Smartec CLD 130 User manual

BA 001C/07/en/02.97

No. 50040314 smartec

CLD 130

Conductivity

Measurement

Operating Instructions

Quality made by

Endress+Hauser

ISO 9001

Table of contents

1. General .......................................................... 2–3

1.1 Unpacking............................................................ 2

1.2 Application............................................................ 2

1.3 Ordercode ........................................................... 3

2. Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 5

2.1 Measuring principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Sensor............................................................... 4

2.3 Measuring transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Designs.............................................................. 5

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 9

3.1 Sensor with integrated transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Sensor with separate transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Sensor with integrated transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Immersion sensor with separate transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Separate transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 – 11

4.1 Connection principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Sensor with integrated transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Sensor with separate transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5. Start-up ............................................................ 12

5.1 Power-up............................................................ 12

5.2 Instrument settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 ATCsetting .......................................................... 12

5.4 Measuring mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6. Operation....................................................... 13–16

6.1 Measuringrangechange-over........................................... 13

6.2 ATC adjustment (automatical temperature compensation) . . . . . . . . . . . . . . . . . . . . . 14

6.3 Signal output change-over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Signal output assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.5 Remote switching of current output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7. Maintenance and troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 – 18

7.1 Maintenance ......................................................... 17

7.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.3 Instrument function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8. Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

BE1LD130.CHP

Smartec CLD 130 Table of contents

1

1. General

1.1 Unpacking

•Inspect for any damaged packaging!

The post office or forwarding agent must be

informed of any damage.

Damaged packaging material must be

retained until the matter has been settled.

•Verify that the contents are undamaged!

Inform the post office or forwarding agent as

well as the supplier of any damage.

•Check if the delivery is complete and

agrees with the shipping documents as well

as your order:

•Delivered quantity

•Instrument type and version

•Accessories

•Operating instruction(s)

•Instrument identification card(s)

If you have any questions, consult your

supplier or the Endress+Hauser sales center

in your area (see back page of these

operating instructions for addresses).

1.2 Application

Use: Conductivity measurement

Measuring

principle: inductive

Application area: in liquids

Measuring range: medium to high

conductivities

Special features: sterilizable

no influence of

contamination on

measurement, resistant to

chemicals, fully

encapsulated

Applications: food industry,

chemical industry,

electroplating

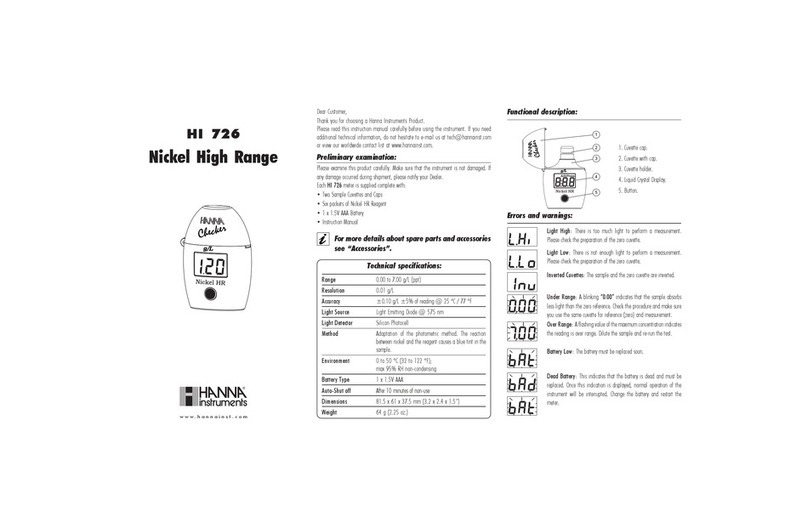

Fig. 1.1: Nameplate

Smartec CLD 130

1. General Smartec CLD 130

2

1.3 Order code

Inductive instrument Smartec CLD 130

Design

P Compact design with in situ measuring transmitter / PEEK

W Separate measuring transmitter with 5 m cable / PEEK

X Separate measuring transmitter with special cable length (max. 15 m) / PEEK

Version

MV1 Dairy fitting connection DN 50 to DIN 11851

RF1 Round flange DN40/PN10 and loose flange

TF1 Immersion sensor IP68 / loose fl. UP-GF DN50 / PN10 (W/X design only)

CS1 2" clamp fitting

ET1 Immersion version with round flange, l=2000mm

GE1 Internal thread G 1 1/2"

IF1 2" IDF flange

VA1 Varivent fitting for housing TN

Measuring ranges

0 0 ... 2000 µS/cm

1 0 ... 20 mS/cm

2 0 ... 200 mS/cm

3 0 ... 1000 mS/cm

4 20 / 2 mS/cm with remote switching

5 200 / 20 mS/cm with remote switching

6 1000 / 100 mS/cm with remote switching

ATC range

A ATC range 1 ... 3 %/K

Power supply

0 Power supply 230 V, 50 / 60 Hz

1 Power supply 110 V, 50 / 60 Hz

2 Power supply 200 V, 50 / 60 Hz

3 Power supply 24 V, 50 / 60 Hz

4 Power supply 48 V, 50 / 60 Hz

5 Power supply 100 V, 50 / 60 Hz

6 Power supply 127 V, 50 / 60 Hz

7 Power supply 240 V, 50 / 60 Hz

8 Power supply 24 V m. sep. DC/AC converter

Instrument output

0 0 ... 20 mA, max. 500 Ω

2 4 ... 20 mA, max. 500 Ω

CLD 130– ⇐complete order code

BE1LD130.CHP

Smartec CLD 130 1. General

3

2. Measuring system

2.1 Measuring principle

The test medium is a liquid conductor

coupling the magnetic field of two

magnetically isolated induction coils. The

AC voltage U1applied to coil T1is transmitted

to the second coil T2proportional to the

conductance G of the test medium. This

yields a linear relationship between the

conductance G and the output voltage U2

which is converted and rectified into a voltage

proportional to the conductance.

This measuring principle offers following

advantages:

•no electrodes, therefore no polarization

•faultless measurement in media or solutions

with a tendency to form deposits

A Pt 100 temperature sensor is fitted inside

the sensor to measure the temperature.

2.2 Sensor

The sensor is injection-moulded of chemically,

mechanically and thermally resistant PEEK

(polyether ether ketone), ensuring that it is

free of crevices and joints, and making it

biologically safe.

The sensor shaft contains the two induction

coils and a temperature sensor Pt 100 which

is in direct contact with the test medium.

The use of special elements and materials

makes the sensor suitable for continuous

operation at temperatures of up to + 100 °C,

and short-term operation at up to + 130 °C.

Therefore, Smartec can be sterilized.

The sensor is available in different mounting

variants with integrated or separate

measuring transmitter.

2.3 Measuring transmitter

The measuring transmitter

•determines the conductivity of the liquid,

and indicates the conductivity value based

on reference temperature 25 °C and

•supplies this measured value as current

(0 or 4 ... 20 mA) at the signal output.

The instrument requires power supply (see

cover label).

The actual measured value and the set

temperature coefficient can be read externally

through a viewglass in the housing cover.

Four basic measuring ranges can be freely

selected:

•0 ... 2000 µS/cm

•0 ... 20 mS/cm

•0 ... 200 mS/cm

•0 ... 1000 mS/cm

The zero point can be displaced within the

selected measuring range, increasing the

sensitivity, and thus spreading the range,

considerably. This permits precise

measurement even in media with slight

conductivity changes.

Medium

Chemical attack Resistance

Medium Concentr.

(%) Temp.

(°C) PVC-C PVDF PEEK

Nitric acid HNO35

up to 40

20

60

20

60

+

+

+

+

+

+

+

+

+

+

+

–

Phosphoric acid H3PO4up to 10 20

60 +

++

++

+

Caustic soda solution

NaOH 320

50

90

+

+

+

+

0

–

+

+

+

sodium hypochlorite

Labarraque's solution

NaOCl

diluted

aqueous 20

50

90

+

+

0

0

0

–

+

+

+

Fig. 2.2 Excerpt from resistance

tables for PVDF, PEEK

and PVC-C

Legend:

+ resistant

0 conditionally resistant

– not resistant

Fig. 2.1: The inductive conductivity

measuring principle

2. Measuring system Smartec CLD 130

4

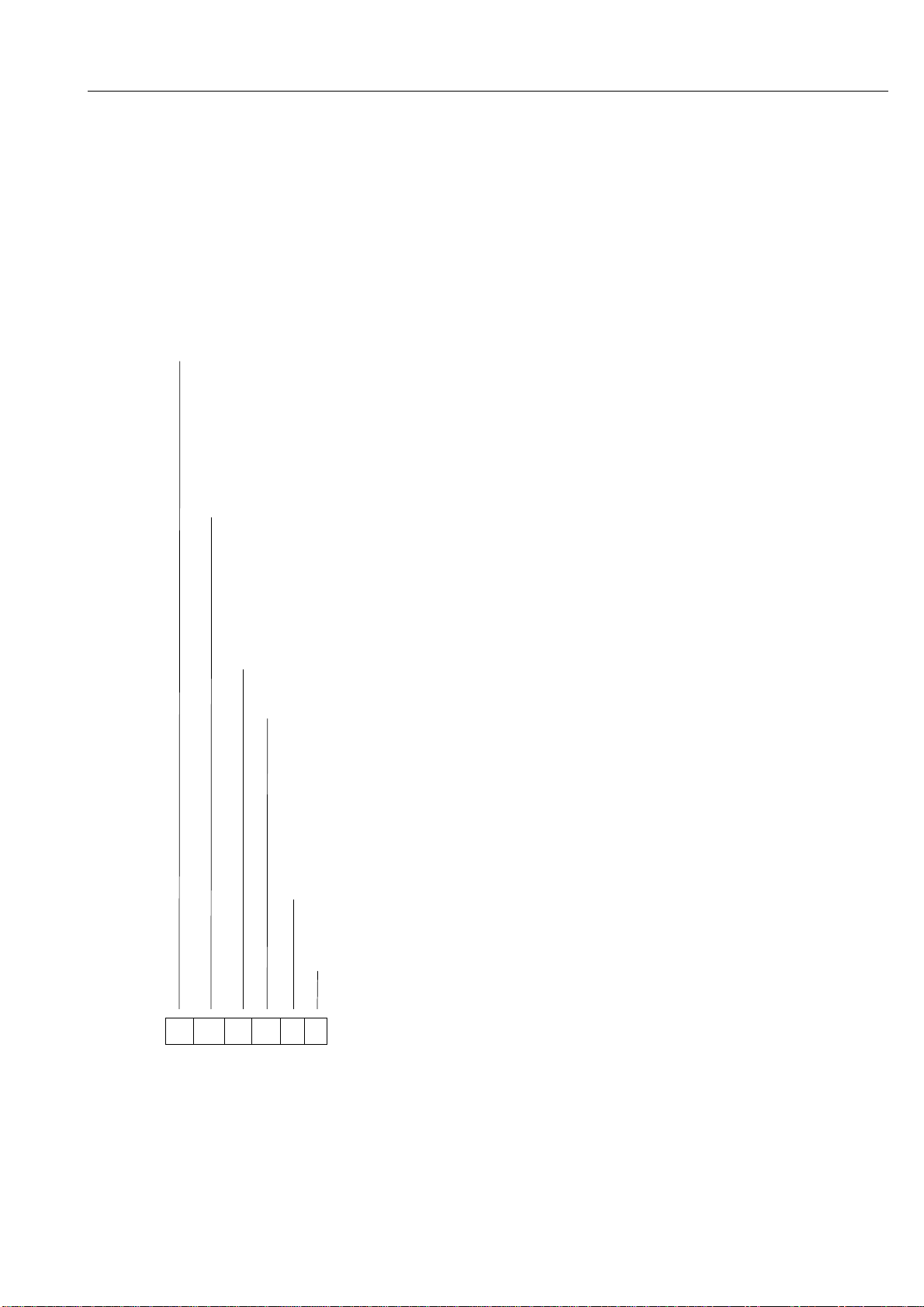

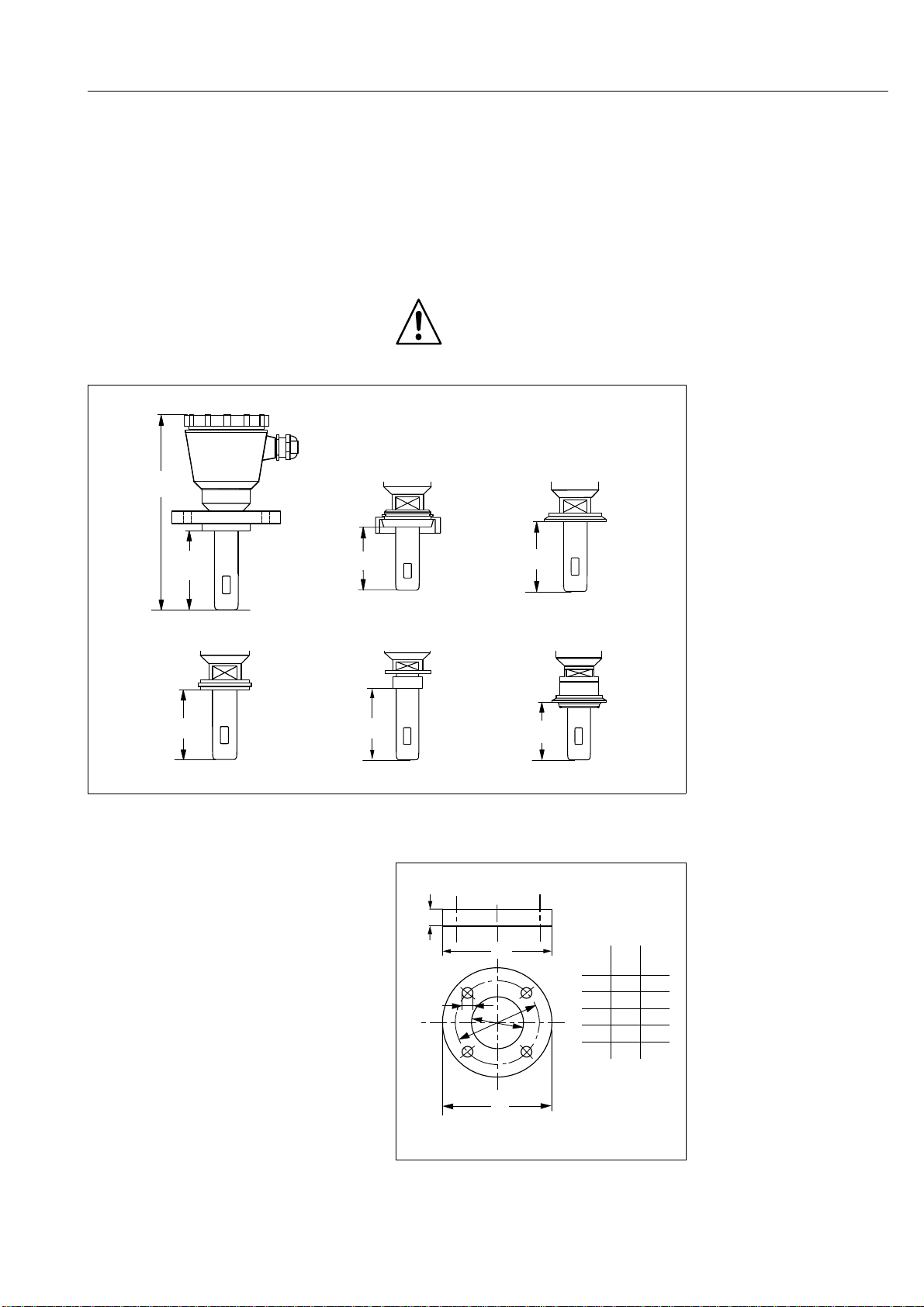

2.4 Designs

2.4.1 Sensor with integrated

transmitter

The sensor with integrated measuring

transmitter including screw connection,

provides a complete measuring unit.

2.4.2 Sensor with separate

transmitter

The standard version provides the measuring

transmitter with 5 m connected cable. The

sensor is connected to the fitted cable plugs.

2.4.3 Immersion sensor with

integrated transmitter

The measuring system comprises:

Measuring transmitter with immersion pipe,

sensor and round flange.

2.4.4 Immersion sensor with

separate transmitter

The measuring system comprises:

Separate transmitter, immersion sensor IP 68

with connected cable, round flange with strain

relief for freely suspended sensor.

Power supply

Signal output

0 / 4 … 20 mA

Measuring cable

Double coaxial cable

double shielded with fitted

plugs for connection of

sensor

Power supply

Transmitter

Signal output 0 / 4 - 20 mA

7-pole connection

with cable

Power supply

Signal output

0/4-20mA

Fig. 2.3: Sensor with integrated

(left) transmitter

Fig. 2.5: Immersion sensor with

(right) integrated transmitter

Fig. 2.4: Measuring transmitter

(left) connected to separate

sensor via 5 m cable

Fig. 2.6: Immersion sensor with

(right) separate measuring

transmitter

BE1LD130.CHP

Smartec CLD 130 2. Measuring system

5

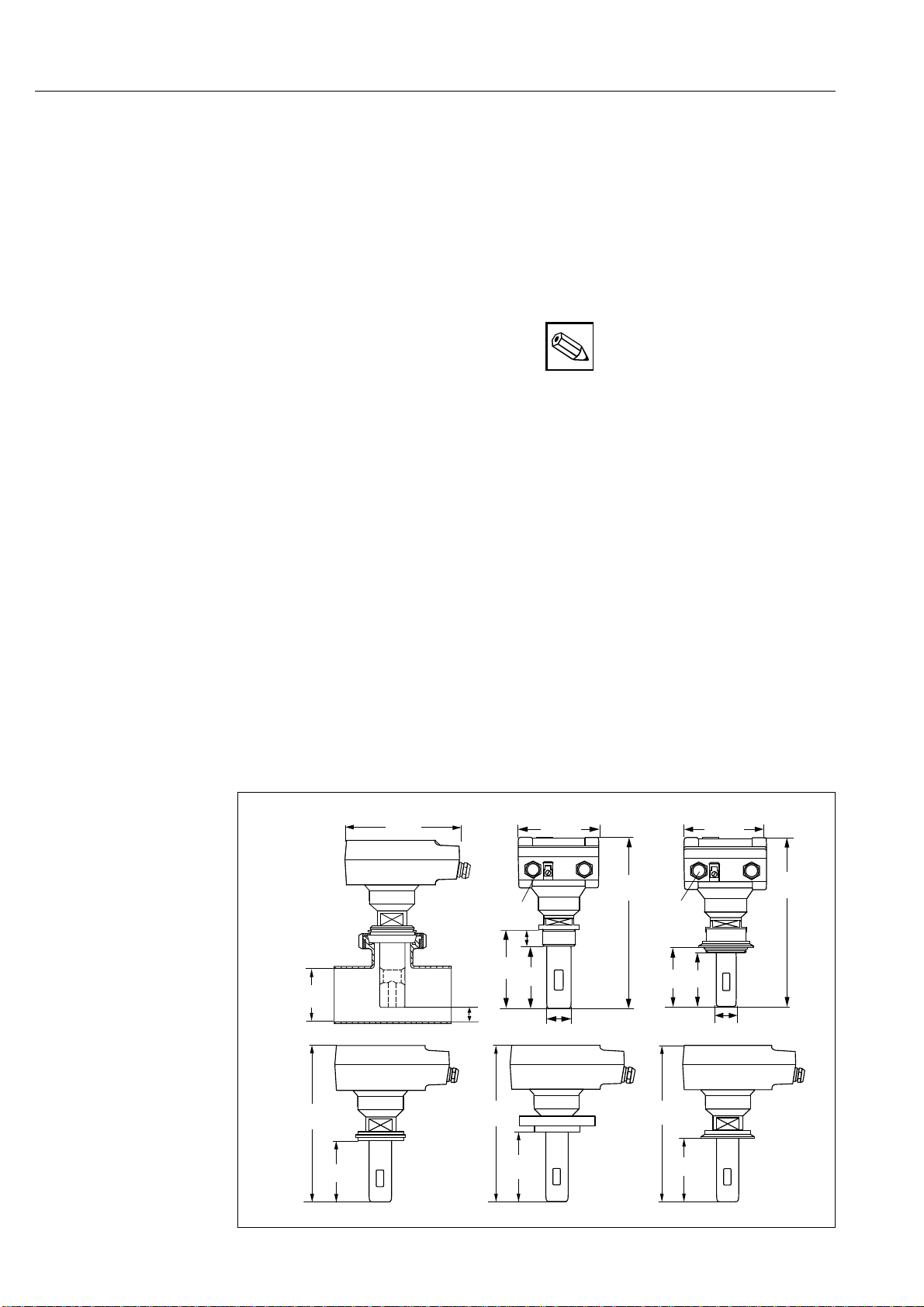

3. Installation

3.1 Sensor with integrated

transmitter

The Smartec measuring system is available in

different designs for all commonly used

mounting and installation versions for

industrial applications:

•Dairy fitting connection DN 50, DIN 11851

•Internal thread G 1 1/2"

•Varivent fitting

•2" IDF flange

•2" clamp fitting

•Round flange DN 40 / PN 10

The instrument is installed at the measuring

point using the selected connections, i.e.

dairy fitting connection (see fig. 3.1).

For installations in pipelines it must be

ensured that the sensor is mounted at a point

which is always fully flooded during the

measuring process.

If the sensor is mounted vertically onto the

pipeline, it should be installed in a culvert.

For measurements in high viscosity media

(e.g. emulsions) the sensor should be

installed in a pipe bend so that the media

flows directly through the measuring channel.

The version with integrated measuring

transmitter is suitable for use with continuous

medium temperatures of up to 90 °C and

ambient temperatures of up to 50 °C.

Note:

The suitable connection flange for

pipe or tank has to be provided

by customer.

➡155.5

min. 20

min.

DN 65

➭

Pg 16,

reduced

G 11/2"

118.5

250

ø34

107

85 22

Pg 16,

reduced

118.5

250

ø34

69

57

➳

➺

234

85

➑

234

85

➱

250

102

Fig. 3.1: Sensors with integrated

transmitter in the

connection head

➡Sensor with dairy fitting connection

DN 50, DIN 11851

➭Sensor with internal thread G 1

1

/

2

"

➳Sensor with Varivent fitting

➺Sensor with 2" IDF flange

➱Sensor with round flange

DN 40 / PN 10

➑Sensor with 2" clamp fitting

3. Installation Smartec CLD 130

6

3.2 Sensor with separate

transmitter

Smartec with a separate measuring

transmitter is available for industrial

applications with high permanent

temperatures (>90 °C) and hardly accessible

measuring points.

The sensor is mounted at the measuring point.

The measuring transmitter is then mounted

separately and connected to the sensor via a

5 metres long double shielded double coaxial

cable.

The ambient temperature of the measuring

transmitter may be max. + 60 °C.

Warning:

The ready-made cable must not be

shortened in any case!

230

102

➡

85

➳

85

➭

85

➺

85

G1

1/2"

➱➑

69

DN

40 DN

50

D 150 165

k 110 125

l1818

a6278

b1618

ak

D

b

D

l

Fig. 3.2: Sensors with connection

head without measuring

transmitter

➡Sensor with dairy fitting connection

DN 40 / PN 10

➭Sensor with dairy fitting connection

DN 50, DIN 11851

➳Sensor with 2" clamp connection

➺Sensor with 2" IDF flange

➱Sensor with internal thread G 11/2"

➑Sensor with Varivent fitting

(stainless steel adapter)

Fig. 3.3: Dimensioned drawing

of the used flanges for the

corresponding installation

versions

BE1LD130.CHP

Smartec CLD 130 3. Installation

7

3.3 Immersion sensor with

integrated transmitter

Smartec as an immersion assembly with an

integrated measuring transmitter is used in

large basins or open channels.

The measuring signal (0/4 ... 20 mA) can be

transmitted across larger distances (up to a

maximum of 1000 m).

The immersion assembly is installed with a

round flange DN 50 / PN 10. It is made of

PVC-C and is available in different lengths

(400 bis 2000 mm).

This assembly can be used in temperatures

of up to 90 °C (permanent temperature 80 °C)

and under pressures of up to 6 bar (at 20 °C)

in closed containers.

3.4 Immersion sensor with

separate transmitter

For installation in tanks or other closed

containers, Smartec CLD 130 is available as

an immersion assembly with a separate

measuring transmitter.

The inductive sensor is mounted in the

assembly using a bayonet lock. The assembly

material PVC-C is resistant to aggressive

chemicals. For application in CIP systems, the

assembly is mounted in a V4A version using a

DN 65 dairy pipe fitting.

For open containers and channels the sensor

is mounted freely suspended with clamp

connection and strain relief.

In case of the IP 68 immersion sensor the

measuring cable is protected from the

medium by a pressure-proof silicone hose.

The cable gland in the immersion sensor is

mounted by means of a bayonet lock.

➡

Ø 123

Ø47

82

277

➭

86

172

82

Ø 123

Ø 47

Ø88

400 – 2000 mm immersion depth 220

82

63172

Pg 16

reduced

∅47

measuring

cable

∅49

Fig. 3.5: Immersion sensors for

measuring transmitters

➡Immersion sensor TF1 (ingress

protection IP 68)

with PVDF sensor cap,

2 m silicone hose and round

flange DN 50/PN 10

➭Immersion sensor ET 1 made of

PVC in different lengths

(400 to 2000 mm immersion depth)

with round flange DN 50 / PN 10

Fig. 3.4: Immersion sensor with

integrated transmitter

3. Installation Smartec CLD 130

8

Exchanging of the sensor

1. Unscrew Pg thread of cable duct on top

of the assembly (see fig. 3.5, ➡or ➭).

2. Loosen sensor by turning it anticlockwise

(bayonet lock ➑).

3. Withdraw the sensor part with protection

sleeve ➺from immersion tube ➡.

4. Unscrew Pg thread ➳of protection sleeve.

5. Take sensor out of guide notch of

protection sleeve and loosen plug

connections ➭,➱.

6. Assembe the sensor in reverse order.

Warning:

When assembling or disassembling

the sensor the Pg thread must be

unscrewed before pulling the

measuring cable (see fig. 3.5).

110

18

133

87

54

70

155

Ø 40

min.

9

Retaining

strap

Fig. 3.7: Mounting plate for wall

and post mounting of

separate measuring

transmitter

➡

➳

➑

➱

➭

➺

Fig. 3.6: Cable connection and

assembling of sensor

for immersion versions

3.5 Separate transmitter

The separate measuring transmitter can be

easily installed on wall and posts using a

mounting plate.

The mounting plate is secured to a wall using

3 screws and the supplied spacer bushes.

The transmitter is attached to pipes or posts

by means of a retaining strap.

The sensor cable with 4 plugs is introduced in

the sensor housing through the Pg thread.

Then put together the cable plugs, tighten

Pg 16 thread and screw cover on the

connection head.

BE1LD130.CHP

Smartec CLD 130 3. Installation

9

4. Electrical connection

4.1 Connection principles

Attention:

•The instrument must be grounded

before operation!

•If malfunctions cannot be

remedied, the instrument must be

removed from service and

protected against accidental

start-up.

Repair work can only be carried

out directly by the manufacturer or

by the Endress + Hauser service

organization.

Warning:

•Notes and warnings of these

operating instructions must be

strictly adhered to! Maintenance

work can only be carried out by

qualified personnel if the

instrument remains connected to

the power supply!

•The instrument is protected

against interference, pulse-shaped

transients, high frequency and

electrostatic discharges according

to the Namur recommendations,

IEC 801 und DIN VDE 0843.

However, this is only valid for a

properly grounded instrument with

a screened measured value output

line.

•For the separate version of the

instrument we recommend not to

wire the measuring line to the

sensor directly next to a

high-voltage line. If this is

unavoidable, embed measuring

line in a grounded steel pipe.

Note:

•This instrument has been built and

tested in accordance with VDE

0411, part 100, and left the

manufacturer's works in perfect

condition concerning safety

regulations.

•This instrument has been tested

under reference conditions

concerning electromagnetic

compatibility according to

EN 50081-2.

•Malfunctions of the instrument can

be remedied by means of the error

list in chapter 7.2 without requiring

intervention in the instrument itself.

Alterations to the instrument are

not allowed and make any

guarantee claim invalid.

•After installing and connecting the

instrument and sensors the whole

measuring system has to be

checked for function.

Instrument connection to

direct voltage mains

(24 V AC version)

Smartec CLD 130 can be operated in the

direct voltage mains by inserting of a DC/AC

converter:

DC/AC converter

Input voltage 15 bis 32 V DC

Output voltage 24 V AC 2%

Output frequency 50 Hz

Output power 4.5 VA

Order no. 50038935

KL1(A) KL2

0/4-20mA

PE

NL1

–+

PE

NL1PE

–+ AC

Power supply

24 V to 240 V AC

(see nameplate)

Fig. 4.1: Connection diagram for

sensor with integrated

transmitter

4.2 Sensor with integrated transmitter

4. Electrical connection Smartec CLD 130

10

4.3 Sensor with separate

transmitter

KL3KL4

0/4-20mA

KL1(A) KL2

KL5

Measuring cable

Pt 100

Measuring

transmitter

blk rd bn gn

Inductive

Sensor

21321321

+–

PE

PE N

L1PE N

L1

Pt 100

+–

AC

gnbnwtwtrdblk

wt wt

κ

Ι

Power supply

24 V to 240 V AC

(see nameplate)

Fig. 4.2: Connection diagram for

sensor with separate

transmitter

BE1LD130.CHP

Smartec CLD 130 4. Electrical connection

11

5. Start-up

5.1 Power-up

Before switching on, ensure that all

connections have been correctly made

according to chapter 4.

5.2 Instrument settings

Normally no settings need to be made since

the instrument has been preset at the factory

according to the order code.

The settings concerned are as follows:

•Measuring range and decimal point of

display,

•Signal output function (0 or 4 ... 20 mA),

•Mains voltage coding,

•Signal output variation and zero point

suppression, if ordered.

The settings are recorded on the inside of the

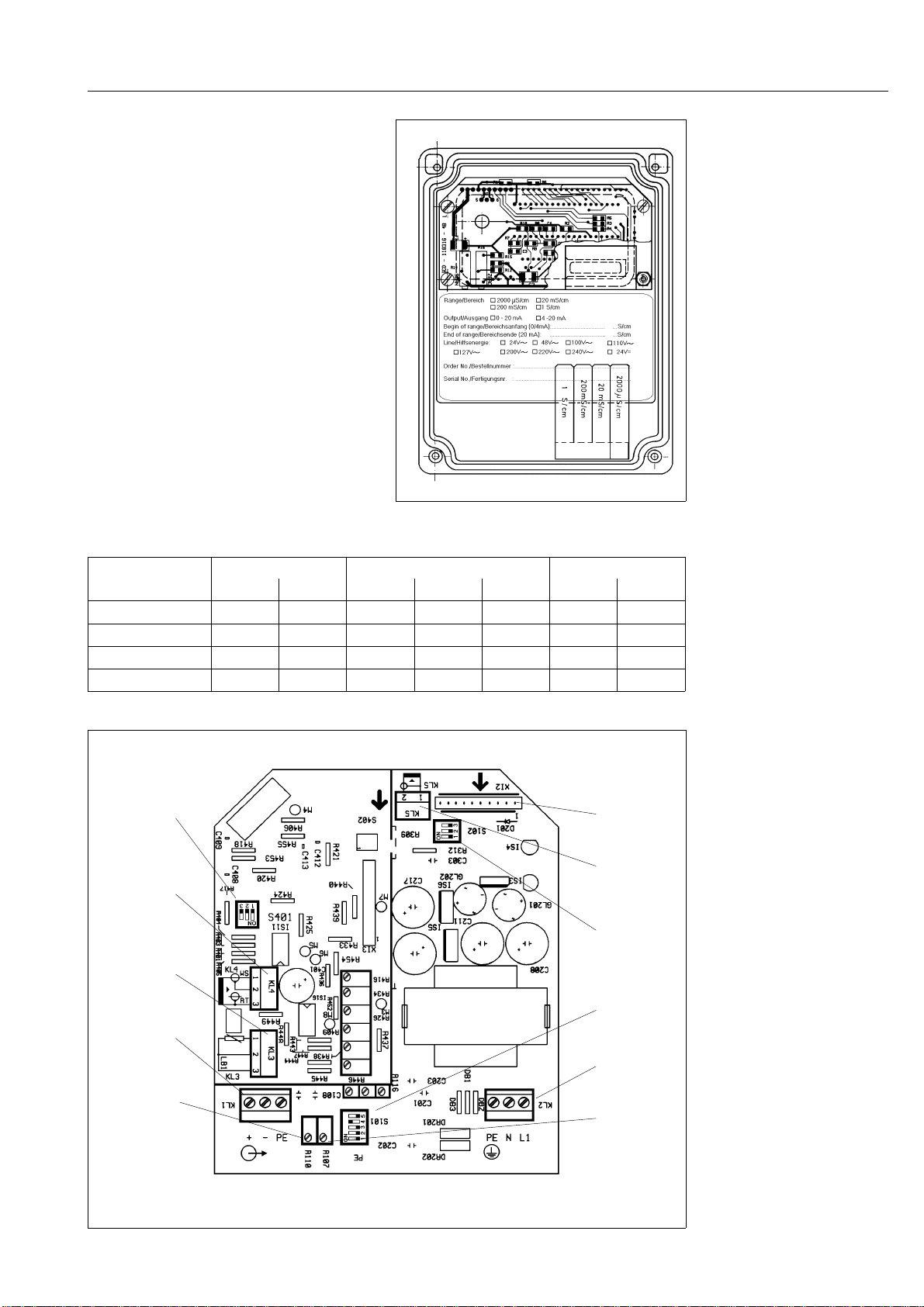

cover (see figure 6.1).

Any changes required should be made

according to chapter 6.

5.3 ATC setting

The automatic temperature compensation

(ATC) factor can be set externally on the

scaled ATC control (see chapter 6.2). If the

factor is not known refer to chapter 6.2.

5.4 Measuring mode

After applying the mains voltage, the

instrument must operate correctly and display

a temperature-compensated conductivity

value in mS/cm or µS/cm.

5. Start-up Smartec CLD 130

12

6. Operation

All information in the following chapters

relates to the items in figures 6.1 and 6.2.

6.1 Measuring range

change-over

The instrument has four measuring ranges

which can be changed over by means of

coding switches S 101 and S 401.

The decimal point in the display must be

adjusted with switch S 102 whenever the

measuring range is changed.

A corresponding measuring range plate can

be removed from the label in the cover and

inserted into the pocket on the rear of the

transparent front panel. The measuring range

plates are self-adhesive.

Measuring range Switch S 101 Switch S 102 Switch S 401

1212312

0 ... 2000 µS/cm –––––––

0 ... 20 mS/cm –––on –on –

0 - 200 mS/cm ––––on on on

0 - 1000 mS/cm on on –––on on

Measuring

range

change-over

S 401

Terminal 4

Receiving coil

Terminal 3

temperature

sensor

Pt 100

Terminal 1

signal output

Control R110

end of range

Display

connector

Terminal 5

Transmitting coil

Decimal point

change-over

S102

Change-over

signal output

S101

Terminal 2

Power supply

Control R107

start of range

Fig. 6.1 Inside view of cover with

measuring range plates

Fig. 6.2: Inside view Smartec

CLD 130 - componentry

with terminals and plugs

for measuring range

change-over

Table 6.1: Switching of

measuring range

BE2LD130.CHP

Smartec CLD 130 6. Operation

13

•If the temperature coefficient is known it is

set on the scaled ATC control on the front

panel using a screwdriver.

Typical temperature coefficients are:

Water > 1 µS/cm: 2.1 % / °C

Lye (NaOH) approx. 2 %: 1.9 % / °C

Acid (HNO3) up to 2 %: 1.6 % / °C

Salty solutions: 2.2 % / °C

Milk, beverages: 2.0 % / °C

•If the temperature coefficient is unknown

determine the coefficient as follows:

Determination of actual temperature

coefficient:

The reference temperature of automatic

temperature compensation is 25 °C. At this

temperature the setting of the ATC control has

no influence, this means the ATC is virtually

switched off.

•Carry out a measurement in the test

medium at 25 °C

•Note the display value

•Heat the test medium to operating

temperature

•Wait until the value of the measurement has

stabilized (adjustment time of temperature

sensor)

•Set the display to the value noted previously

(at 25 °C) using the ATC control.

The actual temperature coefficient for the

medium used is now indicated on the ATC

scale.

Note:

The temperature sensor in the

sensor requires approx. 10 minutes

to adjust to the changed

temperature. Therefore wait until

display has stabilized when the

temperature of the test medium has

changed.

Concentration

Temperature coefficient

Salts

Strong alkalis

Strong acids

Fig. 6.3: Concentration dependency

of the temperature

coefficient for several

electrolyte solutions

6.2 ATC adjustment

(automatical temperature

compensation)

6. Operation Smartec CLD130

14

6.3 Signal output change-over

The signal output can be switched to

0 ... 20 mA or 4 ... 20 mA using switch S 101

(see fig. 6.2).

6.4 Signal output assignment

(MR versions 0/1/2/3)

The signal output can be spread continuously.

Also the beginning of the signal output can be

continuously set within 0 ... 80 % of the

measuring range.

This enables to extract virtually any window

from the measuring range and output it as a

current signal.

Procedure:

•Connect an ammeter 0 ... 20 mA to the

signal output.

•Simulate the conductance at which the

signal output should be 0 or 4 mA

(conductance simulation see chapter 7.3).

•Set 0 or 4 mA with control R 107 (see

fig. 6.2).

•Simulate the conductance at which the

signal output should be 20 mA.

•Set 20 mA with control R 110 (see fig. 6.2).

Output range Switch S 101

345

0 ... 20 mA –on –

4 ... 20 mA on –on

Example:

A signal output of 0 ... 20 mA corresponding

to 100 ... 150 mS / cm is to be set in the range

0 ... 200 mS / cm.

This is possible following the above

instructions. The spread is factor 4 which

equals 25 % of the measuring range, the zero

point suppression corresponding to 50 % of

the measuring range.

Then align the equipment at 0 mA for 50 Ohm

and 20 mA for 33.3 Ohm (see chapter 7.3.)

20 mA

4mA

20 80 100

Max.

spread Min.

spread

Max.

spread

Allowed simulation value end of measuring range

Selected measuring range (%)

Allowed simulation value start of measuring range

Control

R 110

Control

R 107

Selected

signal output

0to20mAor

0to20mA

Fig. 6.4: Assignment of measuring

range - current output

Table 6.2: Switching of output range

BE2LD130.CHP

Smartec CLD 130 6. Operation

15

6.5 Remote switching

of current output

(MR versions 4/5/6)

With the option remote switching of current

output the following measuring ranges are

usable:

•1000 mS / cm

•200 mS / cm

•20 mS / cm

Remote switching spreads current output and

measuring range by factor 10, e.g. the

original indication range from

•0 or 4 ... 20 mA

corresponding to 0 ... 200 mS / cm

changes to

•0 or 4 ... 20 mA

corresponding to 0 ... 20 mS / cm.

Note:

Zero-point adjustment of measured

value output is not possible by

remote switching!

Control connection

remote switching Assigned

current output

0 / 4 - 20 mA)

Selected measuring

range

Selected measuringrange

10

Terminal 1 A

signal output

Terminal 1 B

remote switching

Fig. 6.5: Inside view of Smartec

CLD 130 - remote

switching connection

Table 6.3: Measuring range

assignment for remote

switching

6. Operation Smartec CLD130

16

7. Maintenance and

troubleshooting

7.1 Maintenance

Measuring transmitter and sensor are

maintenance-free. No parts wear out.

7.2 Troubleshooting

Error Possible cause Remedy

No display

No signal output

(display present)

Display unsteady, flickers,

susceptible to faults

Display 1---

Display 000

No power supply

Output line interrupted

Grounded conductor not

connected and / or shield of

output line not connected

Measuring range exceeded

Sensor does not immerse into

the medium

Check mains supply

Check line, terminals and

connected analyzer

Check grounded conductor

connection (should be short

and have a large cross-section)

use a shielded cable and

connect shield to grounded

conductor

Select the next higher range

(see chapter 6.1)

Check flow of pipe system or

level at tank installation as well

as installation position (air

bubbles) Table 7.1: Troubleshooting, cause

and remedy

BE2LD130.CHP

Smartec CLD 130 7. Maintenance and troubleshooting

17

7.3 Instrument function test

Simulation values for simulating the

conductance of the medium

For simulation purposes a wire is looped

through the sensor (looped through the

central hole and out through one of the holes

at the side).

The simulation resistance is connected to this

wire loop, either as an individual resistance or

using a resistance decade.

A large wire cross-section and low transition

resistances must be ensured when high

conductance values, i.e. low resistance are

involved (short connections, solder carefully!).

For intermediate values, the simulation

resistance is calculated according to the

following fomula:

R=1

Conductance ⋅k

Conductance in S/cm yields R in ohm

Conductance in mS/cm yields R in kohm

Conductance in µS/cm yields R in Mohm

k (cell constant) = 5

Attention:

The displayed value will only

correspond with the siumulation

value if

•the temperature is 25 °C or

•a simulation resistance of

109.72 ohm is connected to

terminal 3 instead of the Pt 100

sensor.

•Precision resistances must be

used for simulation, allowed

tolerance 0.1 %.

•The transition resistances for wire

coil and soldering joint must be

considered for the allowed

tolerance value.

Conductance Simulation value

100 µS/cm 50 kOhm

200 µS/cm 25 kOhm

500 µS/cm 10 kOhm

1000 µS/cm 5 kOhm

2000 µS/cm 2.5 kOhm

5 mS/cm 1 kOhm

10 mS/cm 500 Ohm

20 mS/cm 250 Ohm

50 mS/cm 100 Ohm

100 mS/cm 50 Ohm

200 mS/cm 25 Ohm

500 mS/cm 10 Ohm

1000 mS/cm 5 Ohm

7. Maintenance and troubleshooting Smartec CLD130

18

8. Technical data

Measuring transmitter

Measuring ranges (switchable). . . . . . . . . . . . . . . . 0 ... 2000 µS/cm; 0 ... 20/200/1000 mS/cm

ATC range (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 ... 3 %/K (–5 ... +105 °C)

(option). . . . . . . . . . . . . . . . . . . . . . . . . 0.5 ... 3 %/K (–5...+105°C); 2.1 ... 6 %/K (0 ... +40 °C)

ATC reference temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 °C

Measured value deviation

Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 % of meas. range final value

Signal output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 % of meas. range final value

Smallest measured value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 µS/cm

Power supply AC. . . . . . . . . . . . . . . . 110/127/220 V, 50 ... 60 Hz; 100/200/240 V, 50 ... 60 Hz

........................................ 12/24/48V,50...60Hz;–10 % ... +15 %

Power supply DC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . with seperate DC-AC converter

Power consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . approx. 4.5 VA

Signal output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 / 4 ... 20 mA, switchable

Load........................................................... max.500Ohm

Measured value output spread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 % ... 100 % of MR

Measured value zero shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 % ... 80 % of MR

Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.5 mm LC display, 3 1/2digits;

Permissible operating temperature (with integrated transmitter) . . . . . . . . . . . . . –10 ... +50 °C

Permissible operating temperature (with separate transmitter) . . . . . . . . . . . . . . –10 ... +60 °C

Permissible storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –25 ... +80 °C

Permissible humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 % ... 95 % rel.

Ingress protection (DIN 40050). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP 67

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 x 120 x 70 mm (HxWxD)

Housing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . coated aluminium,

Terminal wire cross section. . . . . . . . . . . . . . . . . . . . . . . . . terminals 2.5 mm2; sensor 1.5 mm2

Housing ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x Pg 9 glands; (replaceable by Pg 16)

Sensor connection Pg 16 (only for separate sensor)

Sensor with integrated transmitter

Sensor material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PEEK (Polyether-ether-ketone)

Operating temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –5 ... +110 °C (permanent temp.)

Temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pt 100, built-in

Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . max. 16 bar (20 °C)

Shaft immersion length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 mm

Pipe cross section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . min. DN 65

Weight................................................................ 0.5kg

Mounting versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dairy pipe fitting DN 50, DIN 11851

............................................ internalthreadG11/2"; 2" IDF flange

............................................................. 2"clampfitting

................................................... roundflangeDN40/PN10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . immersion sensor IP 68

Sensor with separate transmitter

Mounting versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . as above, add. immersion sensor IP 68

Cable length and type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 m long, pre-assembled

Cable connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . permanently connected to sensor;

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . with terminals in meas. instrument

Immersion sensor (integrated and separate measuring transmitter)

Pipe material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PVC-C

Pipe length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400 ... 2000 mm

Installation (compact version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . round flange DN 50 / PN 10

Installation (separate version) . . . . . . . . . round flange DN 50 / PN 10; dairy pipe fitting DN 65

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . max. 80 °C

Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . max. 6 bar (20 °C)

Immersion sensor

Ingress protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP 68

Material of protection cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PVDF

Material protection hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . silicone

Length..............................................................2000mm

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . flange DN 50 / PN 10 with strain relief

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . oval flange or mounting bracket

BE2LD130.CHP

Smartec CLD 130 8. Technical data

19

Table of contents