PSE540-TF2Z039EN

Page 1 of 2

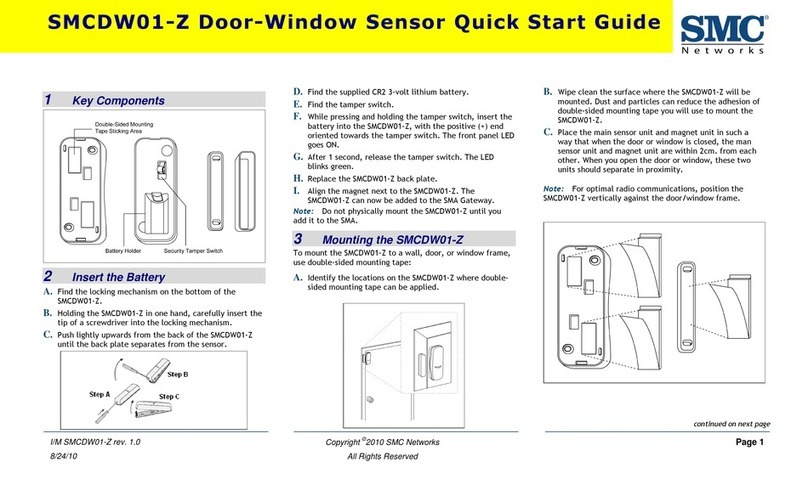

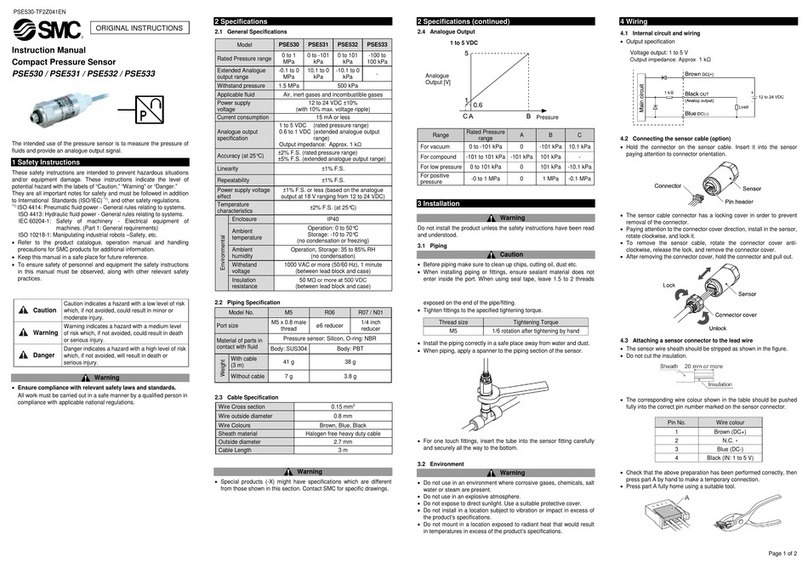

Instruction Manual

Compact Pressure Sensor

PSE540 / PSE541 / PSE543

The intended use of the pressure sensor is to measure the pressure of

fluids and provide an analogue output signal.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of

machines. (Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots –Safety, etc.

•Refer to the product catalogue, operation manual and handling

precautions for SMC products for additional information.

•Keep this manual in a safe place for future reference.

•To ensure safety of personnel and equipment the safety instructions

in this manual must be observed, along with other relevant safety

practices.

Caution indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

Warning indicates a hazard with a medium level

of risk which, if not avoided, could result in death

Danger indicates a hazard with a high level of risk

which, if not avoided, will result in death or

Warning

•Ensure compliance with relevant safety laws and standards.

All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

2 Specifications

2.1 General Specifications

2.2 Piping Specification

Model M3 M5 01 N01 R04 R06 IM5 IM5H

Port size M3

x0.5 M5

x0.8

R1/8

M5

x0.8

1/8

M5

φ4 φ6 M5

fem. M5

fem.

Materials of parts in

Pressure sensor: Silicon, O ring: NBR

(kg)

Without lead

2.9 3.2 9.8 9.8 1.9 2.1 3.8 4.6

2.3 Cable Specification

Wire outside diameter 0.9 mm

Brown, Blue, Black, White

Oil resistant vinyl chloride

Warning

•Special products (-X) might have specifications which are different

from those shown in this section. Contact SMC for specific drawings.

2 Specifications (continued)

2.4 Analogue Output

Range

A B C

For vacuum 0.0 to -101 kPa 0

For compound -100 to 100 kPa

-

-0 to 1 MPa 0 1 MPa

3 Installation

Warning

Do not install the product unless the safety instructions have been read

and understood.

3.1 Piping Caution

•Before piping make sure to clean up chips, cutting oil, dust etc.

•When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1.5 to 2 threads

exposed on the end of the pipe/fitting.

•Tighten fittings to the specified tightening torque.

1/4 rotation after tightening by hand

1/6 rotation after tightening by hand

•Only fluids which are non-corrosive to SUS303, C3604BD, and NBR

should be used.

•Install the piping correctly in a safe place away from water and dust.

•When piping, apply a spanner to the piping section of the sensor.

•For one touch fittings, insert the tube into the sensor fitting carefully

and securely all the way to the bottom.

3.2 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not mount in a location exposed to radiant heat that would result

in temperatures in excess of the product’s specifications.

4 Wiring

4.1 Internal circuit and wiring

•Output specification

Voltage output: 1 to 5 V

Output impedance: Approx. 1 kΩ

4.2 Attaching a sensor connector to the lead wire

•The sensor wire sheath should be stripped as shown in the figure.

•Do not cut the insulation.

•The corresponding wire colour shown in the table should be pushed

fully into the correct pin number marked on the sensor connector.

Pin No. Wire colour

•Check that the above preparation has been performed correctly, then

press part A by hand to make a temporary connection.

•Press part A fully home using a suitable tool.

•The sensor connectors cannot be re-used once they have been

pressed fully closed. If connection failure or incorrect wiring occurs a

new sensor connector must be used.

•When connecting the sensor to a PSE200 / PSE300 series monitor,

use the connector for sensor lead wire (ZS-28-C) or an e-Con*

connector from the table below.

* Refer to the manufacturers e-Con connector catalogue.

Model PSE540(A) PSE541(A) PSE543(A)

Rated Pressure range 0 to 1 MPa

Extended Analogue

output range

-

Air, inert gases and incombustible gases

12 to 24 VDC ±10%

(with 10% max. voltage ripple)

Protection Protected against reverse connection

Analogue output

specification

1 to 5 VDC (rated pressure range)

0.6 to 1 VDC (extended analogue output

range)

Output impedance: Approx. 1 kΩ

Accuracy

(at 25°C)

PSE54#

±2% F.S. (rated pressure range)

±5% F.S. (extended analogue output range)

PSE54#A

±1% F.S. (rated pressure range)

±3% F.S. (extended analogue output range)

Linearity ±0.7% F.S. ±0.4% F.S.

Repeatability ±0.2% F.S.

Temperature

characteristics

±2% F.S. (at 25°C)

Environmental

Ambient

temperature

Storage: -20 to 70°C

(no condensation or freezing)

Operation, Storage: 35 to 85% RH

(no condensation)

1000 VAC or more (50/60 Hz), 1 minute

(between lead block and case)

50 MΩ or more at 500 VDC

(between lead block and case)