Table of Contents

Table of Contents - 2

Chapter 6 References

6 - 1 Specifications........................................................................................... 6 - 1

6 - 2 Refrigerant with GWP reference ....................................................... 6 - 1

6 - 3 Dimensions................................................................................................ 6 - 2

6 - 4 Electrical Circuit ...................................................................................... 6 - 3

6 - 5 Compressed Air and Refrigerant Circuit / Operation Principles.....6 - 4

Chapter 7 Option Specification A

7 - 1 Safety instructions.................................................................................. 7 - 1

7 - 2 Specifications........................................................................................... 7 - 1

7 - 3 Air piping.................................................................................................... 7 - 1

7 - 4 Air flow capacity...................................................................................... 7 - 1

7 - 5 CompressedAir and RefrigerantCircuit/ OperationPrinciples... 7 - 2

Chapter 8 Option Specification C

8 - 1 Safety instructions.................................................................................. 8 - 1

8 - 2 Precautions for the installation and handlingof the product...... 8 - 1

8 - 3 Specifications........................................................................................... 8 - 1

Chapter 9 Option Specification K

9 - 1 Safety instructions.................................................................................. 9 - 1

9 - 2 Specifications........................................................................................... 9 - 2

Chapter 10 Option Specification L

10 - 1 Safety instructions................................................................................ 10 - 1

10 - 2 Specifications......................................................................................... 10 - 1

10 - 3 Maintenance............................................................................................ 10 - 2

Chapter 11 Option Specification R

11 - 1 Safety instructions.................................................................................11 - 1

11 - 2 Specifications of GFCI .........................................................................11 - 1

11 - 3 How to connect the power supply...................................................11 - 2

11 - 4 Cautions for handling the GFCI........................................................11 - 2

11 - 5 Electrical Circuit.....................................................................................11 - 2

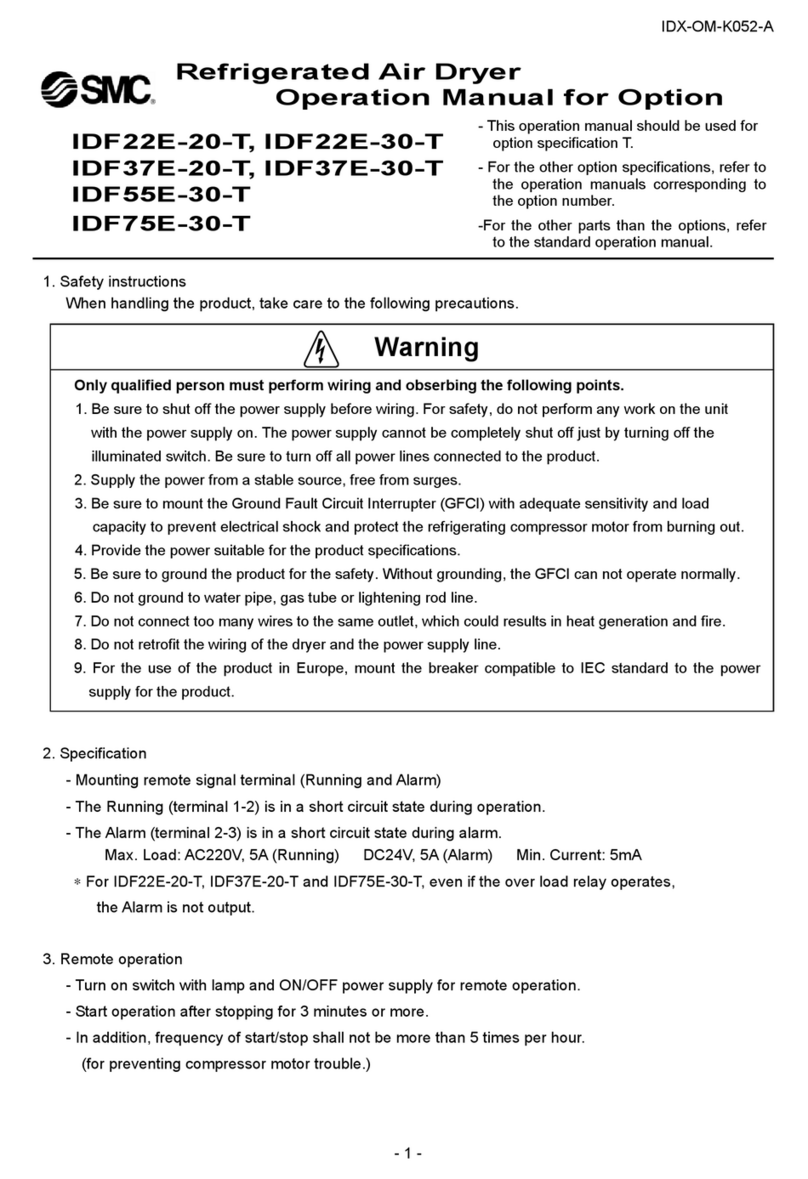

Chapter 12 Specification for Option T

12 - 1 Safety instructions................................................................................ 12 - 1

12 - 2 Specifications......................................................................................... 12 - 1

12 - 3 Remote operation................................................................................. 12 - 1

12 - 4 How to connect the power supply and signal cable................ 12 - 2

12 - 5 How to re-start the operation............................................................ 12 - 2

12 - 6 Electric circuit......................................................................................... 12 - 3

Chapter 13 Specification for Option V

13 - 1 Safety instructions................................................................................ 13 - 1

13 - 2 Specifications......................................................................................... 13 - 2

13 - 3 How to perform maintenance........................................................... 13 - 3

13 - 4 Electric circuit.......................................................................................... 13 - 3

Chapter 14 Service Record

14 - 1 Service Record....................................................................................... 14 - 1