Operating manual

DKS - classic DKS - expert

2Dok. Nr. 112819 31/2011

Contents

1 Information for mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Preparation of the assembly and start-up . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

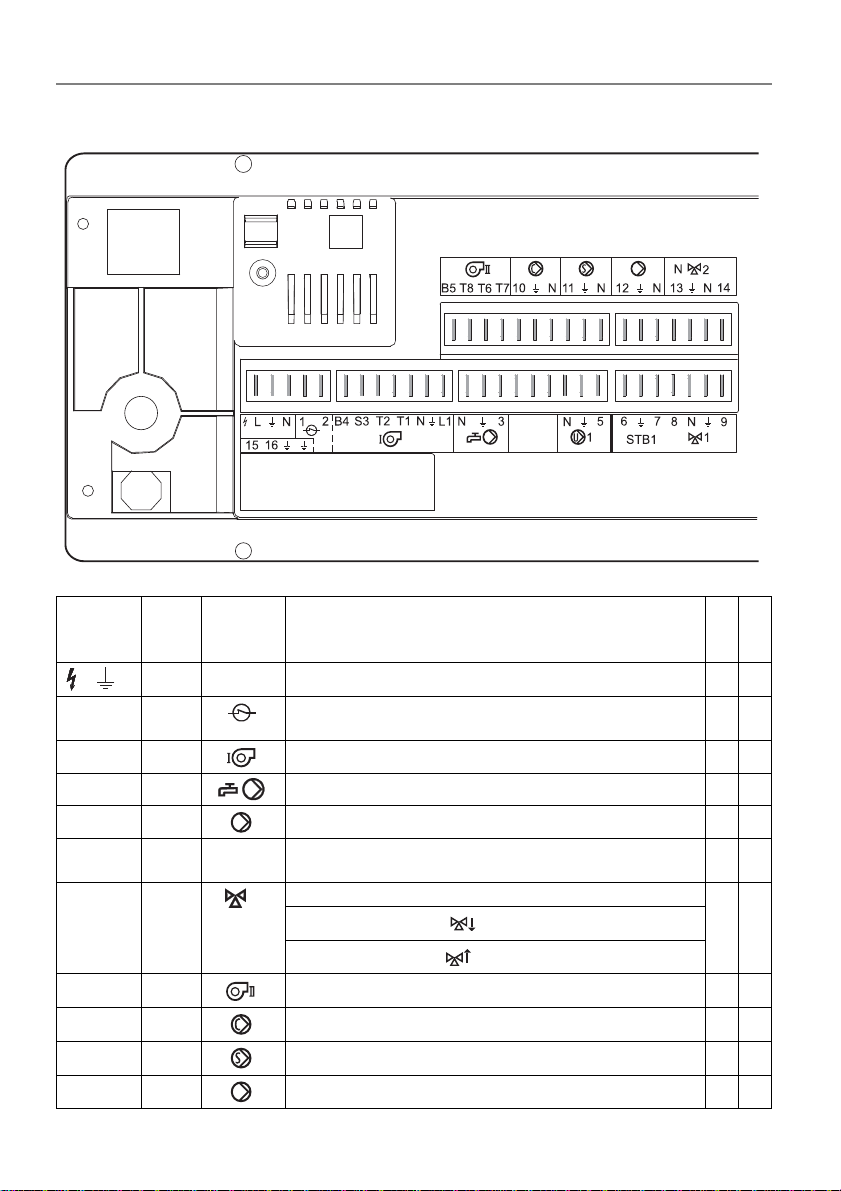

1.4 Allocation of the connectors 230 V parte . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.1 Connection burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.2 1-stage heat generator without burner norm-connector. . . . . . . . . . . 8

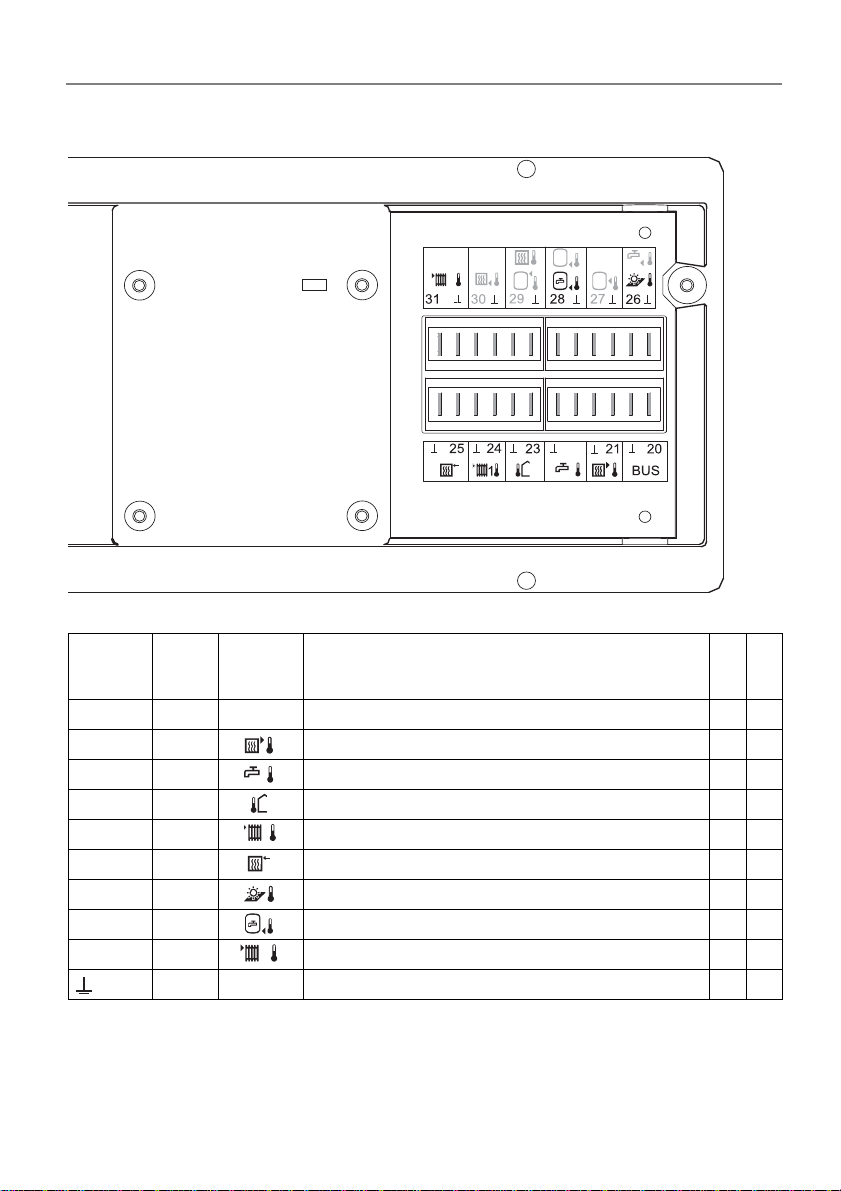

1.4.3 Allocation of the connectors sensors part . . . . . . . . . . . . . . . . . . . . . 9

1.5 Dimensions DKS - classic/ - expert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Specialist notes to the operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Display check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Structure of the parameter levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Parameter levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Level 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Service level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Operating data "dat". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Switching output function on and off . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.3 Displaying the controller output ports. . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.4 Change of parameters on level 3 . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Change of settings in the coded service levels 4 to 12 . . . . . . . . . . . . . . . 17

3.3.1 Example: Sensor configuration store (parameter 4-0) . . . . . . . . . . . 17

4 General description of functions and parameters . . . . . . . . . . . . . . . . 19

4.1 Level 3 - Heating circuits/Domestic hot water . . . . . . . . . . . . . . . . . . . . . . 19

4.1.1 Heating curve/base point (parameter 3-1) . . . . . . . . . . . . . . . . . . . . 19

4.1.2 Room-temperature compensation

(Reinforcement room influence, p-part) (parameter 3-7) . . . . . . . . . . . . . 22

4.2 4th level - Configuration of the plant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 5th level - Domestic hot water production . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.1 Basic function of domestic hot water production . . . . . . . . . . . . . . . 23

4.4 7th level - Heating circle function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.1 Basic functions heating circle function . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.2 Heating limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.5 8th level - Solar function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5.1 Basic functions solar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.6 10th-11th level - Boiler management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.6.1 Basic functions heat generator management. . . . . . . . . . . . . . . . . . 27