smaky SL-500A User manual

Instruction Manual for SL-500A Desktop Mixer

CONTENTS

Overall View of the Mixer ……………………………………….…………….…P. 2

Installation Instructions ……………………………………..………………… P.3

Operating Instructions ……………………………………….….…………… P. 4

Cleaning Instructions …………………………………….……………….………P. 8

Maintenance ………………………………...……….………….…P. 8

Troubleshooting …………………………………………..…..…….………. P.9

Limited Warranty ……………………………………..………..…….…P.10

Capacity Chart Table ………………………………………………....….…P.10

1

CAUTION

Read before you operate the machine

It is important to read this manual and following the instructions before operate the machines. This

mixer is designed as a safe and efficient food processing product as long as the machine is used in

accordance with the instructions in this manual and is properly maintained.

User has taken following precautions in order to operate the mixer safely.

All operators should be at least 18 years old and are adequately trained and supervised. Also,

have fully read and understood this manual.

Owner should not let customer, visitor or other unauthorized people come in contact with this

machine.

Do not wear loose clothes or ring while operating, and keep hands, hair and clothing away the

moving parts.

NEVER use an extension cord to connect electrical power.

Make sure the safety guard is installed and bowl is lifted to right position before operating.

NEVER reach into the bowl when the mixer is running.

NEVER place your hand or any kitchen utensil in the bowl whilst the mixer is in operation.

When mixing product always follow the recommends agitator and speed setting according to the

capacity chart.

STOP the mixer before removing or installing attachments into the hub.

NEVER put your hand and finger into the feed chute when using any mixer attachment.

Always use the pusher plate with attachment.

Always UNPLUG before cleaning or doing any maintenances.

DO NOT hose down or pressure wash any part of the mixer.

NEVER bypass, alter or modify this machine. Doing so may create hazard and will void warranty.

2

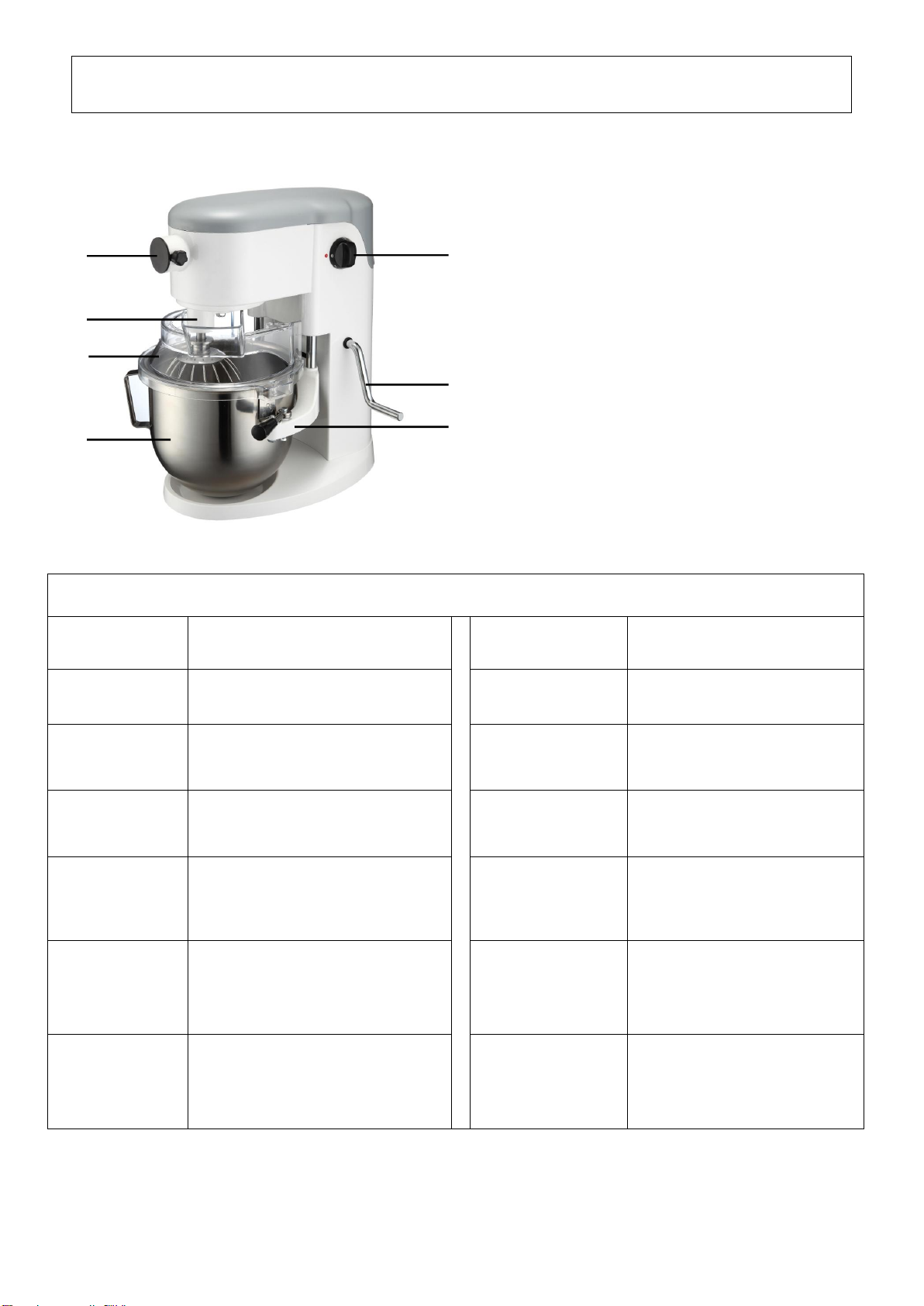

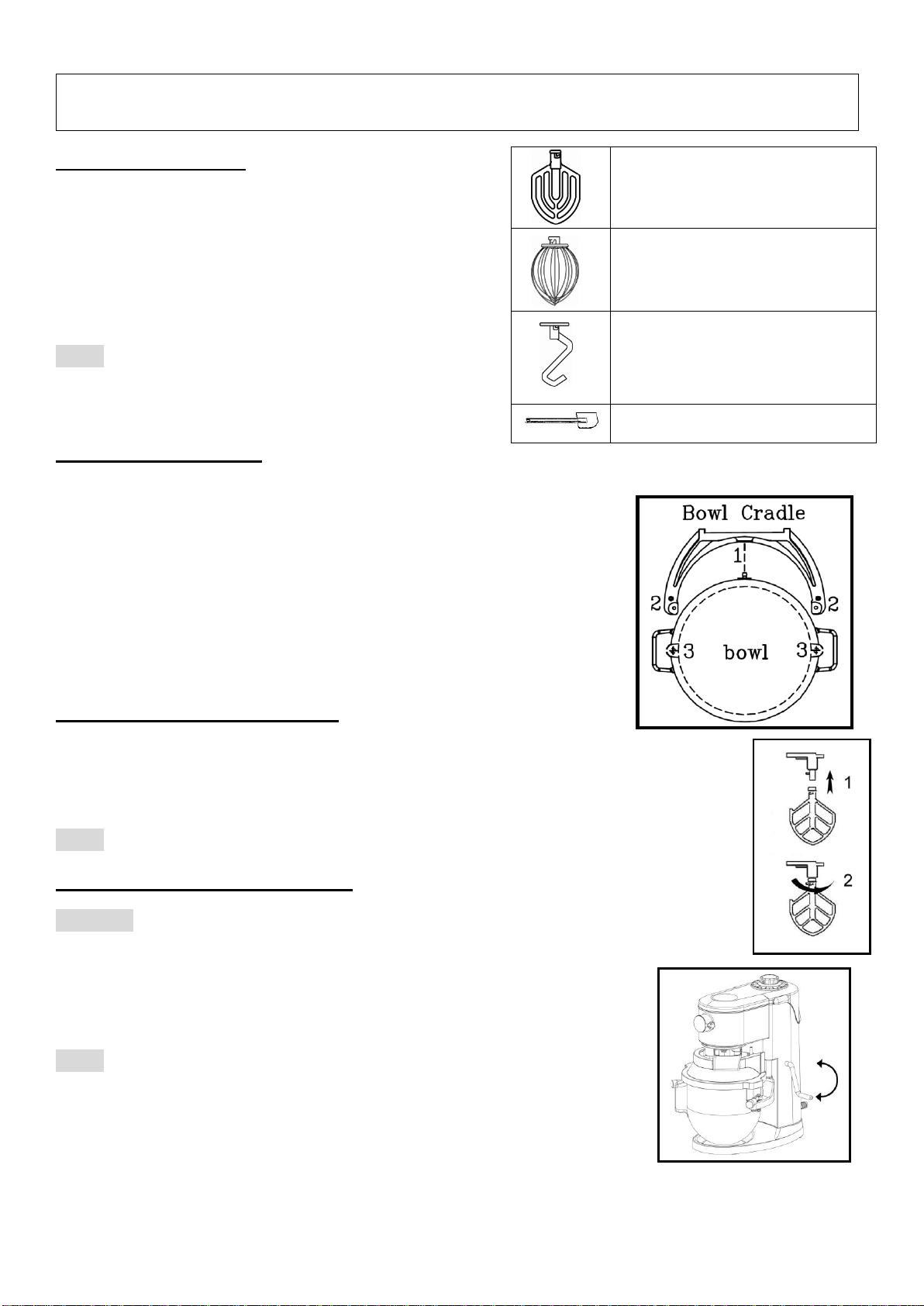

Overall View of the Mixer

(A) On/Off/Speed Selector Button

(B) Bowl Lift Handle

(C) Bowl Cradle

(D) Hub Attachment

(E) Planetary Shaft

(F) Bowl Guard

(G) Stainless Steel Bowl

SPECIFICATION

Model

SL-500A

HubAttachment

60-308 (rpm)

Bowl Size

5 Liters

Noise Value

77.1 dB(A)

Motor

750 W

Dimensions (cm)

(LxWxH)

38 x 31 x 45.5

47 x 37 x 52 carton

Electrics*

100/120V 50/60Hz 1PH

200/240V 50/60Hz 1PH

Weight

Gross 16 kg

Net 15 kg

Electric

Current*

110V/3A

220V/2A

Standard

Equipment

Stainless Steel Bowl, Beater,

Whisk, Spiral Hook, Pastry

Knife and Bowl Guard.

Speeds

(1) 0 stop, 1-3 low speed

(2) 4-7medium speed

(3) 7-10 high speed

Bowl Size (cm)

W. 20.2 x H. 19.3 x TH. 0.1

Planetary Shaft

①40 ②70 ③90 ④106

⑤140 ⑥170 ⑦190 ⑧210

⑨230 ⑩260 (rpm)

Optional

Equipment

Dough Sheeter, Meat Mincer,

Vegetable Slicer…

A

B

C

D

E

F

G

3

INSTALLATION

-The machine is supplied factory lubricated and ready to run. It should be positioned on any solid,

-

-

-

-

level and non-skid work surface that is nonflammable. Install in work area with adequate light

and space.

You may place the mixer on bench which is capable of supporting a load of 25kg. For

operation stability, please punch four holes on the table and fix SL-500A onto the table by

four screws. Please see Figure 1.

DO NOT attempt to lift the mixer alone. This

machine is 15 kg. The transportation should

require two people, please see Figure 2

Clean the mixer before use. It is normal for the

factory to apply a generous amount of grease

in and on the machine before initial use.

During the transportation or fitting, please do

not lean over 35 degree to avoid the gear oil

leaking from the gear oil container.

ELECTRICAL CONNECTION

CAUTION: NEVER USE EXTENSION CORD. Low amp supply could damage the mixer or cause a fire.

Before connecting this machine to the electrical supply, check that the details on the rating plate (located

on the rear of the machine) correspond to the details of your electrical connection.

The mixer is supplied with a trailing lead fitted with a molded plug. If the style of plug is unsuitable for the

socket you plan to use, the plug must be cut off and replaced with an appropriate plug.

Machines are fitted with a color coded three core cable as follows:

(1) Brown: Live

(2) Blue: Neutral

(3) Green/Yellow: Earth

As the color of the wires may not correspond to the colored markings identifying the terminals in your

plug, you should proceed as follows:

-The wire which is colored blue must be connected to the terminal which is marked with the

letter N or colored black.

-The wire which is colored brown must be connected to the terminal which is marked with the

letter L or colored red.

-The wire which is colored green/yellow must be connected to the terminal which is marked with

the letter E or colored green.

The mixer should be plugged into a switched socket which isolates all poles and has a minimum contact

clearance of 3mm and located close to the mixer for use in an emergency and to facilitate servicing.

The machine must be incorporated into a potential equalization system.

The leakage current for this appliance is no greater than 1 mA/KW.

If the electrical supply cable to the machine becomes damaged, it must be replaced by a specification or

higher and suitable for the Mixer’s motor load.

The ground wire is fixed to the machine and this connection must be kept intact.

CAUTION: The mixer MUST be grounded.

Installation Instructions

Figure 1

Figure 2

4

-The minimum requirement for all electrical equipment is correct operation between air temperature

of +5℃and +40℃.

-Electrical equipment is capable of operating correctly when the relative humidity does not exceeding 95% at

a maximum temperature of +40℃.

-Electrical equipment is capable of operating correctly at altitude up to 1000m.

-Electrical equipment is designed to withstand to protected against the effects of transportation, and

storage temperature within a range of -25℃to +55℃and for short periods not exceeding 24h at up

to +70℃.

Operating Instructions

BEFORE USING THE MIXER

Before using the mixer, ensure that all users are familiar with the correct operation of the machine. In

particular, care should be taken to ensure that the bowl and mixing tools are correctly fitted and that the

bowl guard is in position prior to starting the machine.

SAFETY AT WORK

-NEVER place your hand or any kitchen utensil in the bowl whilst the mixer is in operation.

-Keep hands, hair and clothing away from moving parts.

-Isolate the machine from the electrical supply by removing the plug from the socket before

cleaning, servicing or adjusting any parts or attachments.

-Do not use the machine with any cover or guard removed.

-Certain operator notice advising about the safe use of this mixer is attached to the machine.

CORRECT USE OF THE MIXER

-It is the responsibility of the operators to use the mixer correctly within the recommended

limitations. Always follow the instructions on the side of the machine when changing gear. If the

motor labors, please stop the machine and reduce the size of the mix immediately. Damage

resulting from improper use is will void the warranty.

-For operator safety, the machine is fitted with a bowl guard which is electrically interlocker to

ensure that the mixer cannot operate unless the guard is correctly positioned and the bowl is

raised. Excessive force used to open and close the bowl guard may damage the electrically

interlocker, and will void the warranty.

-For additional safety, the mixer has a no volt release feature which means that in the event of a

power failure, the machine will only restart after the control has been rested to OFF. This

arrangement ensures that when the supply is restored, the machine cannot restart on its own.

-Careful handling of bagged products by minimizing the height above the bowl base from which

they are poured.

-Careful slitting of bags in the lower part of the bowl to allow dust free discharge of flour as flour as

possible.

-Use temporary bowl covers to minimize openings through which flour many escape.

Installation Instructions

5

TOOL SELECTION

The beater, whisk and spiral dough hook are tools

for the work implied by their names. Do not use the

beater for dough making or the whisk for anything other

than whisking, aerating or mixing light mixtures.

The Table 1 shows the typical uses for each of the tools.

NOTE: Always wash agitator with mild soap and apply

light quantity of mineral oil to planetary shaft after

cleaning.

FITTING THE BOWL

With the bowl cradle lowered, place the chosen mixing tool in the

bowl and position the bowl on the cradle. There are three location points

when fitting the bowl.

(1) The locking pin at the rear of the bowl should locate in the hole of the

cradle.

(2) The two holes in the bowl handles must engage on the pins located on

the cradle.

(3) Please ensure that the bowl is seated correctly on the cradle before

securing the bowl locking latches prior to use.

FITTING THE MIXING TOOL

Slide the bayonet fitting of the agitator onto the drive shaft and twist clockwise to

secure it in position. To remove the agitator, slide the tool up the shaft slightly and twist

counter clockwise.

NOTE: Install the bowl BEFORE inserting agitators.

BOWL LIFT & BOWL GUARD

CAUTION: Make sure the speed control dial is in the OFF position.

The bowl cradle and bowl guard are electrically interlocked so that the

machine will only operate with the bowl cradle at the raised position. Please

see figure 5. In addition to this, the bowl guard must be installed into place.

NOTE: Only once the bowl is raised with the bowl guard installed, the

machine can operate. Thus ensuring total user safety at all times. Once the

guard has been removed or the bowl lowered, the machine will stop

immediately. The Mixer can only be restarted by turning speed control dial

to OFF position and turn ON again.

Operating Instructions

Beater: Firm mixes such as light

pastry, cakes biscuits, icings

fillings and mashed vegetables.

Spiral Dough Hook: Heavy mixes

such as dough, pie pastry. .

Whisk: Light mixes such as

whipped cream, mayonnaise,

egg whites, pancakes and

soufflés.

Pastry knife

Figure 4

Figure 5

6

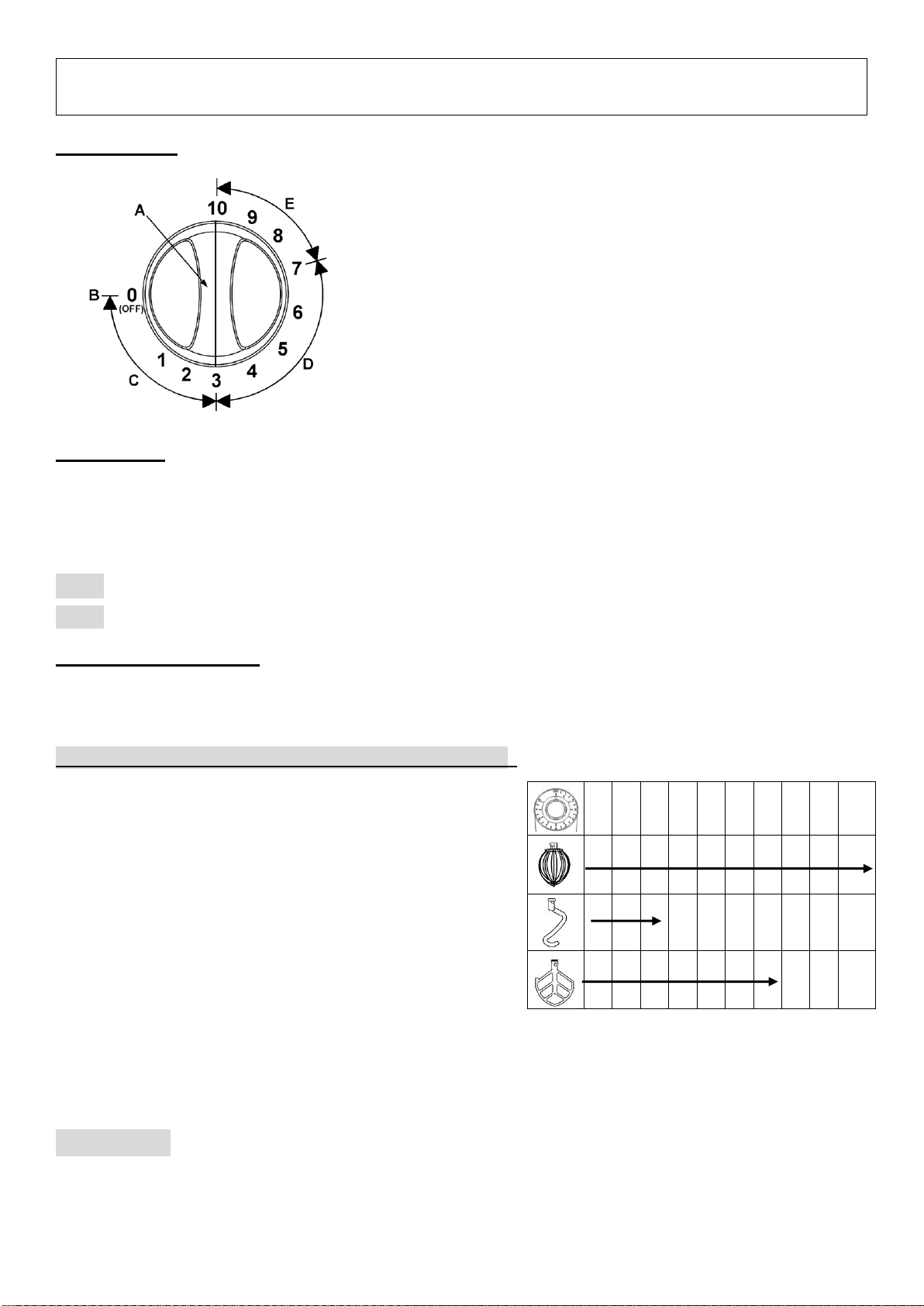

CONTROLS

A: Speed Selector Knob

B: Position 0: OFF

C: Position 1-3: Low speeds (Spiral Hook)

D: Position 4-7: Medium speeds (Beater)

E: Position 7-10: High speeds (Whip)

CAPACITY

Please refer to Page 10. The table shows the recommended capacities of finished weights of regular

mixes. Although the machine may be capable of mixing larger quantities, it will lead to excessive and

premature wear and possible failure. Overloading also results in lengthy processes and unsatisfactory

results.

NOTE: Reduce batch size by 10%, if chilled flour, water below 20 ℃, ice, or high gluten flour is being used.

NOTE: Overloading or not following the chart will damage the mixer and void the warranty.

SPEED SELECTION

Select the appropriate speed setting by rotating the speed selector knob clockwise starting from 0. To

increase mixer speed, continue turning the selector button clockwise to desired speed.

Recommended speed while mixing:

Speed Agitator Product Type/Ingredients

1(stir) All Start to incorporate ingredients

2(low) Spiral Heavy: mixing pizza, bread,

pasta, stuffing and dough,

waffle/cake batter, mashed

potatoes, etc.

3-7 Beater Medium: 2nd stage of mixing for

(medium) donut dough. Etc

8-10 Whip Light: whipping cream, egg whites,

(high) meringue mousse, pancake mix,

sponge cakes, etc

IMPORTANT: When mixing products always follow the recommended agitator and speed setting.

Operating Instructions

1

2

3

4

5

6

7

8

9

10

7

Figure 7

Figure 6

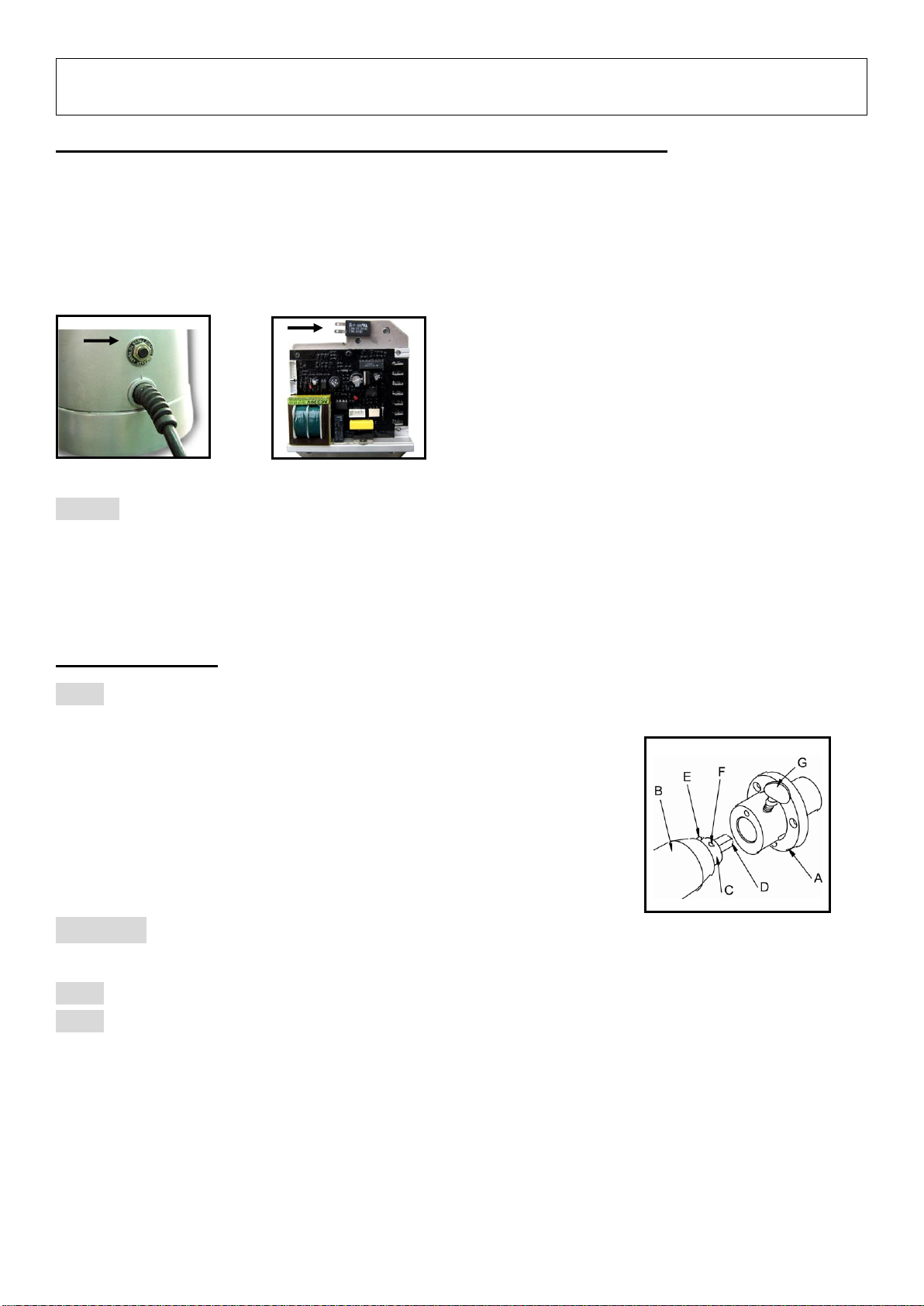

THERMAL OVERLOAD PROTECTION (Automatically Reset)

The thermal overload protection (circuit breaker) will shut off and stop the machine automatically. If

this occurs, please turn the ON/OFF speed selector button to 0-OFF position and reduce the size of batch.

After waiting 1-2 minutes machine shut off, turn the ON/OFF speed selector or button to ON position. The

thermal overload protection is an automatic reset device. The circuit breaker may be different base on

mixer’s voltage.* Figure 6 shows the position of 110V(3A) circuit breaker. Figure 7 shows the position of

220V (2A) circuit breaker.

NOTE: *110V(3A) circuit breaker must be manually reseted.

For heavier loads, the mixer should not run longer than 15 minutes without pausing for a cool down

period of at last 15 minutes or more before resuming mixer. For lighter loads the mixer should not run

longer than 30 minutes without pausing for a cool down period of at last 30 minutes or more before

resuming mixer.

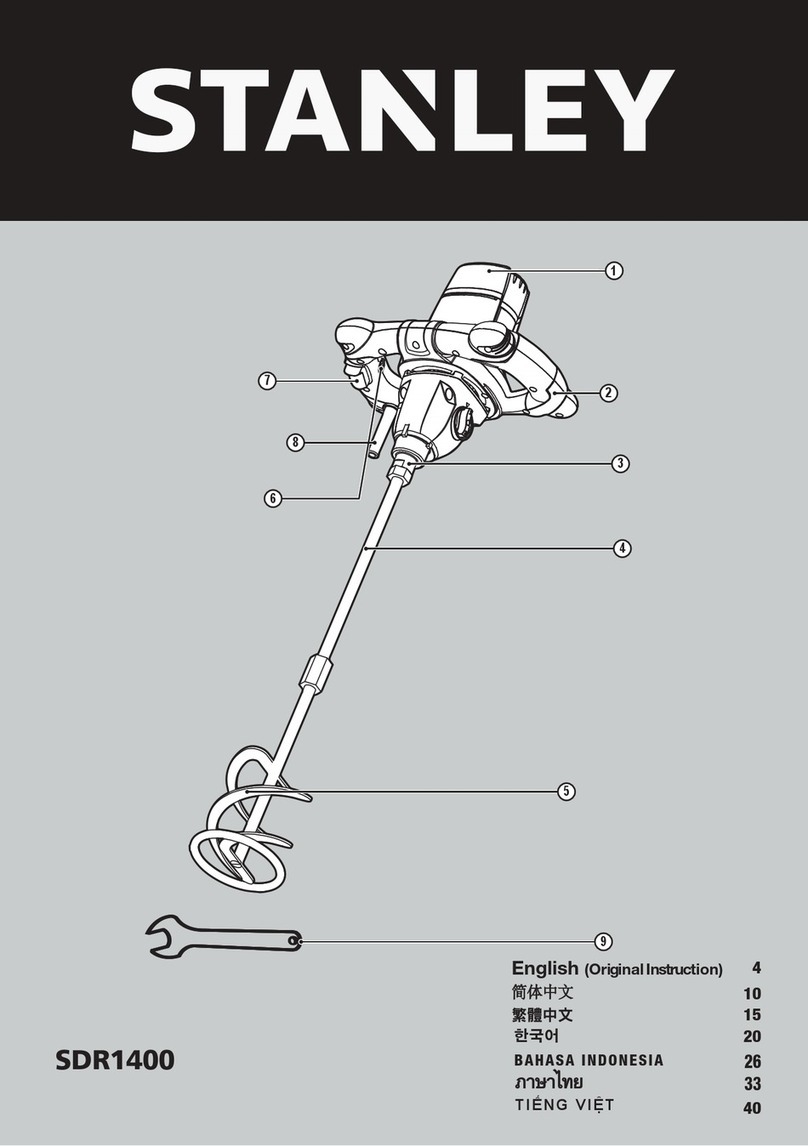

ATTACHMENTS

NOTE: Attachments are optional.

The ranges of attachments that can be operated from the

Attachment Hub are listed below. When using an attachment, lubricate

the Drive Stud (D) using a food quality grease or oil. To fix to the mixer

refer to Figure 8. Release the Thumbscrew (G) and slide the shaft of the

attachment into the hub ensuring that the Drive Stud (D) engages in the

socket within the hub. Rotate the attachment to line up the Location Peg

(E) with its mating hole in the hub and push firmly home. Tighten

thumbscrew to secure.

CAUTION: Only fit attachments when the mixer is stationary and never when it is

operating. Do not use attachments when mixing.

NOTE: Make sure the bowl is up and the bowl guard is installed, otherwise the mixer will not function.

NOTE: If you still don’t understand or have any doubt of operation, please don’t use the machine and

contact the local representative.

Operating Instructions

Figure 8

8

Cleaning Instructions

CARE OF YOUR MIXER

CAUTION: ALWAYS DISCONNECT OR UNPLUG THE ELECTRICAL POWER FROM THE MIXER BEFORE

CLEANING.

The mixer is designed for simple maintenance carried out by operators. It may be necessary from

time to time to apply a little Vaseline and oil to the rods on which the bowl cradle slides. If so, use a little

food quality lubricant, ensuring that there is no excess oil that could contaminate the food mix.

Clean the mixer thoroughly after use. After isolating the machine from the electricity supply, the

body should be wiped down with a damp cloth. Do not spray the machine with or immerse it in water.

Do not forget to clean the rear of the machine and do not allow the rear vents to become blocked as this

may result in overheating.

Pay particular attention to the bowl pins and any surrounding areas of the cradle to prevent the

accumulation of mix, as this could prevent correct location of the bowl. For the same reason ensure that

the beater shaft and each of the sockets on the tools are cleaned thoroughly. The bowl and tools should

be washed in hot soapy water, rinsed and dried before being put into storage. Do not wash the agitator s

in a dishwasher, as the polished finish will be adversely affected by the dishwashing chemicals.

Maintenance

-It is recommended that any servicing or maintenance work must be carried out by a trained

technician or electrician.

-CAUTION: ALWAYS DISCONNECT OR UNPLUG THE ELECTRICAL POWER FROM THE MIXER BEFORE

DOING MAINTENANCE.

Regular maintenance is necessary on all machines if they are to remain in good working condition. It

is strongly recommended that all maintenance must be carried out by trained technicians from an

appointed distributor.

ON A REGULAR BASIS

Clean the machine thoroughly after use and lubricate the rods with Vaseline or lubrication oil which

the bowl cradle slides. After cleaning the beater shaft, please wipe and lightly lubricate the beater shaft

with Vaseline to prevent rusting. (SEE CARE ON YOUR MIXER)

ON AN ANNUAL BASIS*

Check that all bolts are tight and bowl guard secure.

※Carry out on a more frequent basis if machine is arduously used.

※After replacing the parts by technicians, please screw back tightly with anti-leaking coat to avoid the

gear oil leaking after replacement.

※Do not insert any object into the air vent of motor or into the bowl.

※Please unplug while not using the mixer.

GEARBOX AND PLANETARY UNIT LUBRICANT

Please use the right lubricant to re-lubricate the gearbox and planetary gear.

Model

Lubricant for Gear Box

Lubricant for Planetary Unit

SL-500A

Brugarolas ”G. BESLUX ALCO H-2/MF RED”

TACBECON “GL-210”

9

TROUBLESHOOTING

FAULT

CHECK

POSSIBLE REASON AND ACTION REQUIRED

No power to mixer

1. Check plug socket

2. Check wiring in plug

3. Check fuse in plug

4. Check or change cable

5. Check microswitch

6. Check circuit breaker

over load or short

1. Mixer not plugged into a live socket or not switched on

2. Plug incorrectly wired –rewire correctly

3. Possible faulty fuse –replace fuse

4. Cable damaged or split –replace cable

5. Limit switch damaged or faulty –replace switch

6. Circuit breaker shut off or constantly short –reset

or replace the circuit breaker (automatically reset).

Mixer falls to operate

1. Check bowl guard/lift

2. Check transmission belt

3. Check gear change lever

1. Machine will not operate with guards open

2. Belt damaged or broken-replace belt

3. Machine will not operate if out of gear-put in gear

Mixer becomes noisy

1. Check bowl and tools

2. Check work surface

3. Check bearing for wear

4. Check gearbox

5. Check planetary unit

1. Ensure that bowl and tool are correctly seated.

2. Uneven surfaces create excessive resonance.

3. Worn bearings –replace bearings

4. Damaged or faulty gearbox –replace gearbox

5. Reapply high-pressure grease thought grease

fitting. (Please refer to MAINTENANCE)

Mixer loses power

1. Check capacity

2. Check transmission gear

3. Check shaft bias

1. Overloading of bowl –reduce load

2. Gear damaged or worn –replace belt

3. Damaged or faulty gearbox –replace shaft bias

Motor overheating

1. Check capacity/speed

2. Check supply voltage

1. Refer to Table 2 and 3 for details

2. Voltage should correspond to rating plate

Oil on planetary shaft

Check oil seal

Worn oil seal –change oil seal

Mixing tools stuck on

planetary shaft

Check planetary shaft

bent, unclean or rusted.

1. Planetary shaft twisted or bent –please change

planetary shaft.

2. Planetary shaft rusted –please use descaler for

derusting.

3. Turn planetary shaft anti-clockwise to meet square

groove, gently knock down mixing tools.

◎It is recommended that any servicing or maintenance work must be carried out by a trained technician or

electrician.

◎Isolate the mixer from the electricity supply by removing the plug from the socket before cleaning or

servicing.

◎Isolate the mixer from the electricity supply by removing the plug from the socket after long period of no use.

10

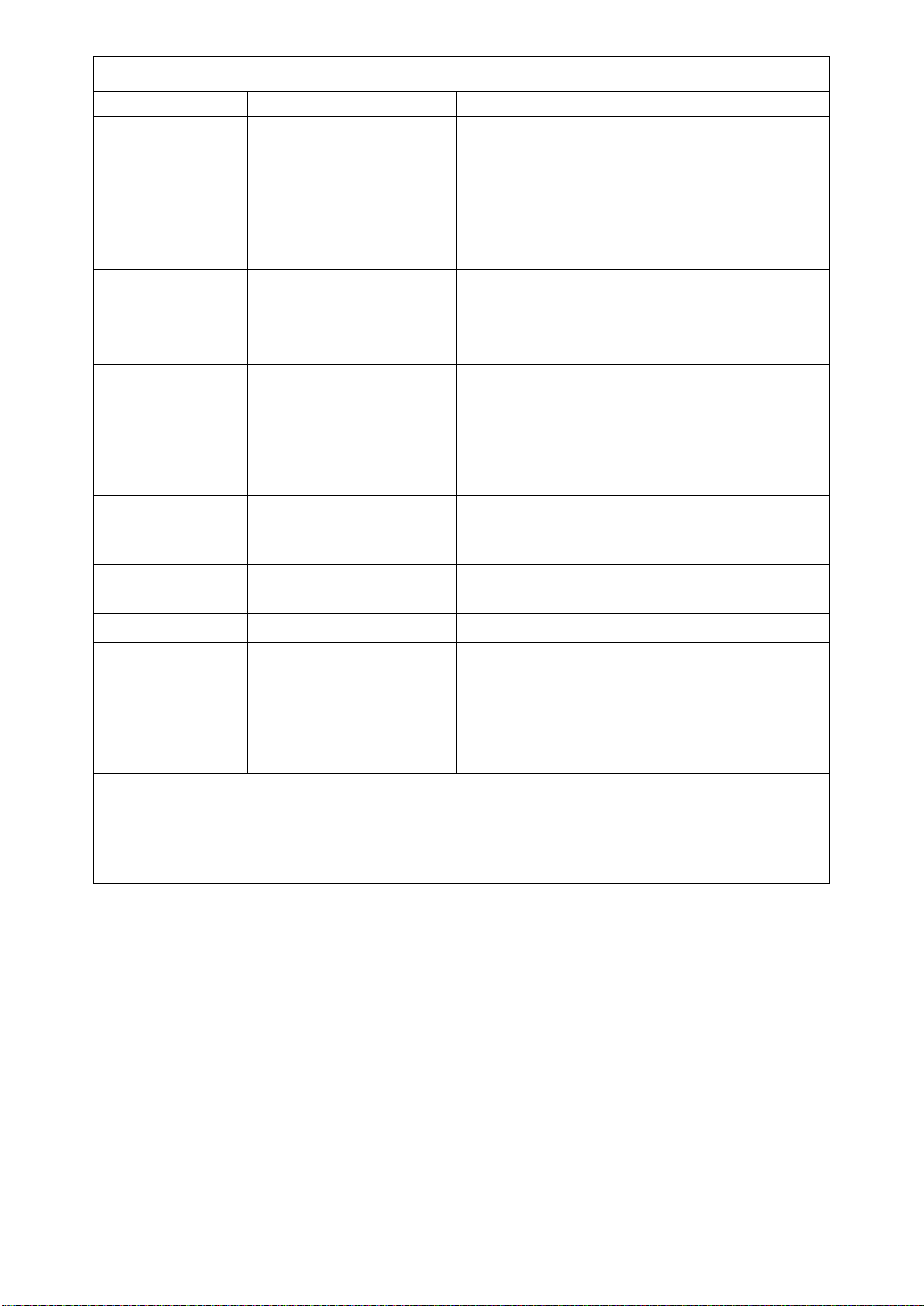

Capacity Chart Table

Product

Agitator

Max Speed

Maximum

Regular Mix (kg)

Egg Whites

Whip

10

0,35 lit.

Whipped Cream

Whip

10

2 lit.

Batter

Beater

8

-

Mashed Potatoes

Beater

8

1,8 kg

Frosting

Beater

8

1 kg

Cookie Dough

Beater

8

-

Cake

Beater

8

1,5 Kg

Pie Crust

Beater

8

1,5 kg

Dough 60% AR

Hook

2

1,25 kg

Pizza dough 50% AR

Hook

2

750 g

Pizza dough 40% AR

Hook

2

650 g

Pasta, Egg noodles

Hook

2

450 g

NOTE: The mixer capacity depends on the moisture content of the dough. When mixing dough (pizza,

bread, or bagels) check your AR%! %AR (% Absorption Ration) = Water weight divided by flour weight. The

capacities listed above are based on flour at room temperature and 70°F water temperature. (1 gallon

water weights 8.33 lbs.)

Limited Warranty

GUARANTEE

SHEANG LIEN provides one year guarantee, either the date of dispatch from our factory, or the

date of purchase from one of our approved distributors. We will replace any defected parts resulted

from faulty design, material or workmanship, provided that no alteration, addition or repair has been

carried out except by an authorized Service Agent and provided that such defective part(s) be returned

to the Company’s nearest authorized representative, postage paid.

Table of contents

Other smaky Mixer manuals