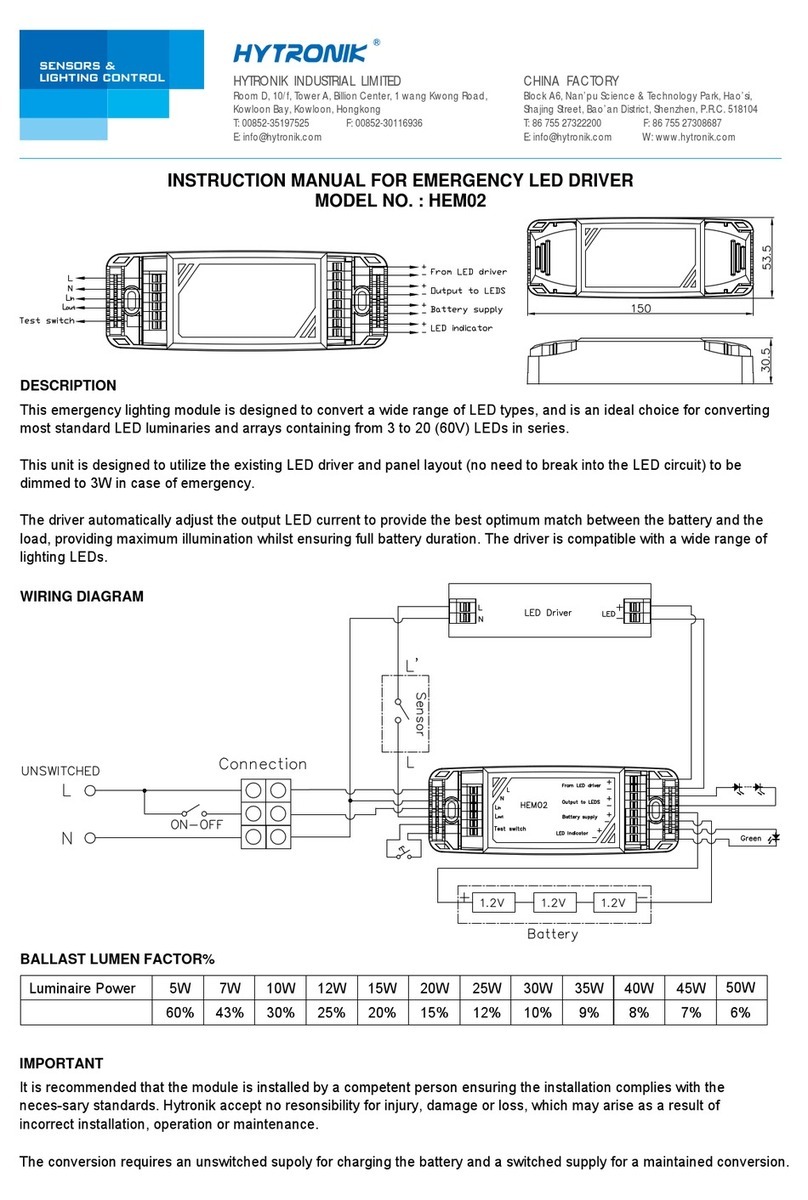

Hytronik HEM02 instruction manual

MKS

MKS 649B instruction manual

Atlas Copco

Atlas Copco MINI-REG-1/4-BSP Product instructions

Rockwell Automation

Rockwell Automation PowerFlex 700S installation instructions

bentrup

bentrup TC 500 Series operating instructions