1THEORY OF OPERATION .................................................................................................................... 1

1.1 INTRODUCTION....................................................................................................................................................1

1.2 SYSTEM COMPONENTS..........................................................................................................................................1

1.2.1 Head Assembly.......................................................................................................................................2

1.2.2 Coupling, Standpipe, and Flange ...........................................................................................................3

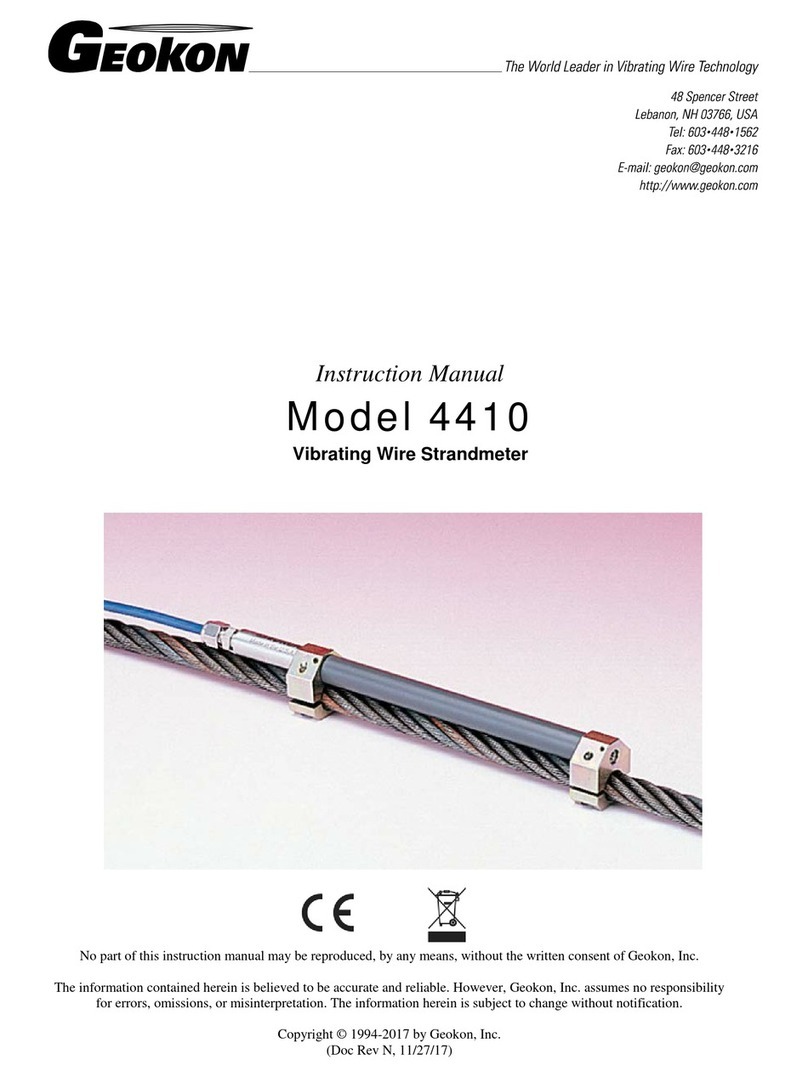

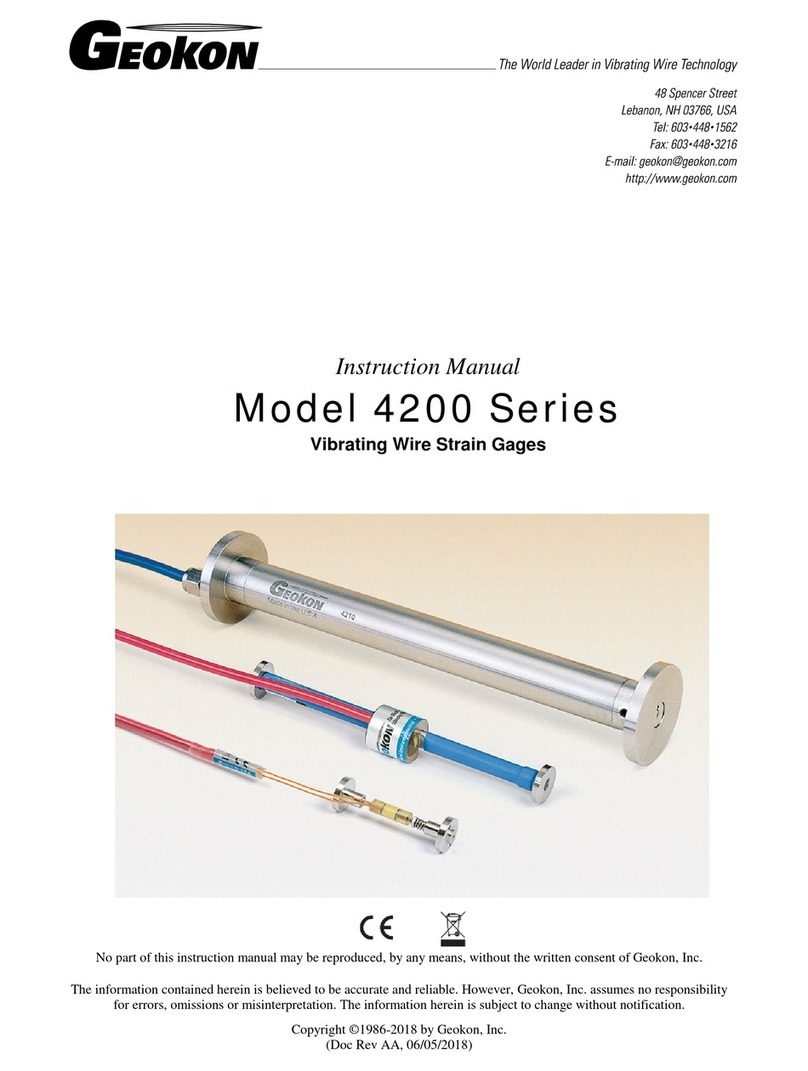

1.2.3 Vibrating Wire Displacement Transducers ............................................................................................4

1.2.4 Connecting Rods ....................................................................................................................................5

1.2.5 Borehole Anchors...................................................................................................................................6

2INSTALLATION CONSIDERATIONS ....................................................................................................... 9

2.1 TOOLS................................................................................................................................................................9

2.1.1 P/N 1100-TOOLKIT (Set of installation tools).........................................................................................9

2.1.2 P/N 1100-RECESSED-TOOLS (Accessories for recessed installations)...............................................9

2.1.3 P/N 1100-GROUT-DOWN (Accessories for inclined downward installations) ....................................9

2.1.4 P/N 1100-GROUT-UP (Accessories for overhead/upward installations) .............................................9

2.2 BOREHOLE DIAMETER .........................................................................................................................................10

2.2.1 Extensometers without an Over Core ..................................................................................................10

2.2.2 Extensometers Recessed in an Over Core Borehole .............................................................................11

2.3 ANCHOR SPACING ..............................................................................................................................................13

2.4 CABLE INSTALLATION AND SPLICING .......................................................................................................................13

3ASSEMBLY AND INSTALLATION .........................................................................................................15

3.1 PREPARATION....................................................................................................................................................15

3.2 CONNECTING ROD ASSEMBLY...............................................................................................................................15

3.2.1 Stainless Steel Connecting Rods...........................................................................................................15

3.2.2 For All Anchor Types: ...........................................................................................................................19

3.2.3 Fiberglass Connecting Rods .................................................................................................................20

3.3 ATTACH EXTENSION RODS TO CONNECTING ROD COLUMN ........................................................................................20

3.4 INSTALL HYDRAULIC LINES (HYDRAULIC ACTUATED ANCHORS ONLY)............................................................................21

3.5 BUNDLE THE RODS AND ANCHORS TOGETHER..........................................................................................................21

3.6 INSTALL GROUT PIPE (GROUTED BOREHOLES/CASING ONLY) .....................................................................................21

3.7 PVC STANDPIPE AND COUPLING ASSEMBLY ............................................................................................................21

3.8 FLANGE INSTALLATION ........................................................................................................................................21

3.9 LIFTING THE EXTENSOMETER ASSEMBLY INTO THE BOREHOLE .....................................................................................22

3.10 SETTING ANCHORS.........................................................................................................................................22

3.10.1 Groutable Anchors ..........................................................................................................................22

3.10.2 Hydraulic Anchors (Bladder and Borros Style) ................................................................................23

3.11 REMOVE ANCHOR HARDWARE.........................................................................................................................23

3.12 ATTACH THE TRANSDUCER HOUSING ASSEMBLY ..................................................................................................24

3.13 INSTALLING THE VIBRATING WIRE TRANSDUCERS.................................................................................................24

3.14 INSTRUMENT HEAD PROTECTION ......................................................................................................................26

4TAKING READINGS ...........................................................................................................................26

4.1 ELECTRONIC READINGS........................................................................................................................................26

4.1.1 Readout Box.........................................................................................................................................26

5TROUBLESHOOTING.........................................................................................................................27

APPENDIX A. SPECIFICATIONS....................................................................................................................28

A.1 MODEL 1100 SPECIFICATIONS .................................................................................................................................28

A.2 ROD SPECIFICATIONS..............................................................................................................................................28

A.3 MODEL 4450 VIBRATING WIRE TRANSDUCER SPECIFICATIONS.......................................................................................28

A.4 HEAD ASSEMBLY DIMENSIONS .................................................................................................................................29

APPENDIX B. THERMISTOR TEMPERATURE DERIVATION ..............................................................................31

APPENDIX C. WIRING CHARTS FOR VIBRATING WIRE TRANSDUCERS .............................................................32